Full-automatic start-stop control system of diaphragm compressor

A diaphragm compressor, start-stop control technology, applied in the direction of pump control, machine/engine, mechanical equipment, etc., can solve the problems of complex control process of diaphragm compressor and manual operation on site, so as to reduce the risk of seal failure and avoid efficiency Reduce and achieve the effect of exhaust pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

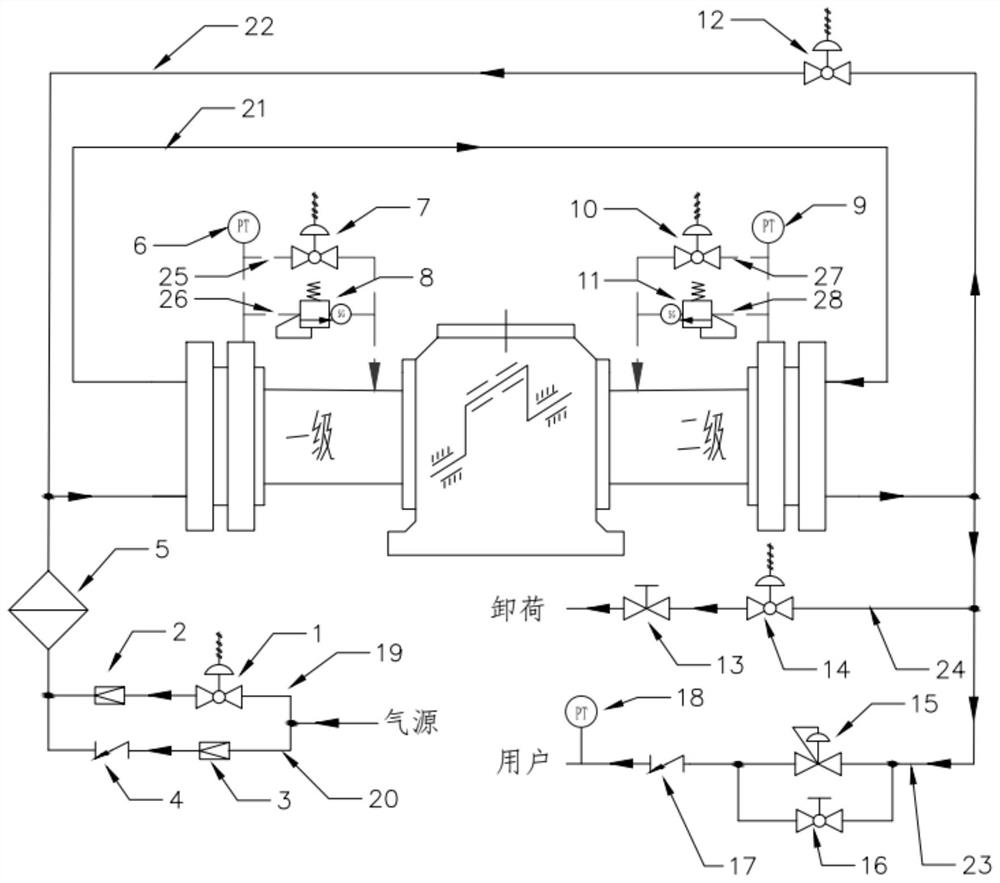

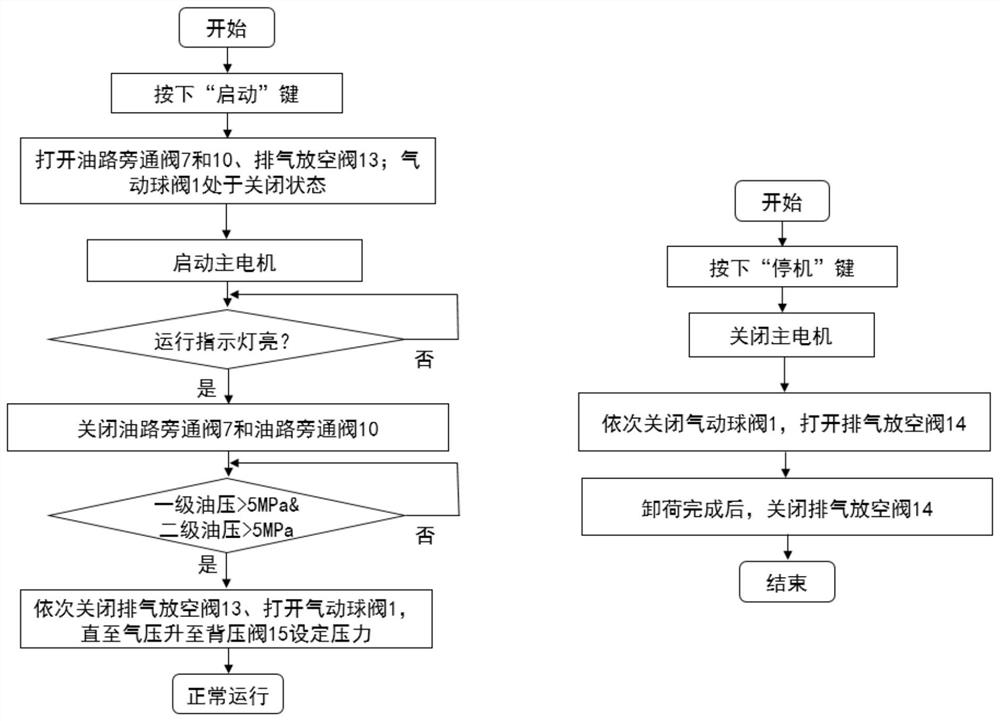

[0038] A fully automatic start-stop control system for diaphragm compressors. The system can realize one-key start-up and one-key stop without manual operation of various valves, saving manpower and ensuring efficient and stable operation of the system. In addition, the operation of the system designed according to the present invention can ensure that the inside of the compressor system always maintains a slight positive pressure state, preventing seal failure and causing leakage; during the start-up pre-operation stage, the compressor can be kept in an unloaded state to reduce the impact current of the motor , to ensure the stable operation of the equipment, and greatly improve the success rate of startup; the system is equipped with a bypass air circuit, which can realize the function of adjusting the flow rate of the compressor with the PLC control circuit.

[0039] Specifically, see figure 1 , a diaphragm compressor automatic start-stop control system designed by the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com