High temperature gas-cooled reactor helium purification regeneration system and regeneration method

A high-temperature gas-cooled reactor and regeneration system technology, applied in the field of nuclear reactors, can solve the problems of frozen regeneration circuit, short running time and diffusion of helium purification system, and achieve efficient regeneration, high-efficiency operation, and high-efficiency desorption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 A high temperature gas-cooled reactor helium purification regeneration system

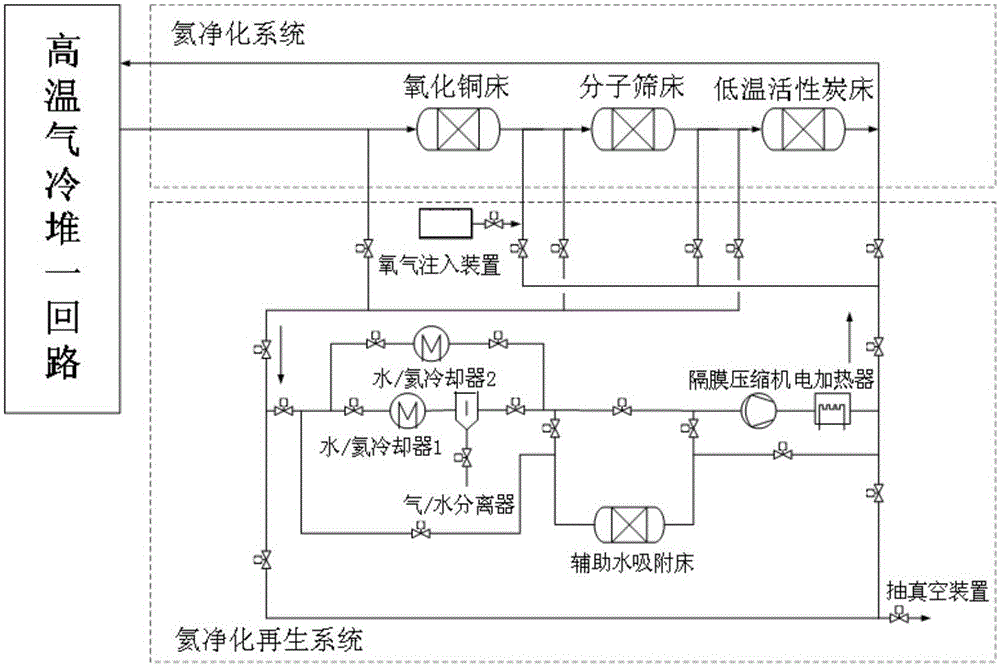

[0040] A high temperature gas-cooled reactor helium purification regeneration system, such as figure 1 As shown, it includes a diaphragm compressor, an electric heater, a water / helium cooler 1, a gas / water separator, an auxiliary water adsorption bed, and a vacuum device with a discharge pipeline inside; wherein, the auxiliary water adsorption bed is also set up a bypass;

[0041] Through each device, the regeneration circuit of the copper oxide bed of the helium purification system, the regeneration circuit of the molecular sieve bed of the helium purification system, the regeneration circuit of the auxiliary water adsorption bed, and the regeneration circuit of the low-temperature activated carbon bed of the helium purification system can be formed;

[0042] Wherein, the regeneration circuit of the copper oxide bed is composed of a diaphragm compressor, an electric heater, a hel...

Embodiment 2

[0051] A high-temperature gas-cooled reactor helium purification regeneration system is similar to the regeneration system described in Embodiment 1, the only difference is that a water / helium cooler 2 can also be set at the water / helium cooler 1 and the gas / water separator. bypass.

[0052] After improvement, the copper oxide bed regeneration circuit is composed of diaphragm compressor, electric heater, copper oxide bed of helium purification system, and water / helium cooler 2 connected in sequence. When the copper oxide bed is regenerated, the regeneration circuit containing the water / helium cooler 2 can be used for regeneration, which can prevent the tritium-containing waste water in the water / helium cooler 1 and the gas / water separator from diffusing to the copper oxide bed regeneration circuit. When there is water in the copper oxide bed regeneration circuit, it can be removed by the auxiliary water adsorption bed.

[0053] After improvement, the low-temperature activated...

Embodiment 3

[0054] Example 3 A high temperature gas-cooled reactor helium purification system regeneration process

[0055] A regeneration method utilizing the helium purification regeneration system described in the above embodiment 2:

[0056] Under normal operating conditions of the high temperature gas-cooled reactor helium purification system, the working pressure of the helium purification system is 3-7MPa, the operating temperature of the copper oxide bed is about 250°C, the operating temperature of the molecular sieve bed is about 10°C, and the operating temperature of the low-temperature activated carbon bed is about - 196°C;

[0057] When a certain gas impurity component at the outlet of the copper oxide bed, molecular sieve bed and low-temperature activated carbon bed reaches the breakthrough point, the copper oxide bed, molecular sieve bed and low-temperature activated carbon bed of the helium purification system must be regenerated respectively;

[0058] Regeneration of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com