Combined pulverized coal burner comprising an integrated pilot burner

A combination of burner and burner technology, applied in the direction of gas fuel burner, burner, burner, etc., can solve the problems of damaging the operation safety, destroying the burner channel, etc., and achieve the effect of ensuring the function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

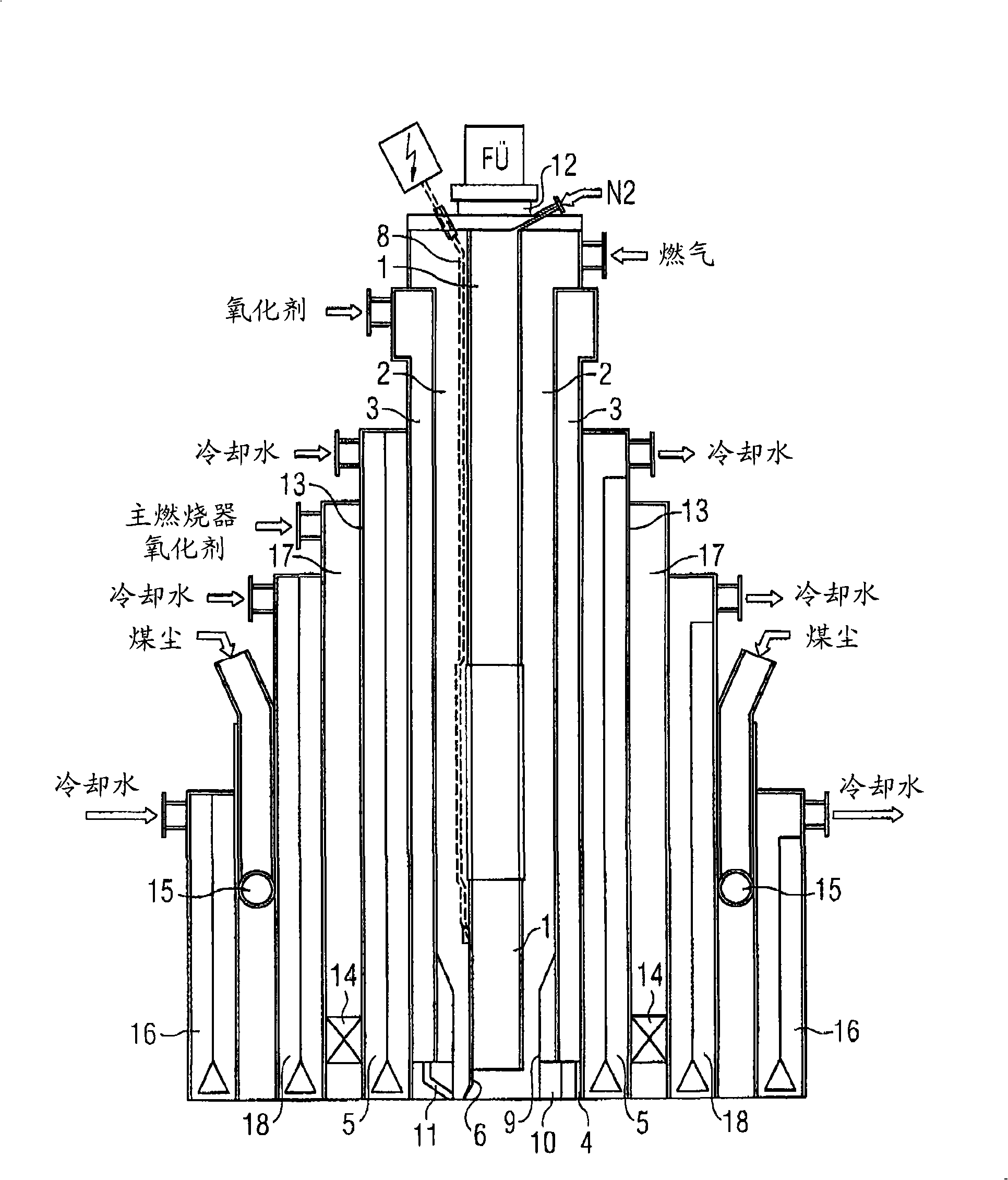

[0044] The coal-dust combined burner according to the present invention comprises a centrally arranged pilot combustion device with separate gas and oxidant delivery in separate pipes and a flame monitoring device and electric high voltage ignition device. Around these components there is an annular chamber 13 for supplying oxidant to the coal-dust combination burner. Rotating vanes 14 for swirling the oxidant flow are mounted on the annular discharge opening.

[0045] The outer cooling element 5 of the central pilot burner and the inner cooling element 18 of the outer main burner form the main burner oxidant channel 17 . Around this main burner oxidizer channel and the inner cooling element 18 are provided a soot conveying device 15 and a cooled outer casing 16 of the main burner.

[0046] The pilot burner includes a pipe 1 for spraying inert gas in the center, an annular chamber 2 for delivering gas around the central pipe, another annular chamber 3 for delivering oxidant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com