Method for recovering and reutilizing waste ammonia gas in LED (light-emitting diode) manufacturing through compression method

A compression method and ammonia gas technology, which is applied in the field of recycling waste ammonia gas in the recycling of LED manufacturing by compression method, to achieve significant energy-saving benefits and solve the effect of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

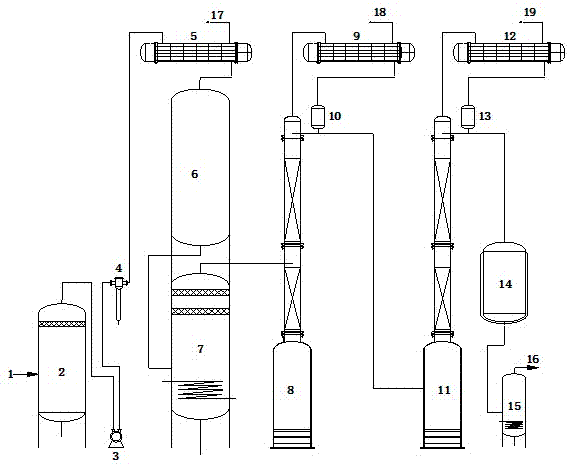

[0014] Below, refer to the attached figure 1 The block diagram of the production system shown illustrates the method of the invention in detail.

[0015] The waste ammonia gas comes from the MOCVD furnace exhaust gas main pipe 1, which is connected to the inlet of the buffer tank 2, and the gas outlet of the buffer tank 2 is connected to the inlet of the diaphragm compressor 3, and the ammonia gas content is sucked in the range of -0.05 ~ 0.01Mpa under a slight negative pressure of 10 % waste gas, the outlet of diaphragm compressor 3 is connected to the inlet of filter 4, and the waste ammonia gas is compressed to 1.3-1.6Mpa through the compressor.

[0016] The waste ammonia gas after pressurization passes through the filter 4 to filter out the metal ions in the waste ammonia gas. The outlet of the filter 4 is connected with the inlet of the condenser 5, and the compressed ammonia gas is condensed into liquid ammonia by cooling water at 20-40°C, and the condensed liquid ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com