Oil pressure and air pressure monitoring device and method for diaphragm compressor

A diaphragm compressor and air pressure monitoring technology, applied in the field of compressors, can solve problems affecting cylinder strength, potential safety hazards, leakage, etc., and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

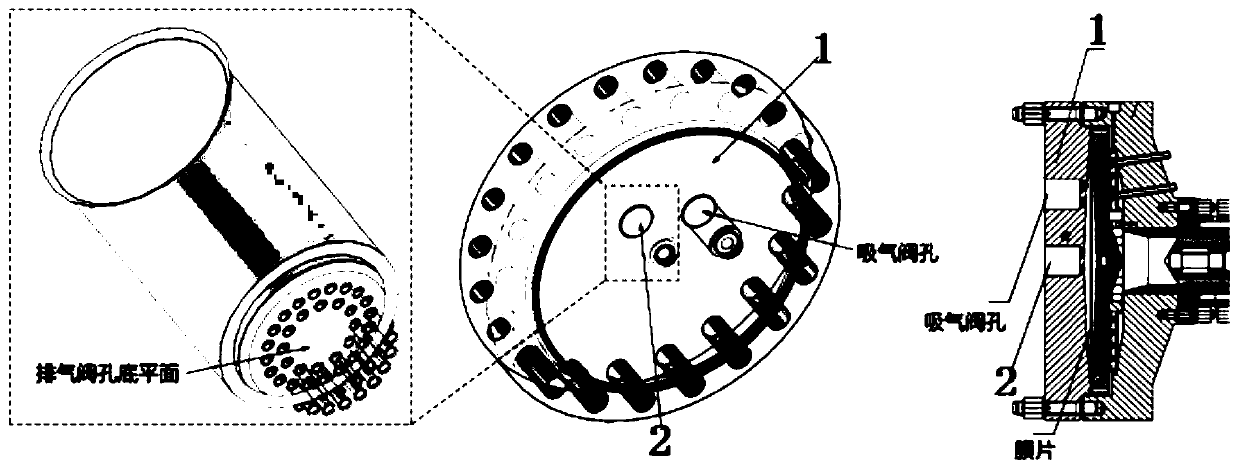

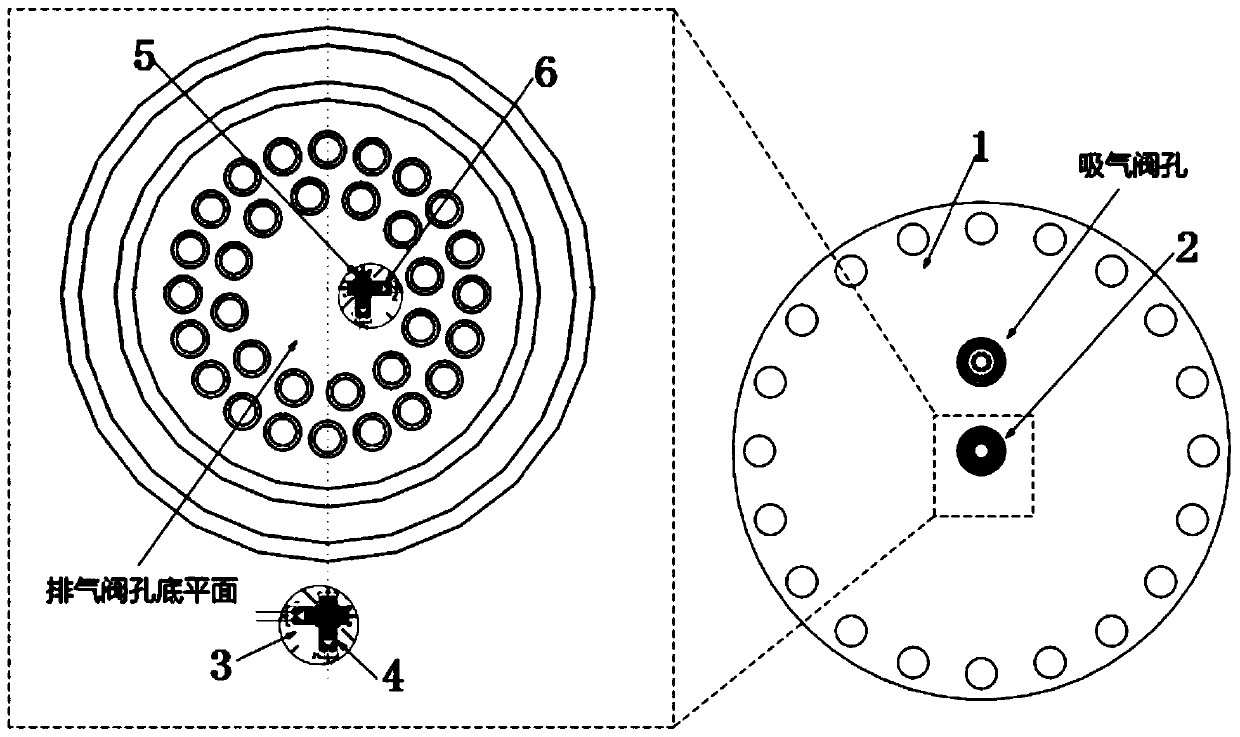

[0042] Hereinafter, specific embodiments of the present application will be described in detail with reference to the accompanying drawings. According to these detailed descriptions, those skilled in the art can clearly understand the present application and can implement the present application. Without departing from the principle of the present application, the features in different embodiments can be combined to obtain new implementations, or some features in certain embodiments can be replaced to obtain other preferred implementations.

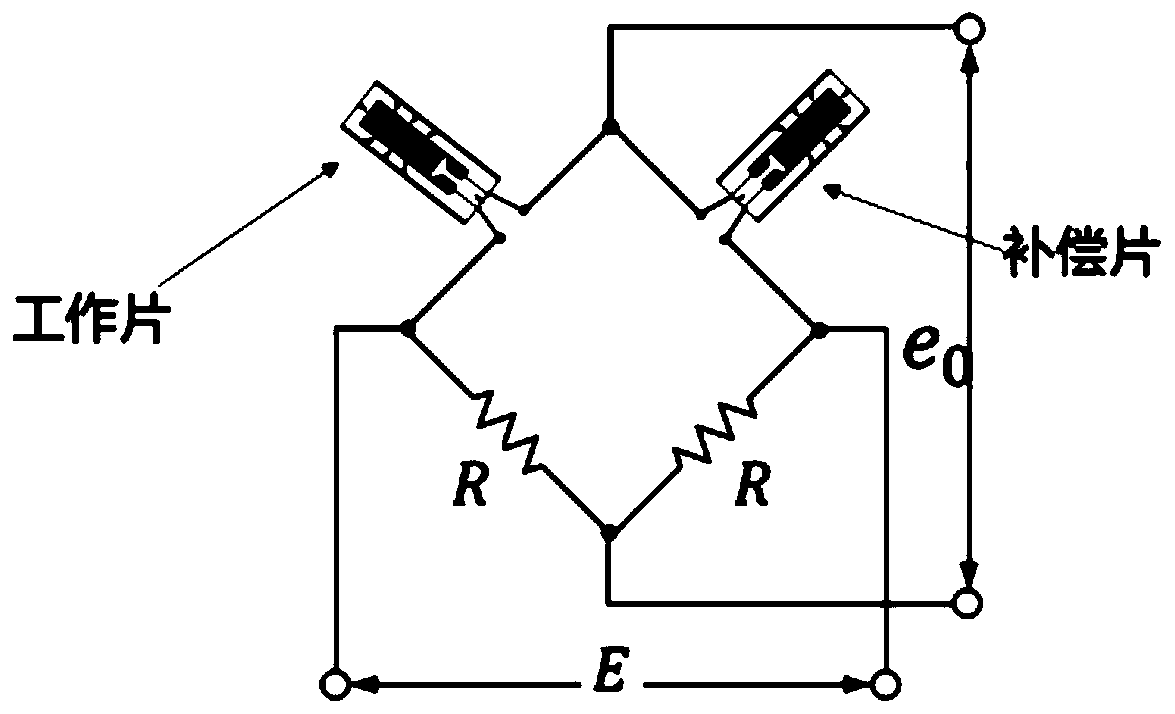

[0043] Strain gauges are components used to measure strain, which are composed of sensitive grids and the like. The working principle of the resistance strain gauge is based on the strain effect, that is, when the conductor or semiconductor material is mechanically deformed under the action of an external force, its resistance value changes accordingly. This phenomenon is called "strain effect".

[0044] A quadrilateral measuring bridge c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com