Hydrogen generating and refilling system and method capable of refilling hydrogen fast

A hydrogen refueling station, hydrogen technology, applied in container filling methods, equipment loaded into pressure vessels, transportation and packaging, etc., can solve the problem of inability to guarantee system safety and commerciality, flow, pressure, temperature, stress deformation, etc. Monitoring and metering, car mileage discount and other issues to achieve the effect of improving filling efficiency, hydrogen filling safety, and good pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

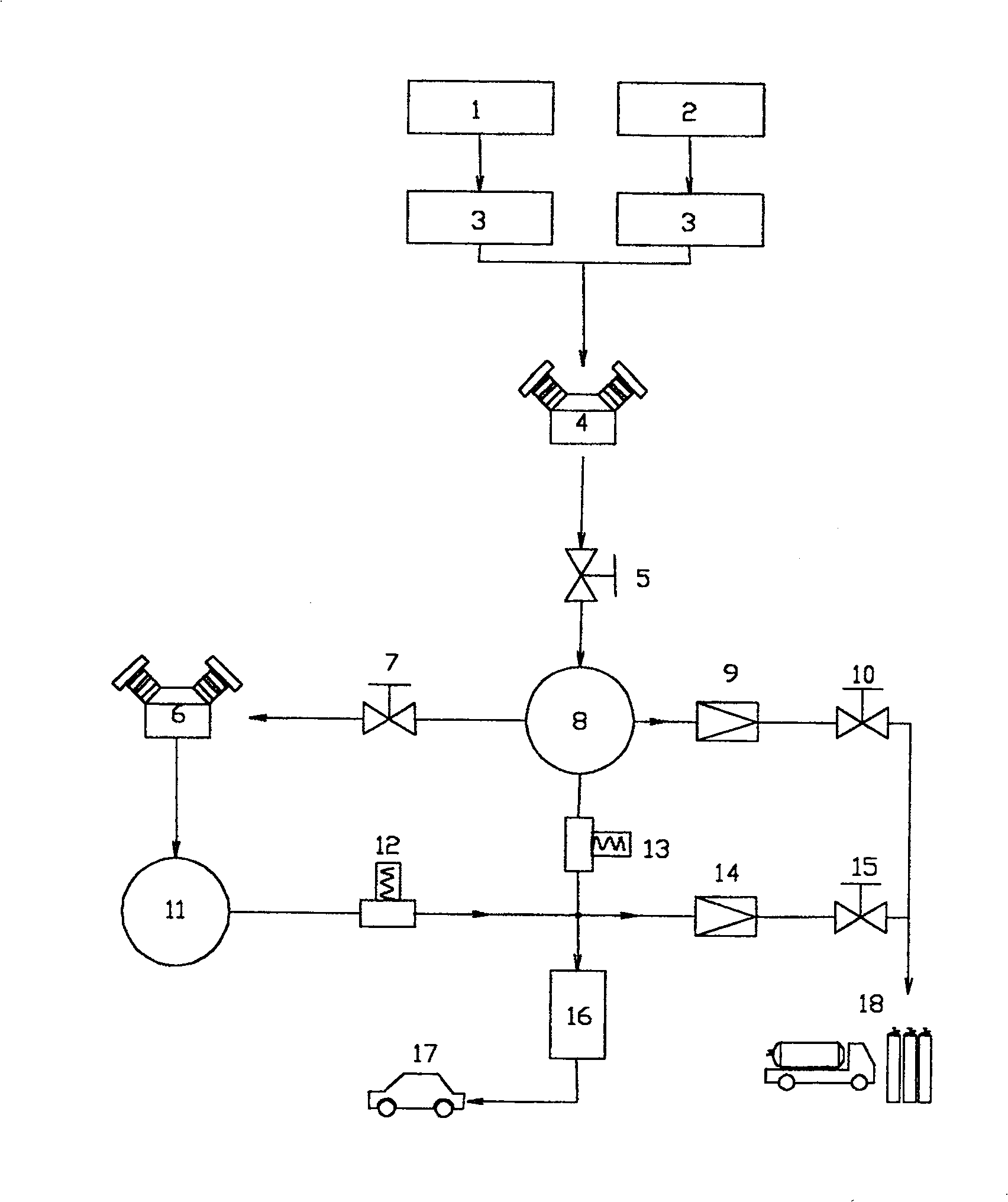

[0018] First, the hydrogen produced by electrolysis of water for hydrogen production 1 and natural gas reforming for hydrogen production 2 is purified through the hydrogen purification device 3 to remove oxygen, CO, sulfide, water, etc. in the hydrogen to meet the quality required for use. Then the purified hydrogen is input to the inlet of the hydrogen diaphragm compressor [4] (pressure is 1.6MPa~4MPa), after the hydrogen is compressed and boosted to 40MPa by the hydrogen diaphragm compressor 4, a multi-layer steel belt with a pressure resistance of 40MPa is input Stored in winding hydrogen high-pressure hydrogen storage tanks [8]. (This method of purifying hydrogen first and then boosting storage is meaningful in the north, which can avoid the problem of freezing unpurified hydrogen in a low-pressure storage tank, and save a large-capacity low-pressure storage tank at the same time investment). Pressure resistance 40MPa, water volume 5~10m 3 The first hydrogen storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com