System and method for tail gas treatment of conversion reaction of organic silicon low-boiling-point substances

A technology for tail gas treatment and low boiling matter, which is applied in the direction of silicon organic compounds, chemical instruments and methods, separation methods, etc., can solve problems such as difficult tail gas treatment, and achieve the effects of improving conversion rate, increasing running time, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

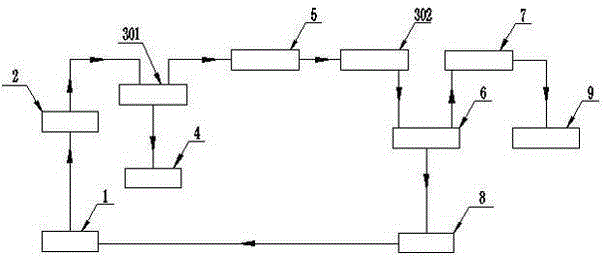

[0023] See attached figure 2 , the tail gas treatment system of a kind of organosilicon low boiler conversion reaction given in this embodiment is as follows, the present invention is described in detail below in conjunction with accompanying drawing and embodiment:

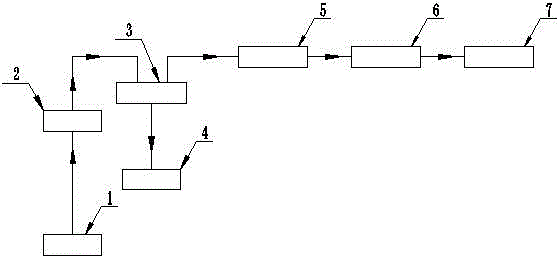

[0024] See attached figure 1 And attached figure 2 , the tail gas treatment system of a kind of organosilicon low boiler conversion reaction given in this embodiment is as follows, the conversion kettle 1 is connected with the washing tower 2 through pipelines, the reflux tank 4 is connected with the condenser pipeline, and the condenser is compressed by a gas diaphragm The machine 5 is connected with the tail gas buffer tank 6; the tail gas buffer tank 6 is connected with the inlet of the conversion tank 1 through the circulation pump 8.

[0025] The condenser is divided into two, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com