Improved system and method for detecting wall thickness and corrosion of well casing of gas storage well

A technology for corrosion detection and gas storage wells, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of no optical fiber sealing joint, detection interruption, too many devices, etc., to reduce the load of detection personnel, connect The effect of fast, convenient and simplified operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with accompanying drawing, the present invention will be further described:

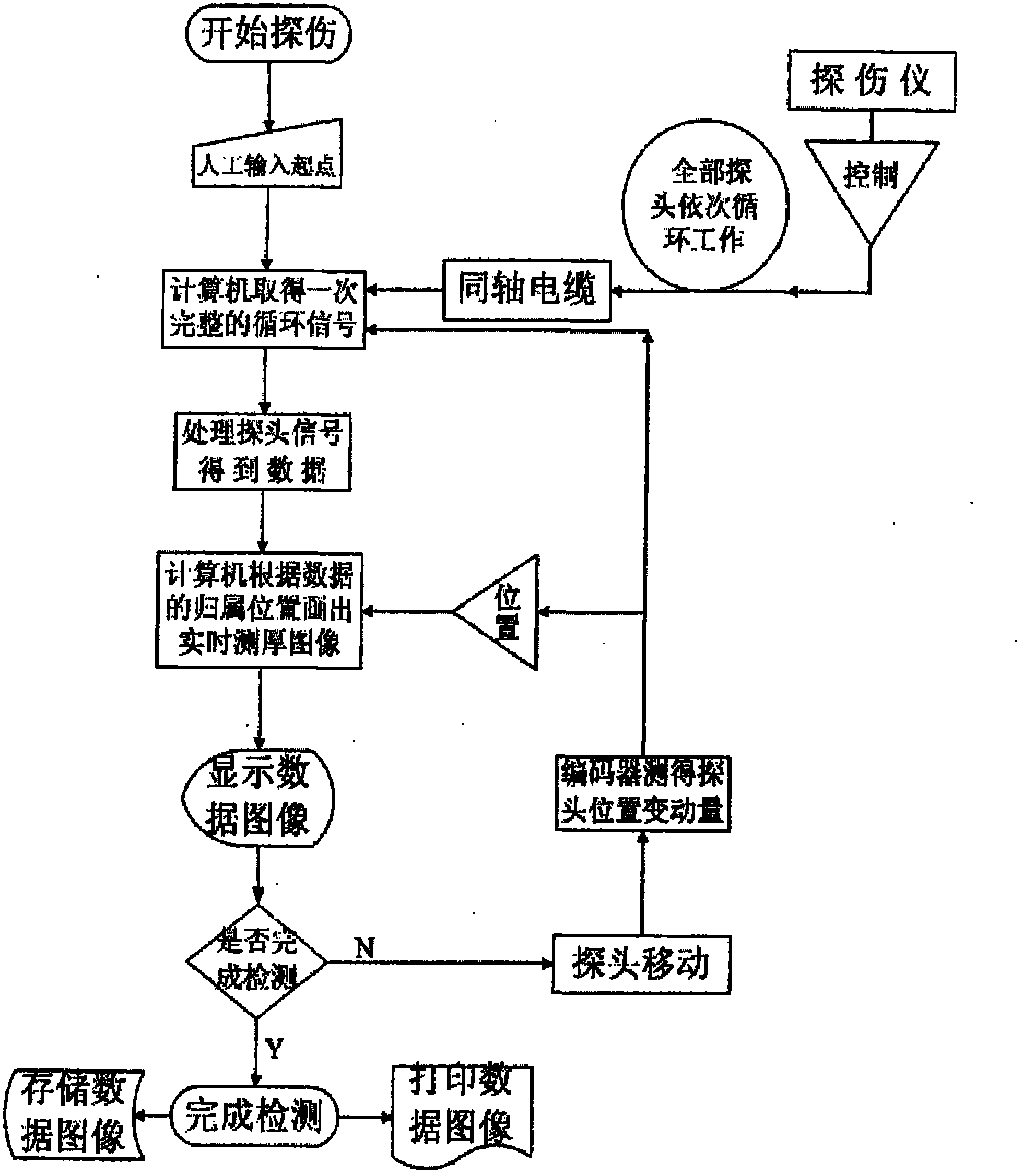

[0045] see figure 1 Shown is the flow chart of the improved wellbore wall thickness and corrosion detection method for gas storage wells.

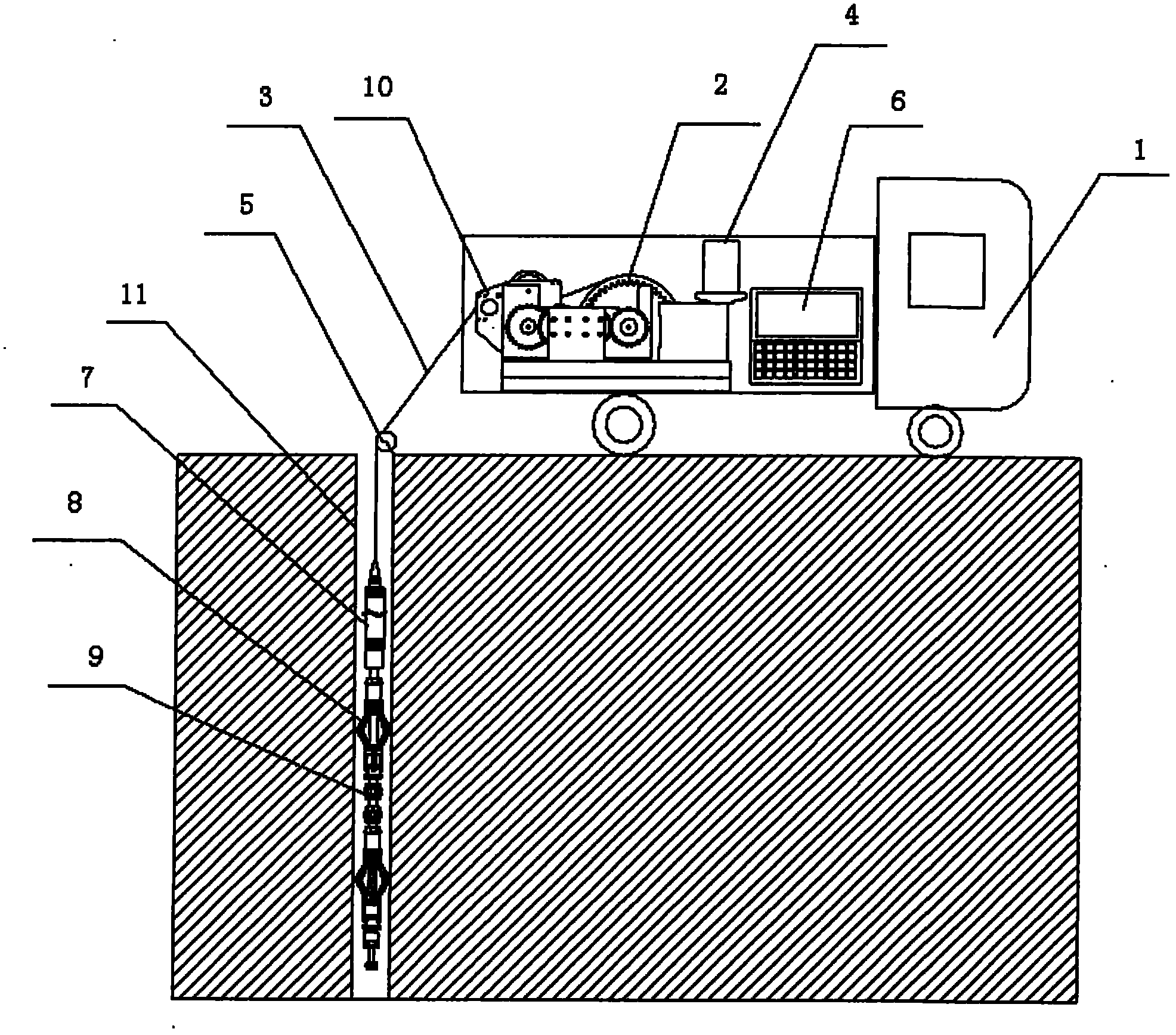

[0046] The improved detection method for wellbore wall thickness and corrosion of gas storage wells first fills the gas storage well 11 with water, installs the fixed pulley 5 at the wellhead, and the position of the mobile detection device 1 enables the armored composite wire 3 to pass through the pulley 5 and enter the storage well smoothly. Inside the gas well 11. Connect the downhole instrument with the armored composite line. In this embodiment, the mobile detection device 1 is a mobile detection system vehicle.

[0047] For the previous equipment, the improvements of the present invention include:

[0048]Combined with the on-site environment, the noise in the ultrasonic frequency band for detection is very small, so the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com