Angle-adjustable self-moving type scraper conveyor

A scraper conveyor, self-moving technology, applied in the direction of conveyors, conveyor objects, underground transportation, etc., can solve the problems of high labor intensity, lagging operation methods, low efficiency of mechanized transportation, etc., to improve construction efficiency, The effect of reducing labor intensity and flexible operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

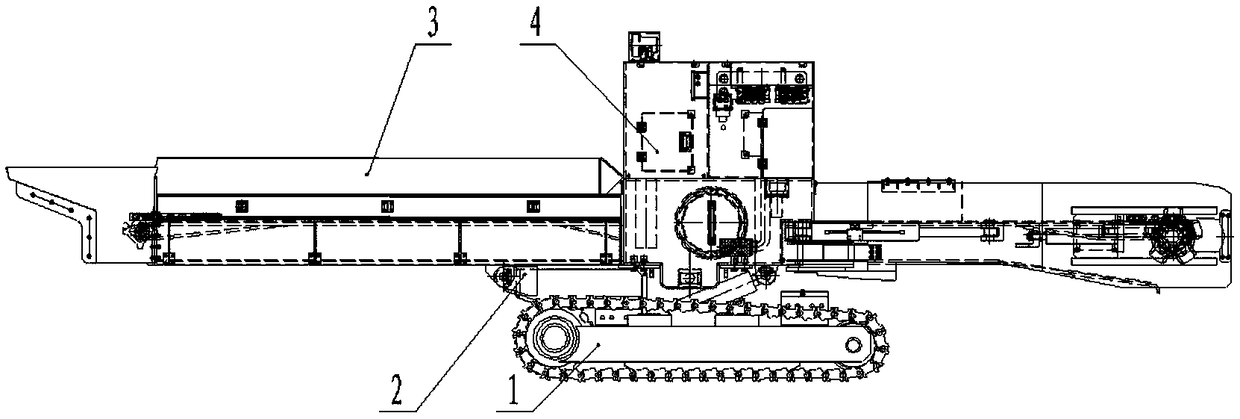

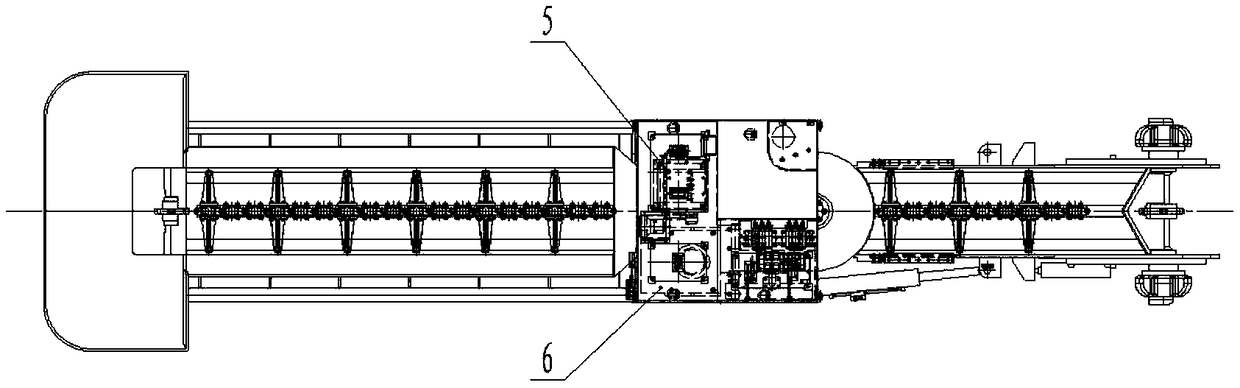

[0026] Such as figure 1 , figure 2 As shown, the adjustable-angle self-moving scraper conveyor in this embodiment is composed of six parts: traveling mechanism 1, body part 2, conveying part 3, guard plate part 4, electrical system 5 and hydraulic system 6. The walking mechanism 1 is arranged below the body part 2, the conveying part 3 is hinged to the upper part of the body part 2, the guard plate 4 is fixed at the upper middle position of the body part 2, and the electrical system 5 is arranged on the right side of the body part 2. , The hydraulic system 6 is provided on the left side of the body 2.

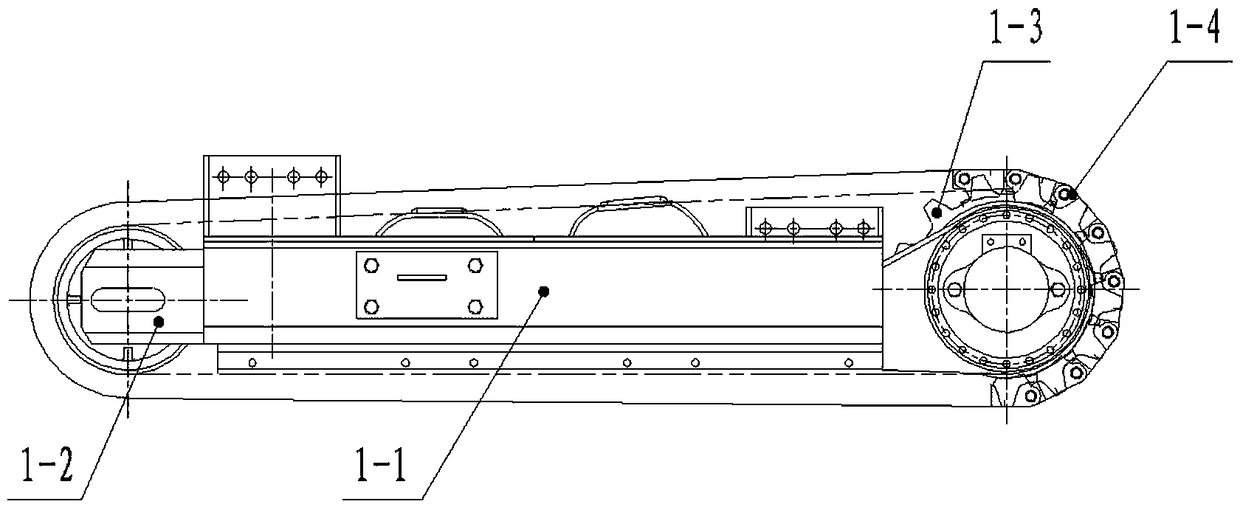

[0027] Such as image 3 , Figure 4 As shown, the walking mechanism 1 consists of a crawler frame 1-1, a reversing sprocket 1-2, a drive sprocket 1-3, a crawler 1-4, a first tensioning cylinder 1-5, a reducer 1-6 and The walking hydraulic motor 1-7 is composed of the reversing sprocket 1-2 and the driving sprocket 1-3 are respectively arranged at the front and rear ends of the cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com