Multifunctional working machine for orchard

A working machine and multi-functional technology, applied in agricultural machinery and tools, gardening, agriculture, etc., can solve the problems of poor operating comfort, small operating space of the operating table, single function, etc., to achieve convenient operation, free rotation, flexible movement and walking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

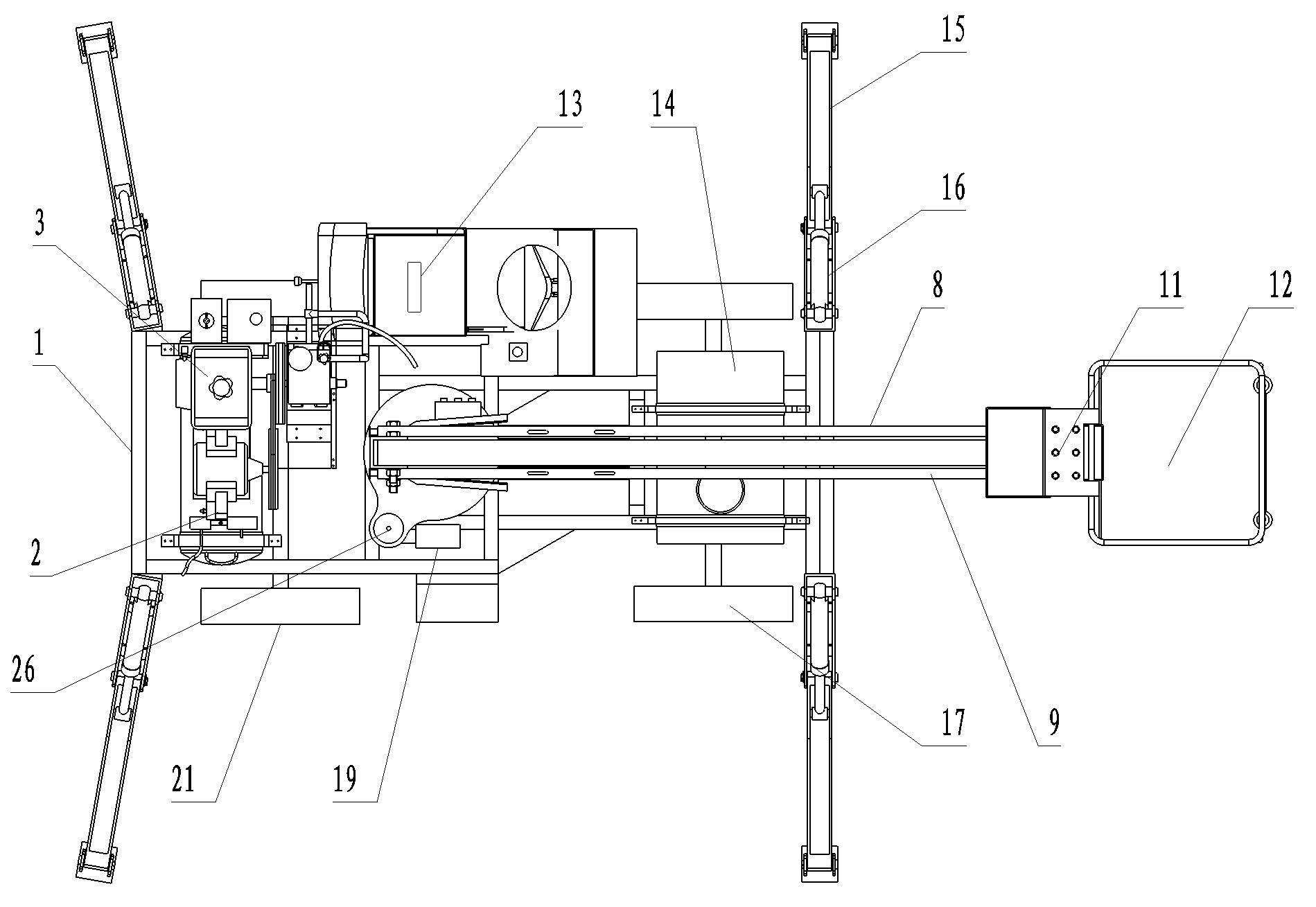

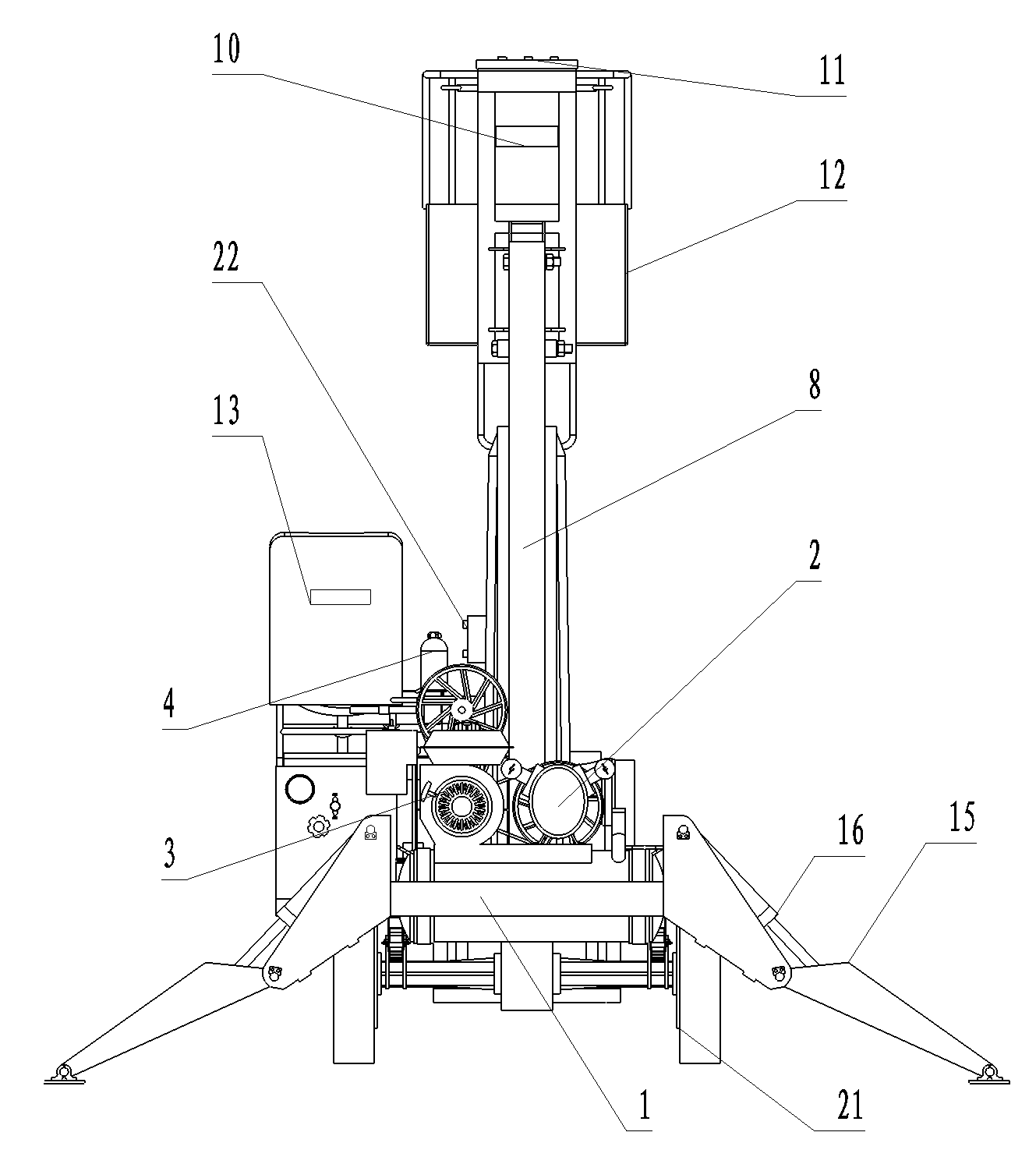

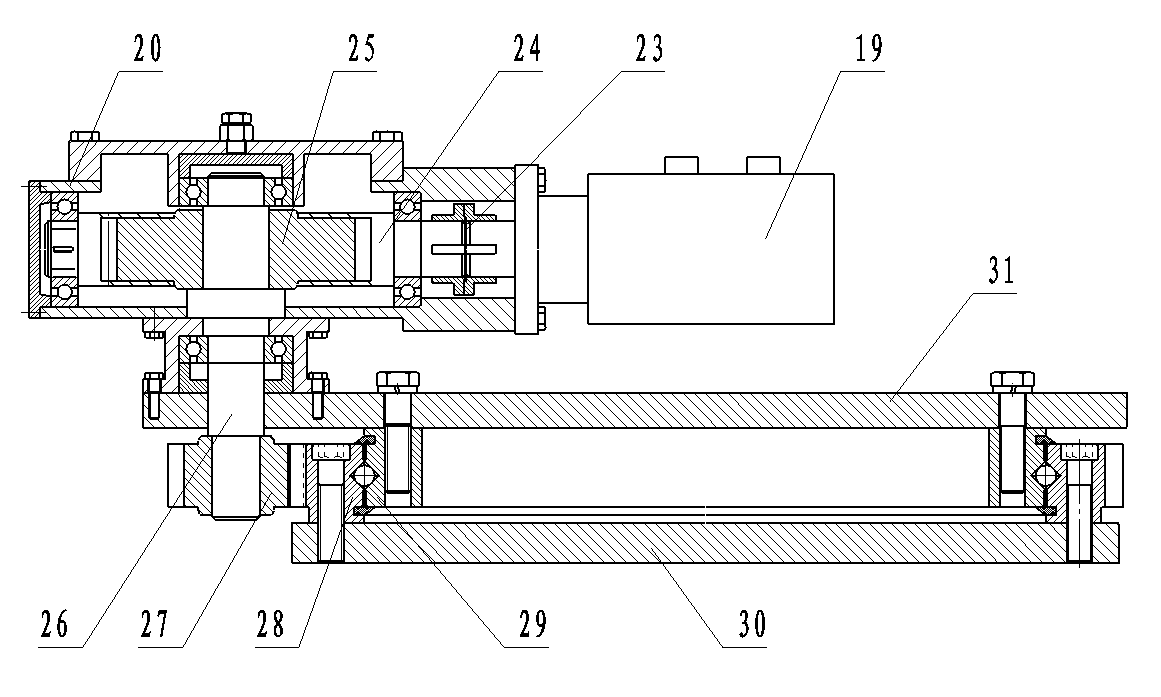

Embodiment 1

[0019] Embodiment 1: the present embodiment comprises operating device and operating platform; Described operating device is provided with traveling device, rotating device and lifting device; Described traveling device comprises engine one (18), traveling wheel, chassis (1) , the steering wheel (13); the rotating device includes a rotating assembly and a rotating column (6), and the rotating assembly includes a hydraulic motor (19), a worm gear reduction mechanism, and a slewing bearing, and the slewing bearing adopts an external gear type, embedded and fixed on the On the chassis (1), the outer ring gear (28) of the slewing support bearing is fixed on the upper surface (30) of the chassis (1), and the inner ring of the slewing support shaft (29) is fixed together with the lower end surface (31) of the rotating column. The hydraulic motor (19) and the worm gear box (20) are all fixed on the rotating column (6), the worm (24) is connected with the hydraulic motor (19) through a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com