Totally-enclosed parallel apparatus of production and dosage

A fully enclosed, parallel technology, applied in feeding devices, mixer accessories, dissolution and other directions, can solve the problems of increasing equipment investment, wasting space and human resources, and many pipelines, etc., to simplify production personnel, shorten production cycles, and improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

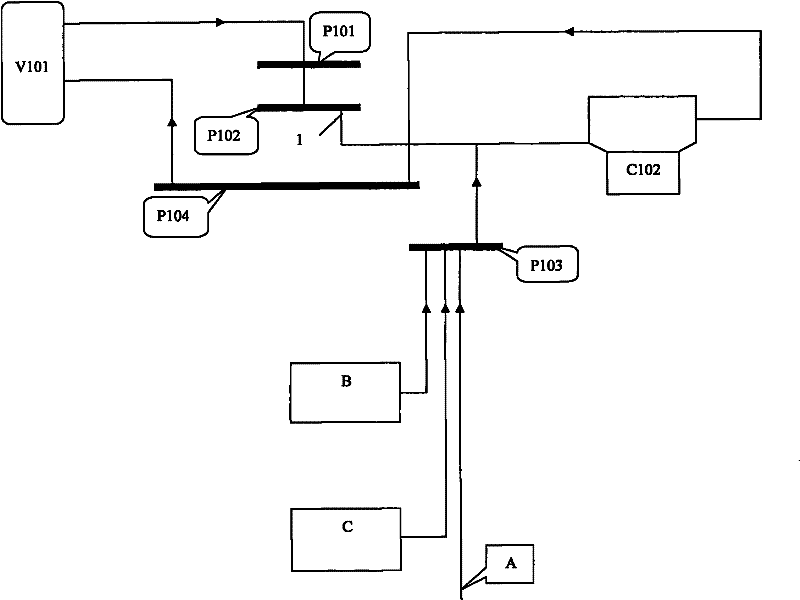

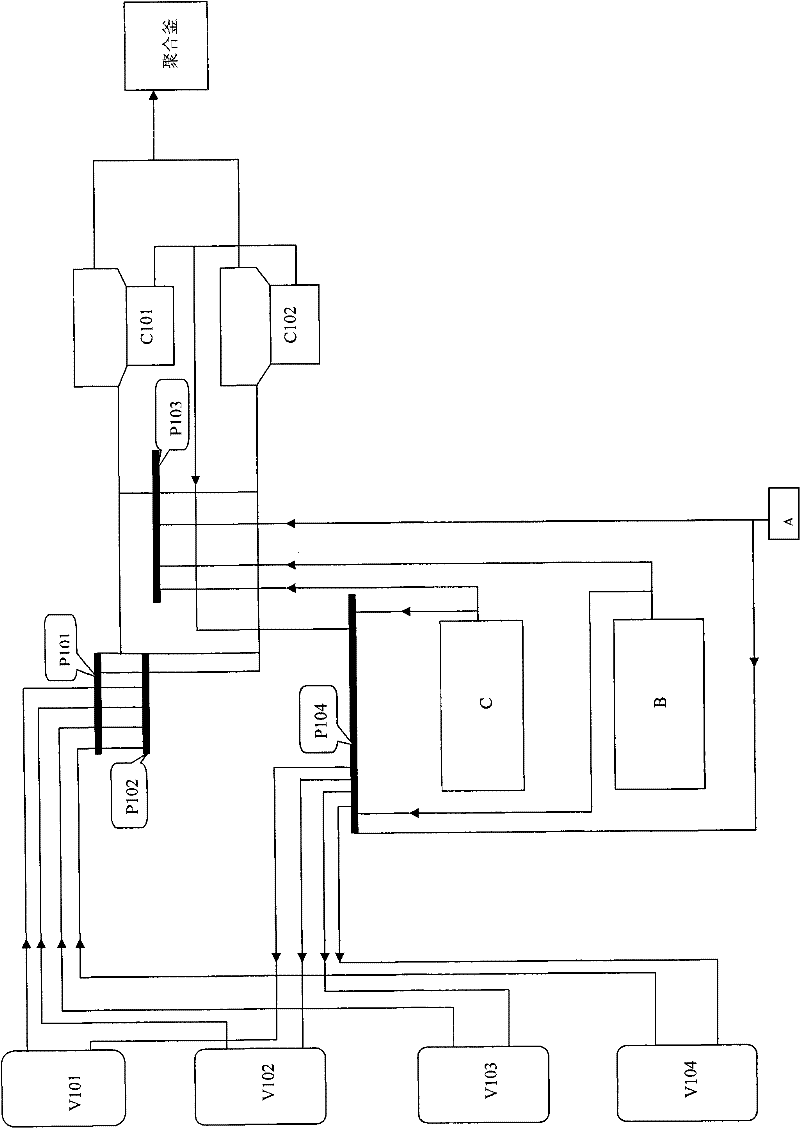

[0011] combine figure 1 , a fully enclosed production batching parallel device of the present invention is characterized in that it includes a batching tank V101, an additional tank V103, a first sealing cylinder P101, a second sealing cylinder P102, a third sealing cylinder P103, a fourth Sealed cylinder P104, first diaphragm compressor C101, second diaphragm compressor C102,

[0012] The batching tank V101 is connected to the second sealed cylinder P102 through pipelines, the discharge port of the first sealed cylinder P101 is connected to the second diaphragm compressor C102 through pipelines, and the output end of the second diaphragm compressor C102 is connected to the fourth sealed cylinder The cylinders P104 are connected through pipelines, and the fourth sealed cylinder P104 is connected with the batching tank V101 through pipelines, wherein the raw materials are added to the second diaphragm compressor C102 through the third sealed cylinder P103.

[0013] combine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com