Walking method of pipeline robot

A pipeline robot and pipeline technology, which is applied to the walking field of pipeline robots, can solve problems such as the inability to change the thickness, the inability to turn the pipeline, and the limitation of the application of pipeline robots.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

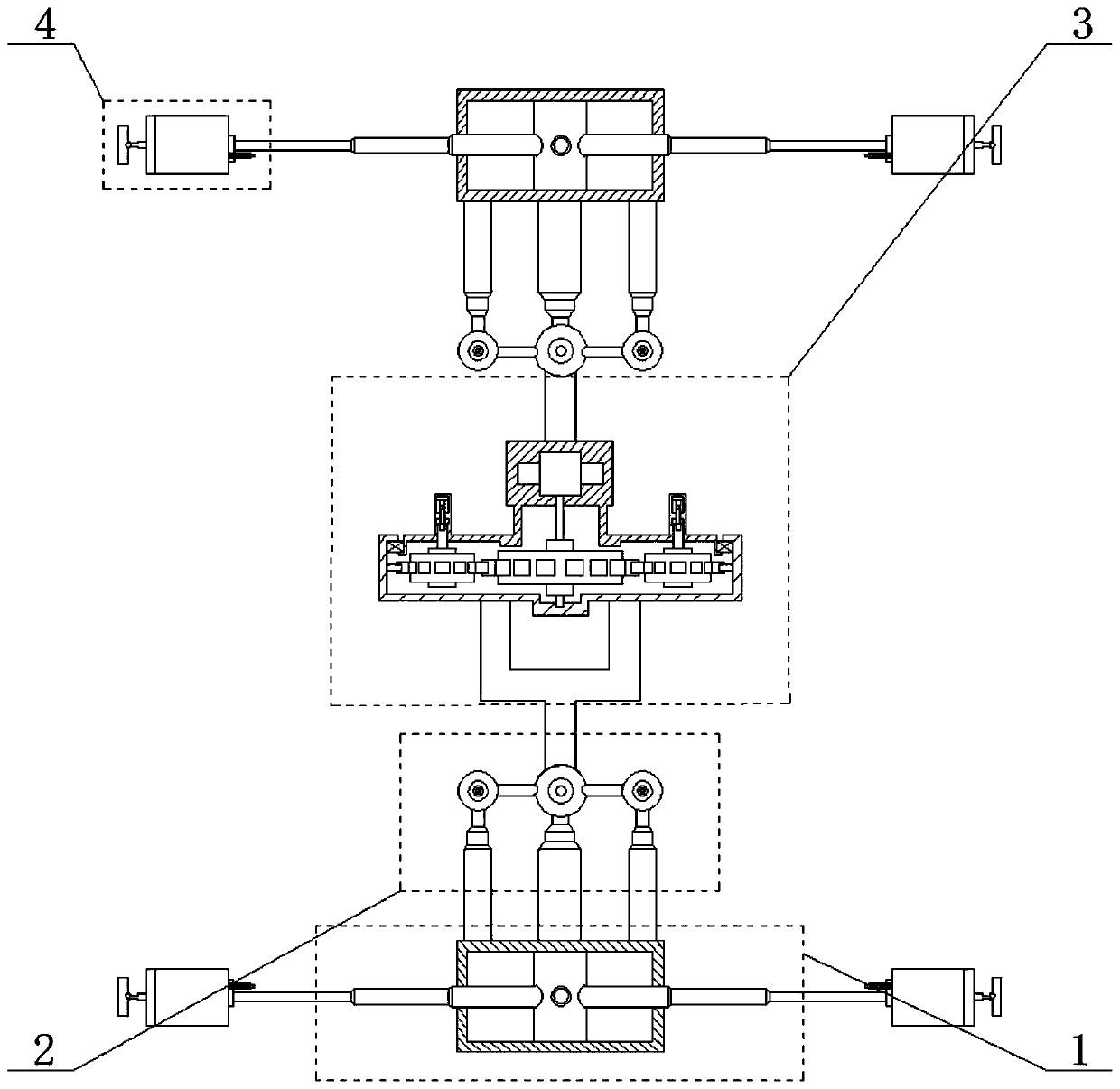

[0067] Such as figure 1 As shown, a pipeline robot disclosed in this embodiment includes: an extension drive device 1, a first steering drive device 2, a second steering drive device 3 and a foot 4; both ends of the second steering drive device 3 are connected to The movable end of a first steering drive device 2 is fixedly connected, and the fixed end of each first steering drive device 2 is fixedly connected with one end of an extension drive device 1, and a plurality of legs 4 are hinged on the extension drive device 1;

[0068] The first steering drive device 2 has a turning function and a telescopic function, and can drive the second steering drive device 3 to perform a turning movement. The first steering drive device 2 can drive the stretching drive device 1 to move through stretching. The stretching drive device 1 has a telescopic function. A steering drive device 2 is combined with the stretching drive device 1 to complete the action of entering the thin pipe from the...

specific Embodiment approach 2

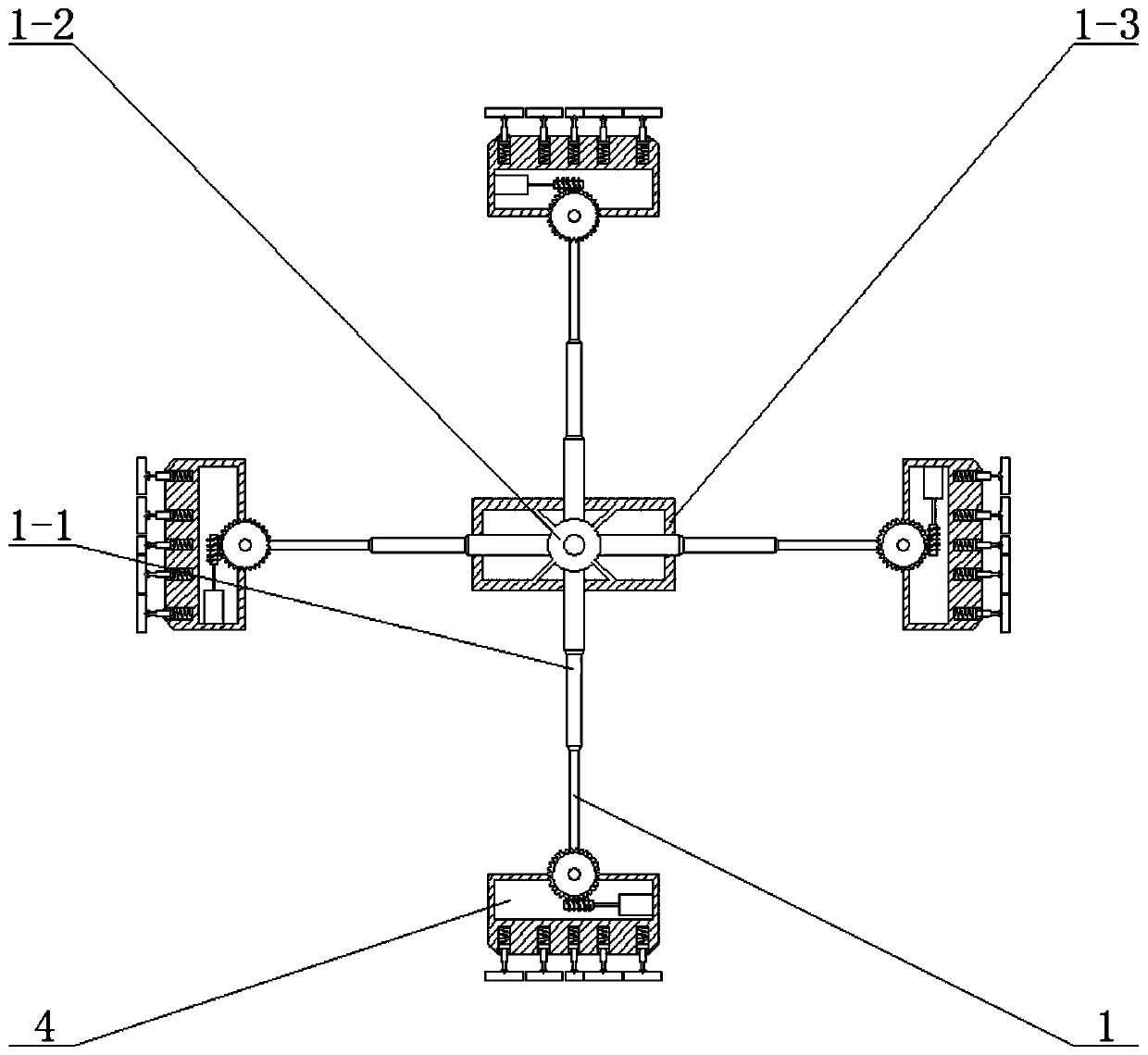

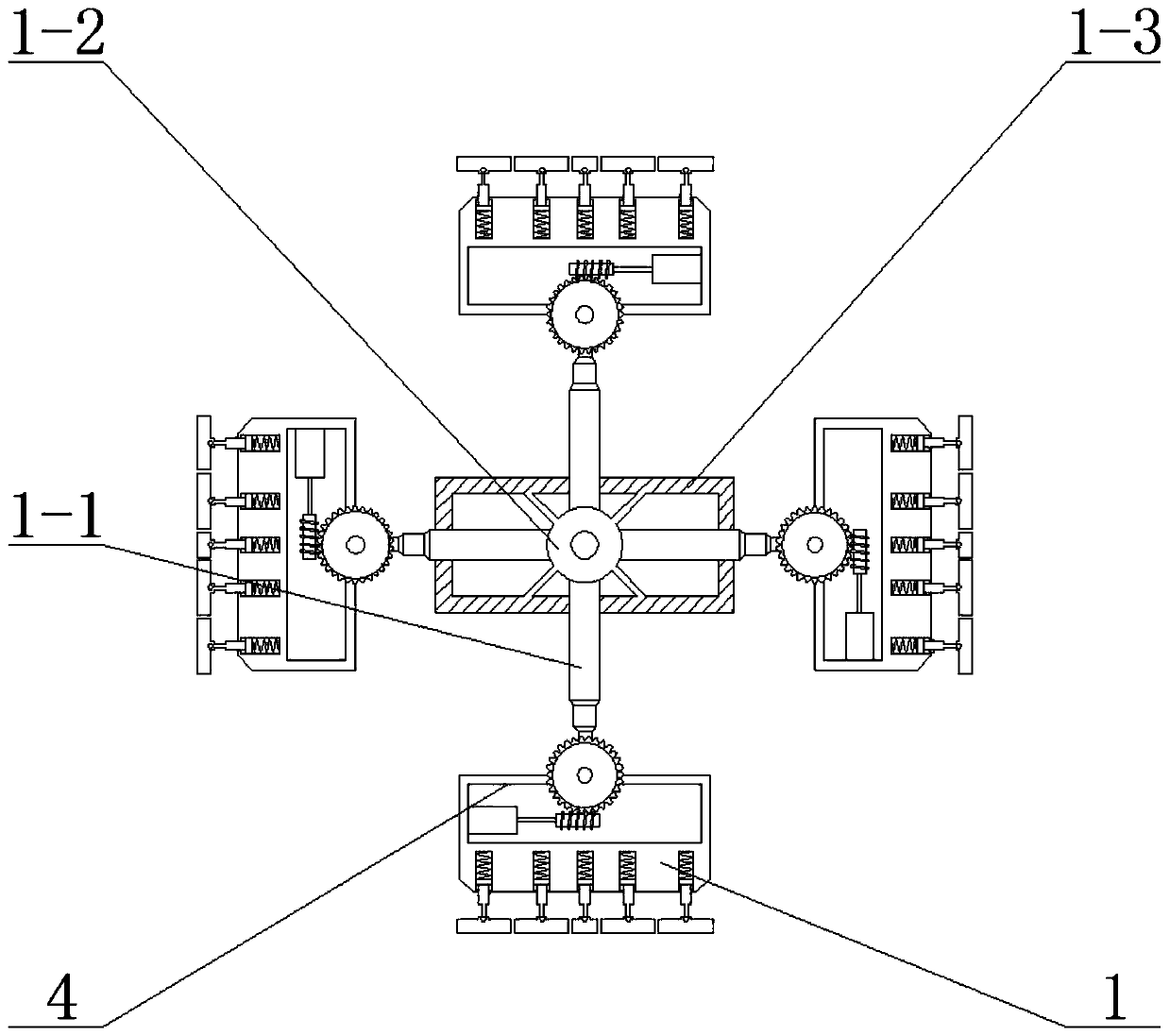

[0070] to combine Figure 1 to Figure 4 , this embodiment is based on the first specific embodiment, the difference is that: the first steering drive device 2 includes: a first telescopic rod 2-1, a second telescopic rod 2-2 and a steering drive rod 2-3; The fixed end of the first telescopic rod 2-1 is fixedly connected to the outer surface of the stretching drive device 1, and the two second telescopic rods 2-2 are arranged in parallel on the outer surface of the stretching drive device 1 and are located on the first telescopic rod 2. On both sides of -1, the fixed ends of the two second telescopic rods 2-2 are fixedly connected to the outer surface of the extension drive device 1, and the steering drive rod 2-3 is provided with multiple connection ends, and the first telescopic rod 2-1 The movable end of the two telescopic rods 2-2 is rotationally connected with the connection end located in the middle of the steering drive rod 2-3, and the movable ends of the two second tel...

specific Embodiment approach 3

[0072] to combine Figure 1 to Figure 4 , this embodiment is based on the second specific embodiment, the difference is that: the extension drive device 1 includes: a third telescopic rod 1-1, a fixed block 1-2 and a first housing 1-3; the first One end of the housing 1-3 is fixedly connected to the fixed end of the first telescopic rod 2-1 and the second telescopic rod 2-2, and the first housing 1-3 is fixedly connected with a fixed block 1-2 inside, and the fixed block 1- 2. A plurality of third telescopic rods 1-1 are welded symmetrically, the fixed ends of the third telescopic rods 1-1 are welded on the surface of the fixed block 1-2, and each movable end of the third telescopic rods 1-1 is hinged with a Leg 4;

[0073] The fixing block 1-2 plays a role of fixing each third telescopic rod 1-3. After the present invention is placed in the pipeline, all the third telescopic rods 1-3 drive each leg 4 to extend outward through elongation, even though each leg 4 is attached t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com