A risk assessment method for hydrogen energy equipment in a hydrogen refueling station

A technology of risk assessment and hydrogen refueling station, applied in the field of safety assessment system, can solve problems such as major dangers and hidden dangers, and achieve the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

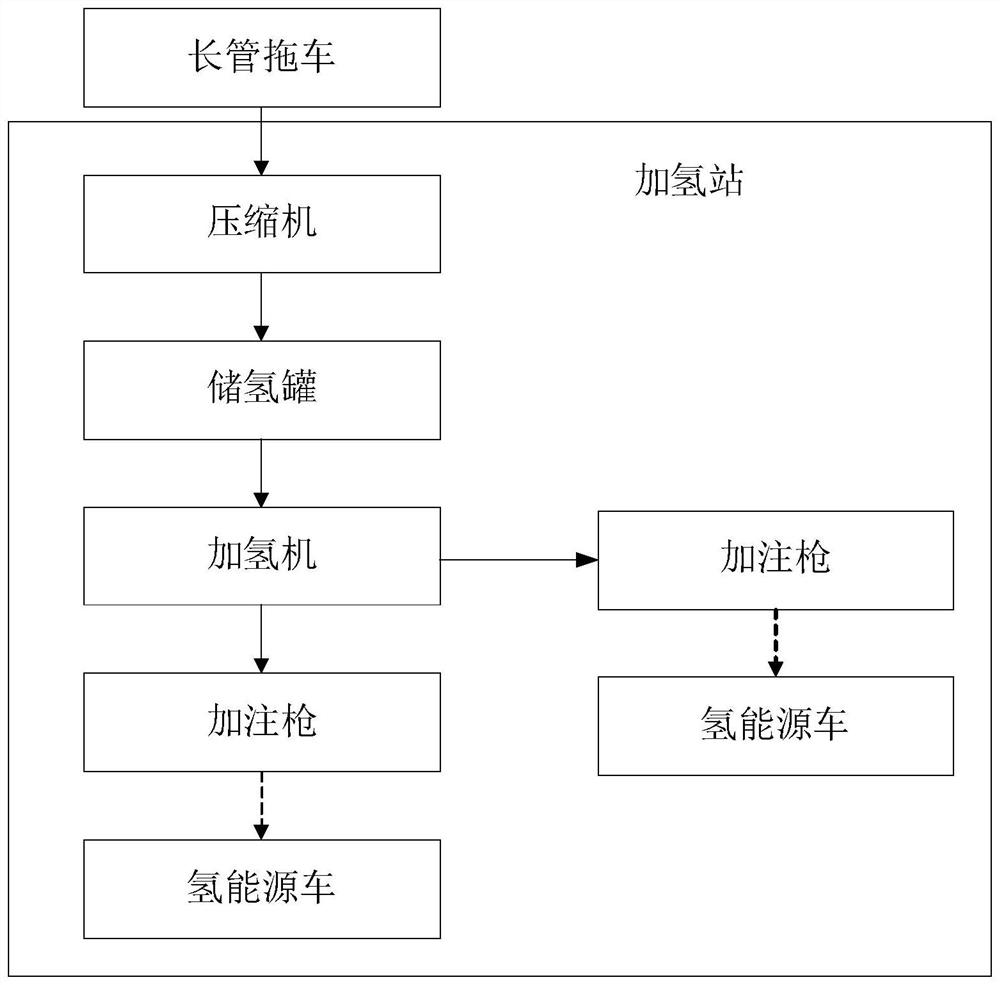

[0059] like figure 1 shown, figure 1 A schematic structural diagram of a hydrogenation station shown in an embodiment of the present invention is shown. The hydrogenation station in this embodiment may include: at least one compressor, a hydrogen storage tank connected to all compressors by pipelines, and the pipelines are connected to hydrogen storage tanks. The hydrogenation machine of the tank, each hydrogenation machine pipeline is connected with a plurality of filling guns for filling the hydrogen energy vehicle with hydrogen.

[0060] The hydrogen storage tank in this embodiment is a 98MPa high-pressure hydrogen storage tank, the compressor is a 90MPa compressor, that is, the exhaust pressure is 90MPa, and the power is 18.5kW; the hydrogenation machine is a 70MPa hydrogenation machine, the filling pressure is 70MPa, and the preset temperature: -40°C.

[0061] In practical applications, the tube bundle truck transports hydrogen to the hydrogen refueling station, fills t...

Embodiment 2

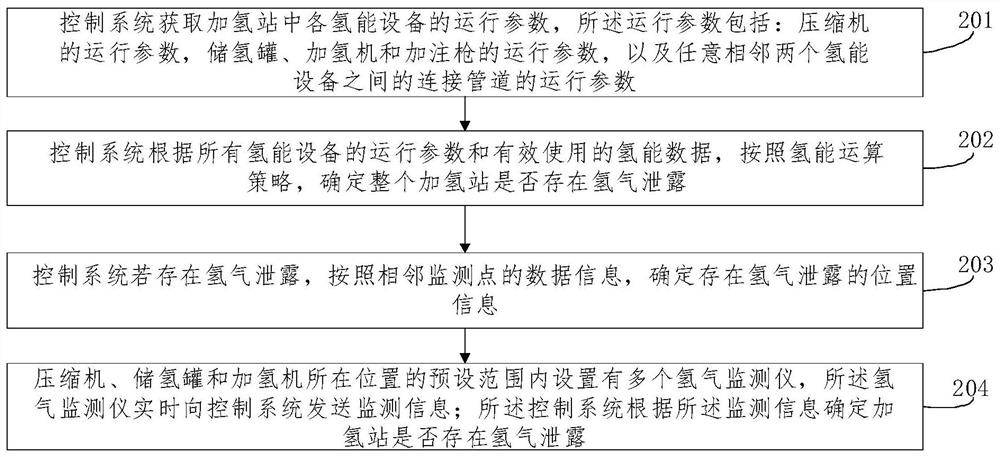

[0107] An embodiment of the present invention provides a schematic flowchart of a risk assessment method for hydrogen energy equipment in a hydrogen refueling station. The execution subject of the method in this embodiment may be any electronic device or computer device, and the method in this embodiment may include the following Steps not shown in the diagram:

[0108] S1. The control system obtains a first operating parameter of the compressor by means of a solenoid valve disposed on the compressor, where the first operating parameter includes: pressure, temperature, volume and / or flow;

[0109] The control system obtains the second operating parameter of the hydrogen storage tank by means of a solenoid valve arranged on the hydrogen storage tank, and the second operating parameter includes: pressure, temperature and / or flow;

[0110] The control system obtains the third operating parameters of the hydrogenation machine by means of a control chip in the hydrogenation machine...

Embodiment 3

[0138] The control system in this embodiment may be set in the control room, or may be set in the cloud server. The specific location of the control system is not limited in this embodiment, and the configuration is performed according to actual needs.

[0139] After determining the position information of hydrogen leakage, the control system of this embodiment sends a closing command to the electromagnetic valve or control valve adjacent to the position information, so as to close the equipment or pipeline of hydrogen leakage.

[0140] Further, the control system is also used to obtain the basic attribute parameters of each hydrogen energy device in the hydrogen refueling station, judge the service life of each hydrogen energy device, and determine whether to issue an early warning message for replacing the device.

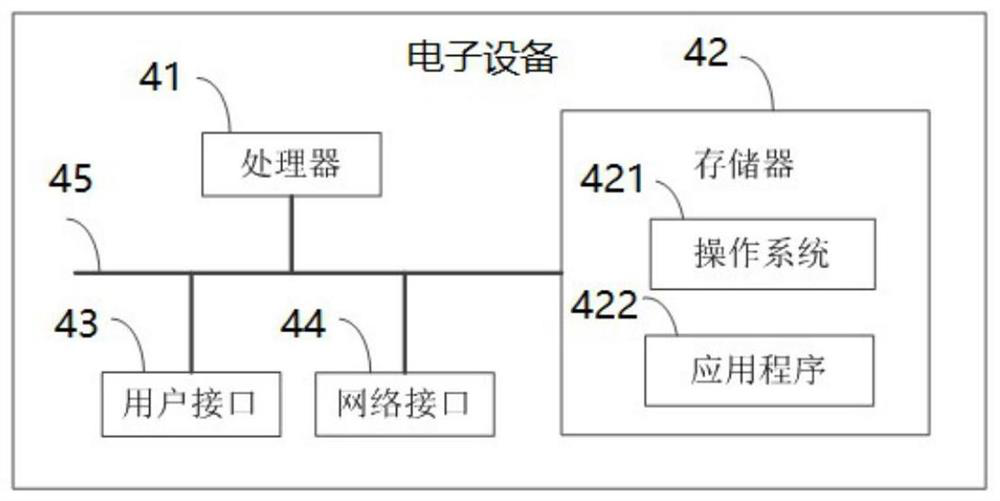

[0141] It should be noted that the control system of this embodiment may be a control program, which is stored in a memory, and the processor executes the program...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com