Water-cutter cutting forming assembly for elbow workpiece

A waterjet cutting and workpiece technology, which is applied to the used abrasive processing device, manufacturing tool, explosion generating device, etc., can solve the problems of grinding wheel consumption, burning loss, oxidation smoke, etc. The effect of reliable positioning and novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

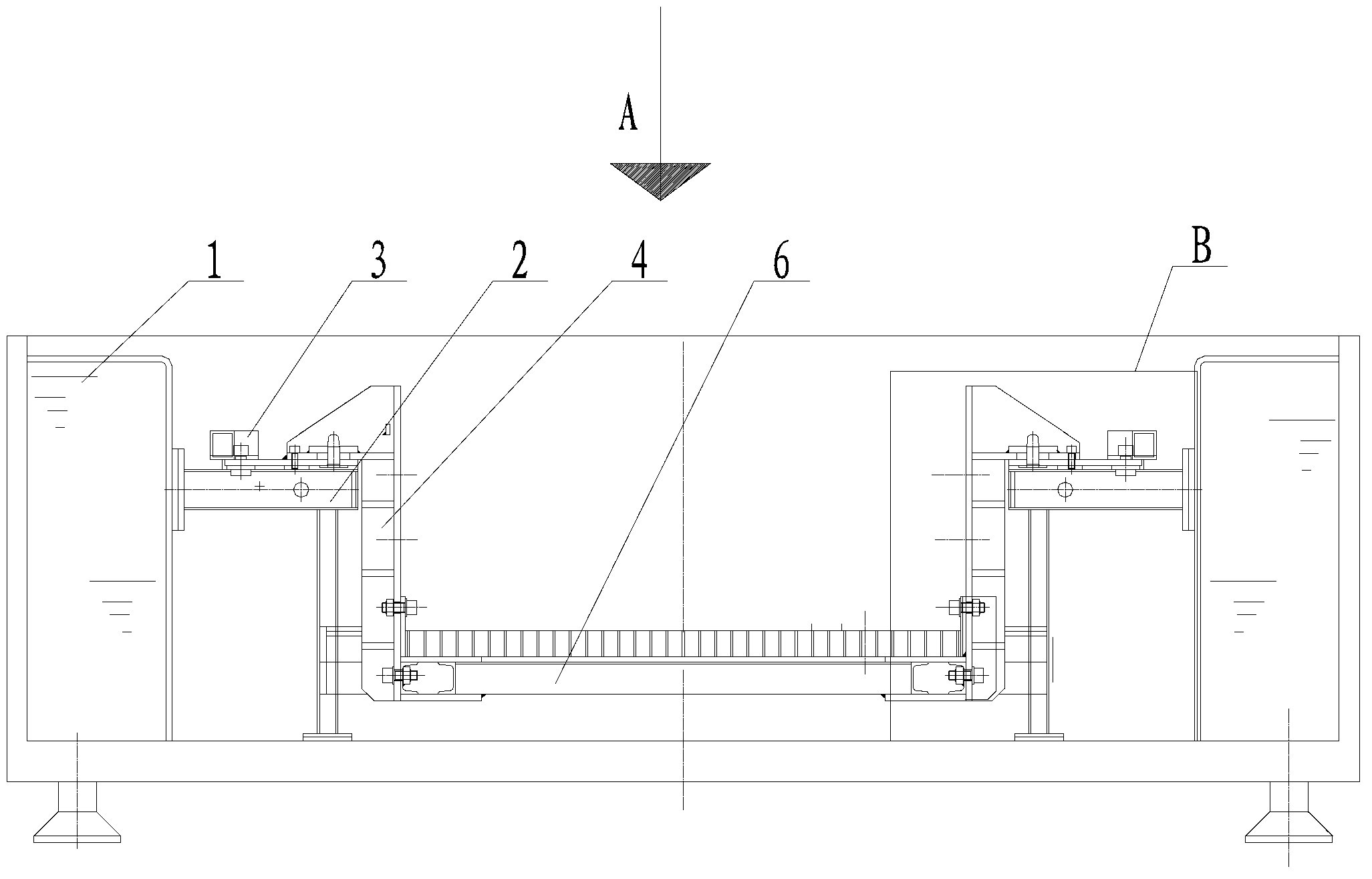

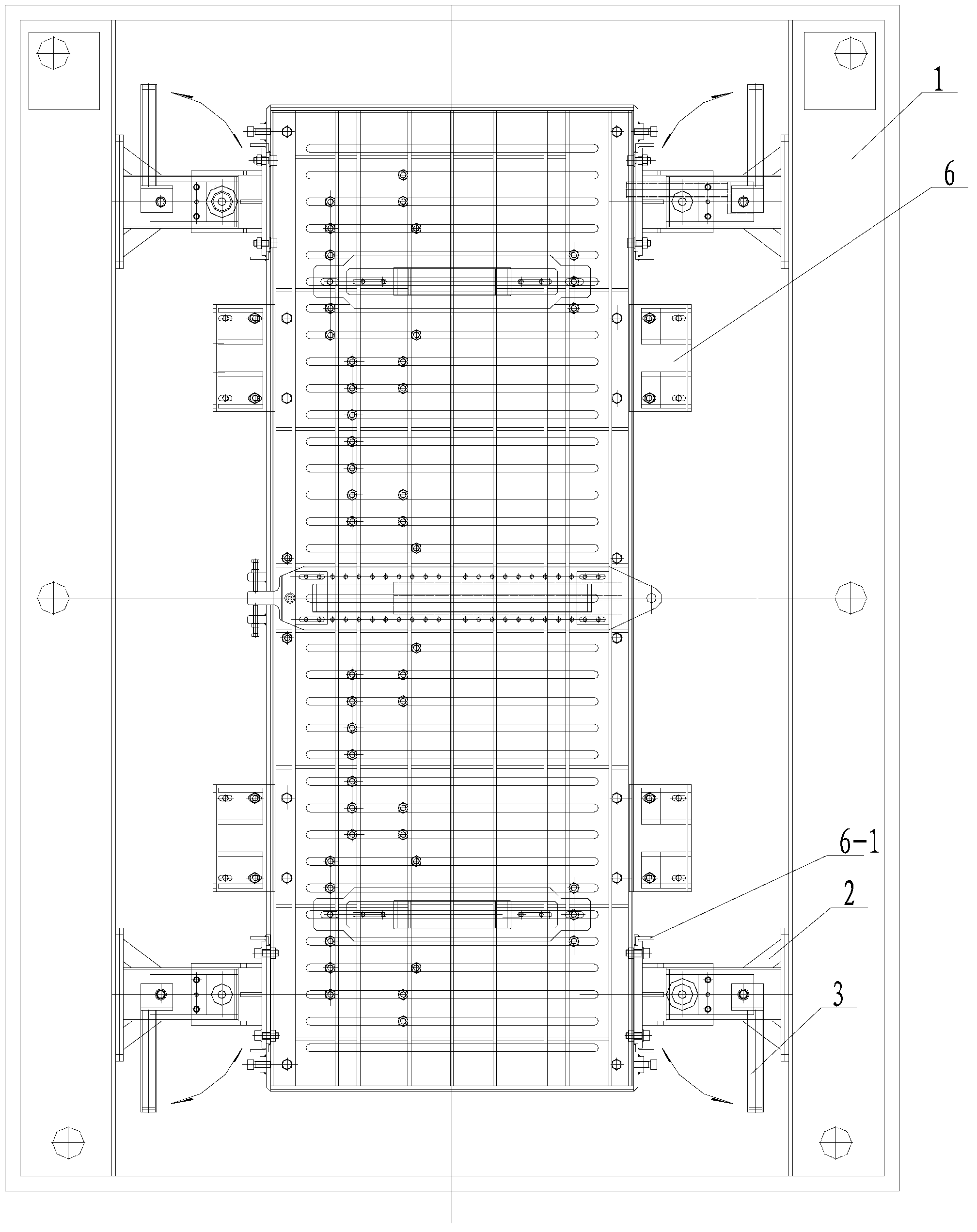

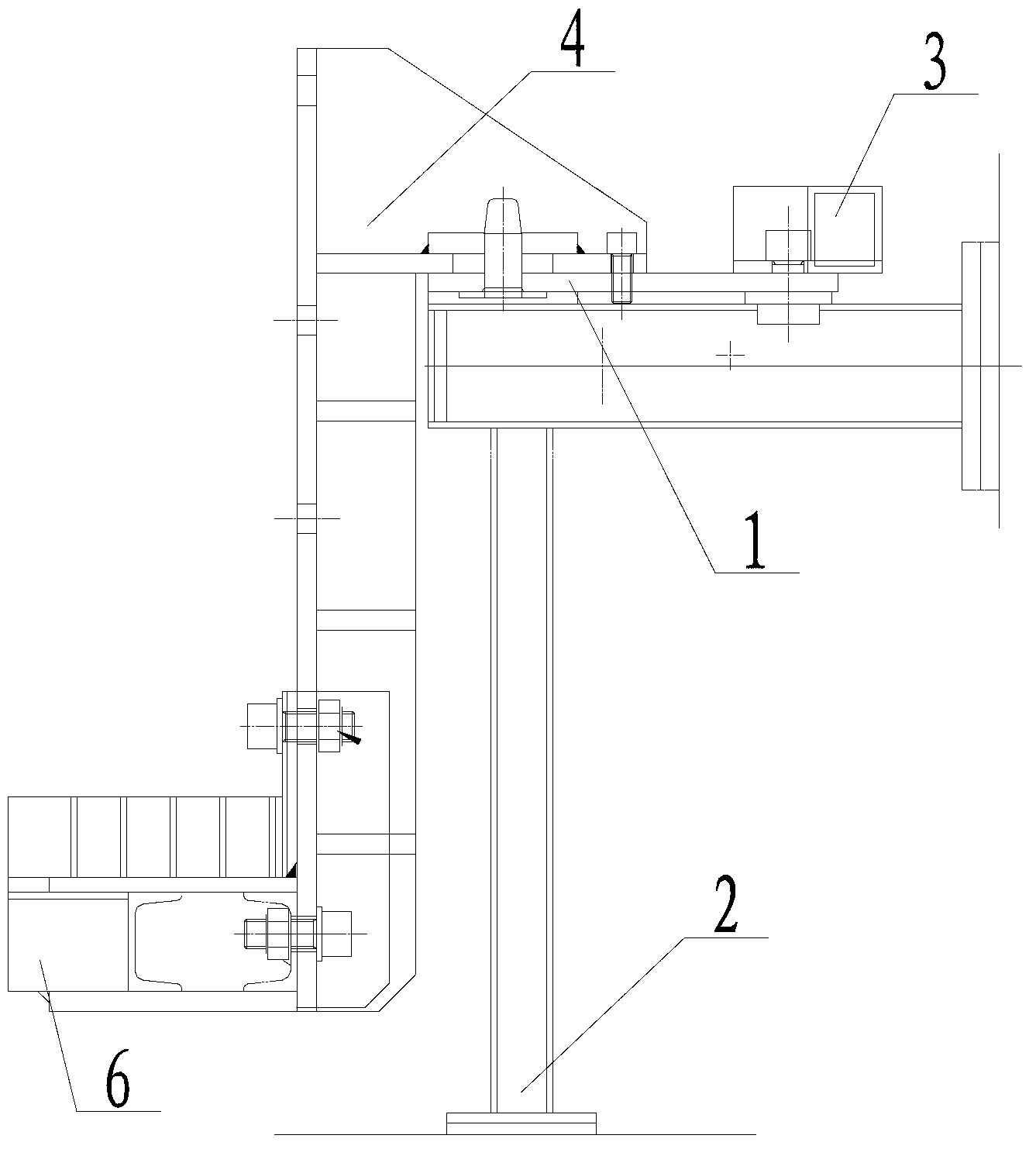

[0020] combined with Figure 1-Figure 3 The present invention is further described:

[0021] A waterjet cutting and forming tool for elbow workpieces of the present invention includes a working water tank 1 , two pairs of fixed supports 2 , rotating legs 3 , hooks 4 , backing plates 5 and racks 6 .

[0022] The working water tank 1 is placed on the ground of the operating room, and the inside of the working water tank 1 is filled with water. Two pairs of fixed supports 2 are symmetrically installed in the working water tank 1, and the fixed supports 2 are "L" shaped, and the ends at both ends are fixedly installed on the bottom surface and the side surface of the working water tank 1 respectively. The rotating outrigger 3 is installed on the backing plate 5 of the fixed support 2 fitted therewith by bolts. The hook 4 is installed on the horizontal supporting surface connected to the side of the fixed support 2 through the backing plate 5 . The hook 4 and the backing plate 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com