Telescopic guide rail

A telescopic and guide rail technology, which is applied to furniture parts, household utensils, drawers, etc., can solve the problems of unfavorable bearing capacity of telescopic guide rails, and achieve the effect of uncomplicated structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

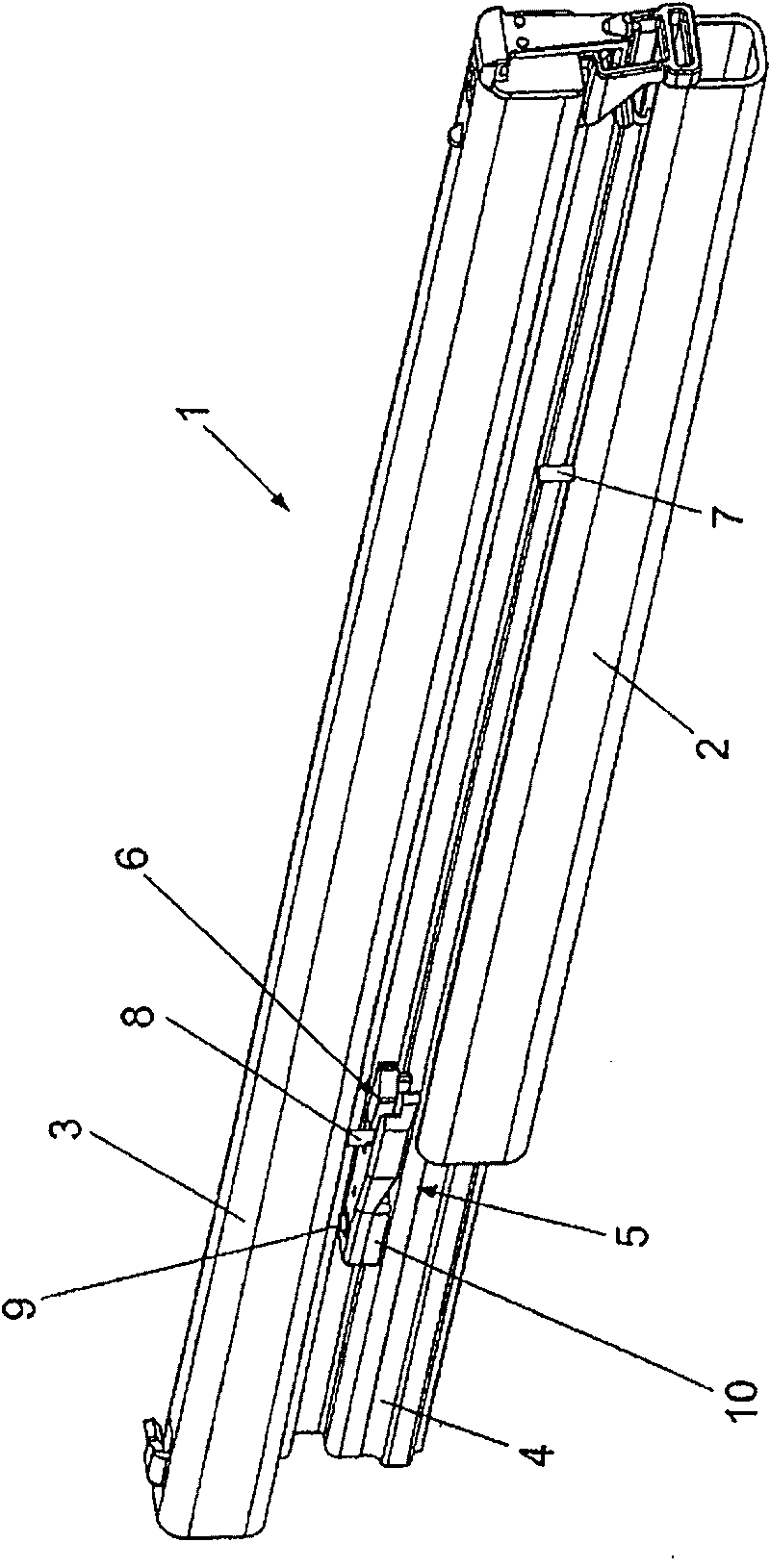

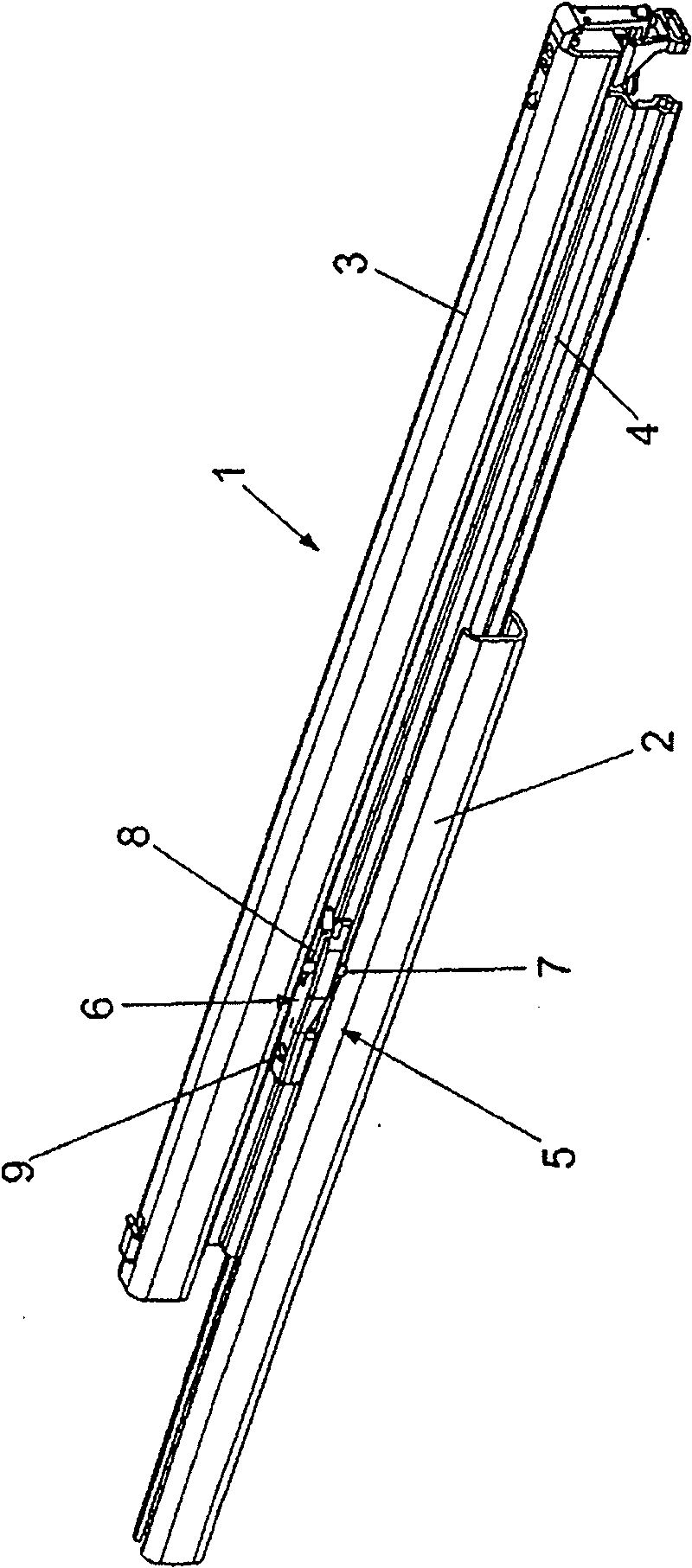

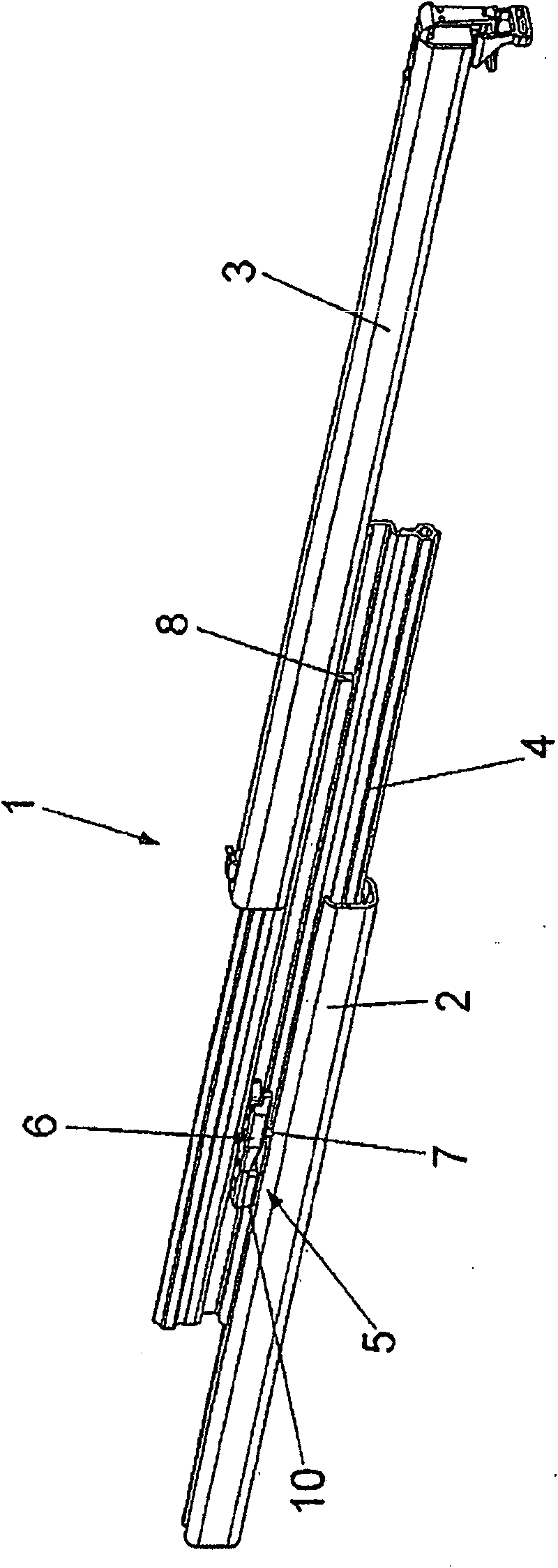

[0027] exist Figures 1 to 3 The telescopic guide rail shown in full is denoted by reference numeral 1, which includes a main body rail 2 that can be fixed on the main body side, a running rail 3 that can be connected to a pull-out member such as a drawer, and a set on the main body rail. 2 and the intermediate rail 4 extending the pull-out length between the running rail 3.

[0028] In addition, the telescopic guide rail 1 is also provided with a process control device 5, which ensures that only when the middle rail 4 is pulled out to the maximum relative to the main rail 2 adjacent to it, the running rail 3 can be moved relative to the The middle rail 4 is moved, and the process control device 5 can also ensure that the middle rail 4 can only move back from its fully pulled-out position when the running rail 3 moves back to the maximum relative to the middle rail 4 in the direction of insertion. back to the closed position.

[0029] Such a process control device 5 is desir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com