Method for synthesizing polysilicon raw material trichlorosilane

A technology of trichlorosilane and polycrystalline silicon, which is applied in the direction of halosilane and silicon halide compounds, can solve the problems of resource waste, low heat transfer efficiency, and high yield, and achieve the effect of improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

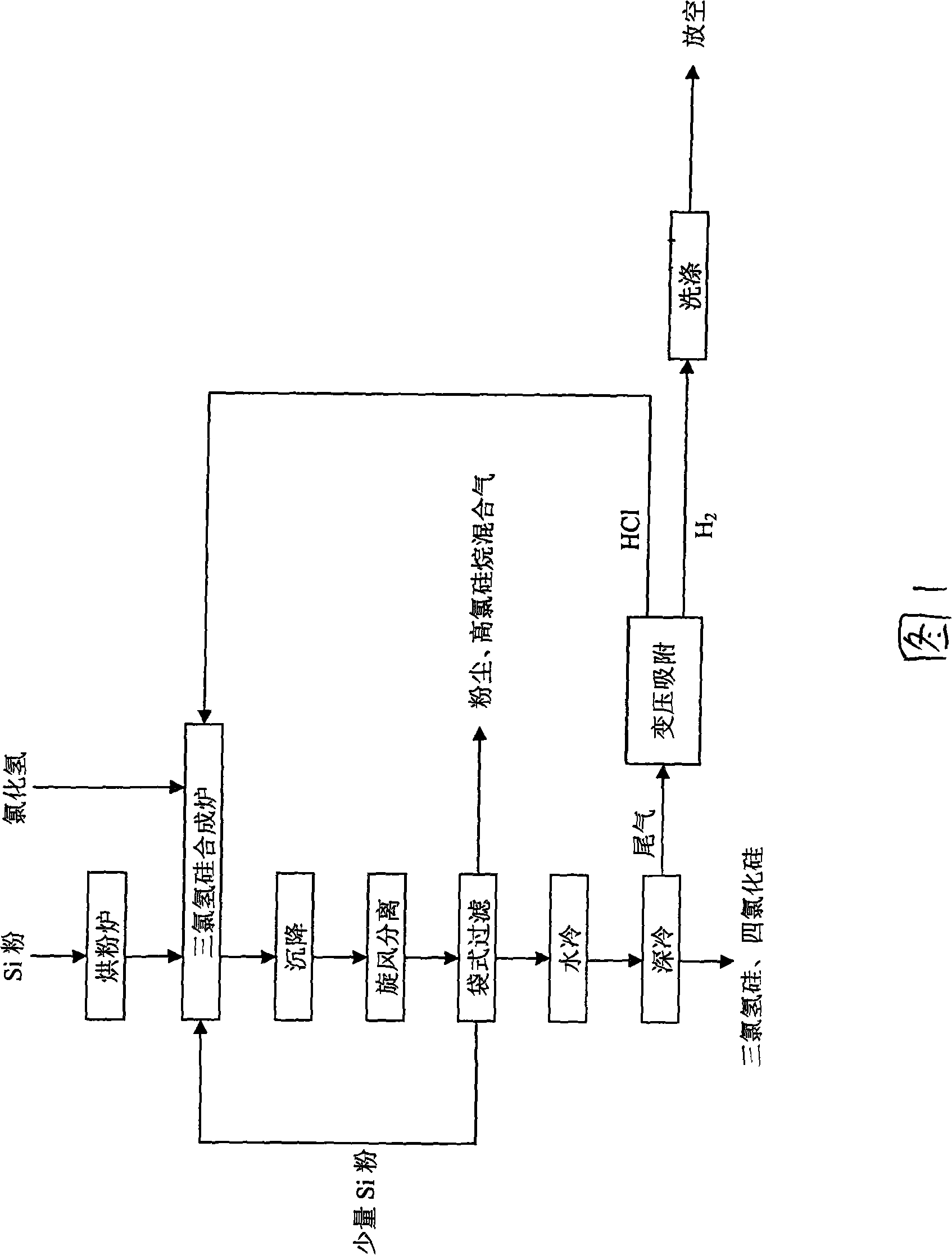

[0022] See process flow diagram 1.

[0023] The raw silicon powder is transported in by tank truck, and is transported to the silicon powder raw material warehouse through pipelines under the protection of nitrogen. The silicon powder in the raw material bin is added to the bin-type pneumatic conveying pump through a star feeder, and the bin-type pneumatic conveying pump continuously feeds the silicon powder into the monomer at a rate of 1200 kg / hour (about 42,900 moles / hour) The powder drying furnace of the synthesis device, and the drying is carried out in the silicon powder drying furnace.

[0024] The qualified silicon powder dried by hot nitrogen in the powder oven is fed with 760 standard cubic meters per hour (about 33,900 mol / hour, the molar ratio of hydrogen chloride to silicon powder is about 0.78) at 100°C. Synthesis Reactor.

[0025] Reactive hydrogen chloride is synthesized by using liquefied chlorine as raw material and hydrogen. 2300 standard cubic meters per...

Embodiment 2

[0028] The silicon powder is continuously sent to the powder drying furnace of the monomer synthesis device at a rate of 1200 kg / hour; the temperature of the hydrogen chloride gas used for transportation is 100°C, the dosage is 900 standard cubic meters / hour, and the molar ratio of the dried hydrogen chloride to the input silicon powder About: 0.94:1; the hydrogen chloride used for the reaction is 2100 standard cubic meters per hour, and the molar ratio of hydrogen chloride and silicon powder is about 2.18; the mixing ratio of silicon tetrachloride and hydrogen chloride used for the reaction is: n silicon tetrachloride / n hydrogen chloride=1 / 8.5; the dried hydrogen is passed into from the bottom of the direct synthesis furnace according to the ratio of n hydrogen / n hydrogen chloride=1 / 11 in molar ratio. Other parameters and preparation steps remain unchanged, and the final yield of trichlorosilane is 88%.

Embodiment 3

[0030] The silicon powder is continuously fed into the powder drying furnace of the monomer synthesis device at a rate of 1200 kg / hour; the temperature of the hydrogen chloride gas used for transportation is 100°C, the dosage is 550 standard cubic meters / hour, and the molar ratio of the input silicon powder to the dry hydrogen chloride is About: 0.56: 1; the hydrogen chloride used for the reaction is 2400 standard cubic meters per hour, and the molar ratio of hydrogen chloride and silicon powder is about 2.48; the mixing ratio of silicon tetrachloride and hydrogen chloride used for the reaction is: n silicon tetrachloride / n hydrogen chloride=1 / 9.8; the dried hydrogen is passed into from the bottom of the direct synthesis furnace according to the molar ratio n hydrogen / n hydrogen chloride=1 / 14.5 ratio. Other parameters and preparation steps remain unchanged, and the final yield of trichlorosilane is 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com