Mixed gas filling device and mixed gas filling method of CNG and HCNG

A gas filling device, hydrogen technology, applied in the direction of container discharge method, container filling method, equipment loaded into pressure vessels, etc., can solve the problems of single function and large demand of gas filling stations, achieve simple and convenient procedures, and reduce costs , The effect of safe and efficient gas supply system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

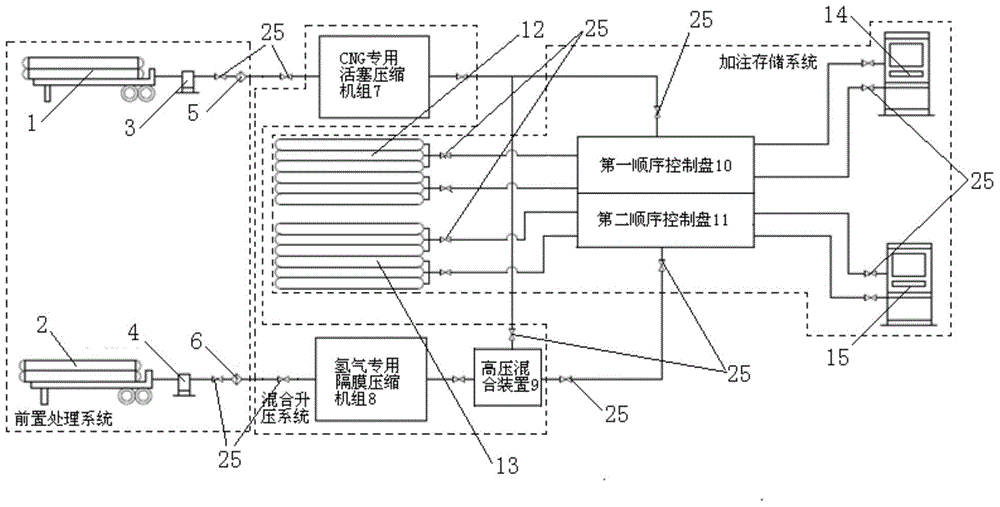

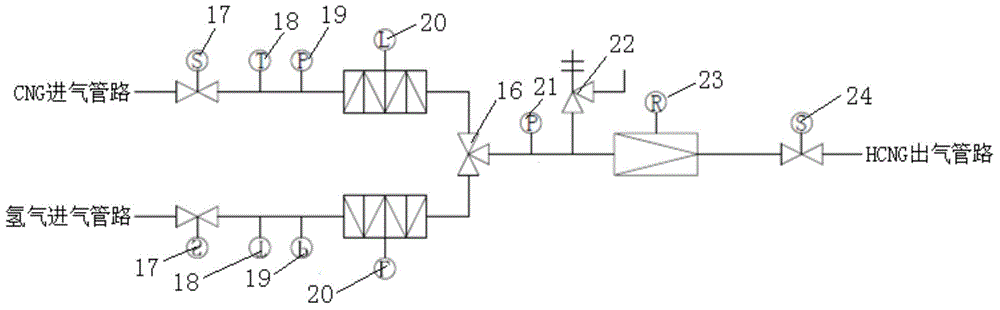

[0018] Such as figure 1 As shown, the present invention provides a mixed filling device of CNG and HCNG, which includes a pre-processing system, a mixed pressurization system and a filling storage system; the pre-processing system is connected to the filling storage system through the mixing boosting system.

[0019]The pre-treatment system includes tube bundle transport CNG trailer 1, tube bundle hydrogen transport trailer 2, CNG unloading column 3, hydrogen unloading column 4, CNG purifier 5 and hydrogen purifier 6; the quick connector of CNG unloading column 3 is connected to the tube bundle On the CNG trailer 1, the gas outlet of the CNG unloading column 3 is connected to the air inlet of the CNG purifier 5 through a gas pipeline; the gas outlet of the CNG purifier 5 is connected to the hybrid boosting system. The quick connector of the hydrogen ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com