Liquid metal plain bearing

A technology of liquid metal and sliding bearings, applied in the direction of sliding contact bearings, bearings, rotating bearings, etc., can solve the problems of reduced efficiency of medical imaging systems, achieve the effect of improving lubricant supply and avoiding gradual damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

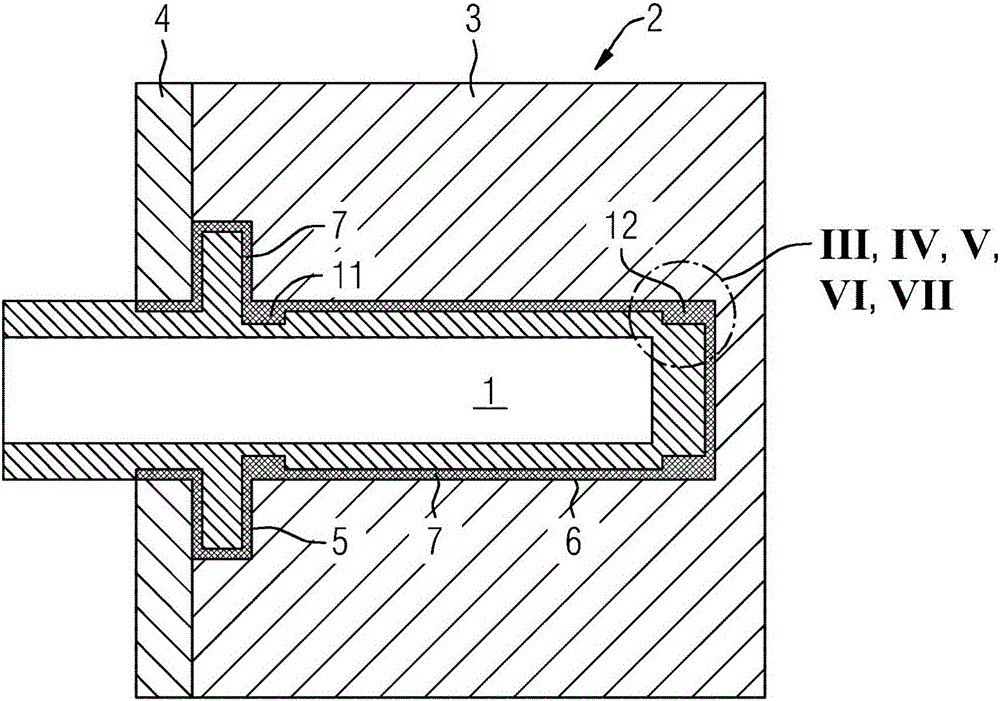

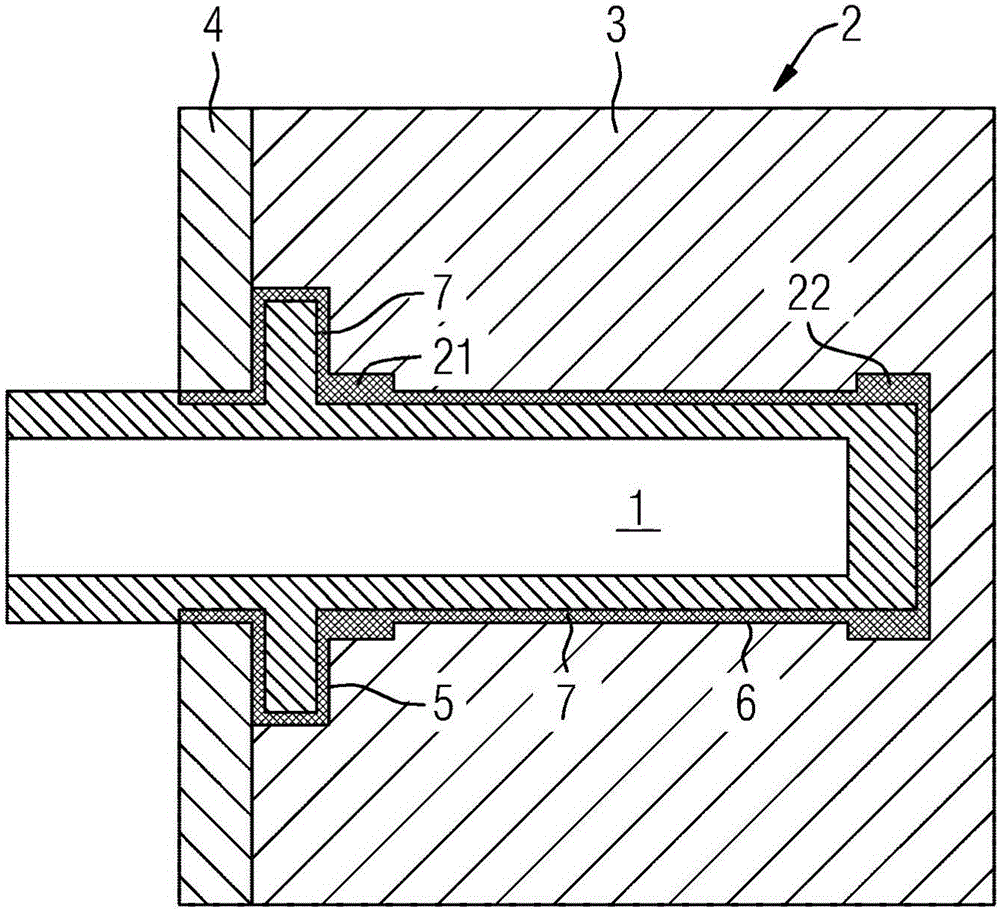

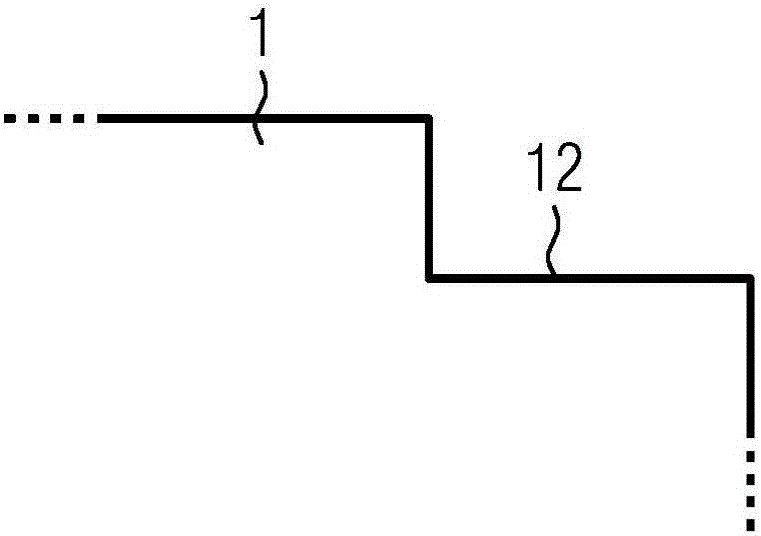

[0052] exist figure 1 neutralize figure 2 The liquid metal sliding bearing shown in respectively includes a first bearing part 1 and a second bearing part 2 .

[0053] The first bearing part 1 and the second bearing part 2 are produced, for example, from molybdenum.

[0054] The first bearing part 1 is designed as a stationary bearing part and forms an inner bearing, whereas the second bearing part 2 is designed as a rotating bearing part and comprises a first sleeve 3 and a second sleeve 4 which are rotationally fixed connected to each other. The first sleeve 3 as well as the second sleeve 4 thus form a rotating bearing sleeve.

[0055] In the assembly of liquid metal plain bearings, the inner bearing 1 (stationary bearing part) is inserted into the first sleeve 3 (part of the rotating bearing part 2) and followed by the second sleeve 4 (part of the rotating bearing part 2). part) is connected to the first sleeve 3 in a rotationally fixed manner.

[0056] After assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com