Patents

Literature

468results about "External parameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

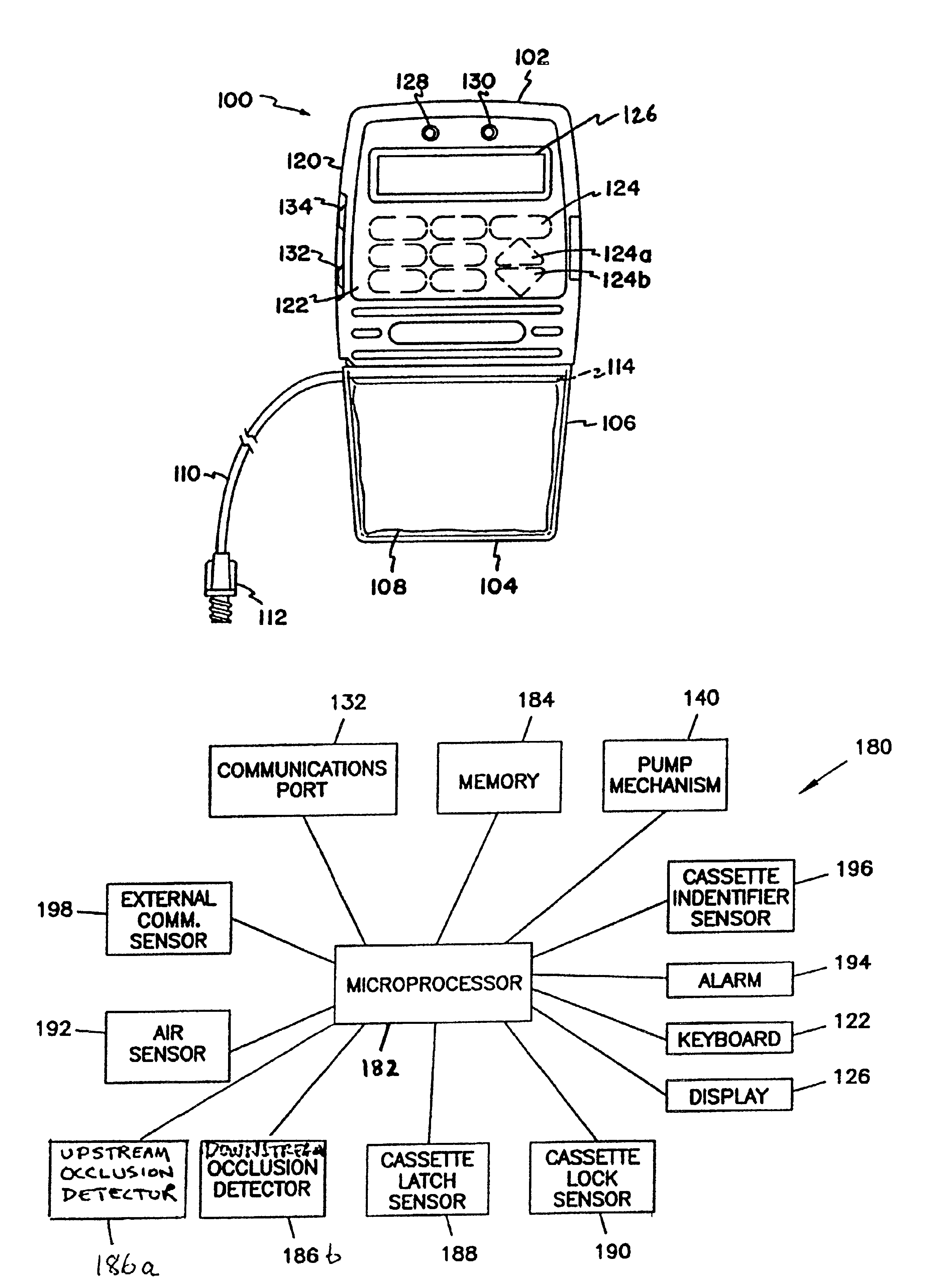

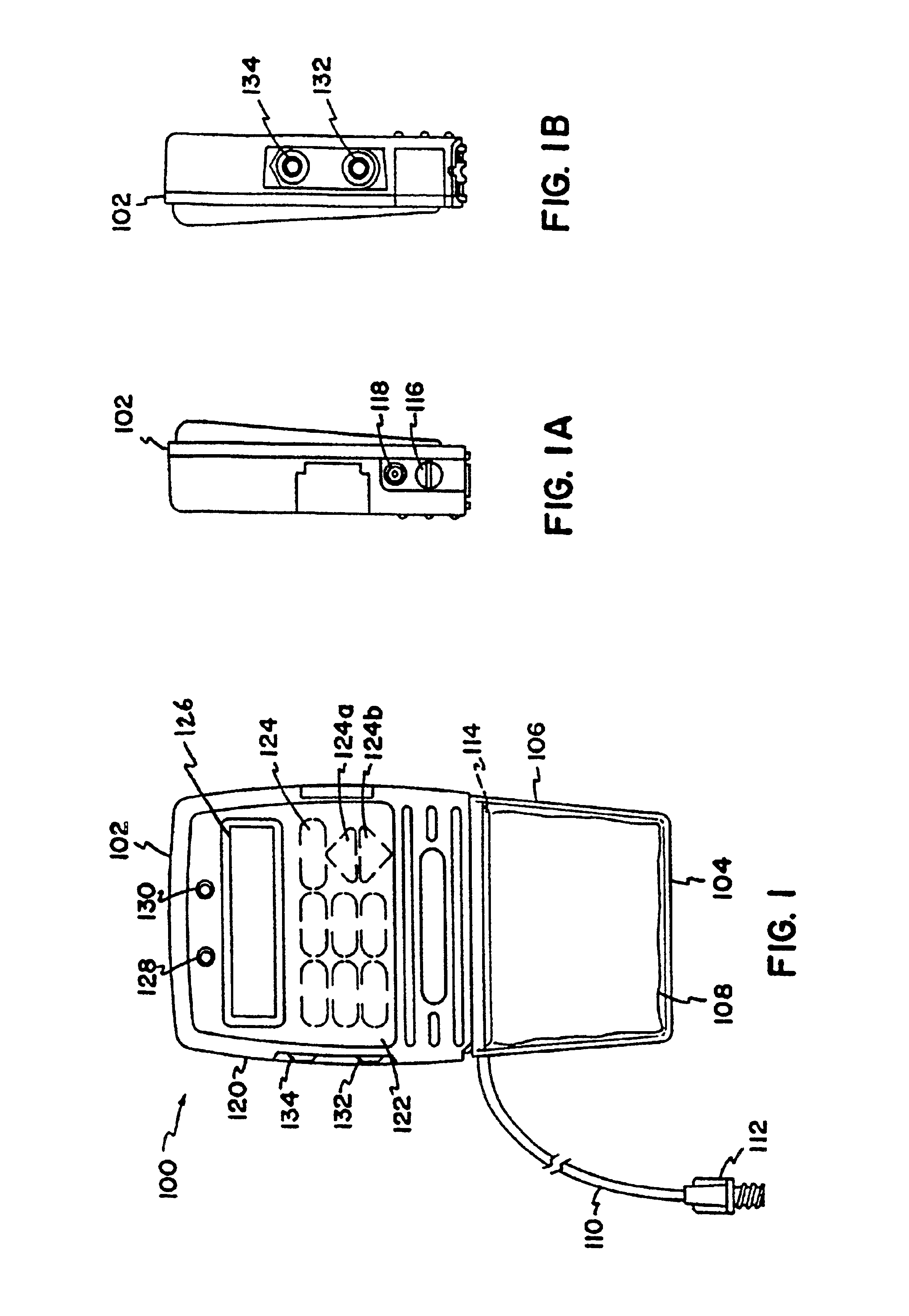

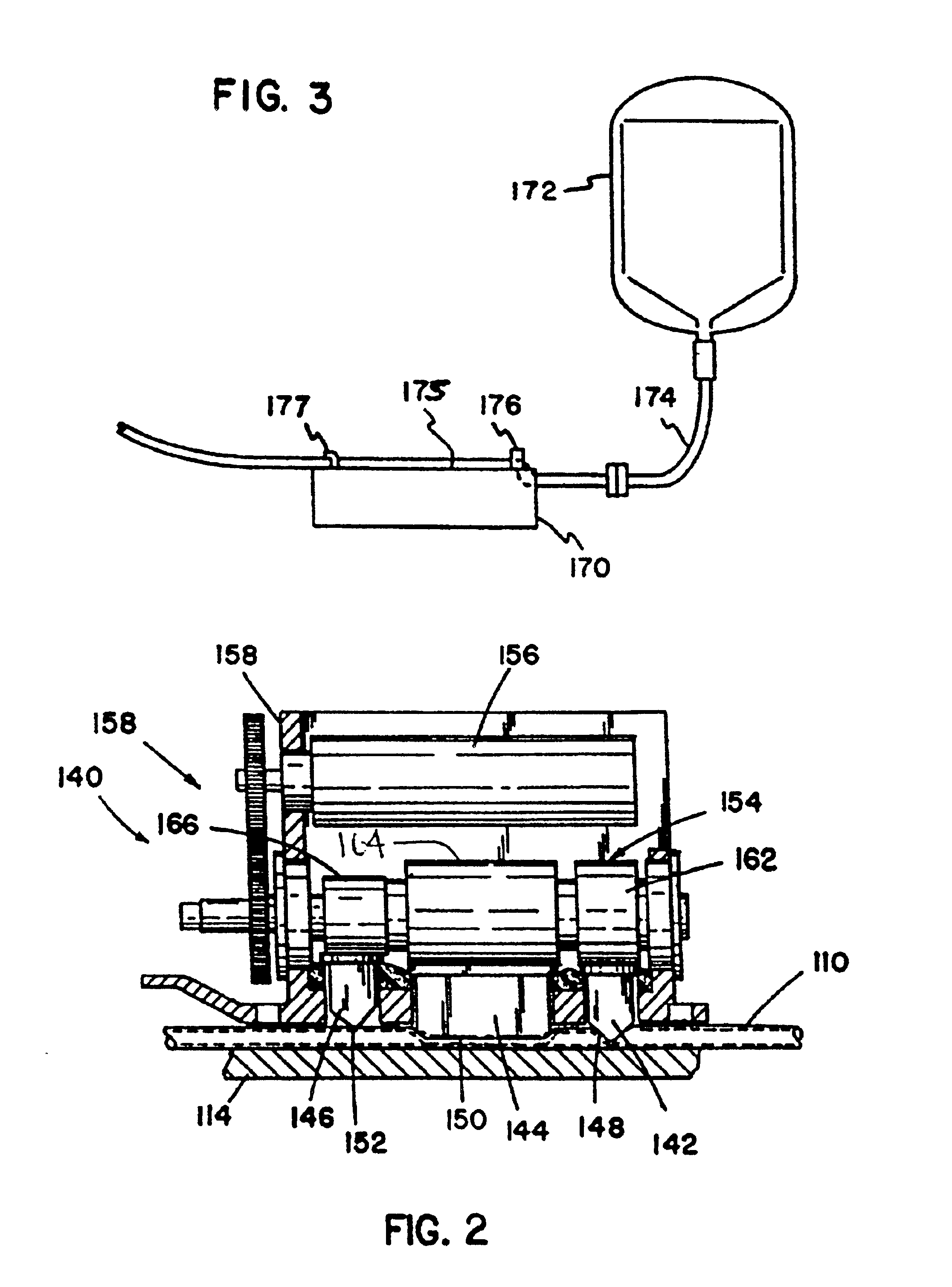

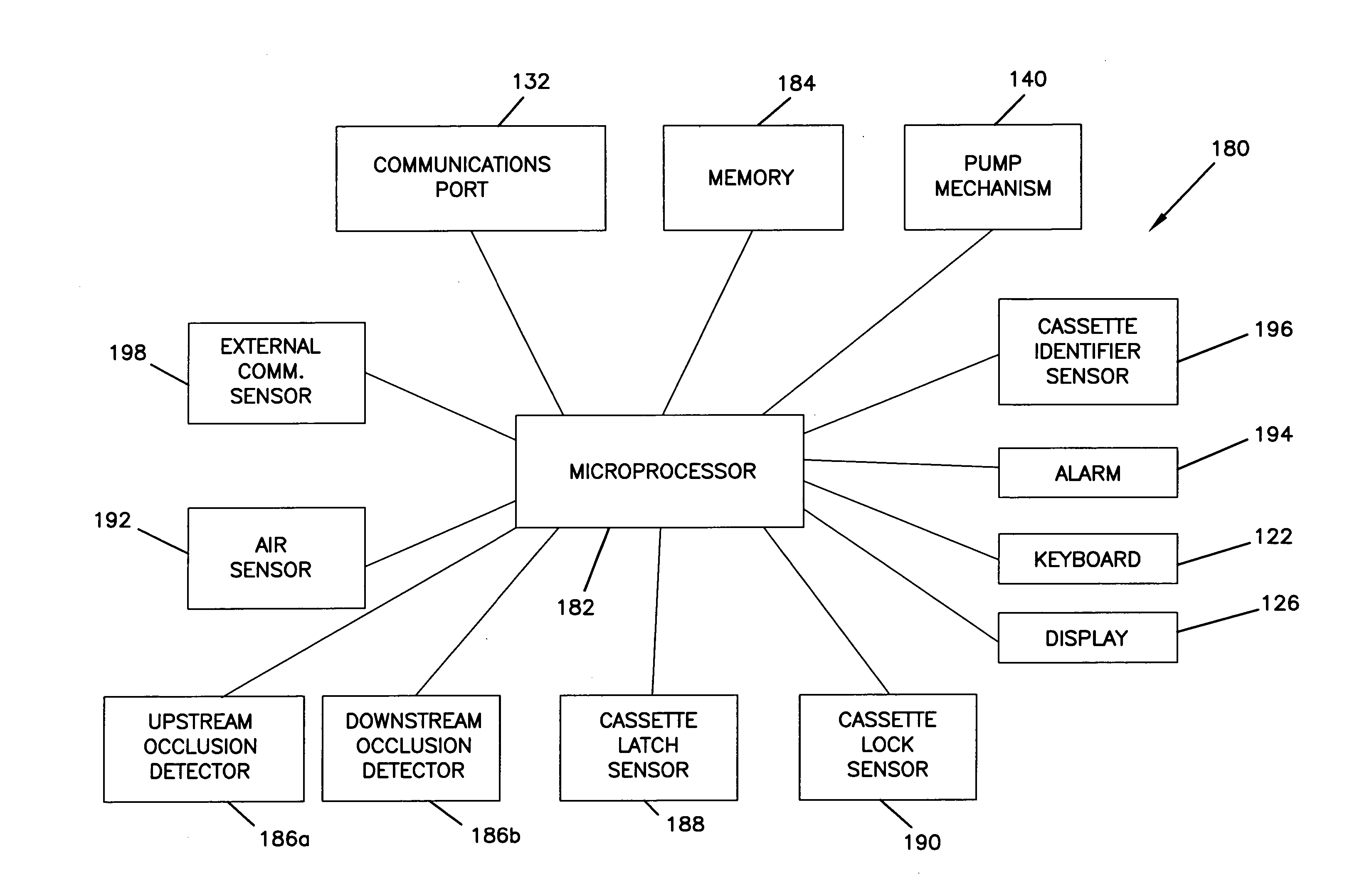

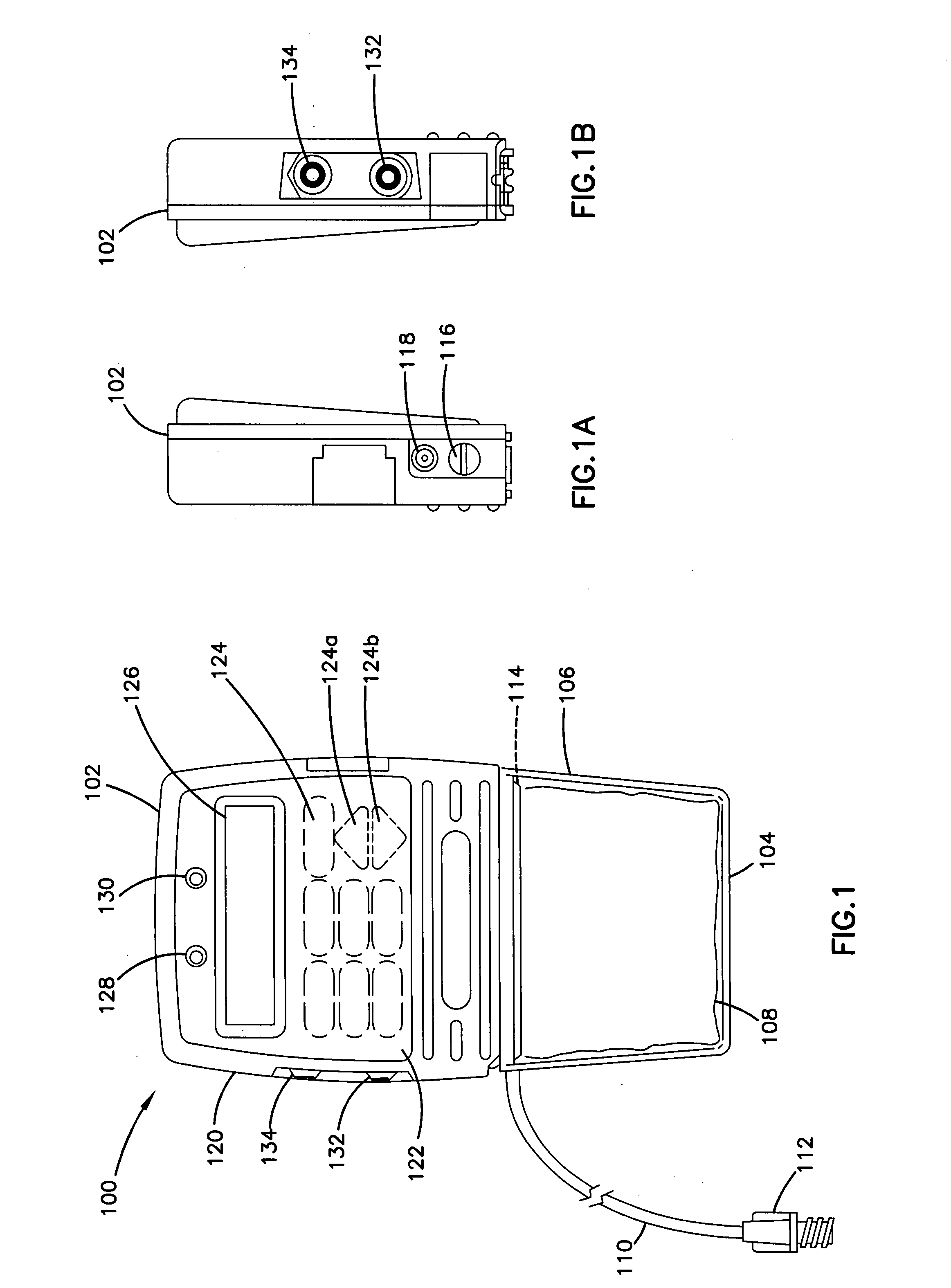

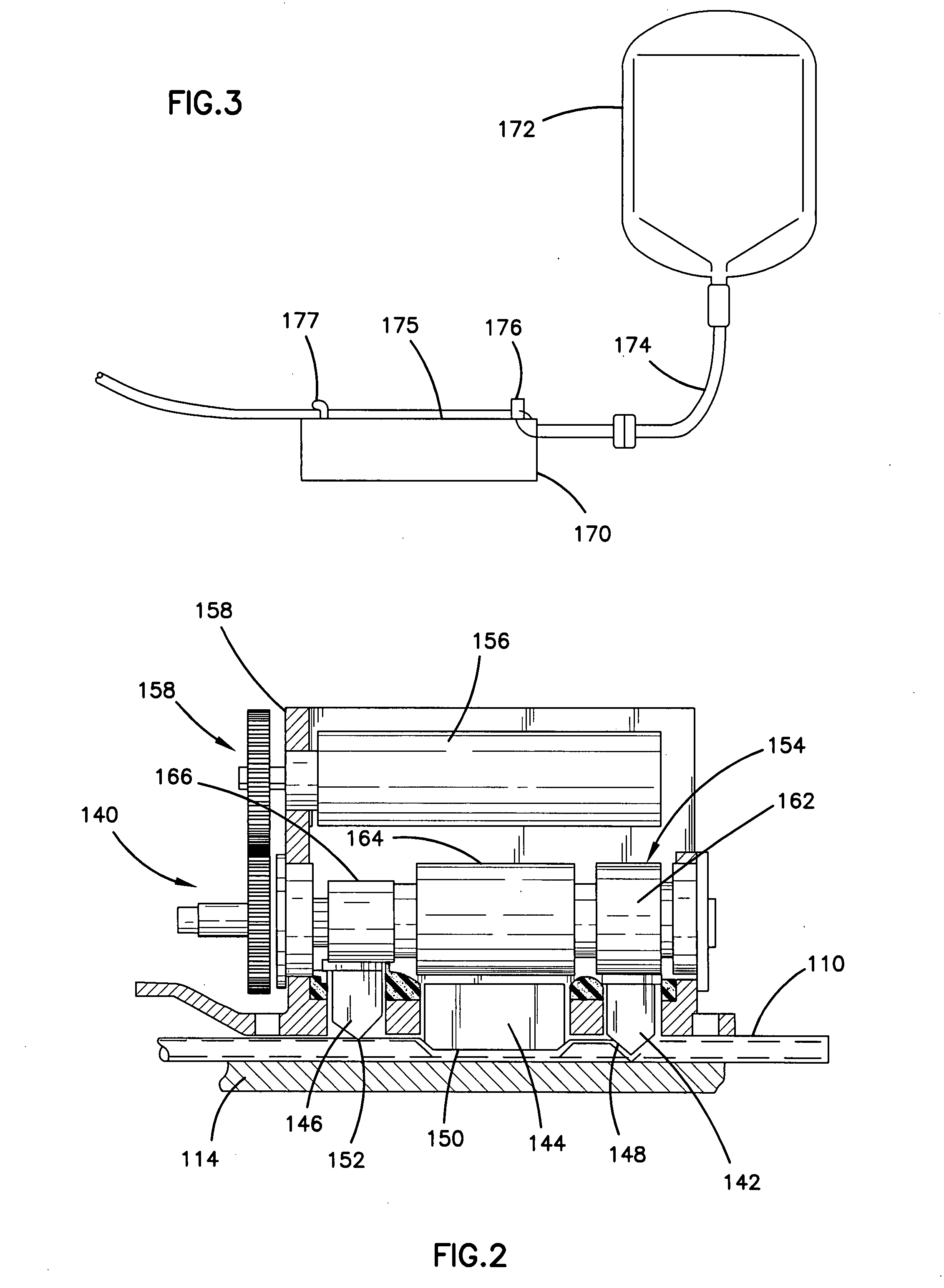

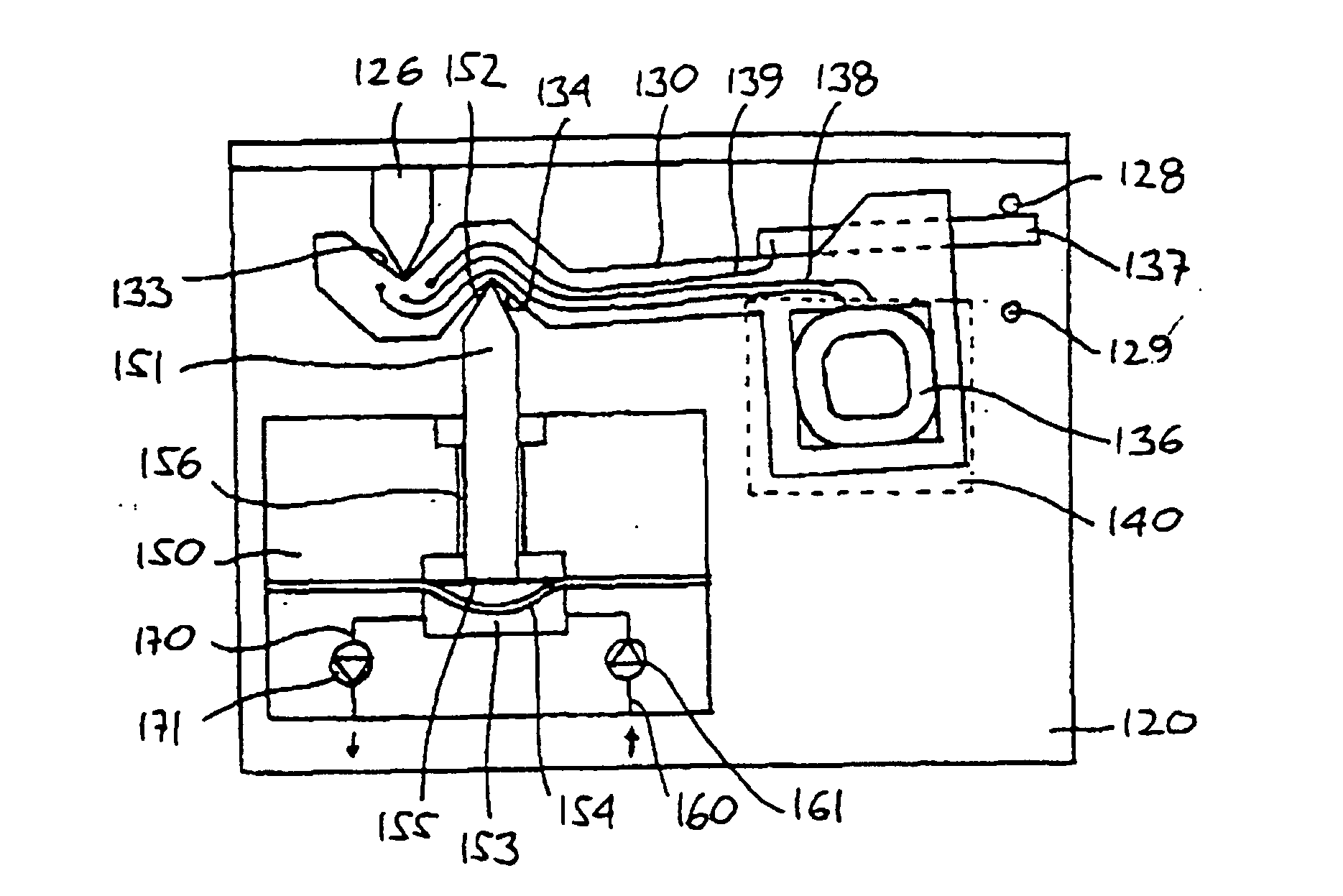

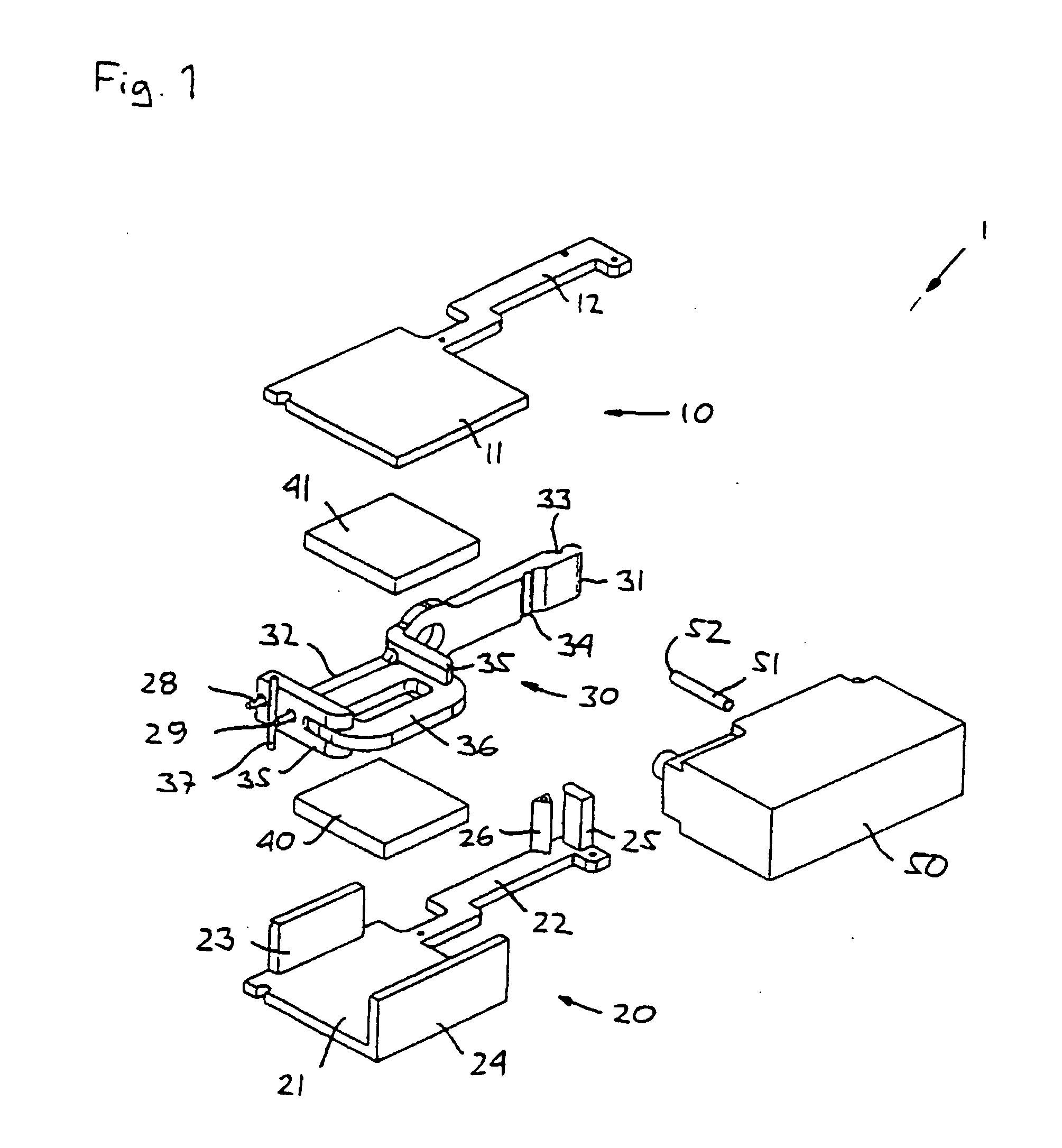

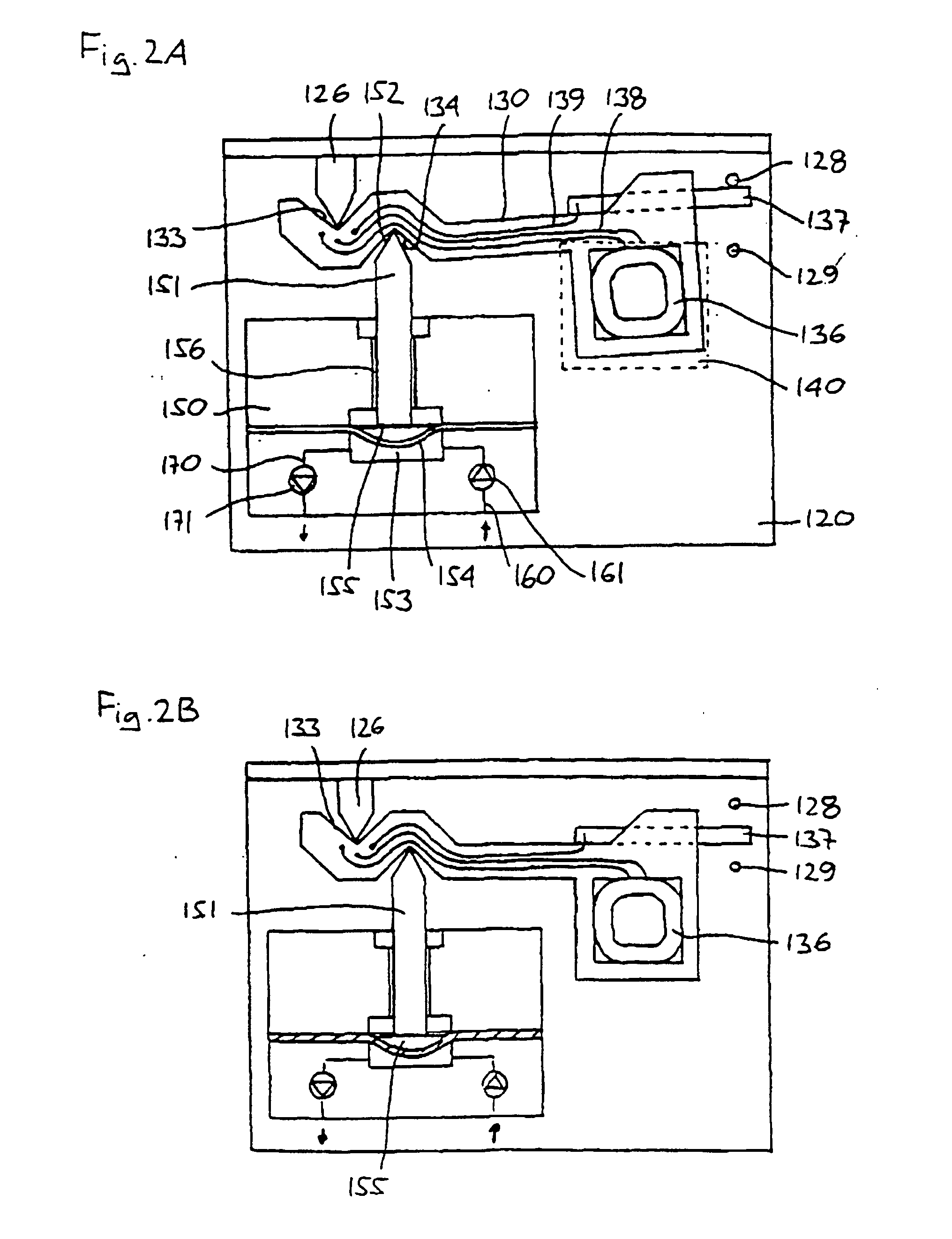

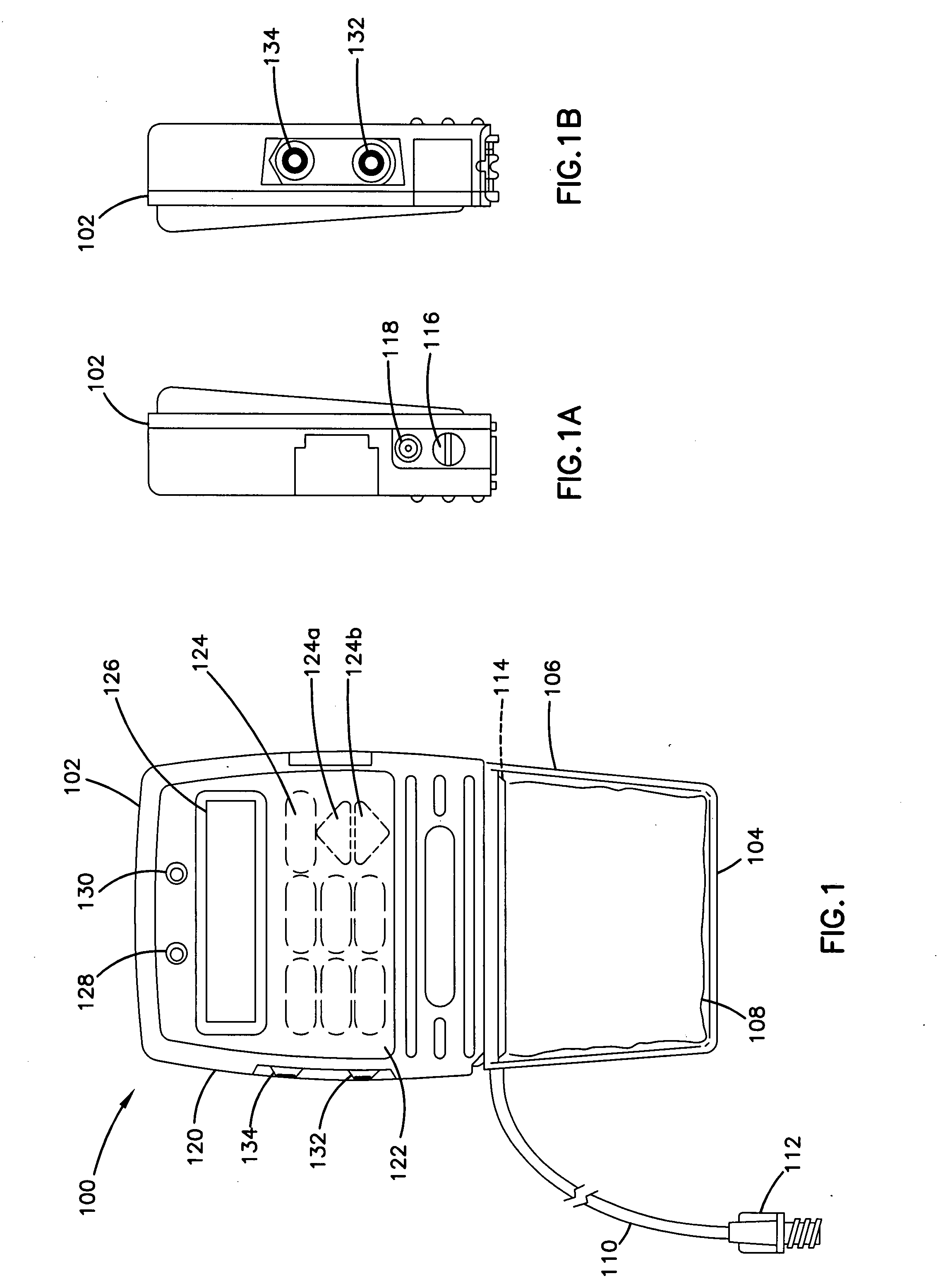

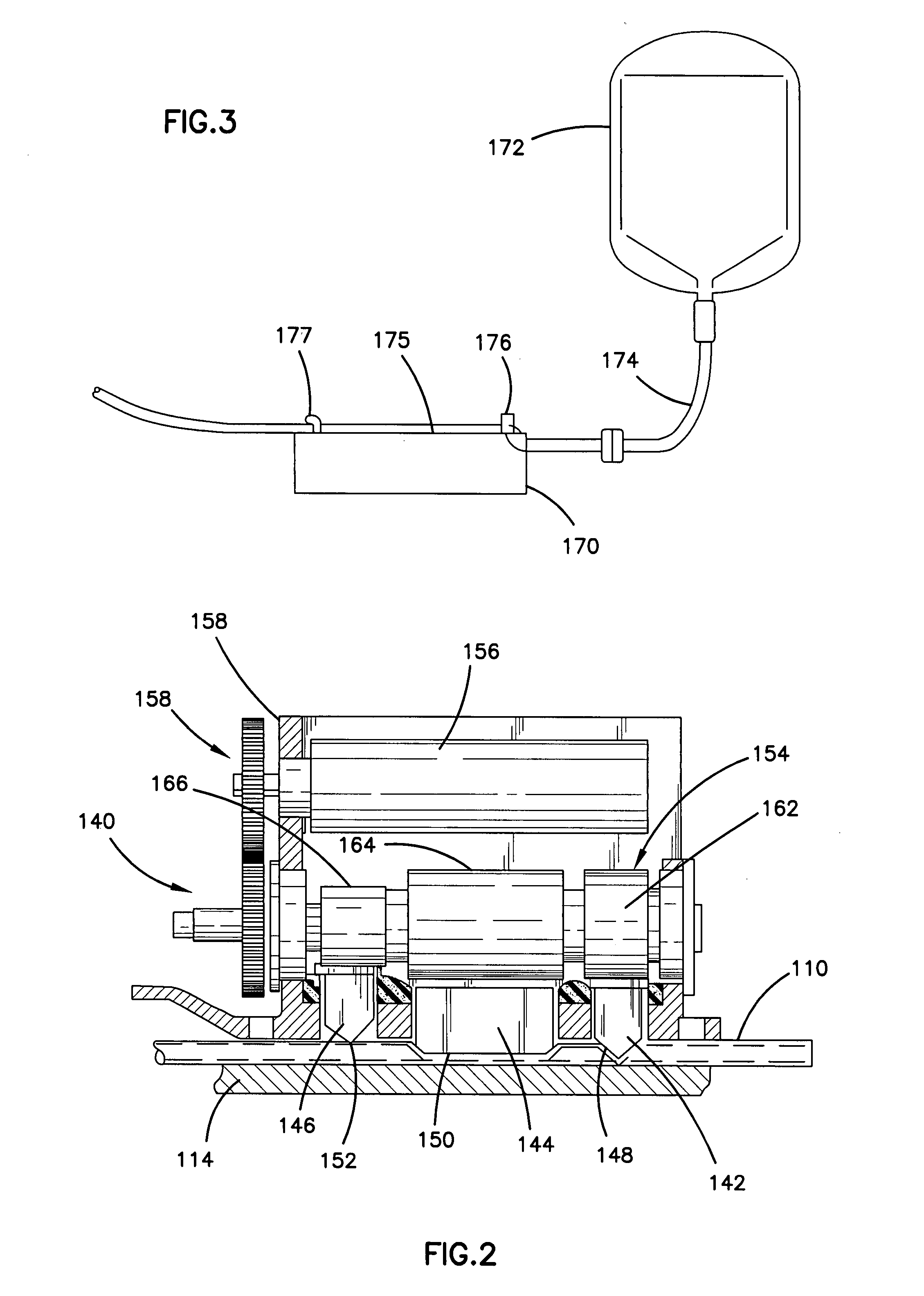

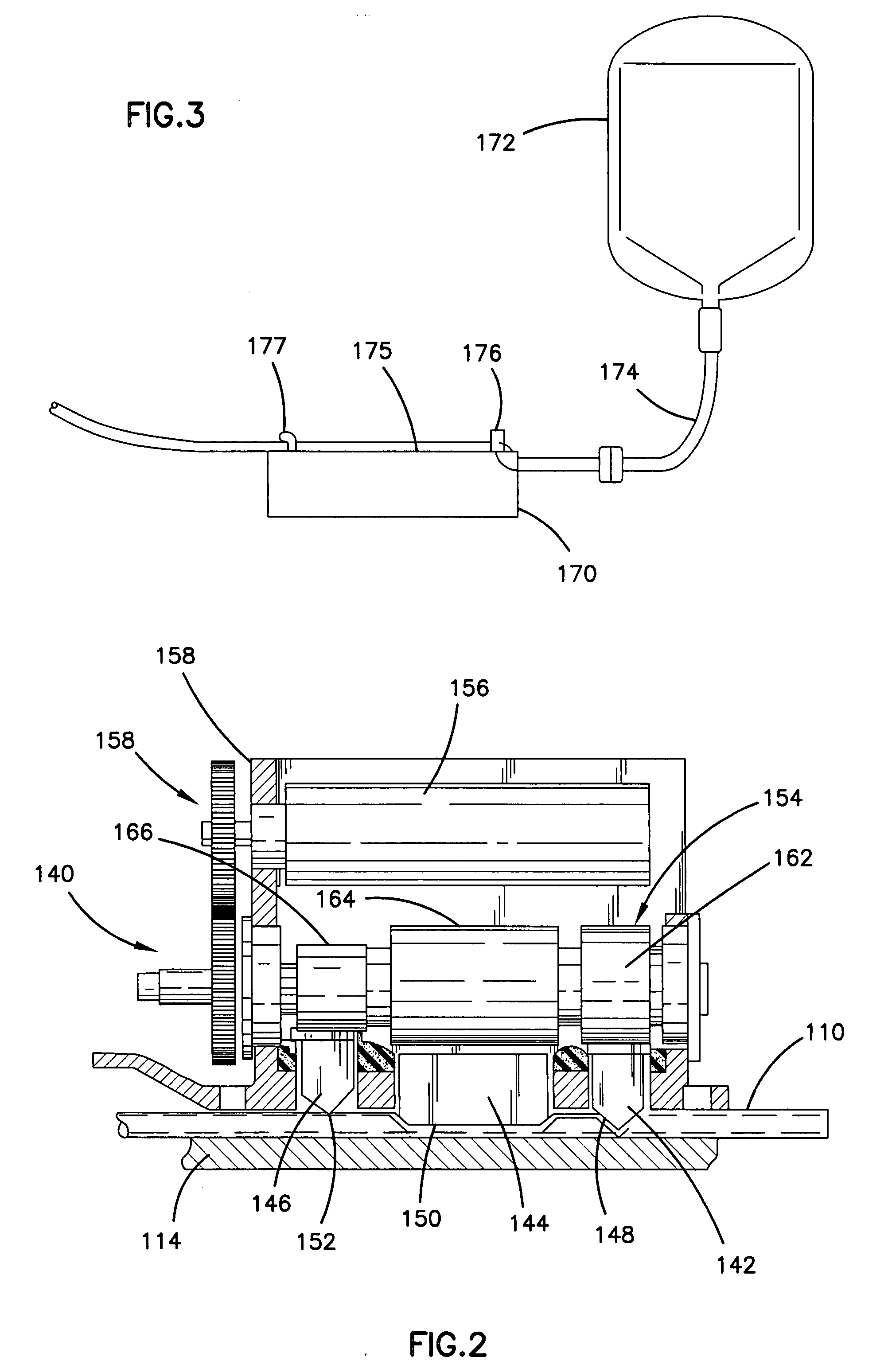

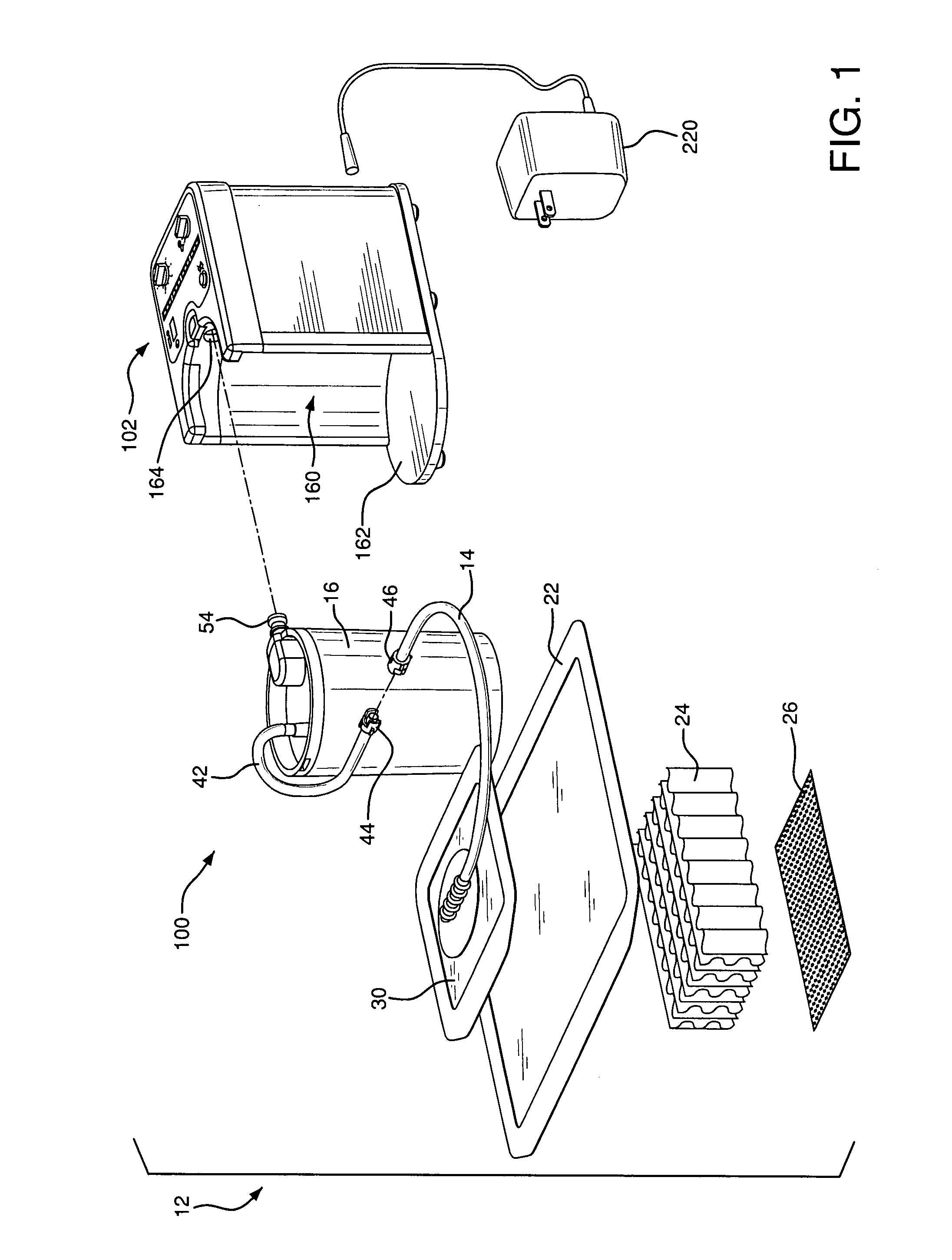

Drug pump systems and methods

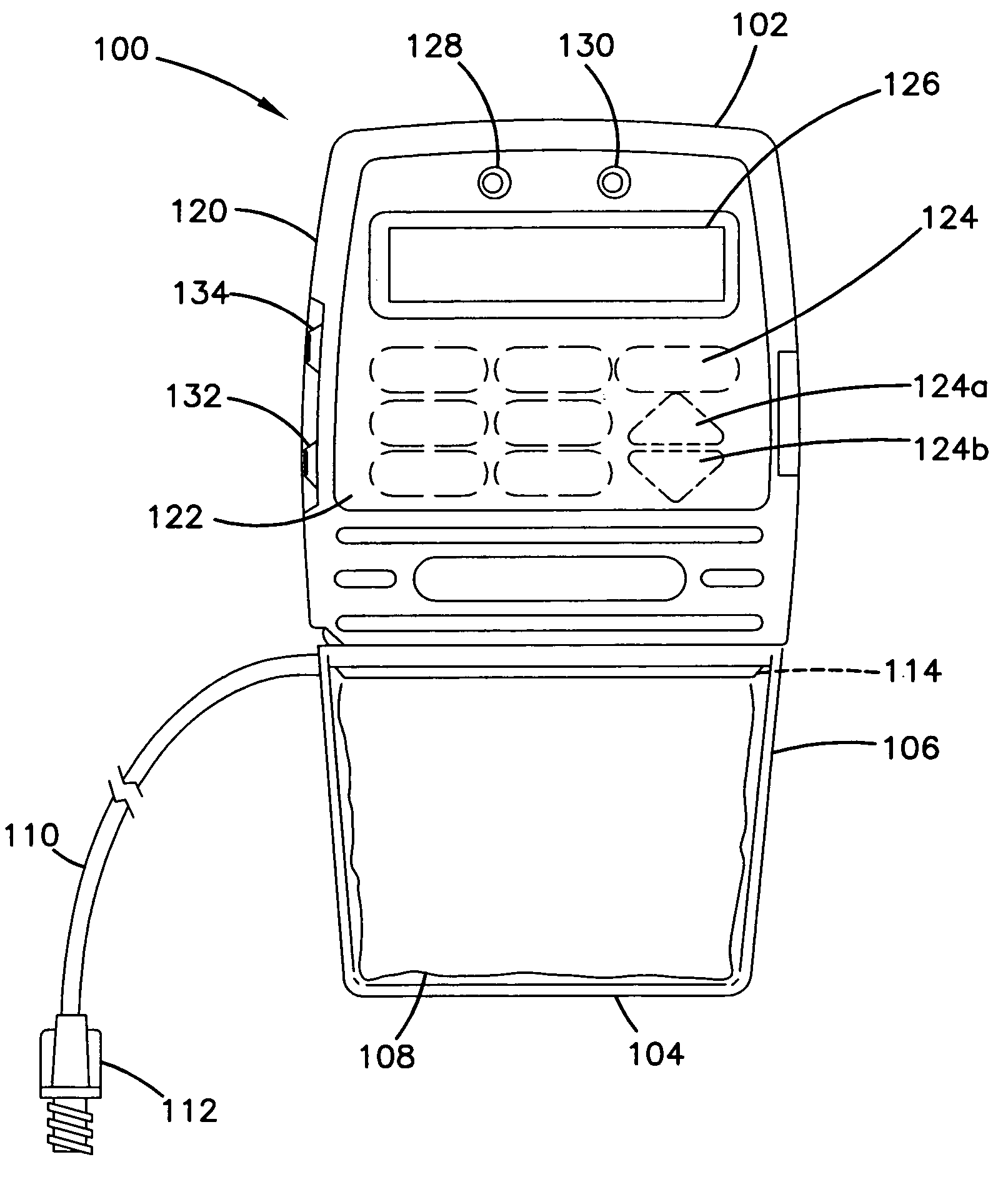

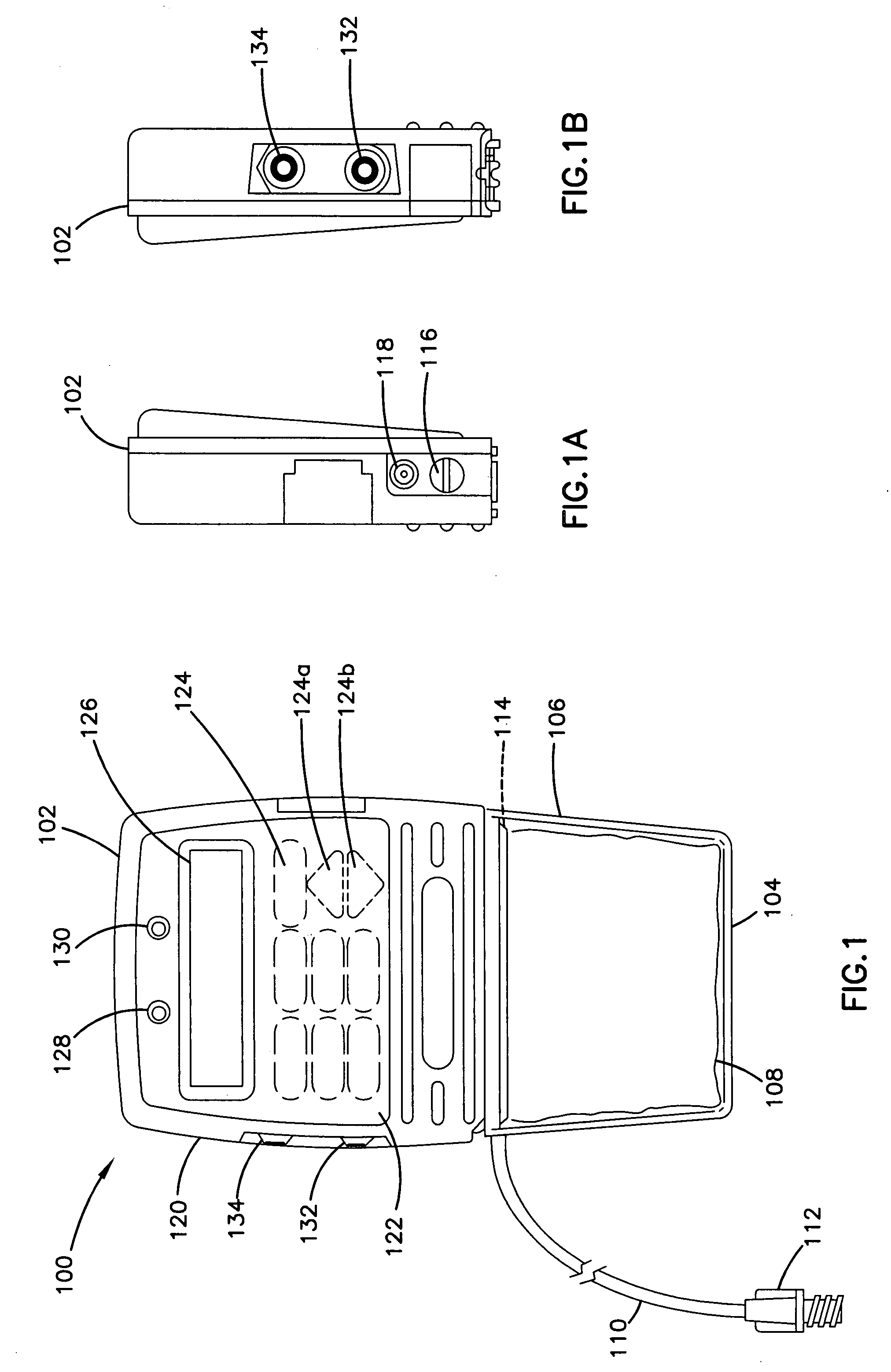

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

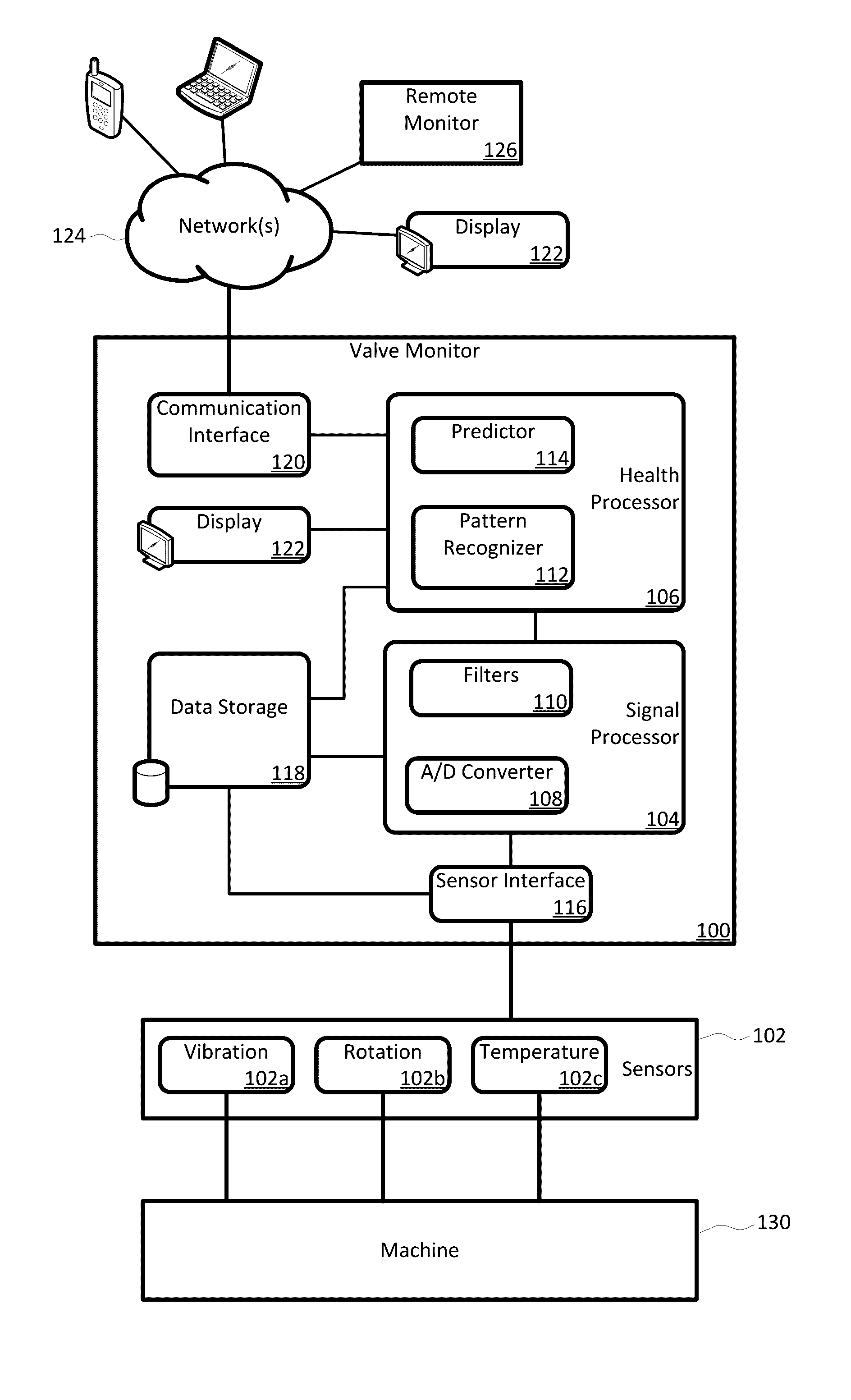

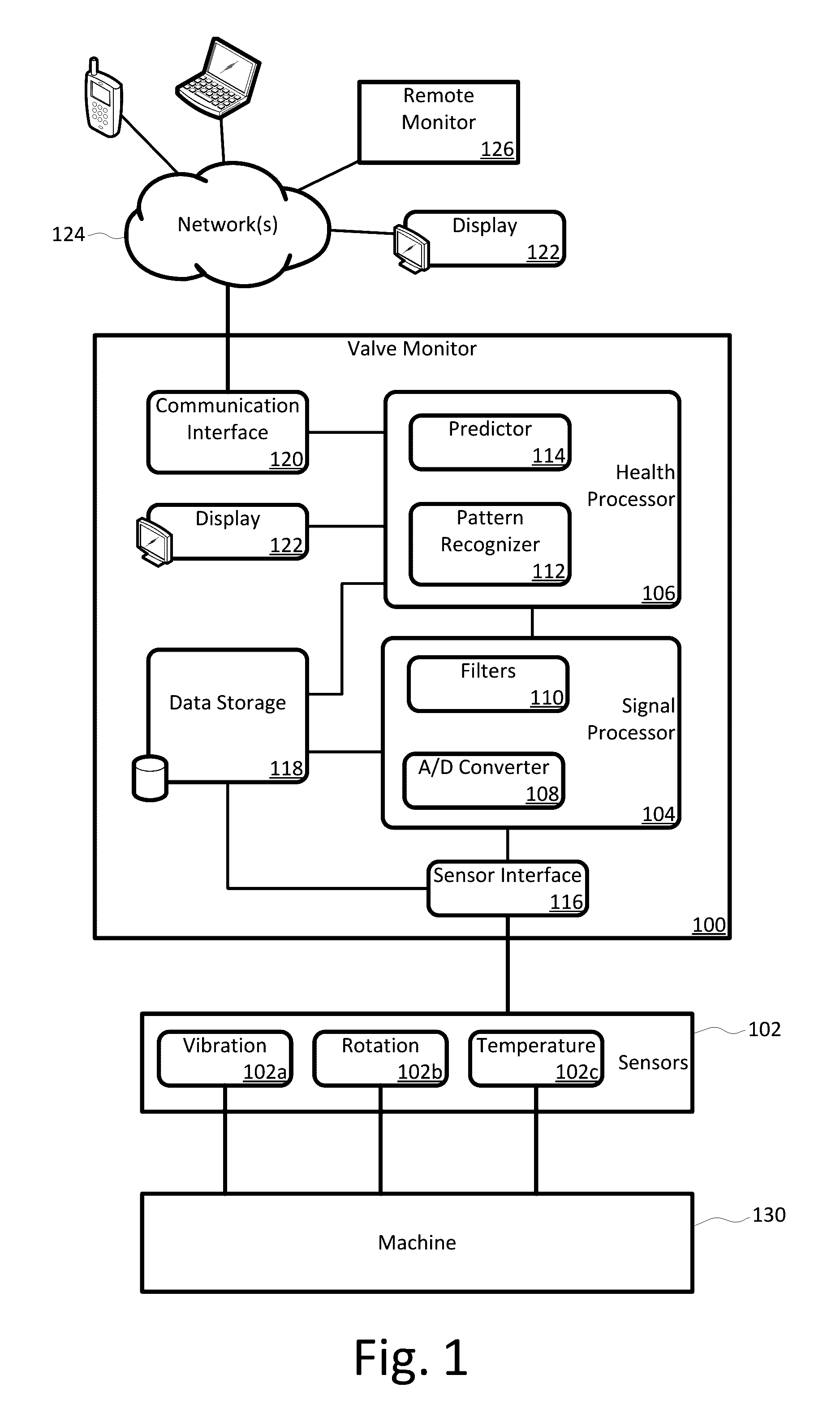

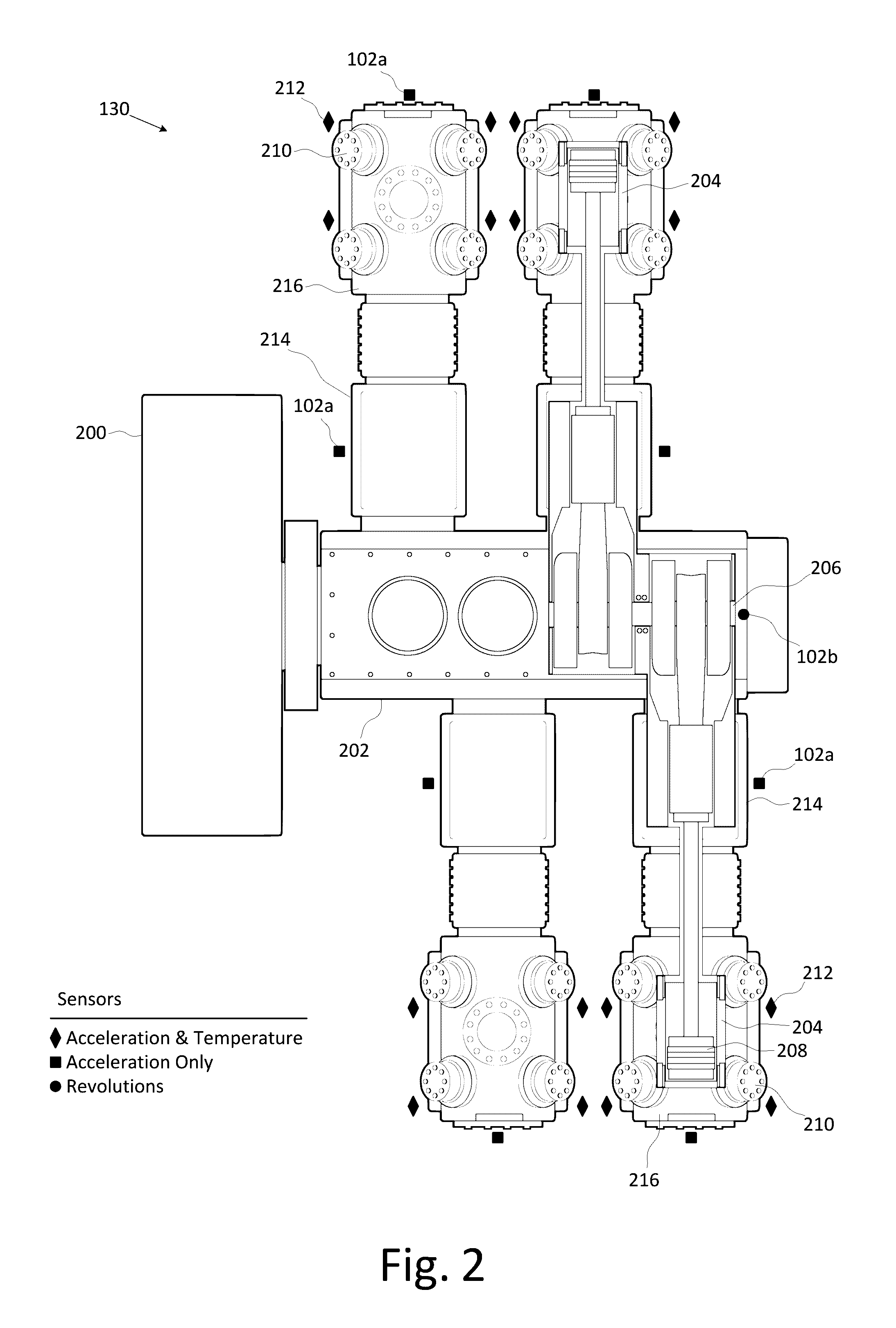

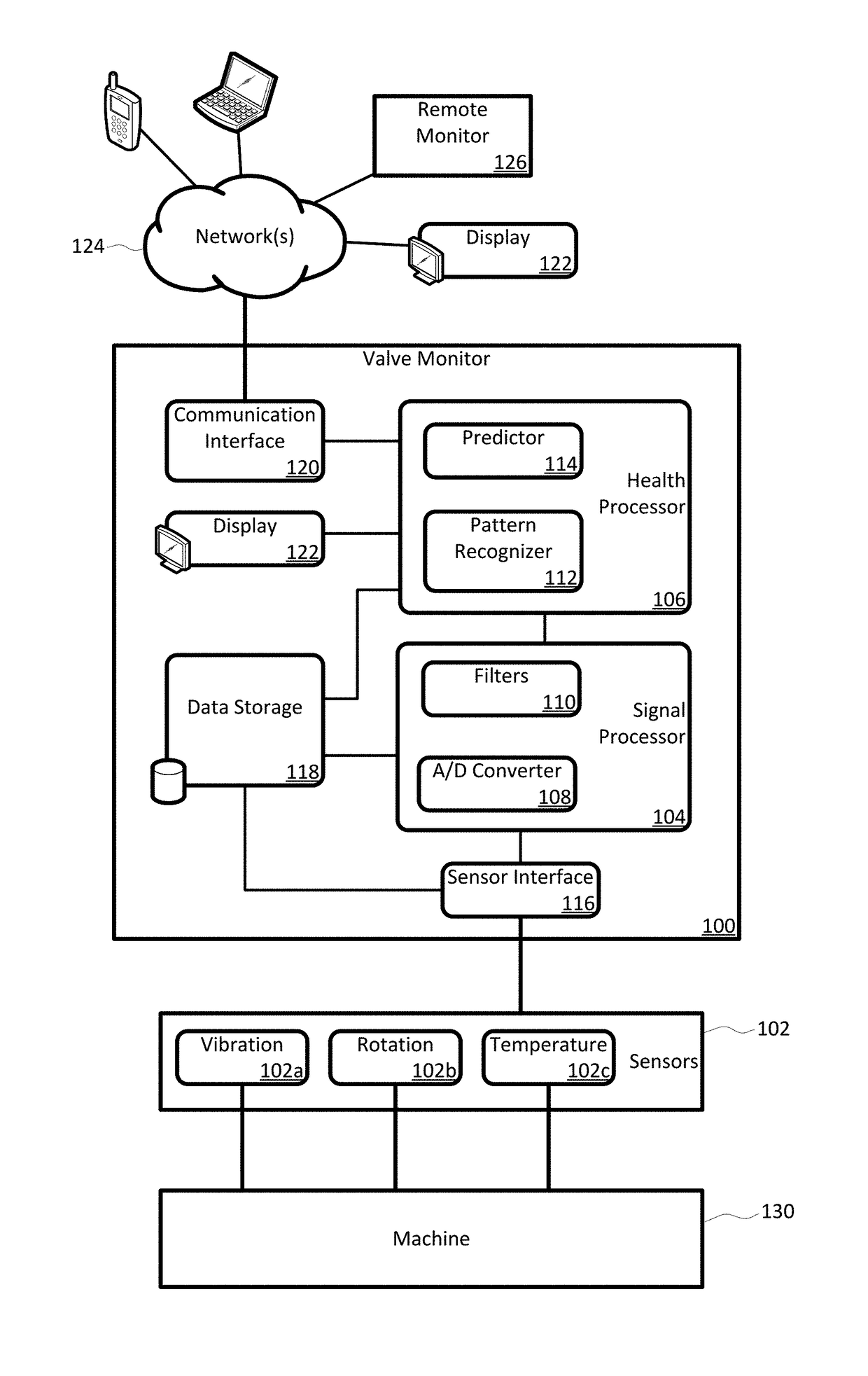

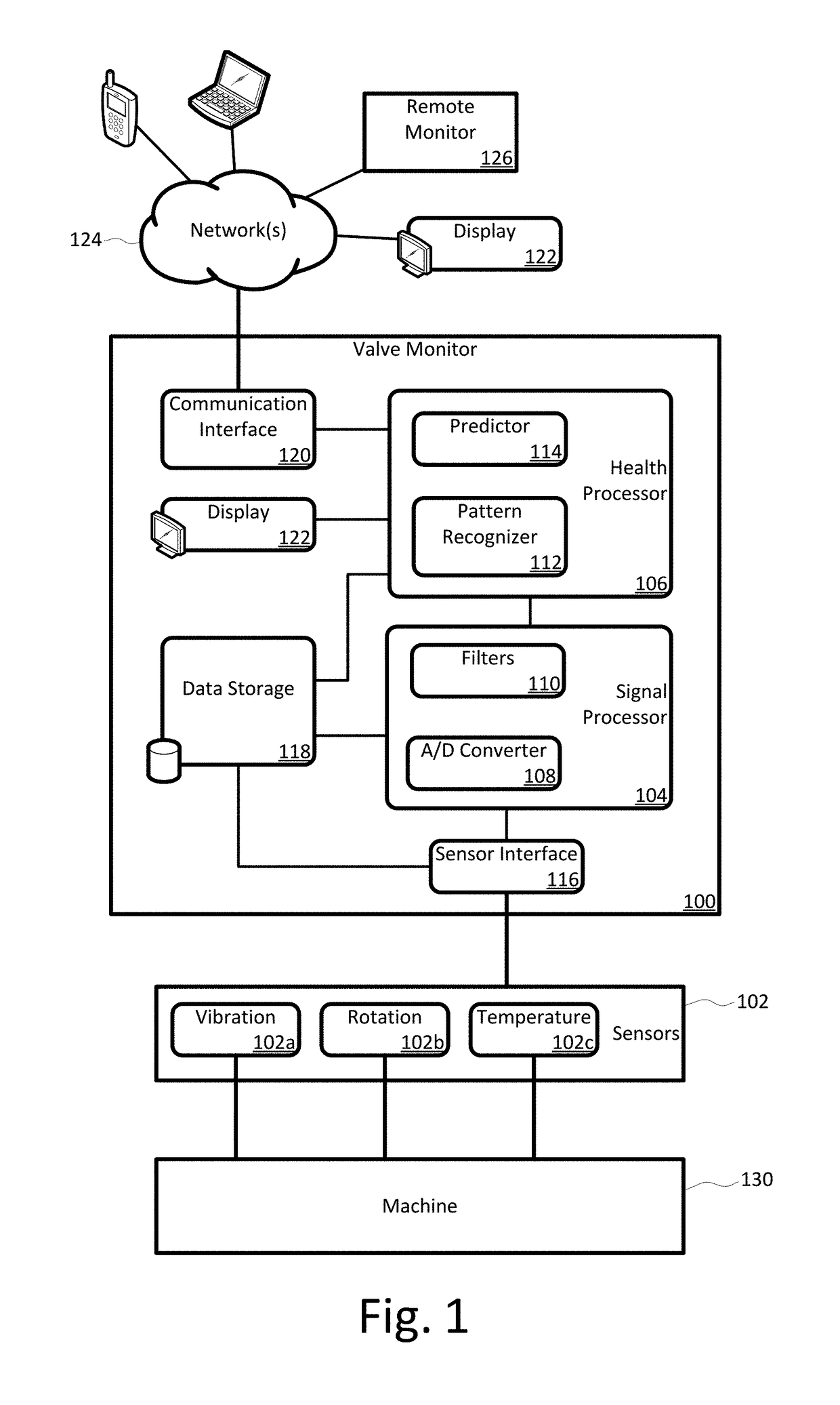

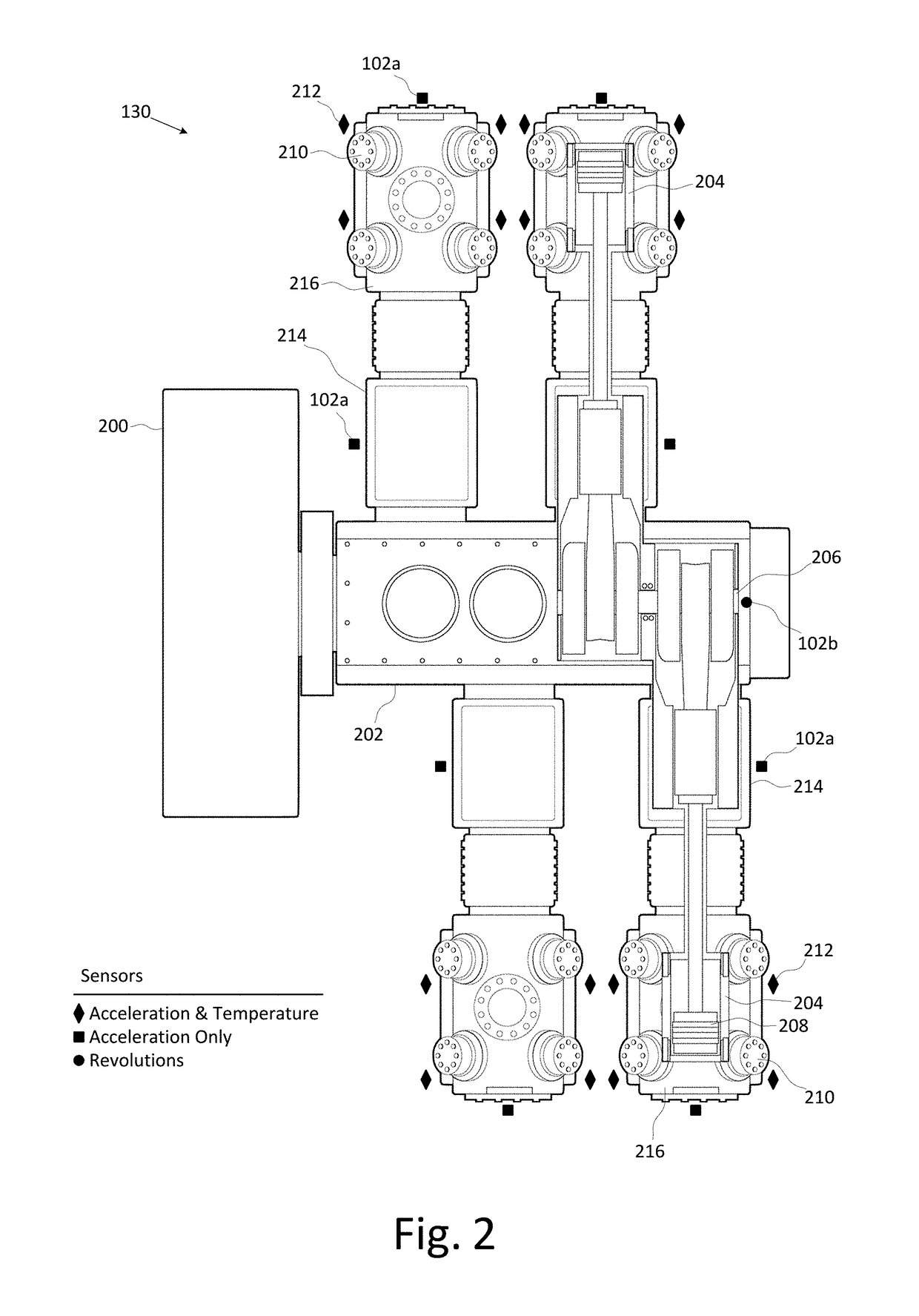

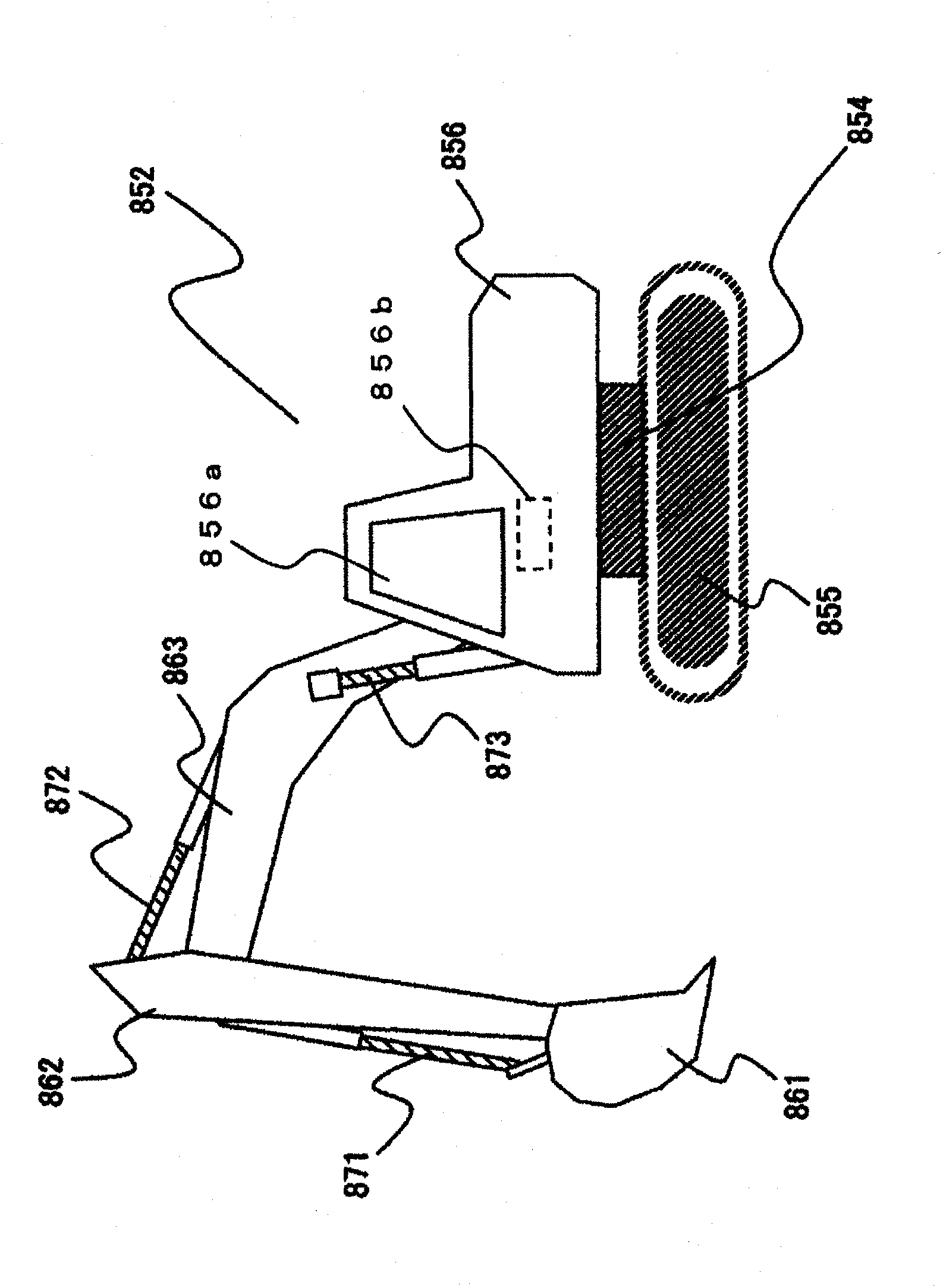

Compressor Valve Health Monitor

ActiveUS20170030349A1Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

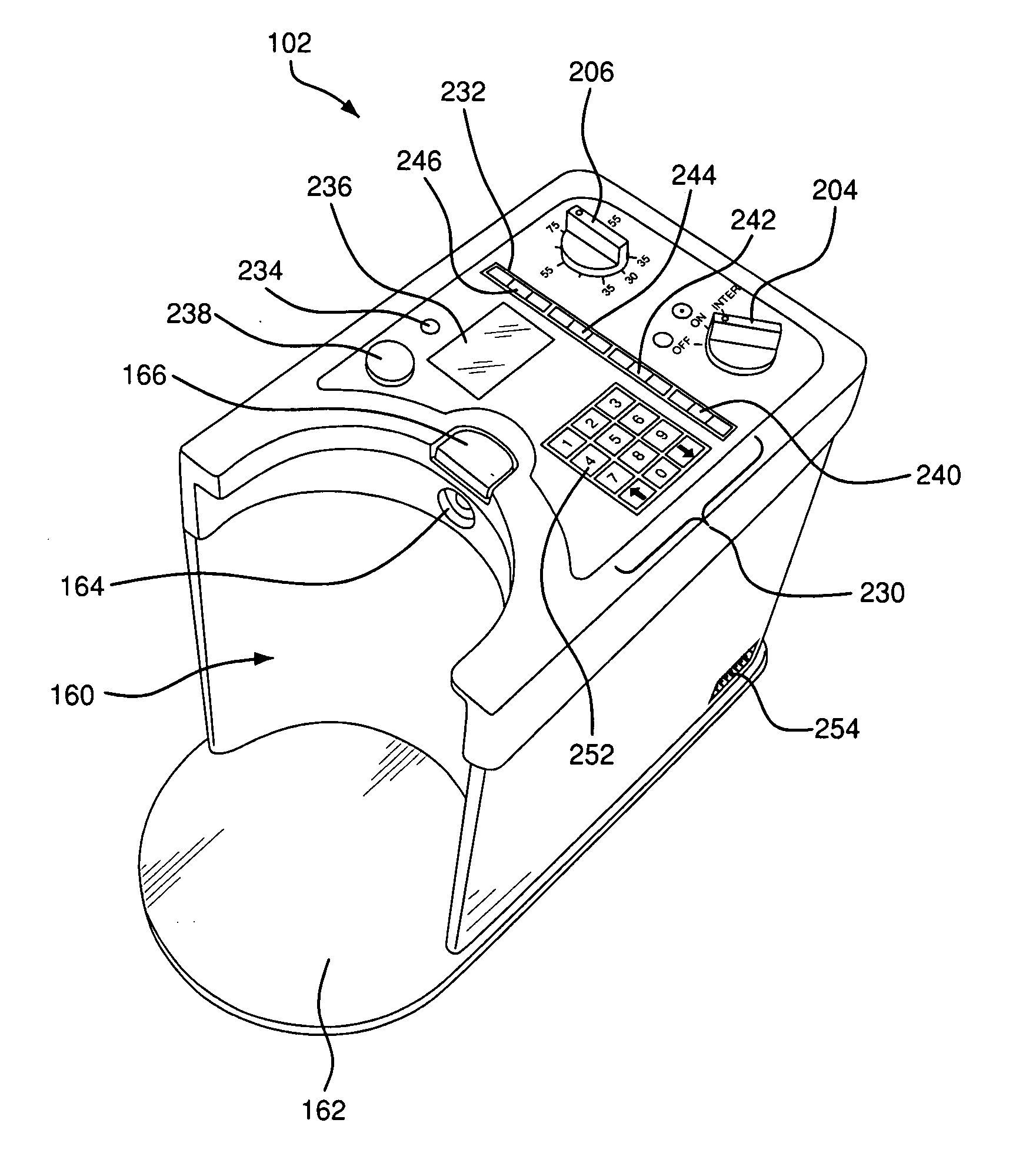

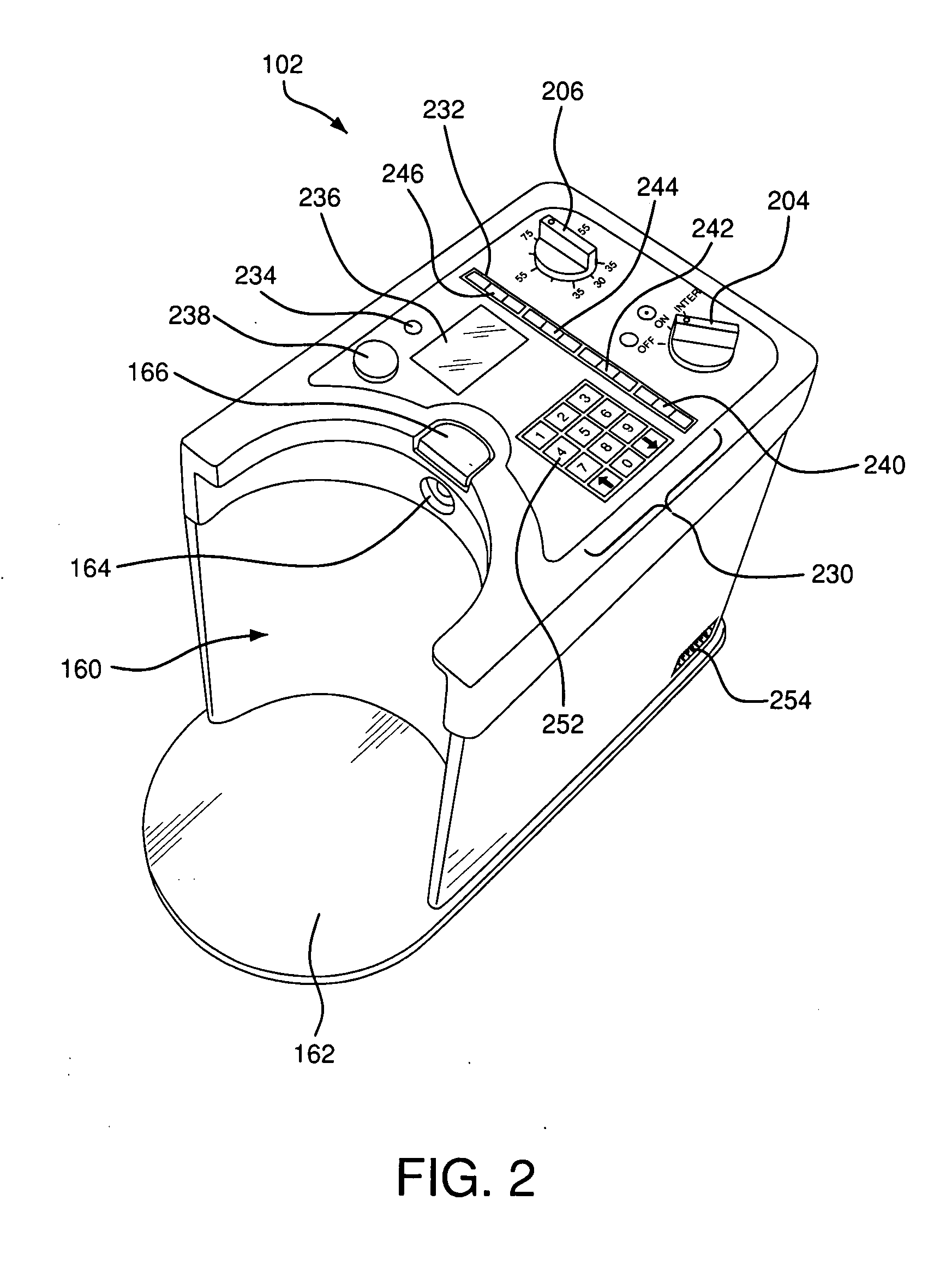

Drug pump systems and methods

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

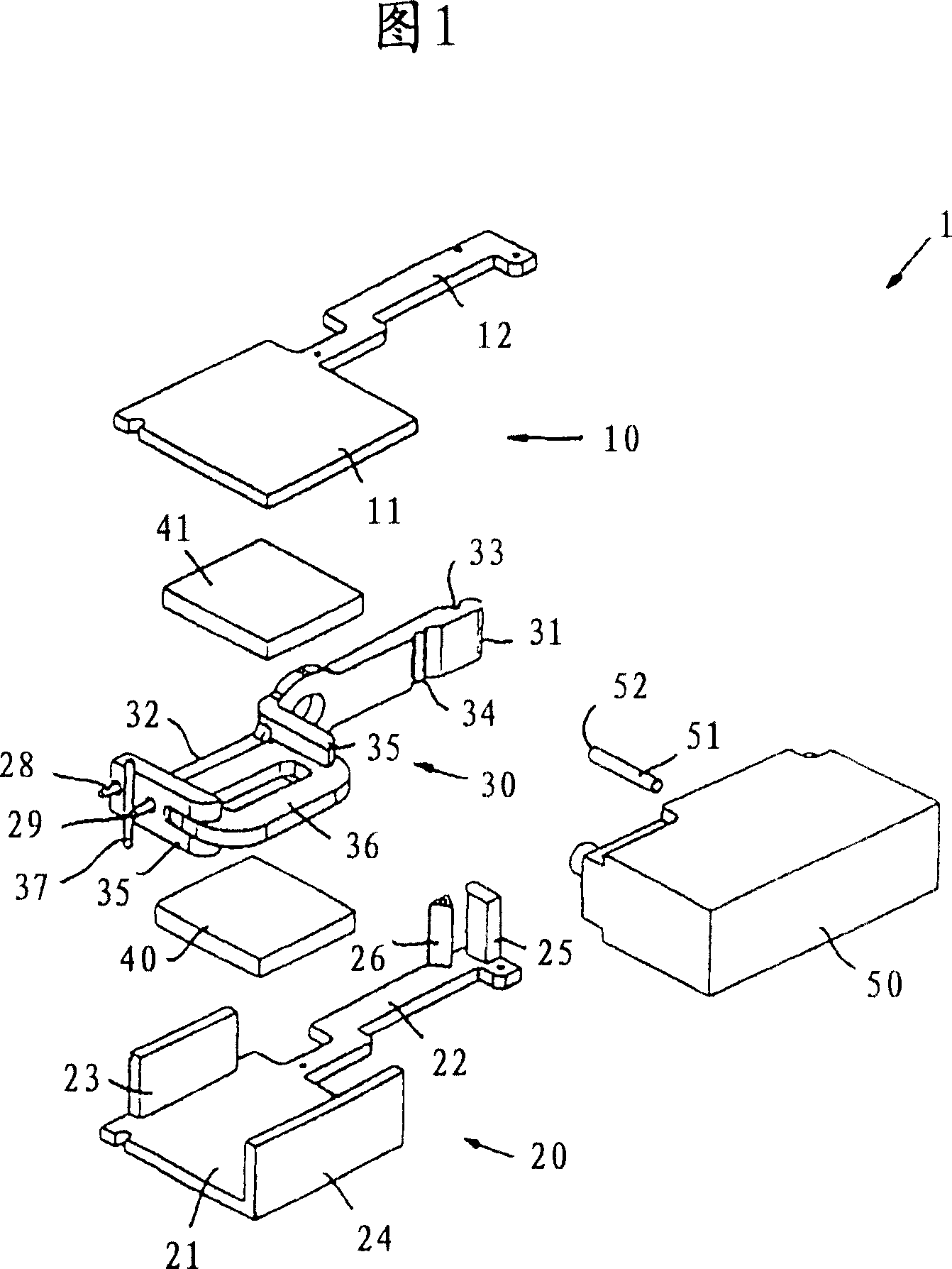

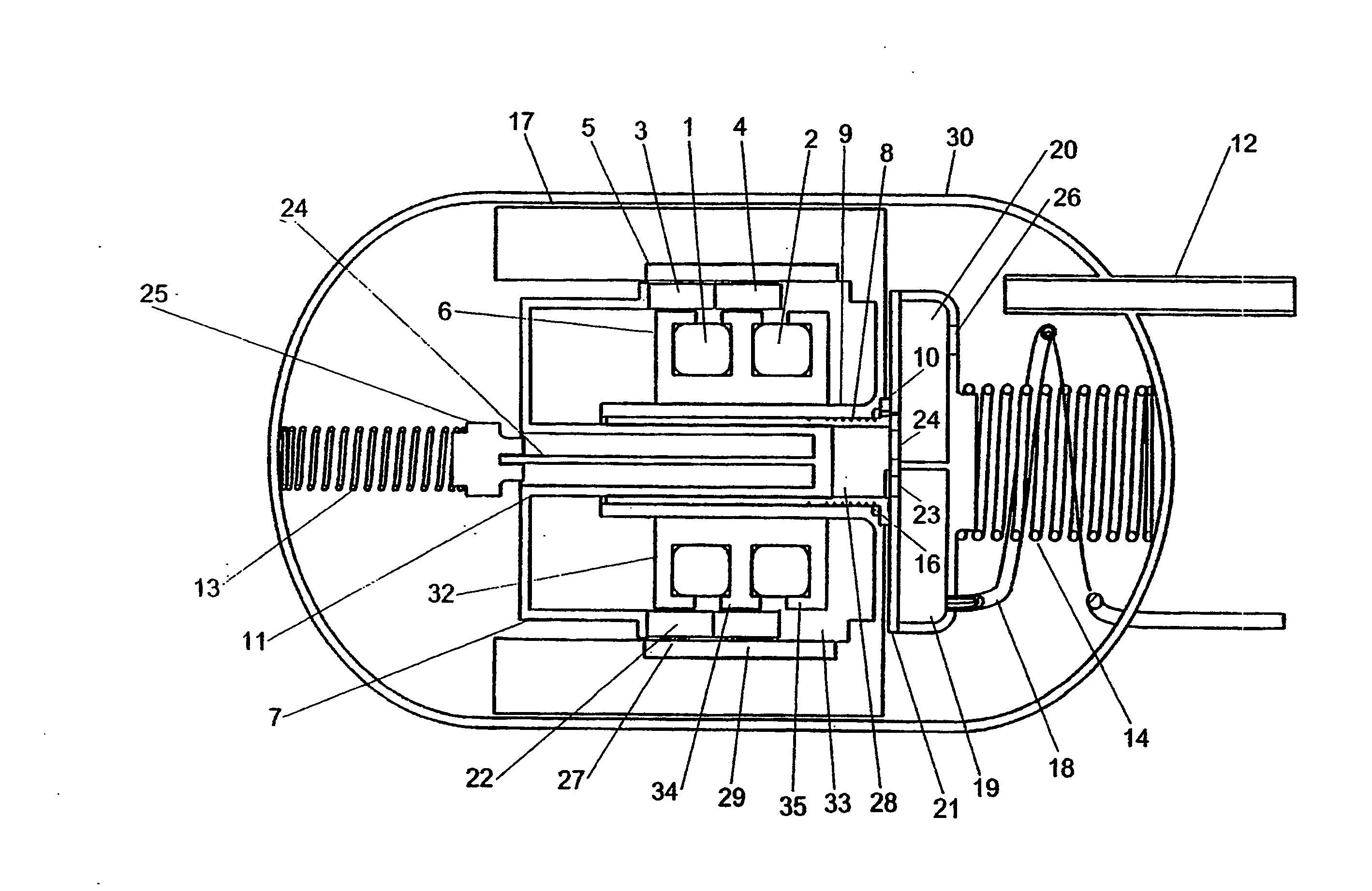

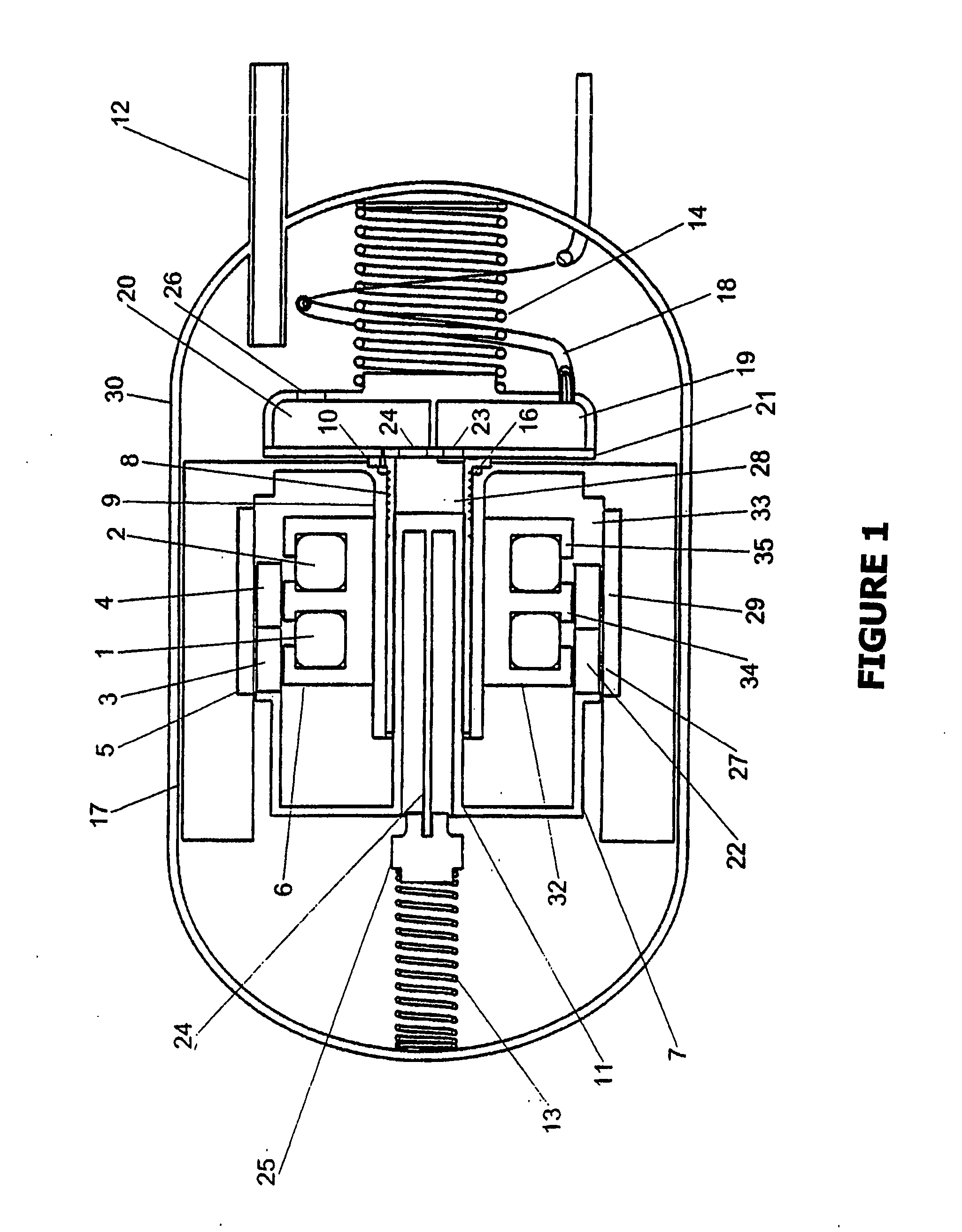

Actuator system comprising detector means

The invention provides an actuator system comprising an actuator member having first and second positions. The system further comprises actuating means for moving the actuator member between the first and second positions and detection means for detecting the first respectively the second position and supplying time signals indicative thereof. A controller determines on the basis of supplied time signals the time lapsed when the actuator member is moved between the first and second positions in a given direction, the controller comprising information representing at least one defined time range, each time range being associated with movement of the actuator member in a given direction between the first and second positions and a given actuation force, the controller being adapted to compare the determined time lapsed with the defined time range(s) and perform an action corresponding to the time range associated with the determined time lapsed.

Owner:TDK CORPARATION +1

Drug pump systems and methods

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

Thermal Monitoring System and Method

InactiveUS20210306720A1Thermometer detailsThermometers using electric/magnetic elementsThermal monitoringProcess engineering

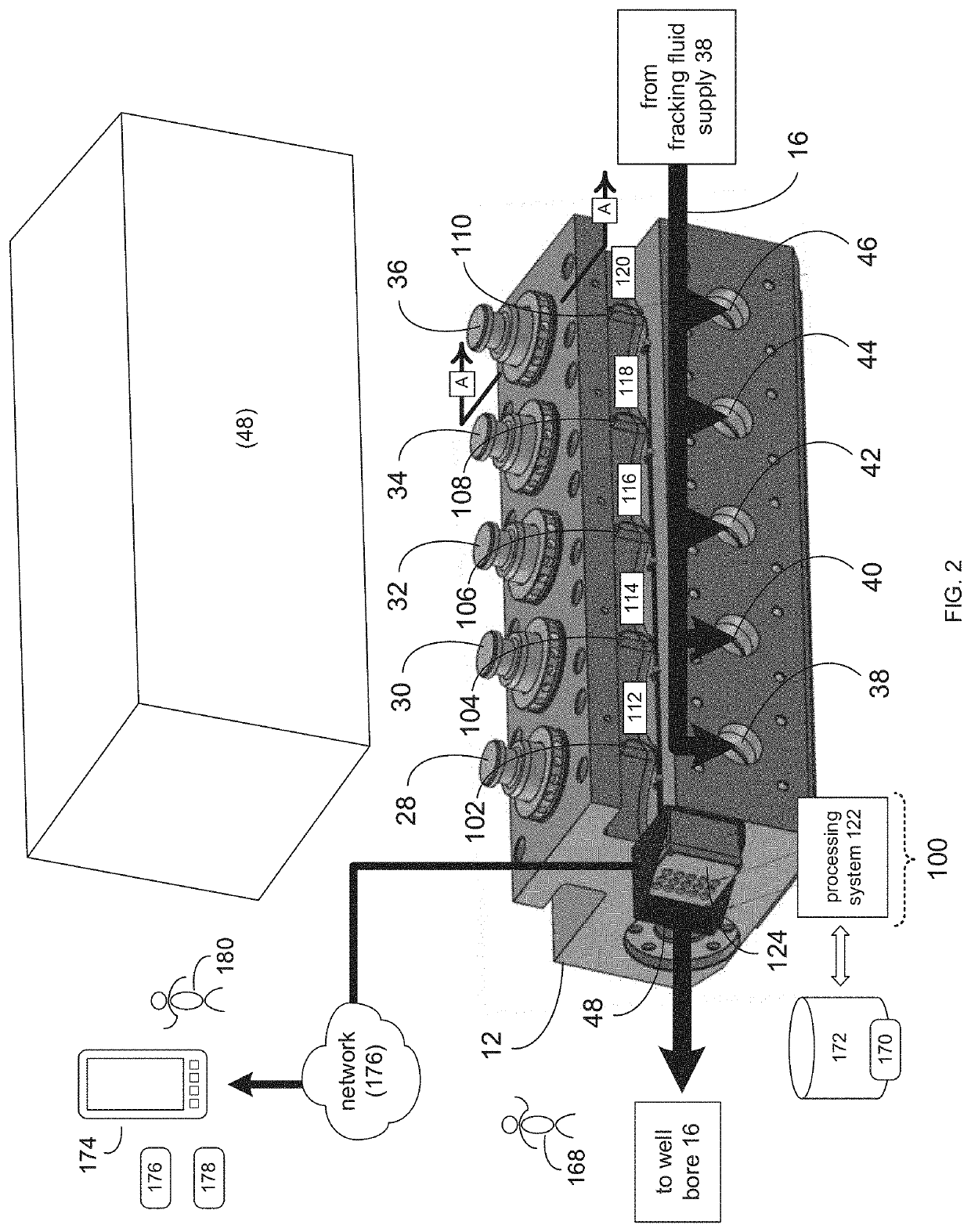

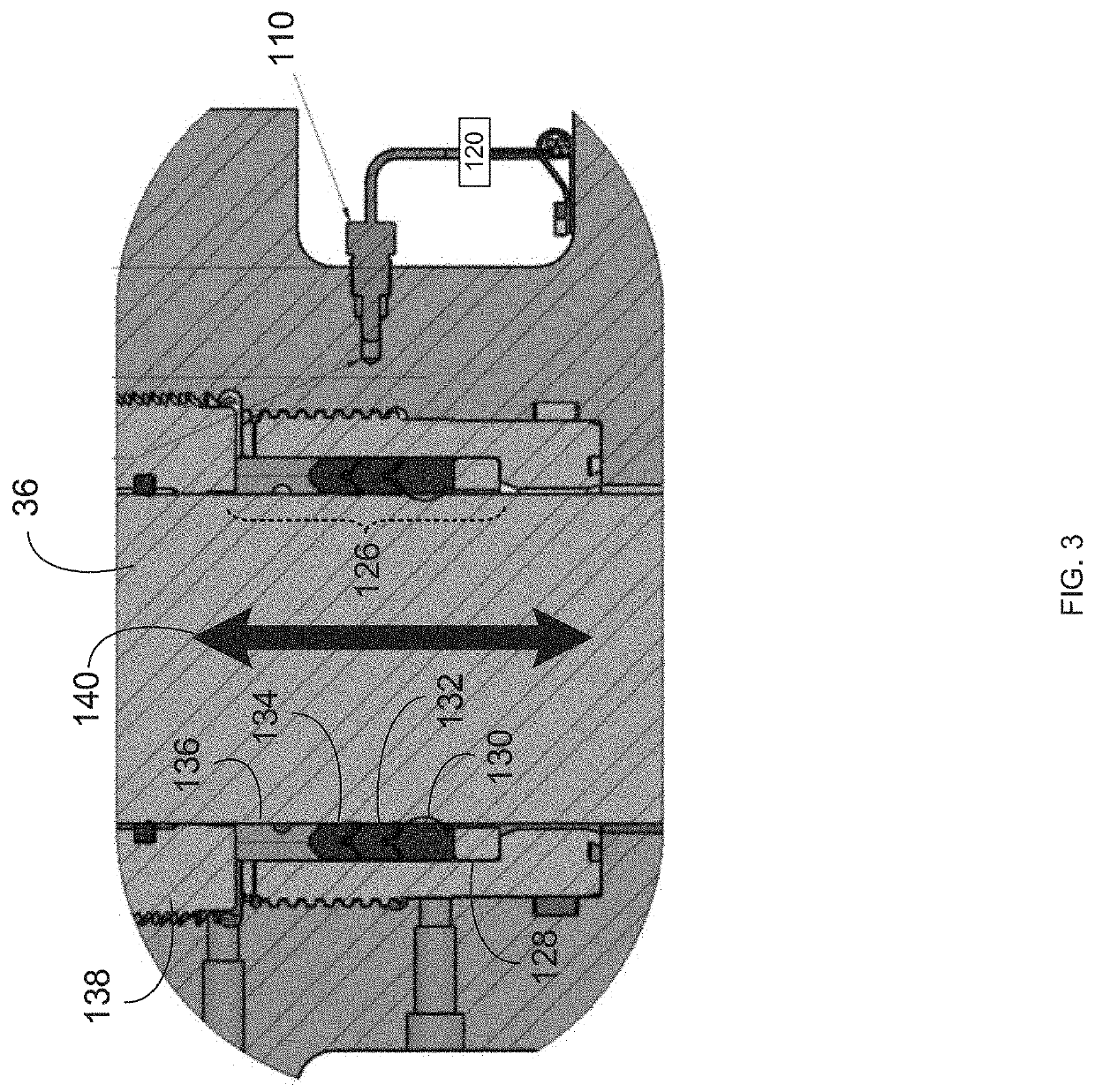

A thermal monitoring system includes: one or more thermal sensors configured to monitor the temperature of one or more portions of a fracking pump and generate one or more thermal indication signals; a processing system configured to receive the one or more thermal indication signals and associate the one or more thermal indication signals with one or more operating temperatures of the one or more portions of the fracking pump; and an indication system configured to provide a thermal condition indicator based, at least in part, upon the one or more operating temperatures of the one or more portions of the fracking pump.

Owner:SALT & LIGHT ENERGY EQUIP LLC

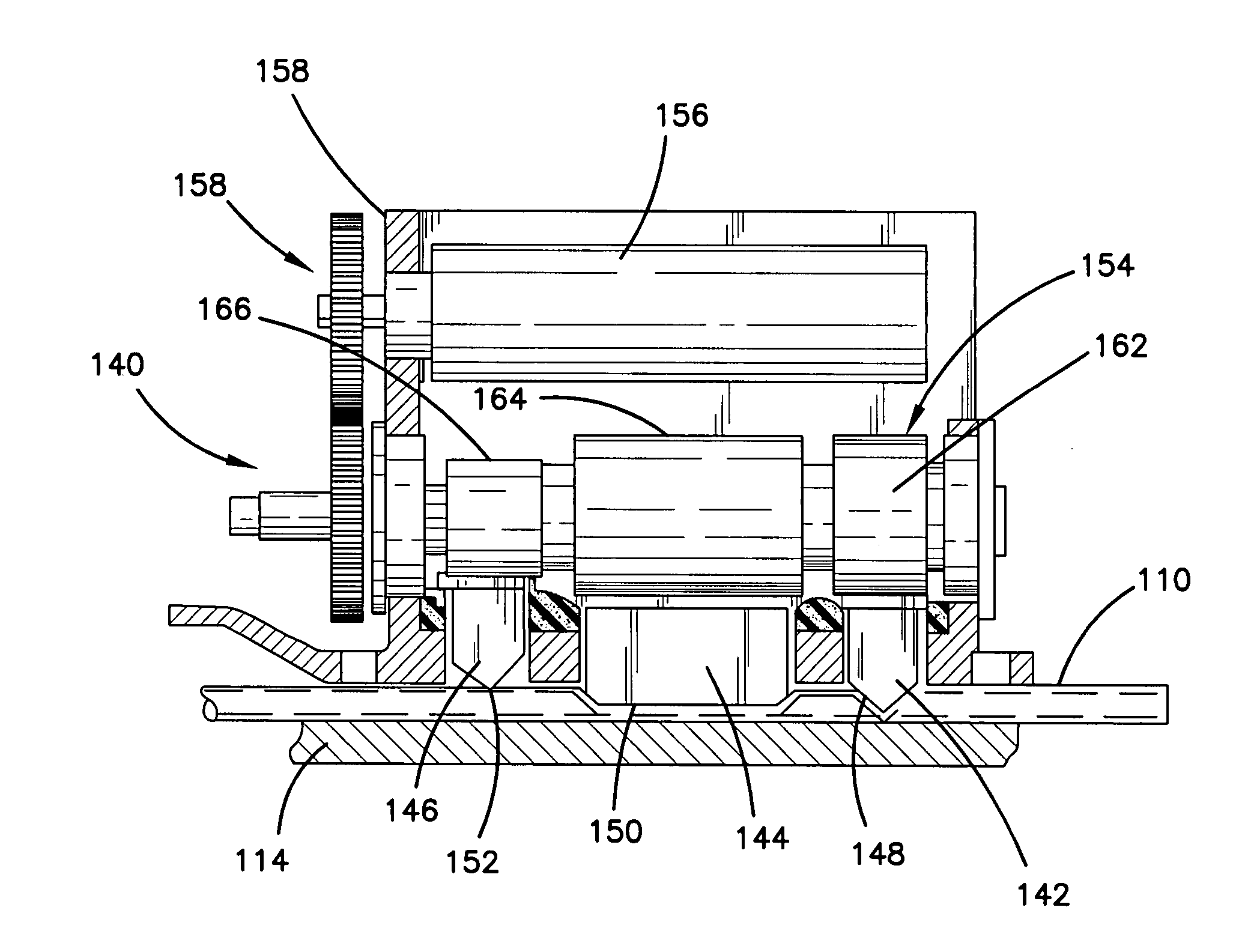

Drug pump systems and methods

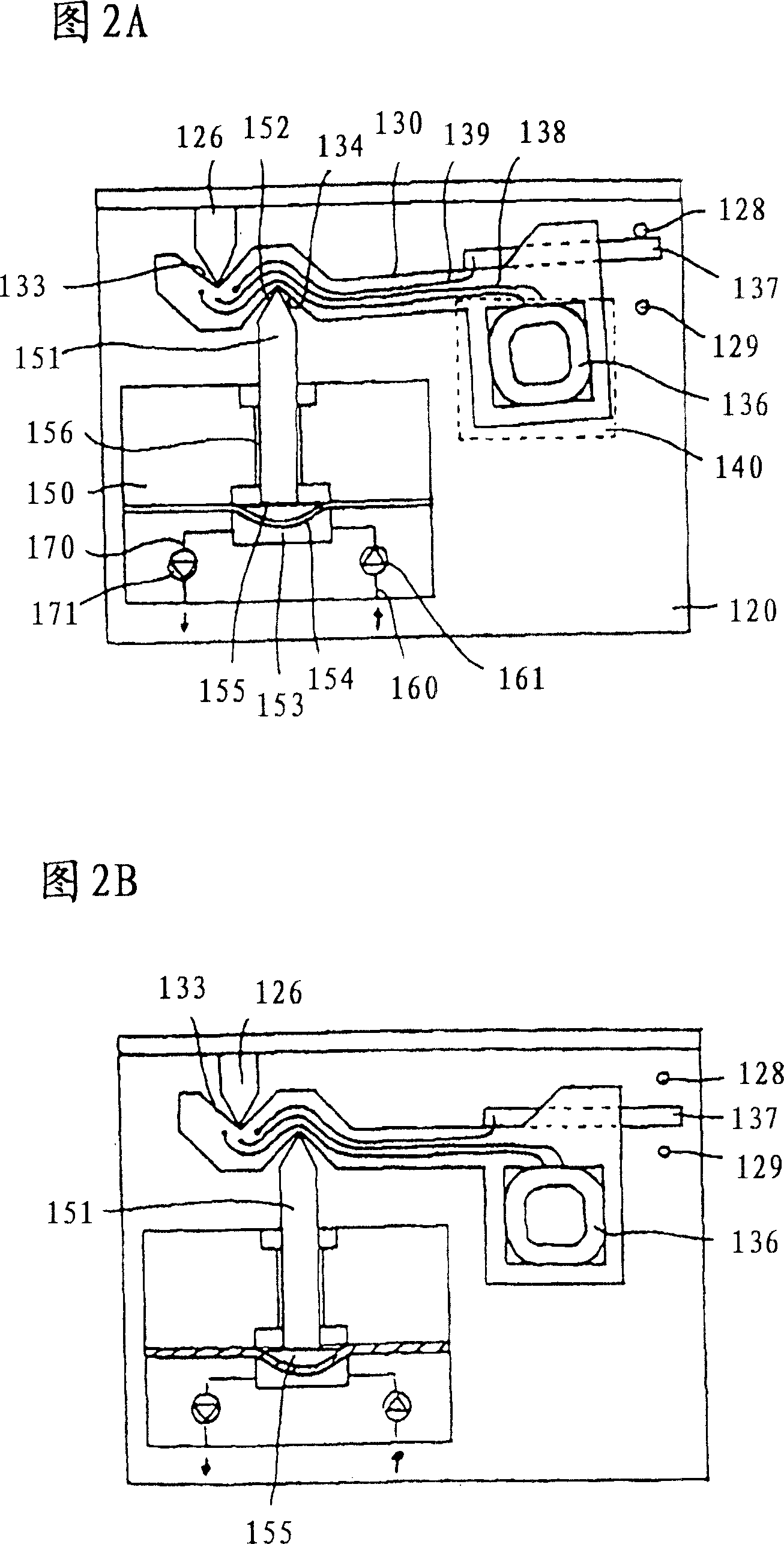

InactiveUS20080132844A1Drug and medicationsFlexible member pumpsClosed loop testingOcclusion detection

A menu driven reprogrammable drug pump is provided with a memory, such as flash memory, a display, a keyboard, and a communications port to allow a generic pump to be programmed with a desired pump application (therapy) program and patient specific settings. Programming and data transfer with another pump or a computer to and from the patient pump is by the communications port that allows local and / or remote communications with the pump. Flash memory stores the pump application program during use. Patient safety is provided by a cassette identification system, an occlusion detection system, and a latch / lock detection system. Automated testing of the pump is by a closed loop testing system.

Owner:SMITHS MEDICAL ASD INC

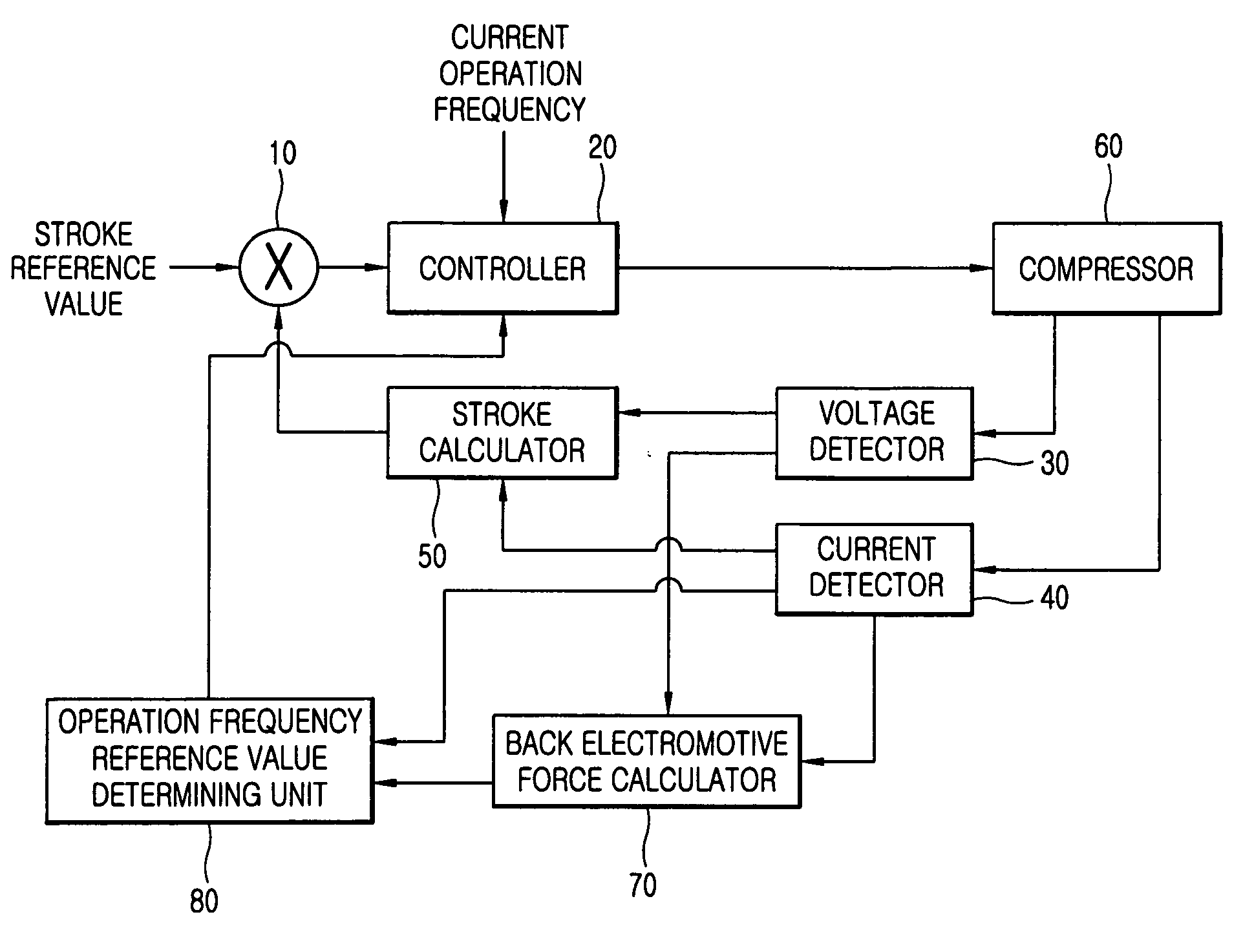

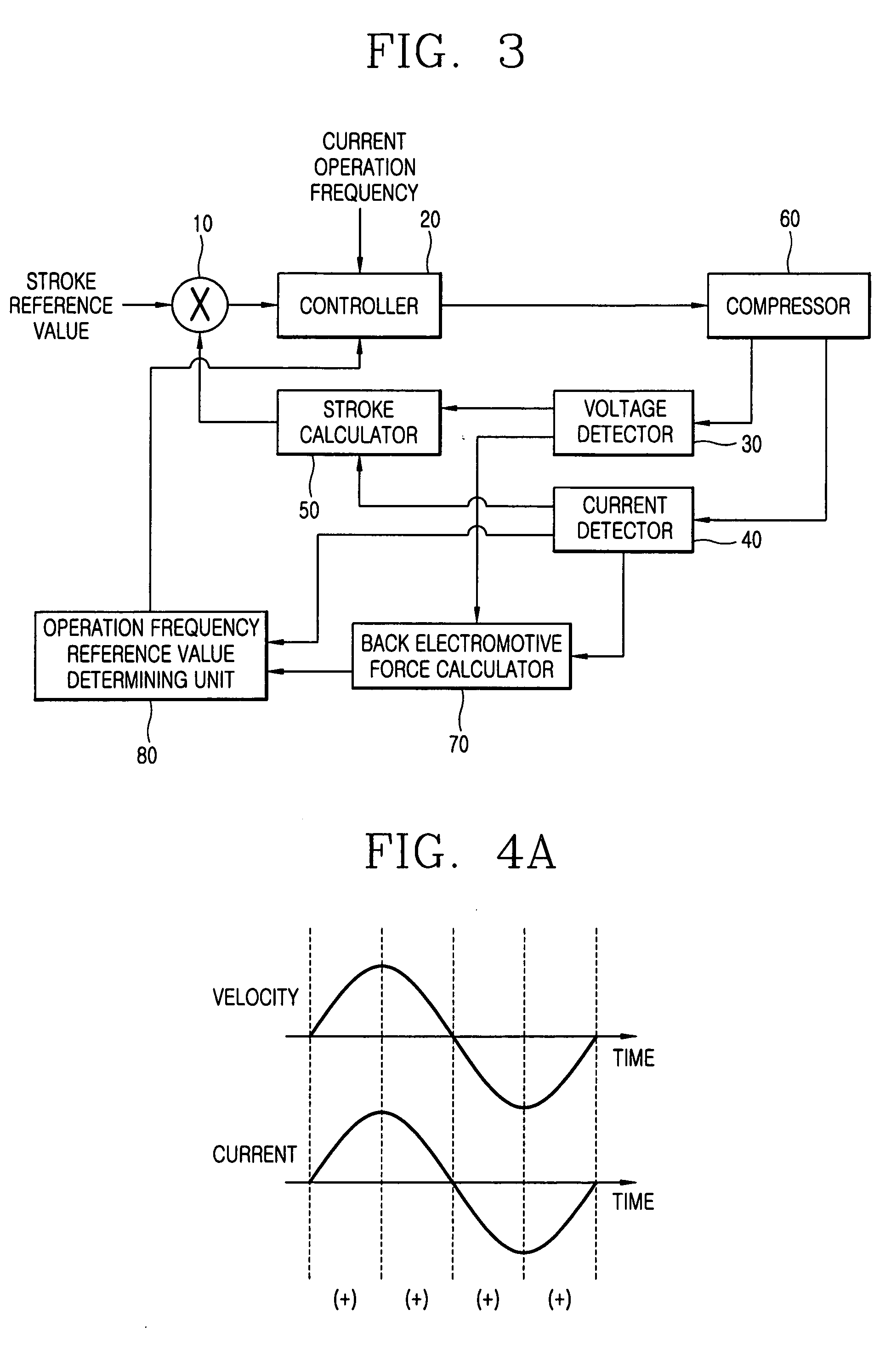

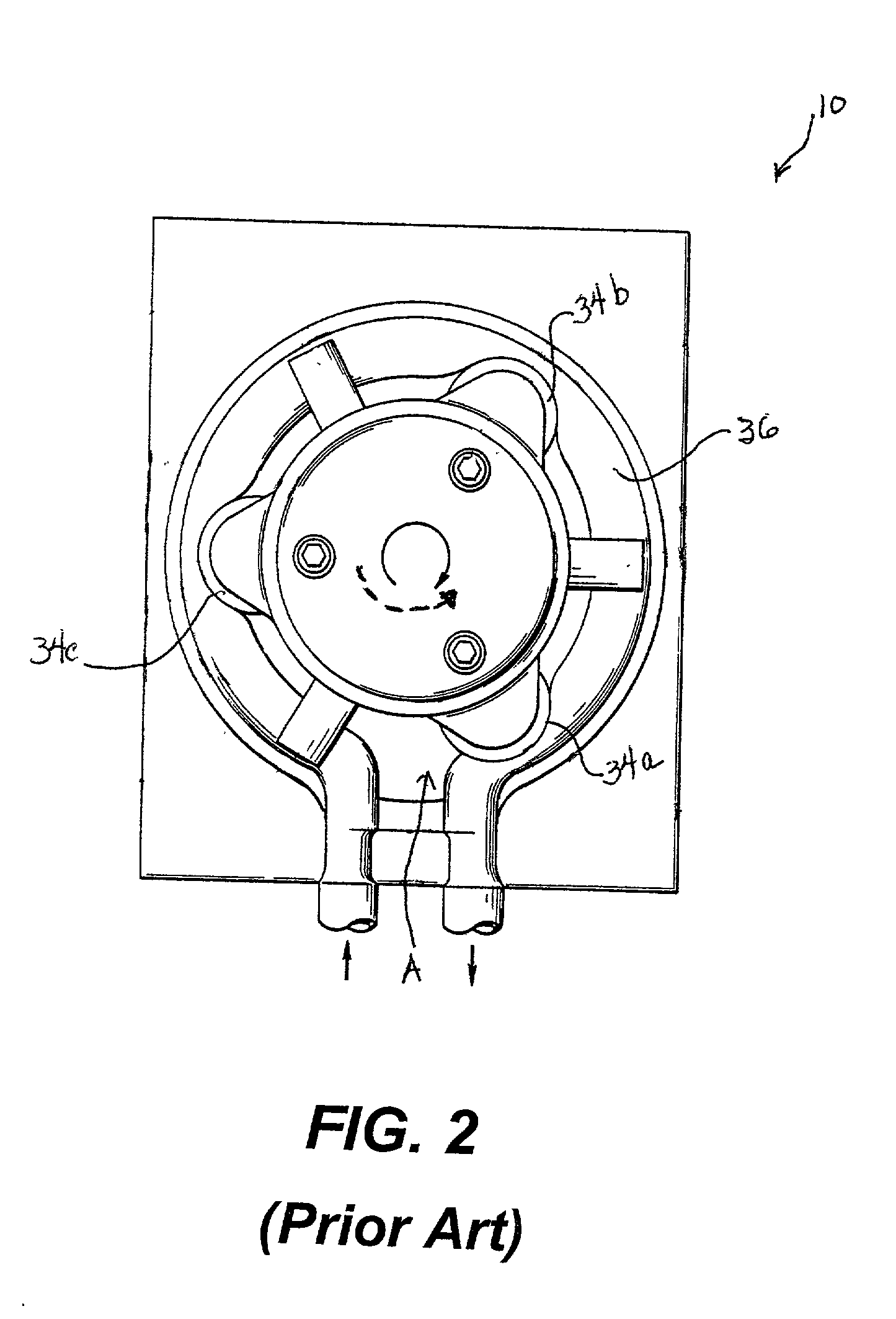

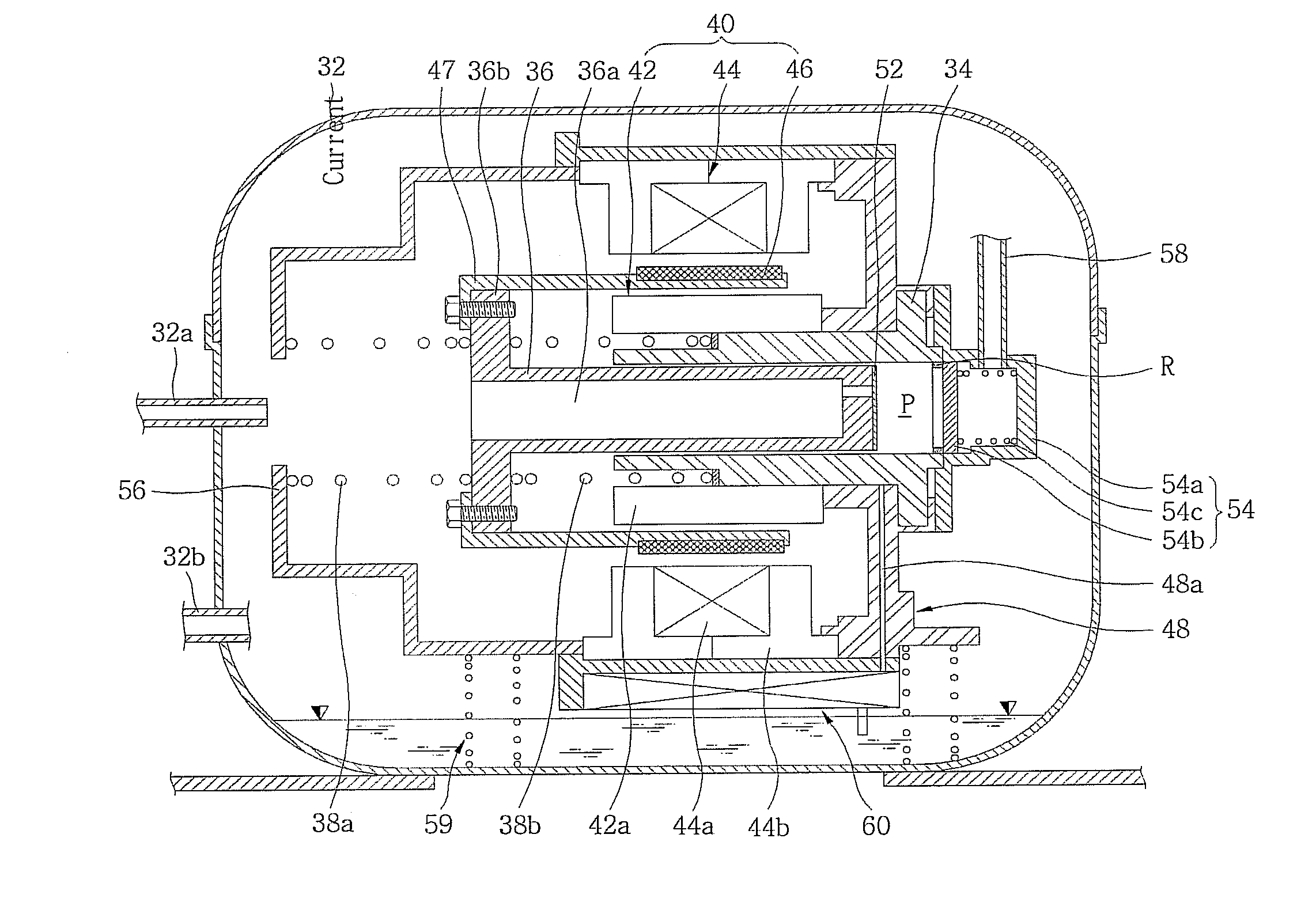

Apparatus and method for controlling operation of compressor

ActiveUS20060056980A1Easy to operateCompressorDC motor speed/torque controlMechanical resonanceElectromotive force

An apparatus for controlling an operation of a compressor includes: a back electromotive force calculator for calculating a back electromotive force of a compressor based on a value of a current applied to a motor of the compressor and a value of a voltage applied to the motor of the compressor; an operation frequency reference value determining unit for detecting a mechanical resonance frequency of the compressor based on the back electromotive force value and the current value and determining the detected mechanical resonance frequency as an operation frequency reference value; and a controller for varying an operation frequency of the compressor according to the determined operation frequency reference value.

Owner:LG ELECTRONICS INC

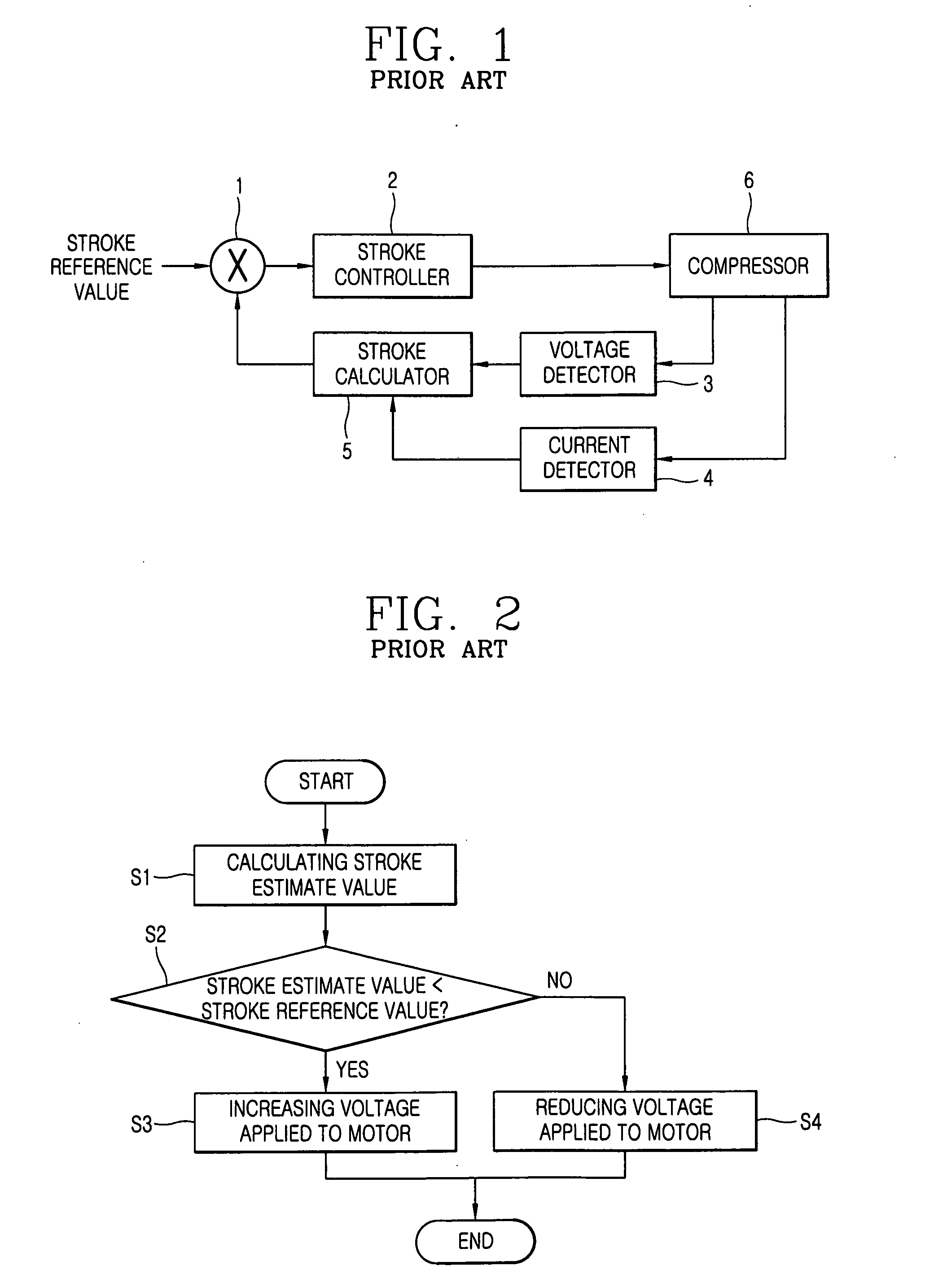

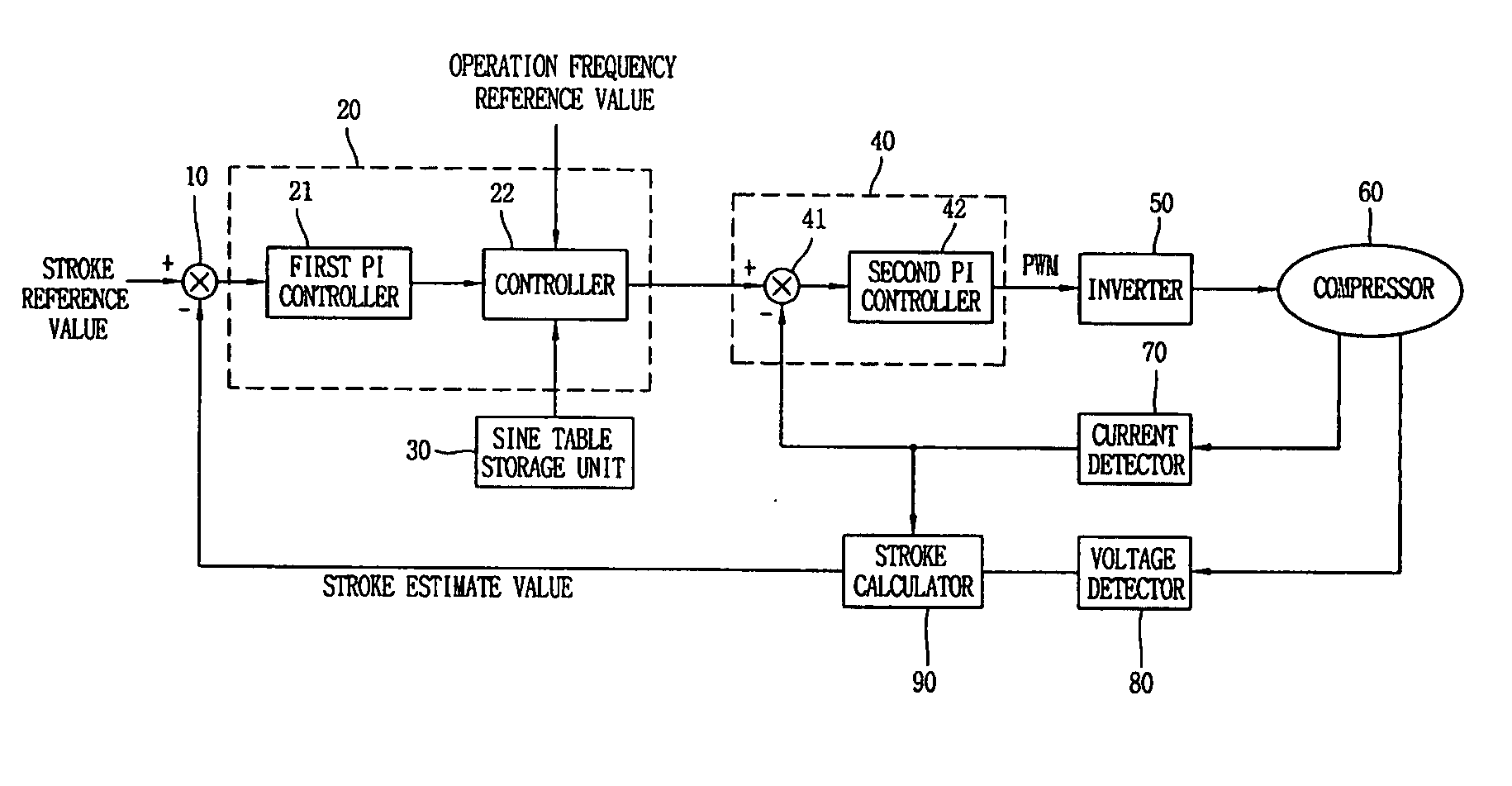

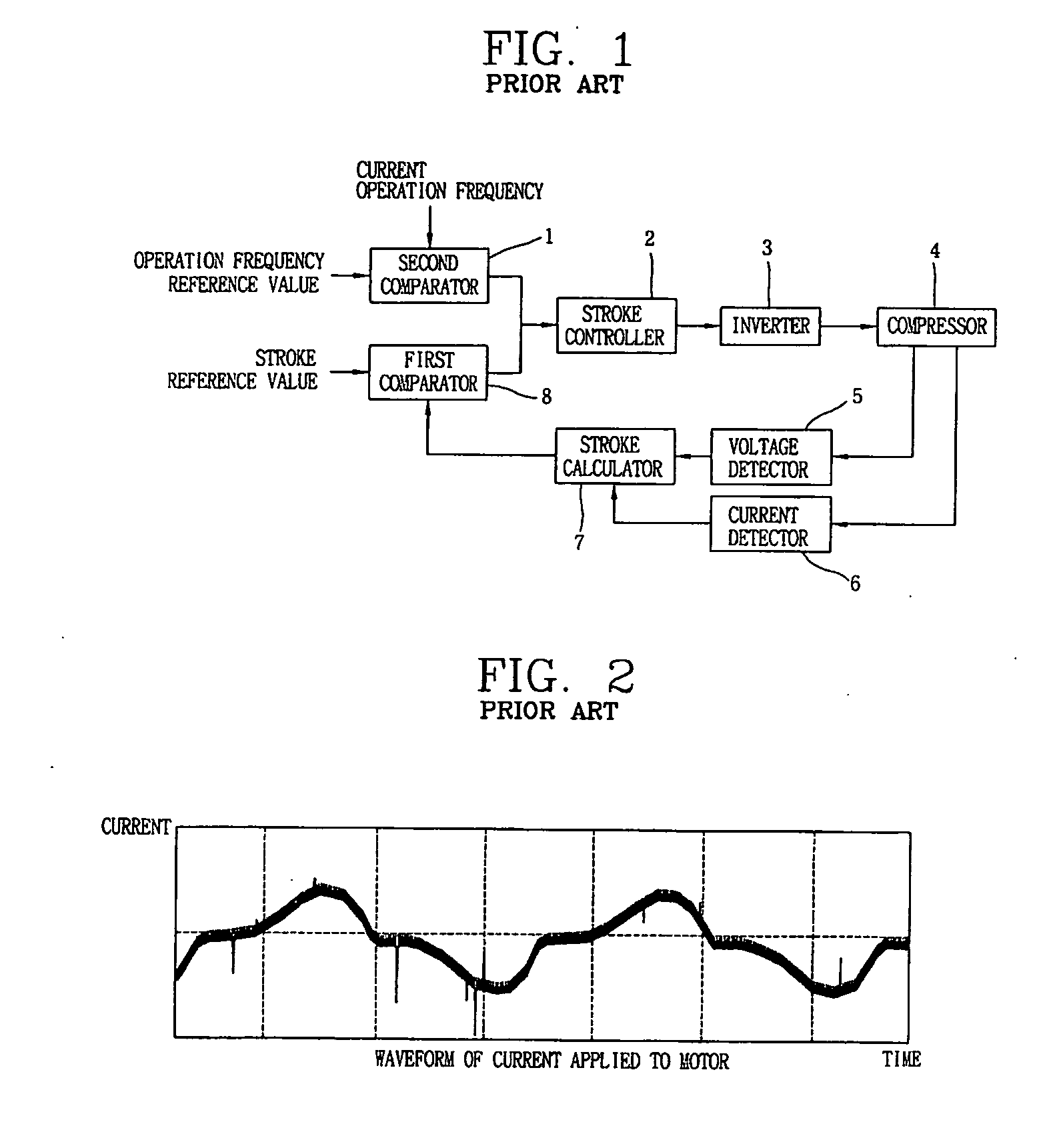

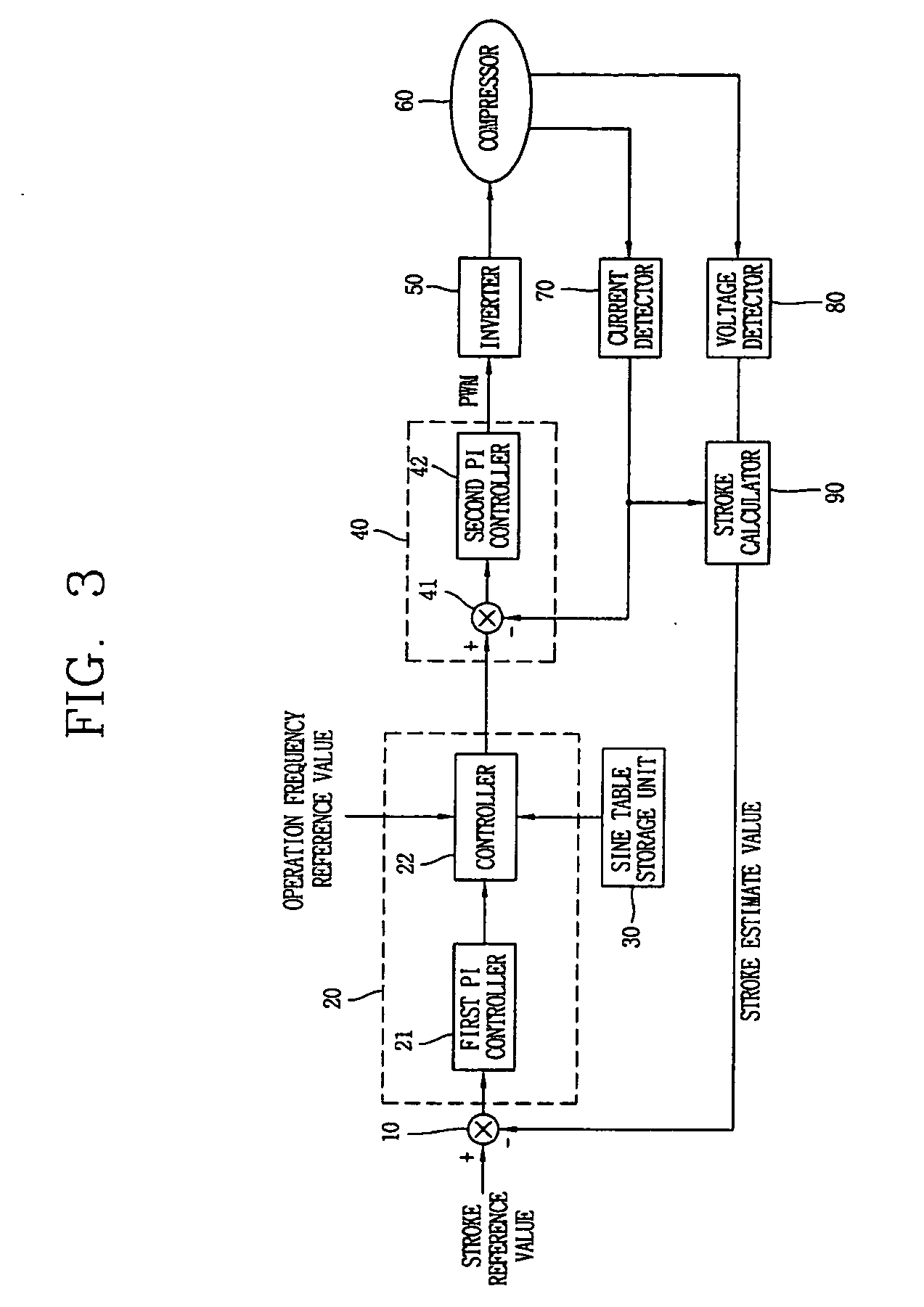

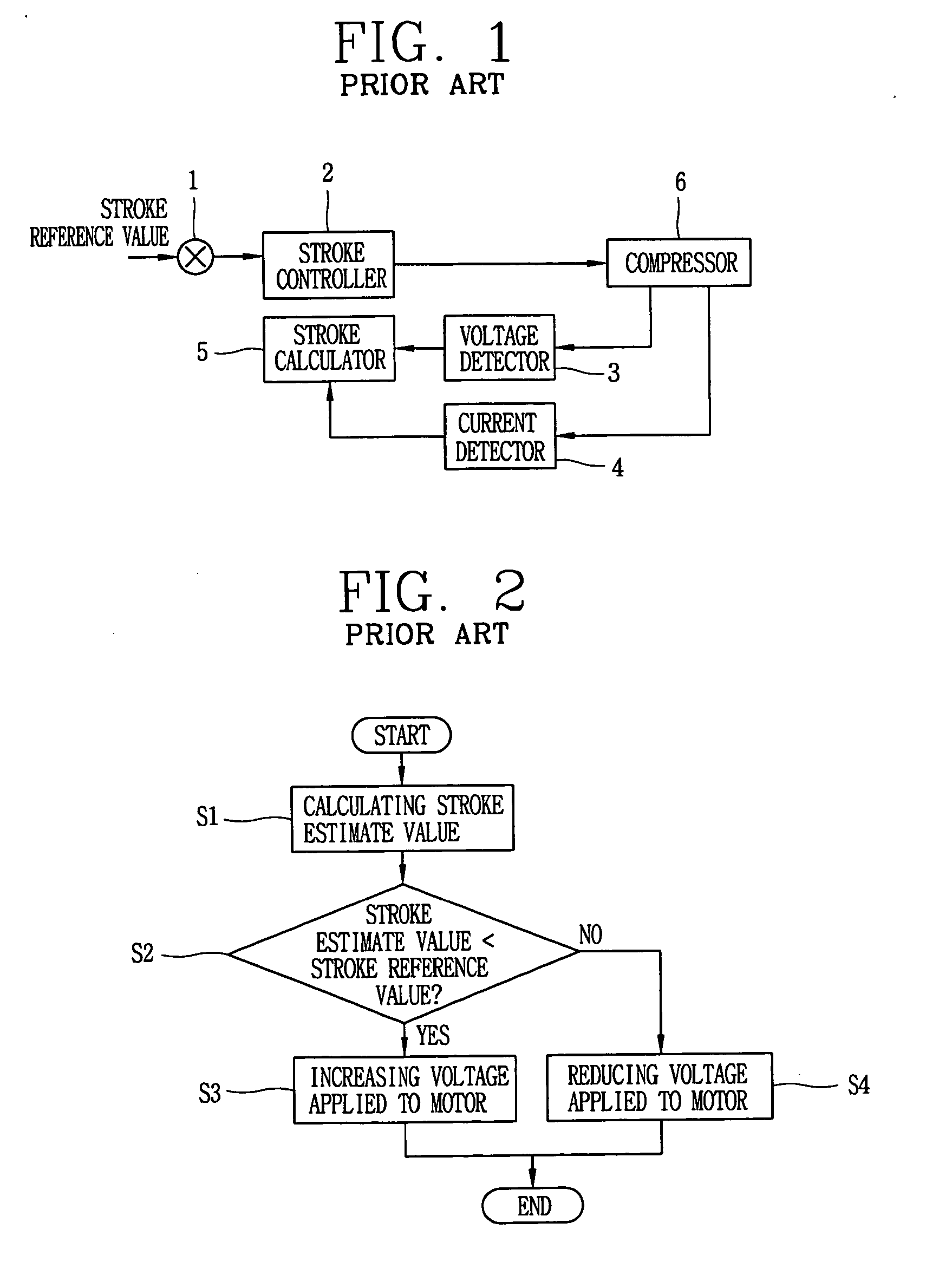

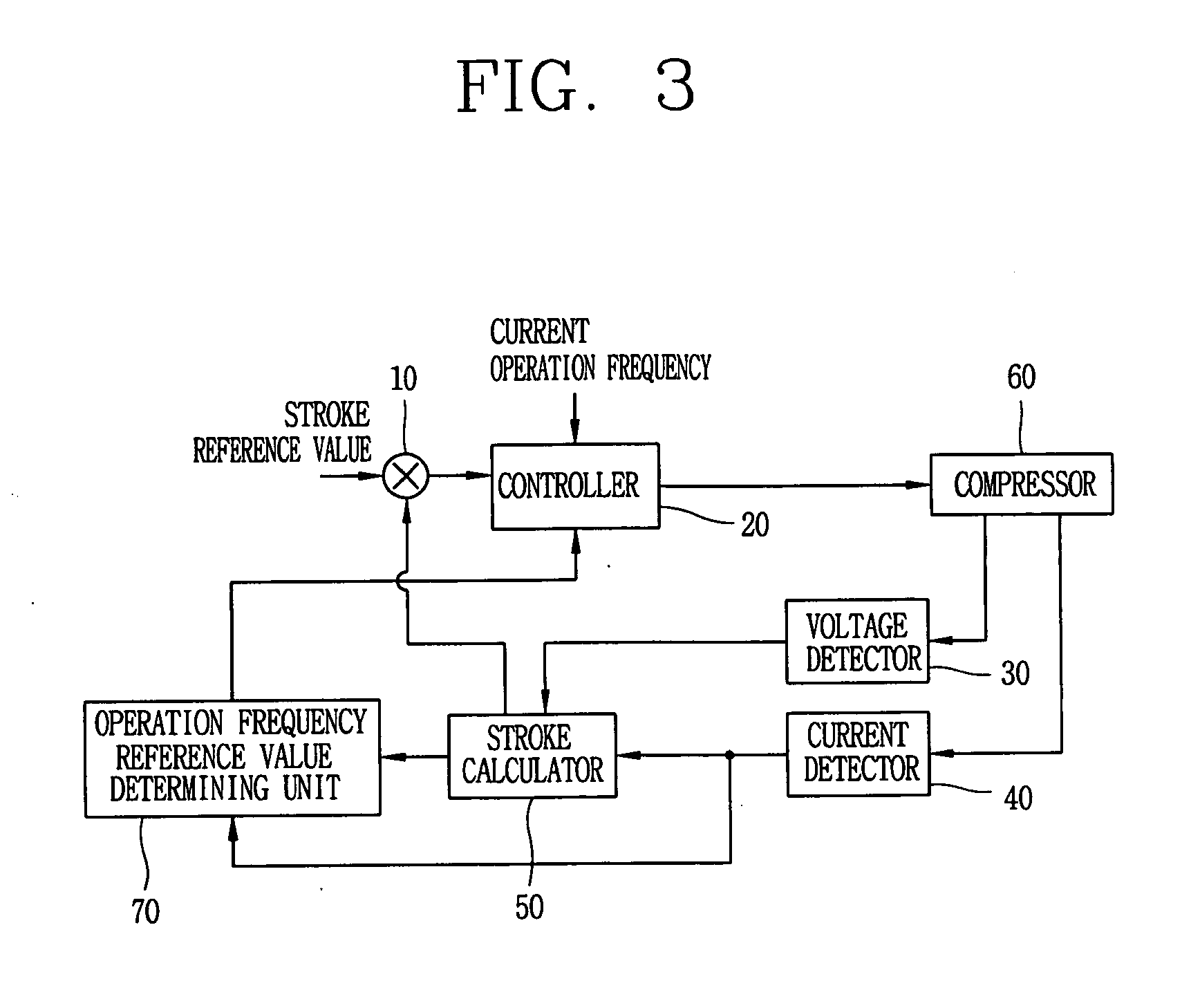

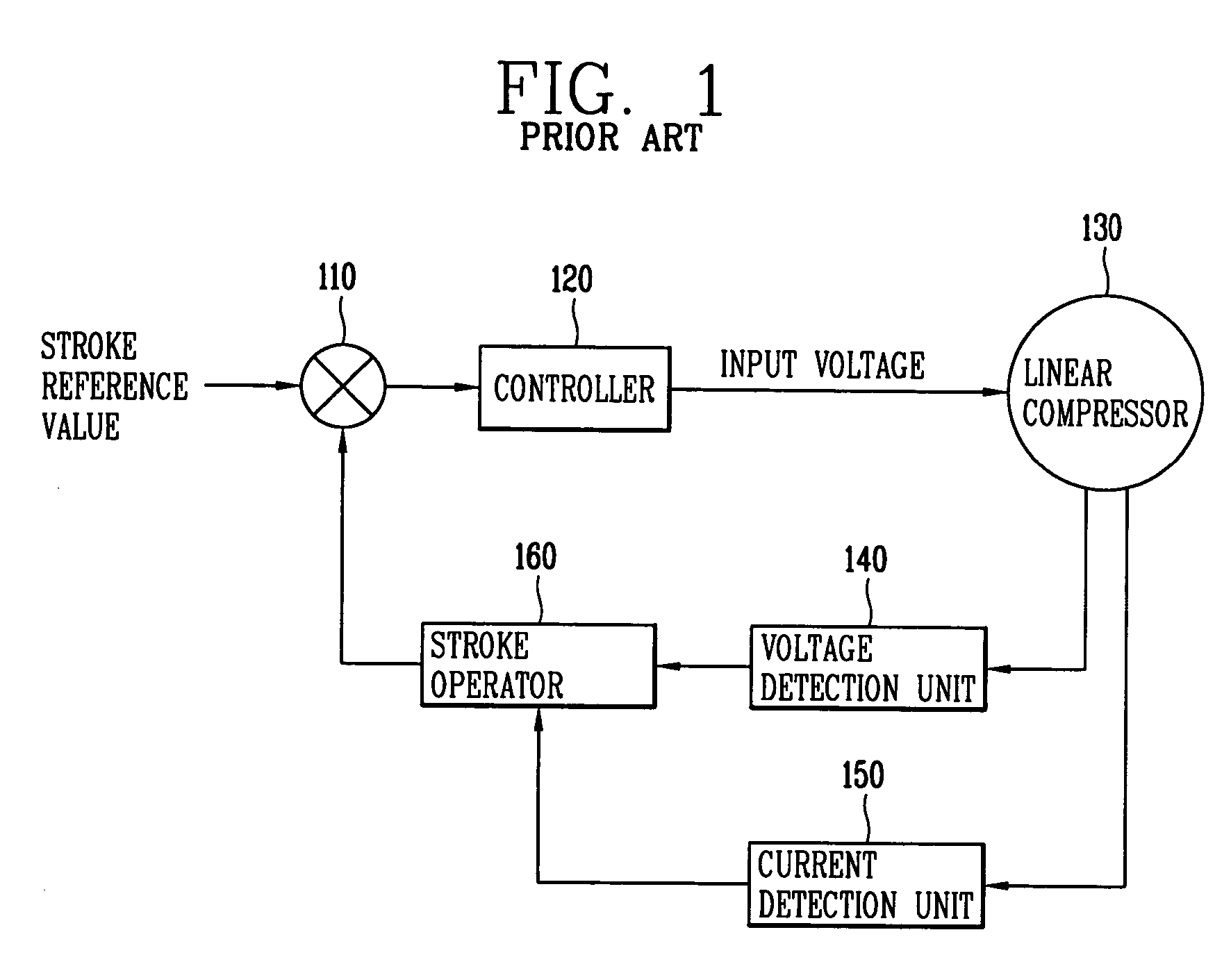

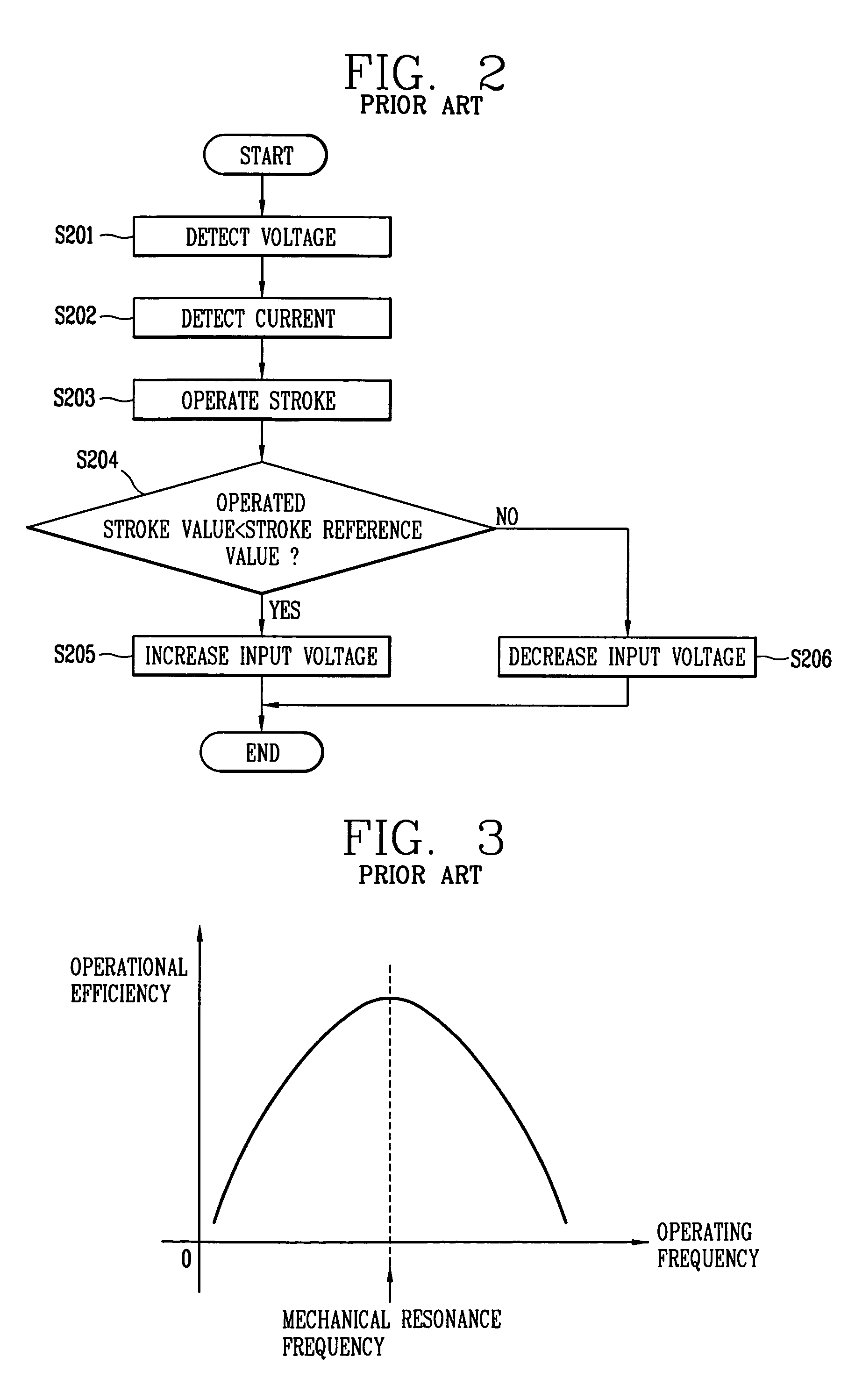

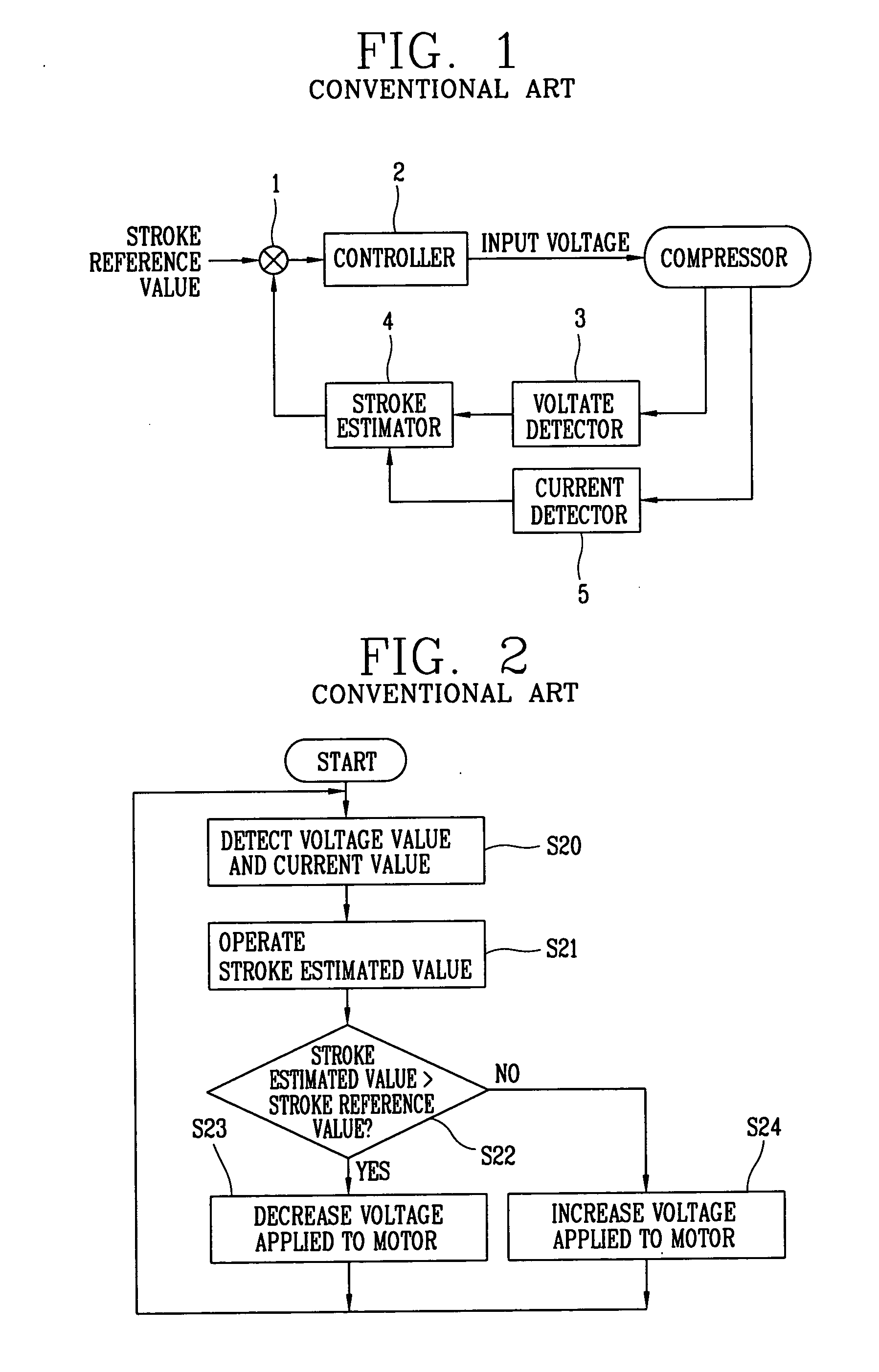

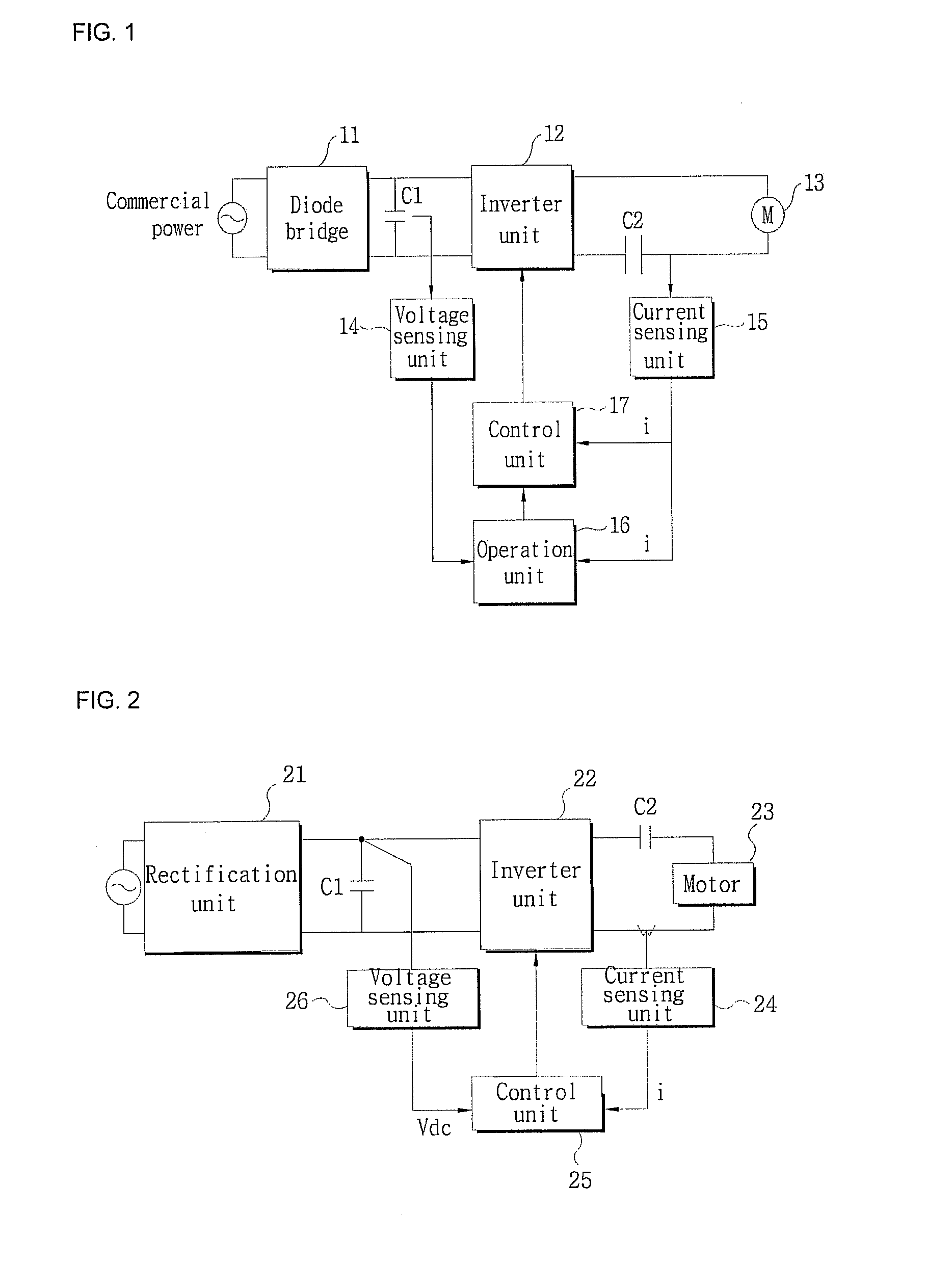

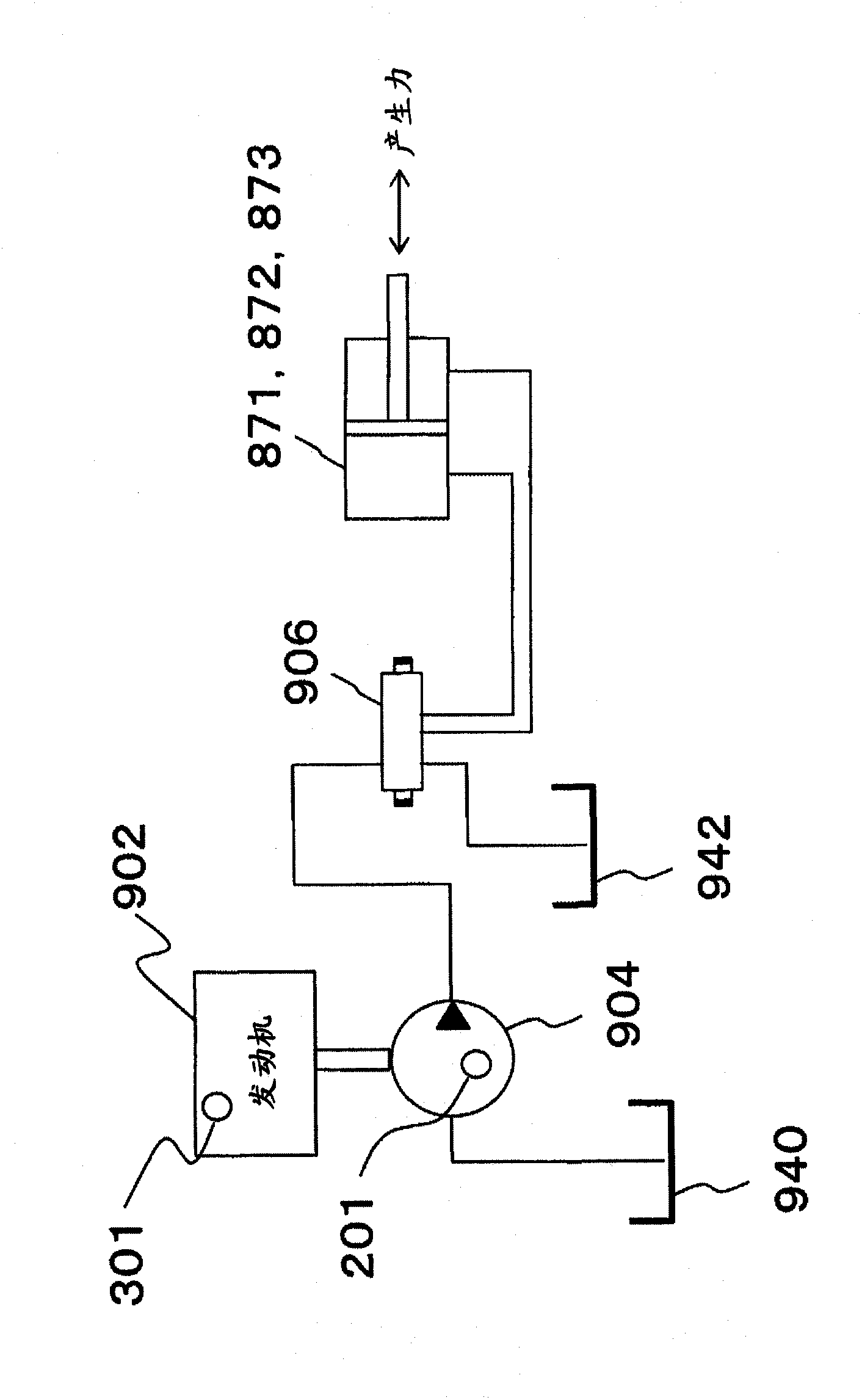

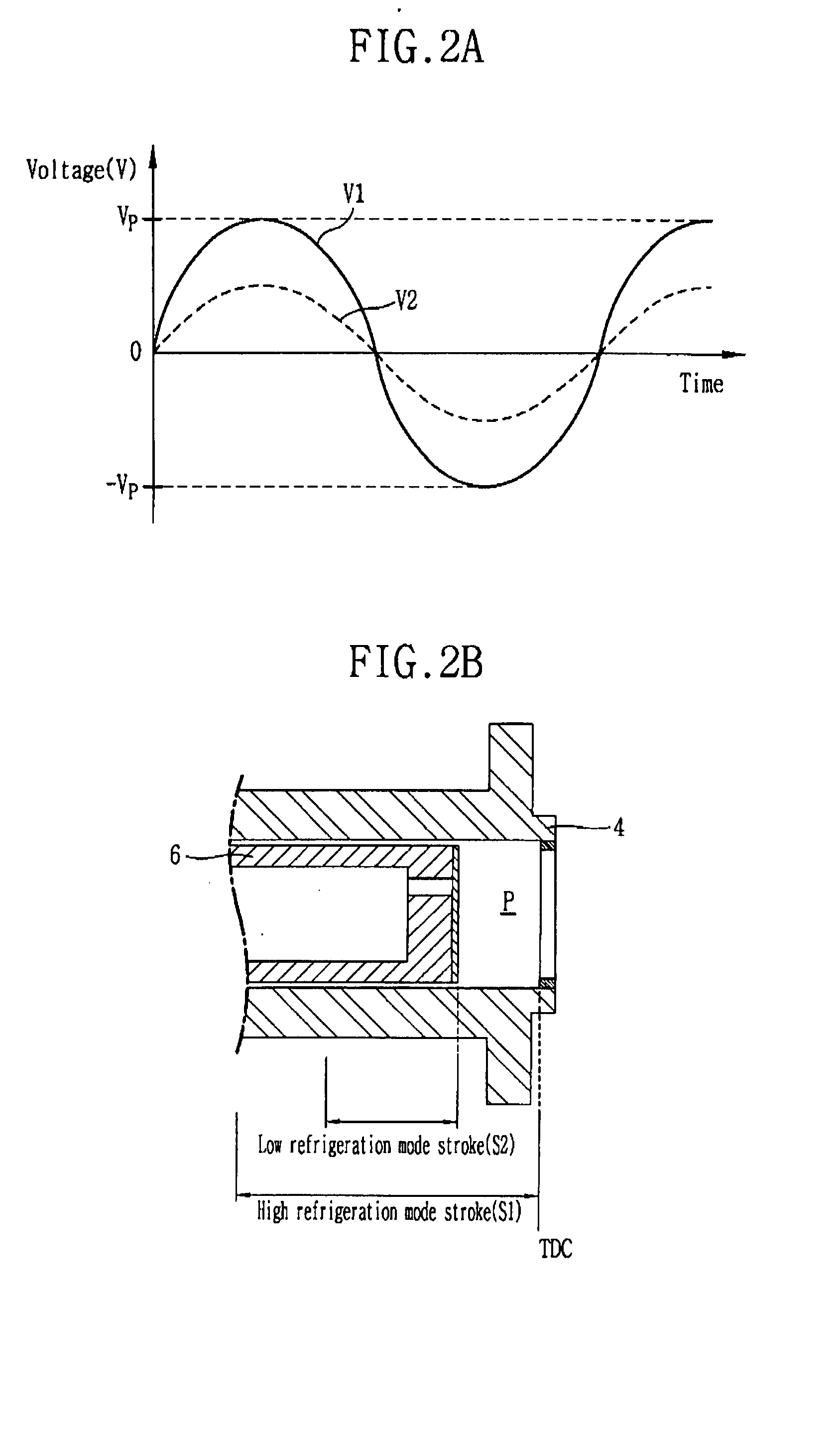

Apparatus and method for controlling operation of reciprocating compressor

InactiveUS20060251523A1Inhibit currentAvoid distortionExternal parameterAC motor controlControl theoryCurrent amplitude

An apparatus and method for controlling the operation of a reciprocating compressor are capable of preventing distortion of a current applied to the reciprocating compressor by generating a current amplitude value for compensating a difference value between a stroke reference value of the reciprocating compressor and a stroke estimate value and outputting the current amplitude value in a form of a sine wave to the reciprocating compressor. The apparatus for controlling an operation of a reciprocating compressor generates a current amplitude value for compensating a difference value between a stroke reference value and a stroke estimate value of the reciprocating compressor and outputs the current amplitude value in a sine wave form to the reciprocating compressor.

Owner:LG ELECTRONICS INC

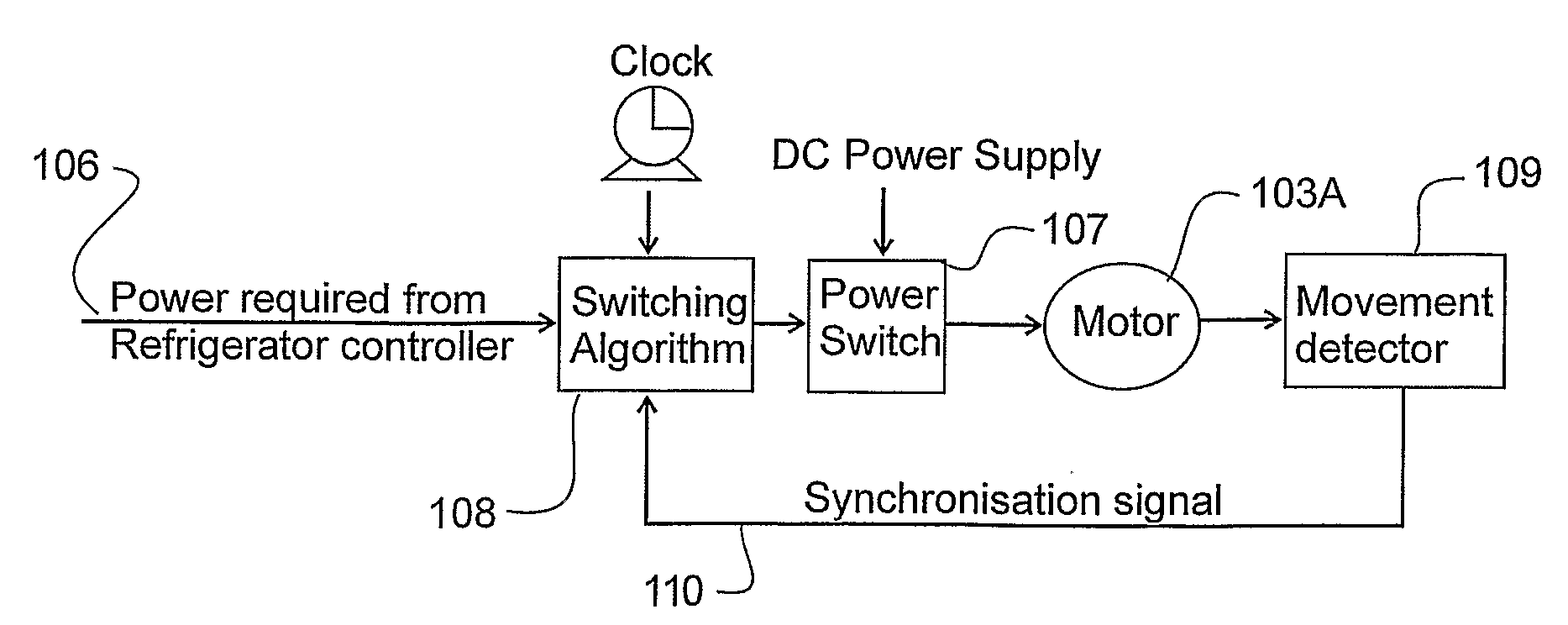

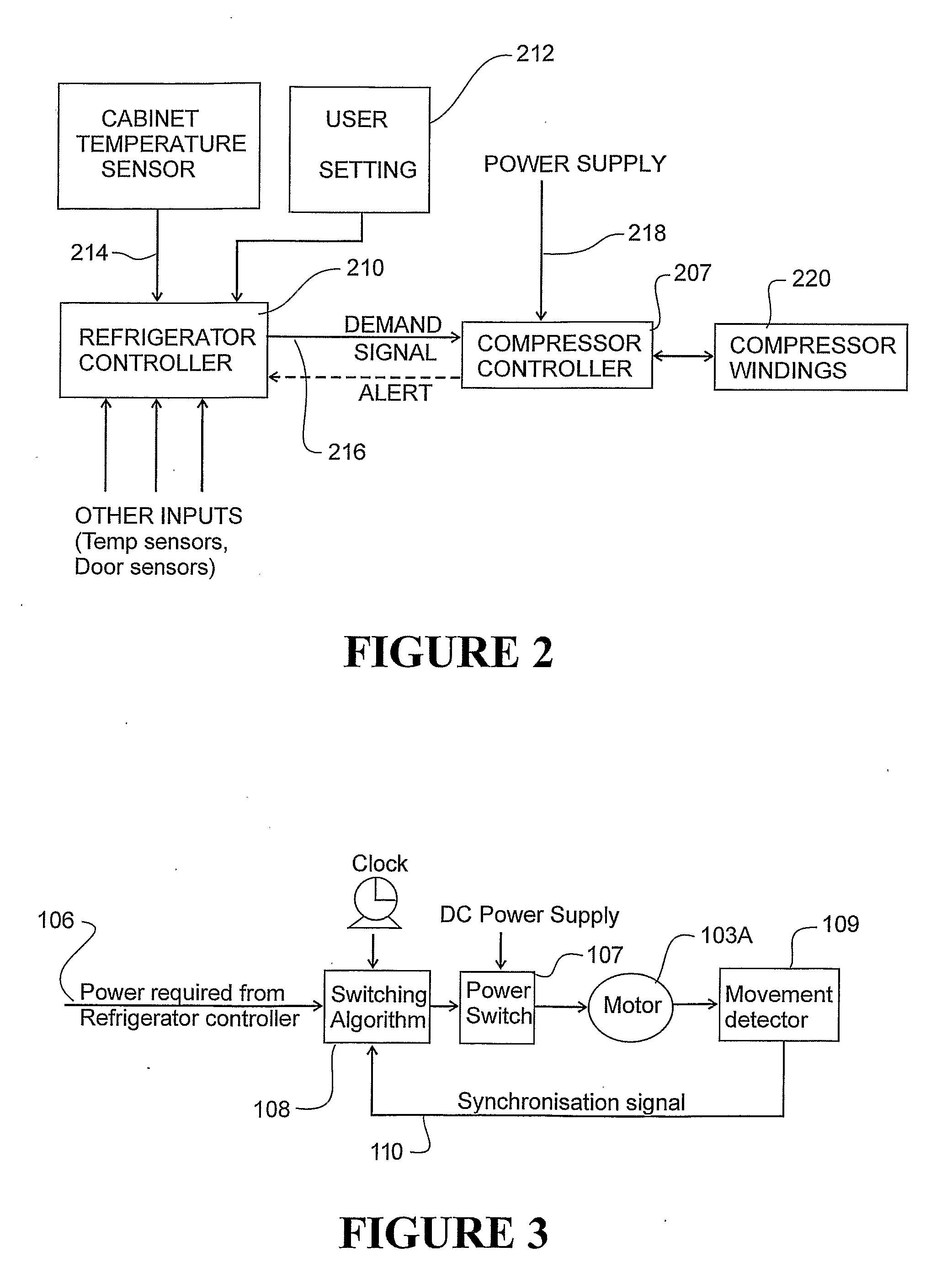

Linear compressor controller

ActiveUS20090081049A1Reduce stepsReduce total powerExternal parameterFluid-pressure actuatorsLower limitLinear compressor

A control for a linear compressor energises the linear motor in harmony with the present natural frequency of the compressor. The controller monitors the present operating frequency and compares the frequency with one or more outer limit thresholds. The control may remove power from the linear motor if the running frequency drops below a lower threshold. The control may reduce power to the linear motor if the running frequency rises above an upper threshold. The control uses compressor running frequency to operate the comperssor within safe operating limits.

Owner:FISHER & PAYKEL APPLIANCES LTD

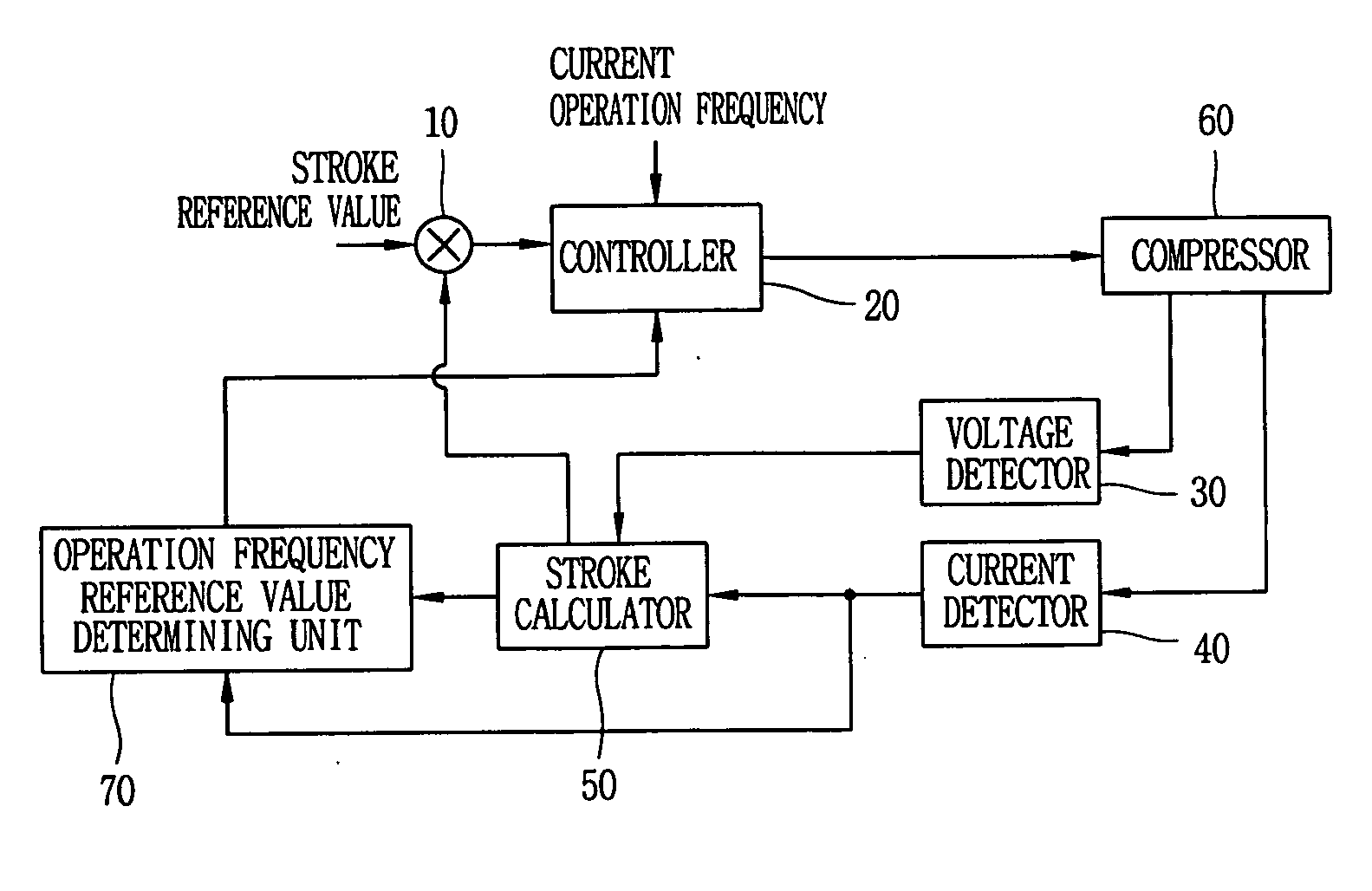

Apparatus and method for controlling operation of compressor

InactiveUS20060056979A1Easy to operateExternal parameterFlexible member pumpsEngineeringMechanical resonance

An apparatus for controlling a compressor includes a stroke calculator for calculating a stroke estimate value of a compressor based on a value of a current applied to a motor of the compressor and a value of a voltage applied to the motor of the compressor; an operation frequency reference determining unit for integrating the stroke estimate value to output an integrated stroke value, detecting a mechanical resonance frequency of the compressor based on the integrated stroke estimate value and the current value, and determining the detected mechanical resonance frequency as an operation frequency reference value; and a controller for varying a current operation frequency of the compressor according to the determined operation frequency reference value.

Owner:LG ELECTRONICS INC

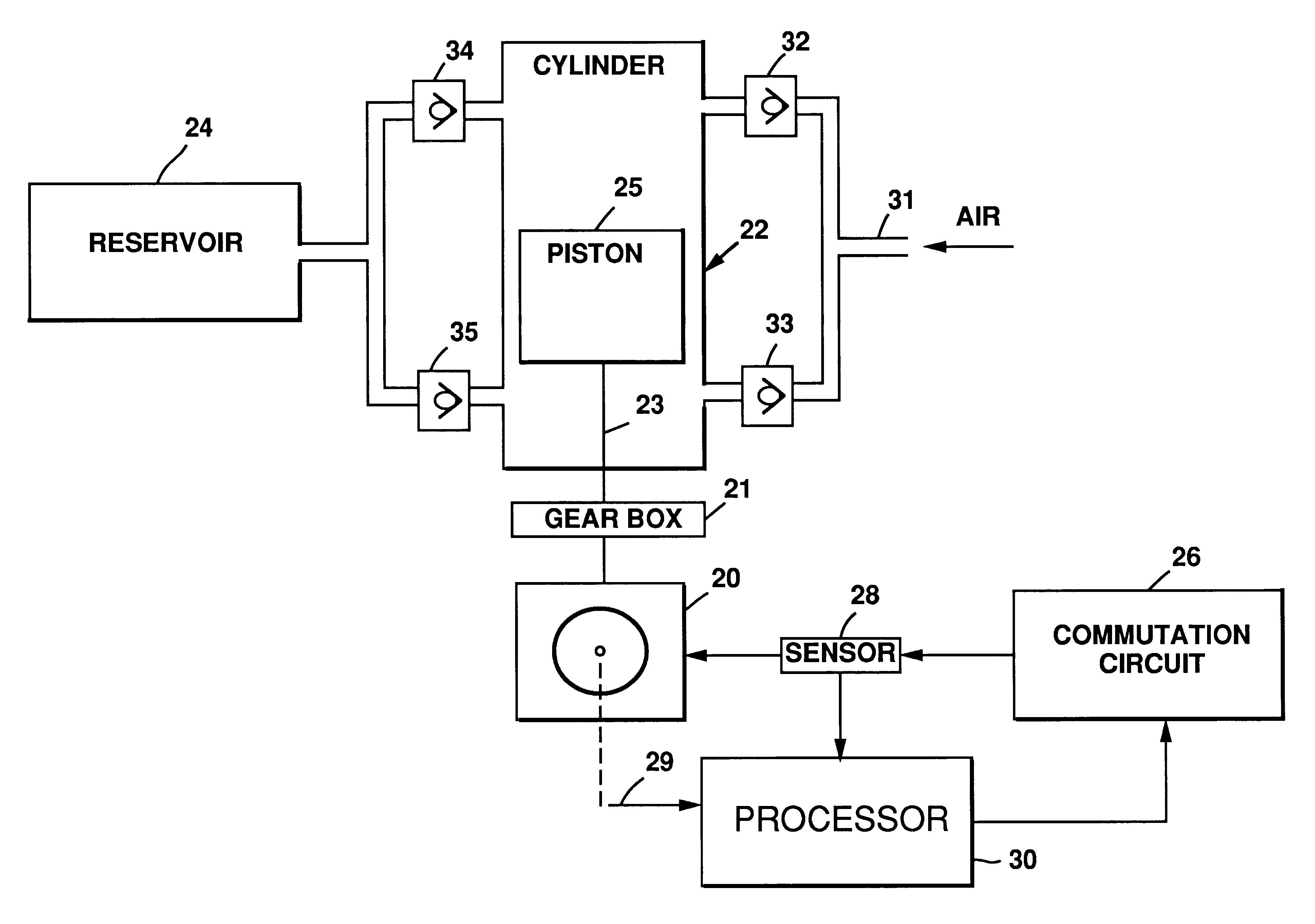

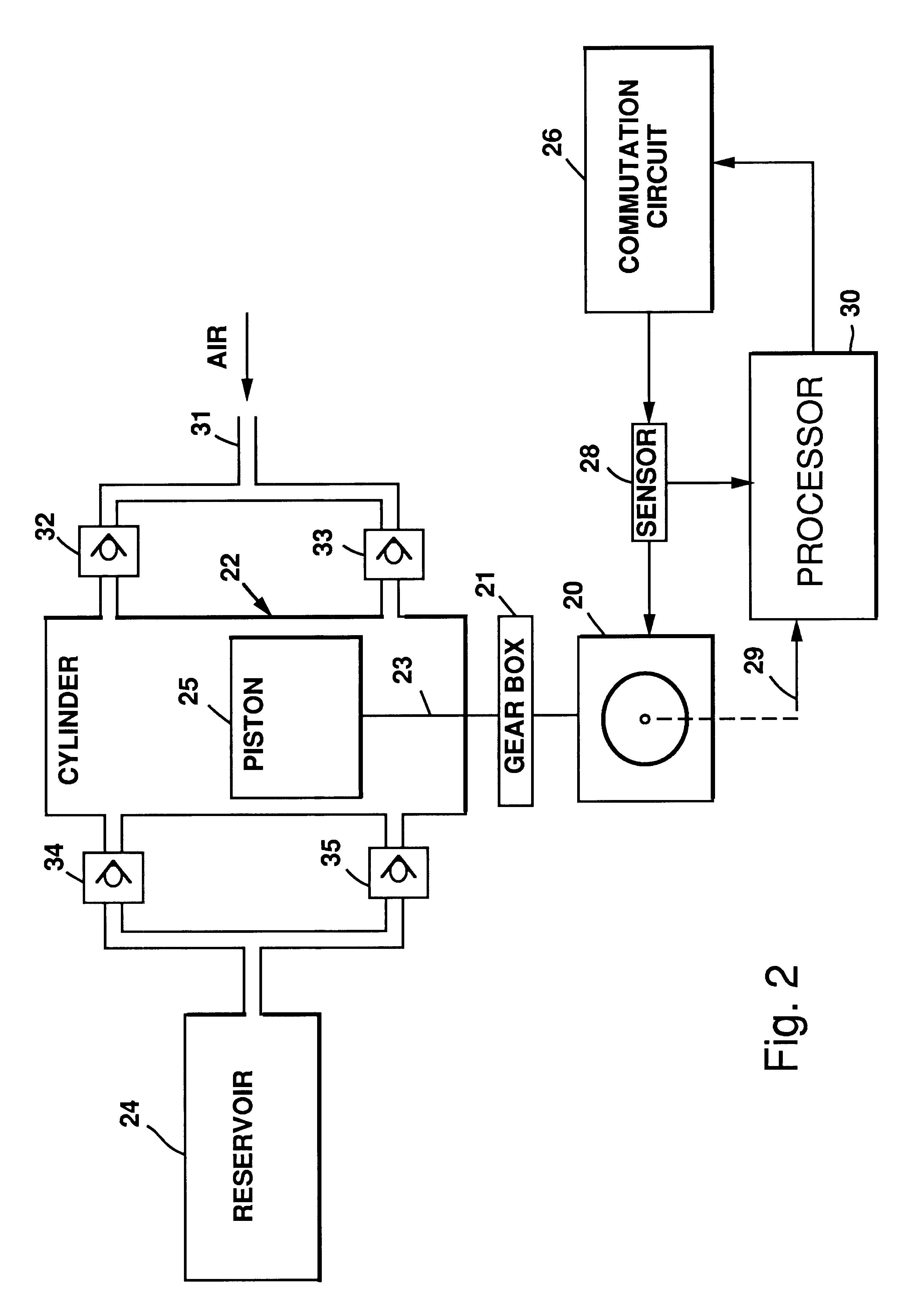

Pressure control system using input current sensing

A method and apparatus for controlling the output function of a permanent magnet brushless DC motor (20), by sensing an input current to the motor (20), by computing an output torque generated by the motor (20) as a function of the input current to the motor (20), by computing an output pressure for a pump (22) in response to the output torque, by reading a set point pressure, and by comparing the set point pressure to the output pressure, and in response thereto controlling on-off operation of the motor (20). The apparatus includes a sensing circuit (28) and a microelectronic processor (30) for performing these functions.

Owner:MOOG INC

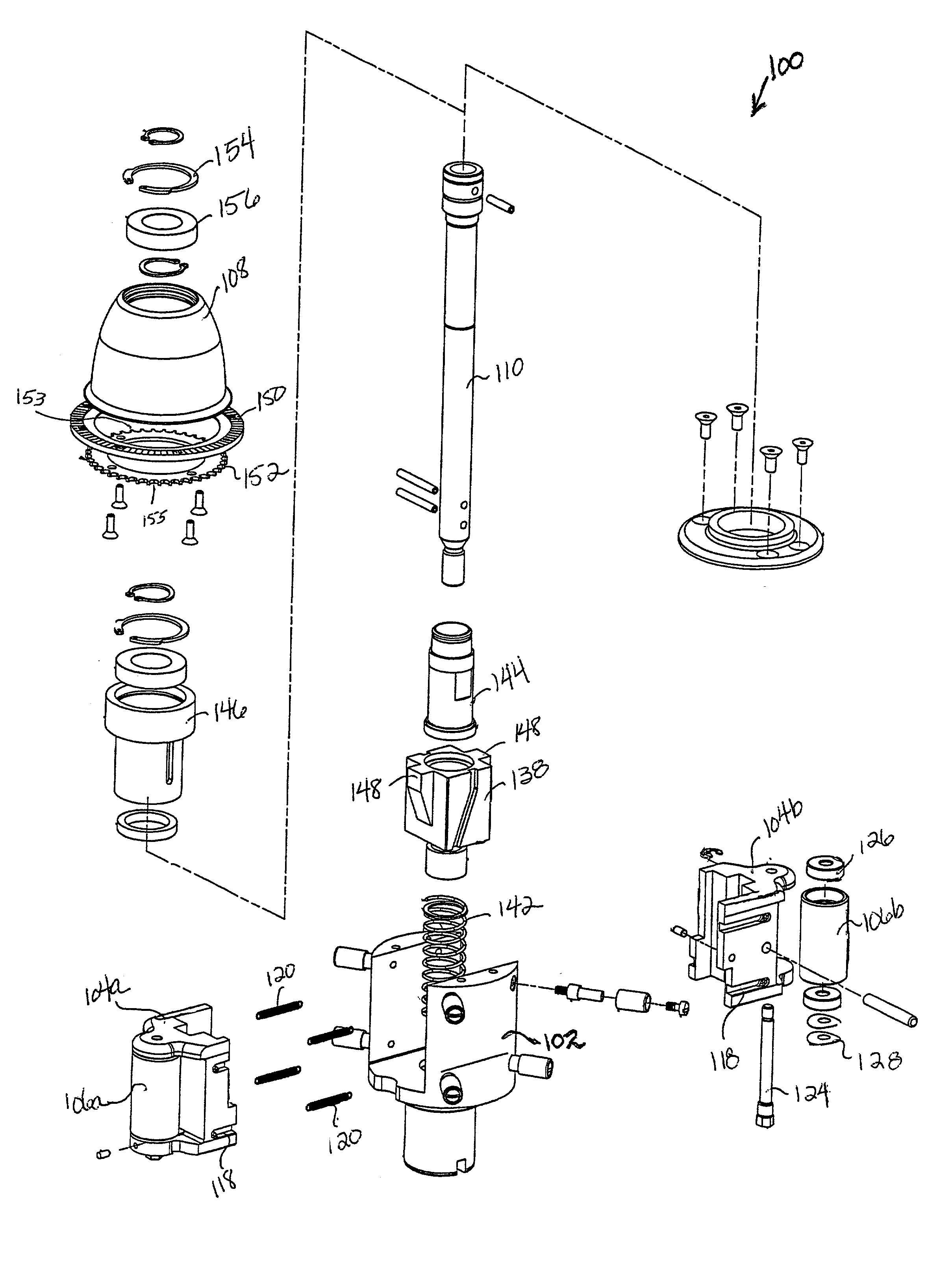

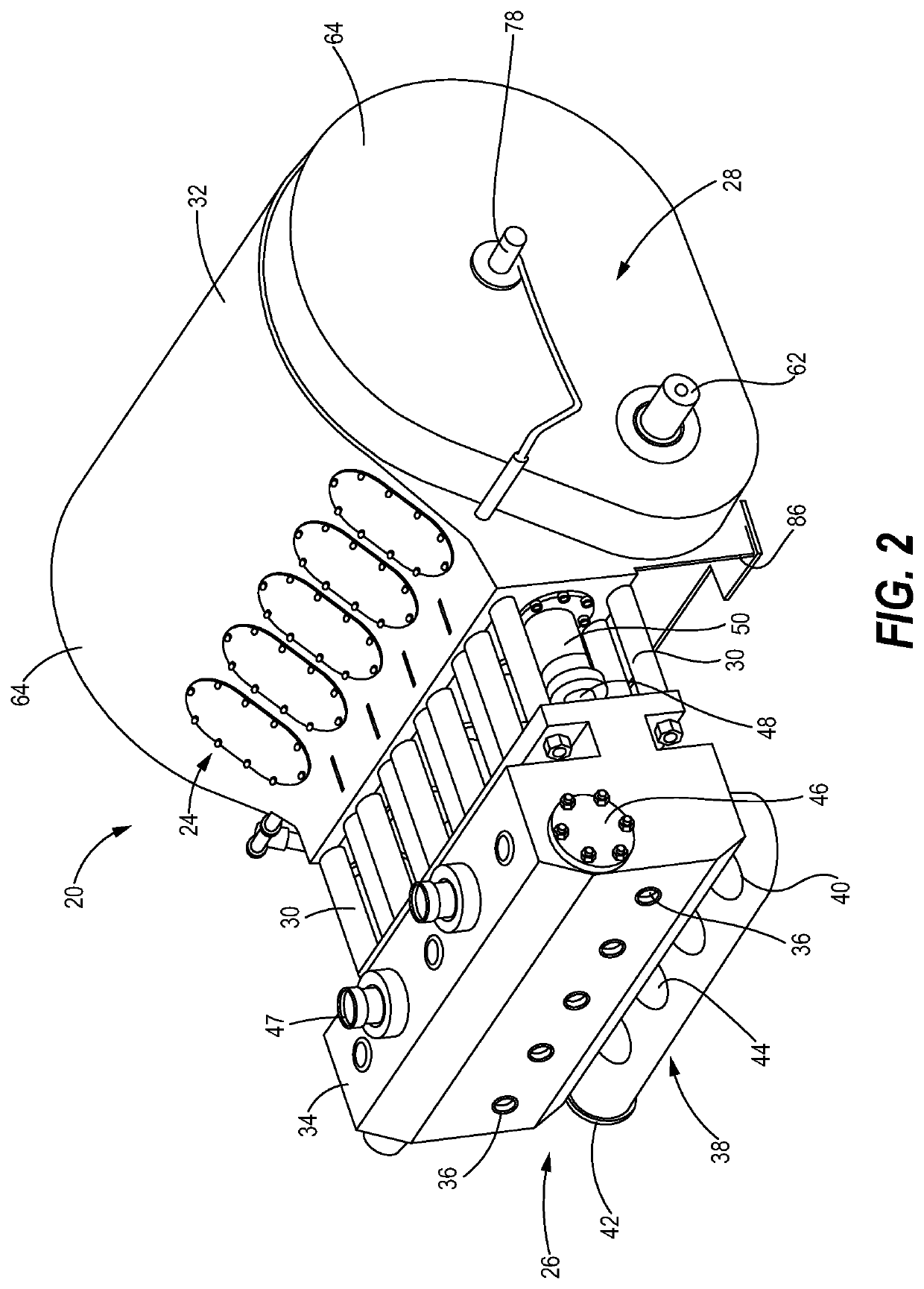

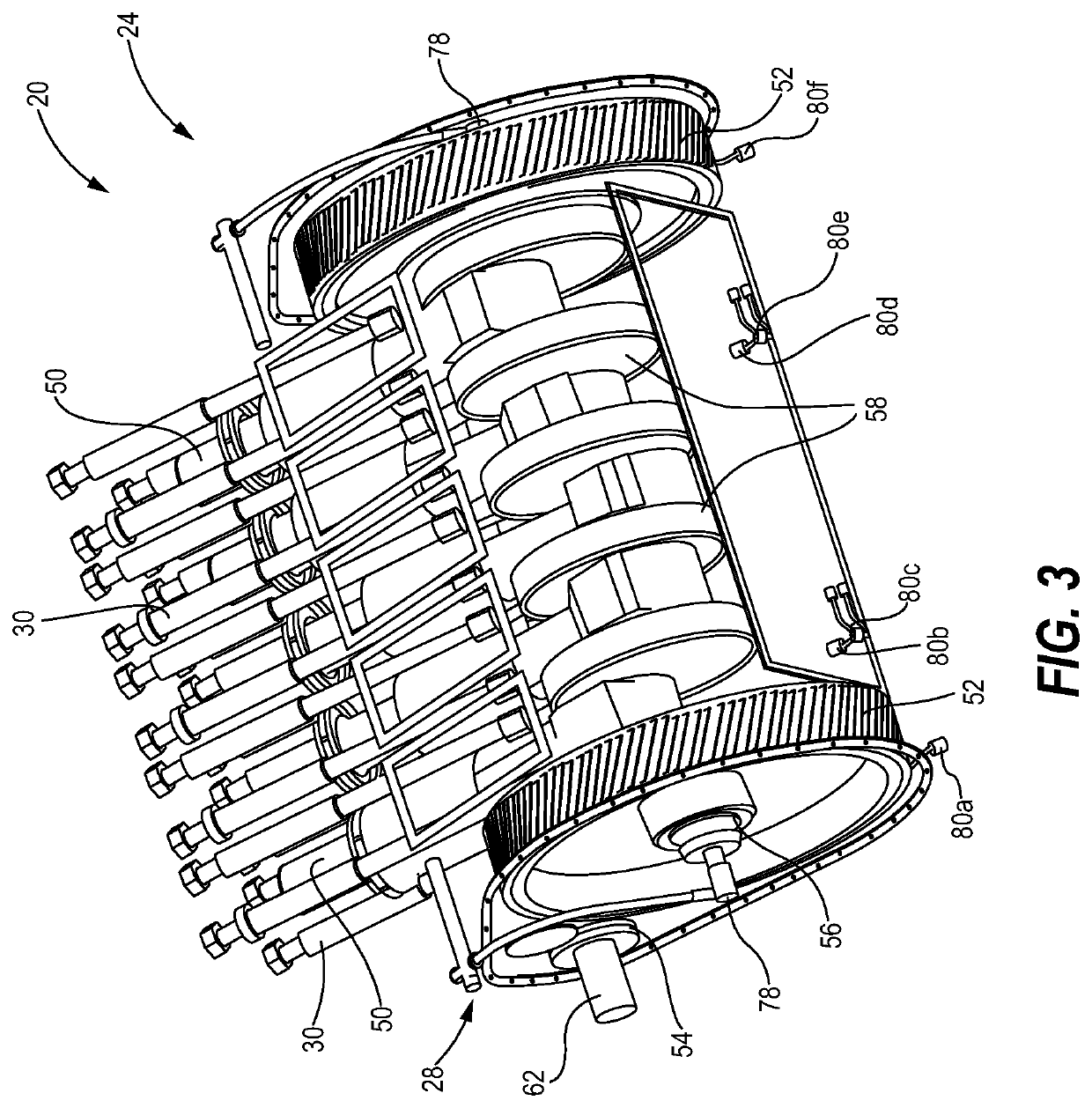

Compressor valve health monitor

ActiveUS9759213B2Improve analysisImprove notificationsExternal parameterPositive displacement pump componentsSignal-to-noise ratio (imaging)Engineering

A rotating machine valve health monitor. Aspects of the valve monitor include instrumenting each valve of a reciprocating compressor, or other rotating machine, with a sensor capable of detecting at least vibration and instrumenting the crank shaft with a sensor capable of detecting at least rotation. A controller directly monitors the operation and condition of each valve to precisely identify any individual valve exhibiting leakage issues rather than only identifying the region of the leakage. The valve monitor uses a relatively high frequency stress wave analysis technique to provide a good signal-to-noise ratio to identify impact events indicative of leakage. The valve monitor uses circular waveforms of vibration data for individual valves to identify leakage by pattern recognition or visual identification. The valve monitor provides ongoing data collection to give warning of predicted valve failure and scheduling of preventative maintenance for failing valves.

Owner:COMPUTATIONAL SYST

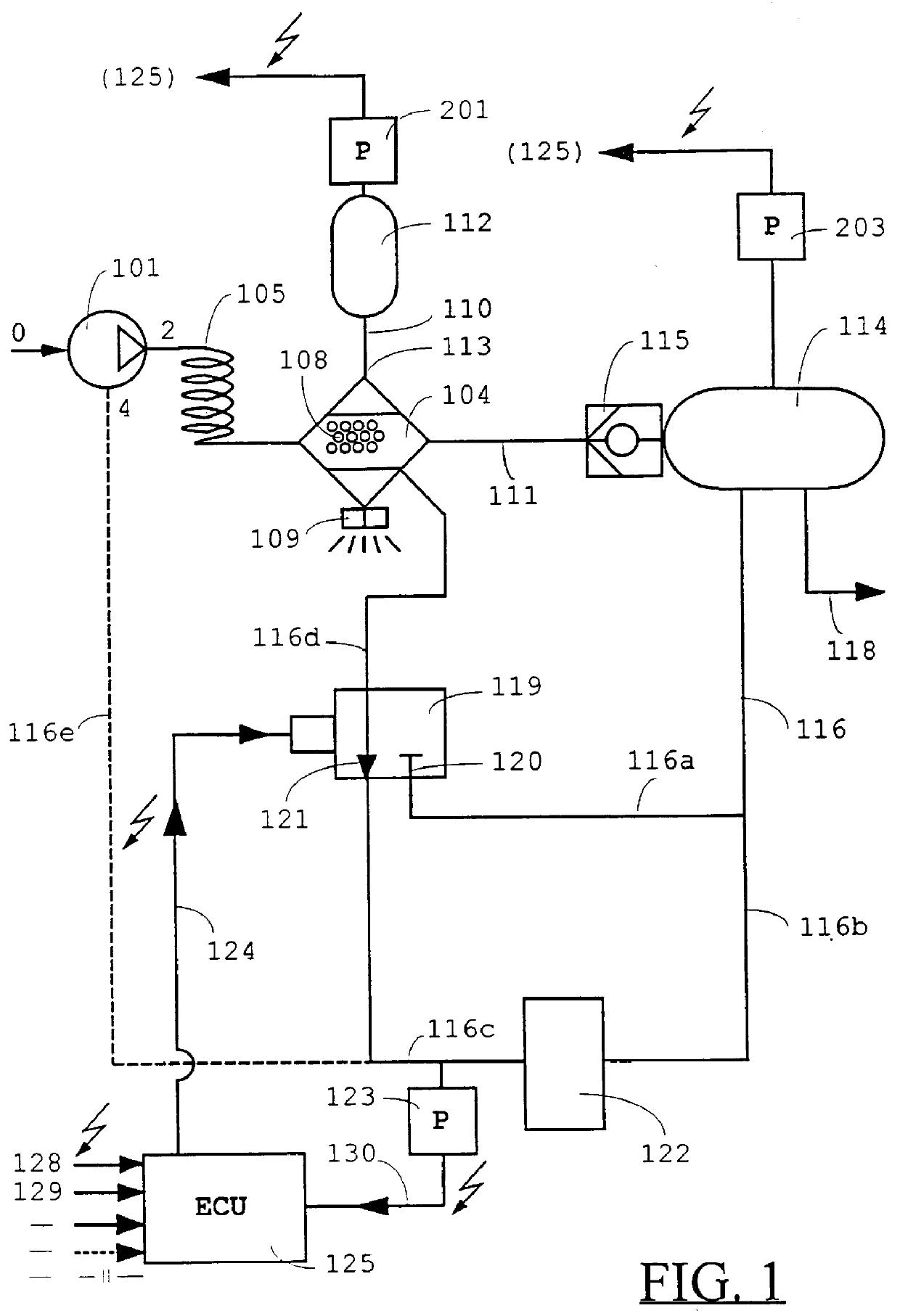

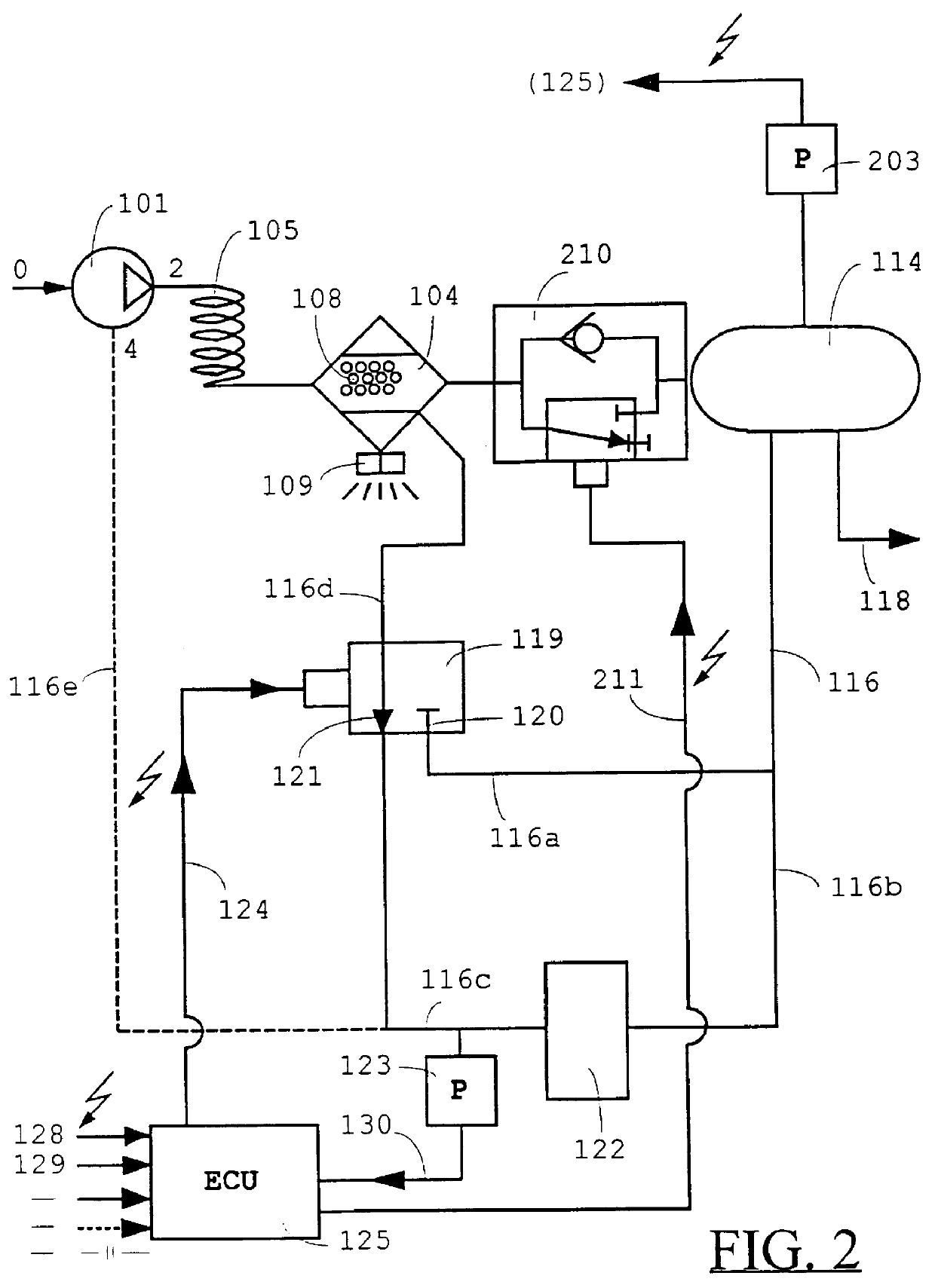

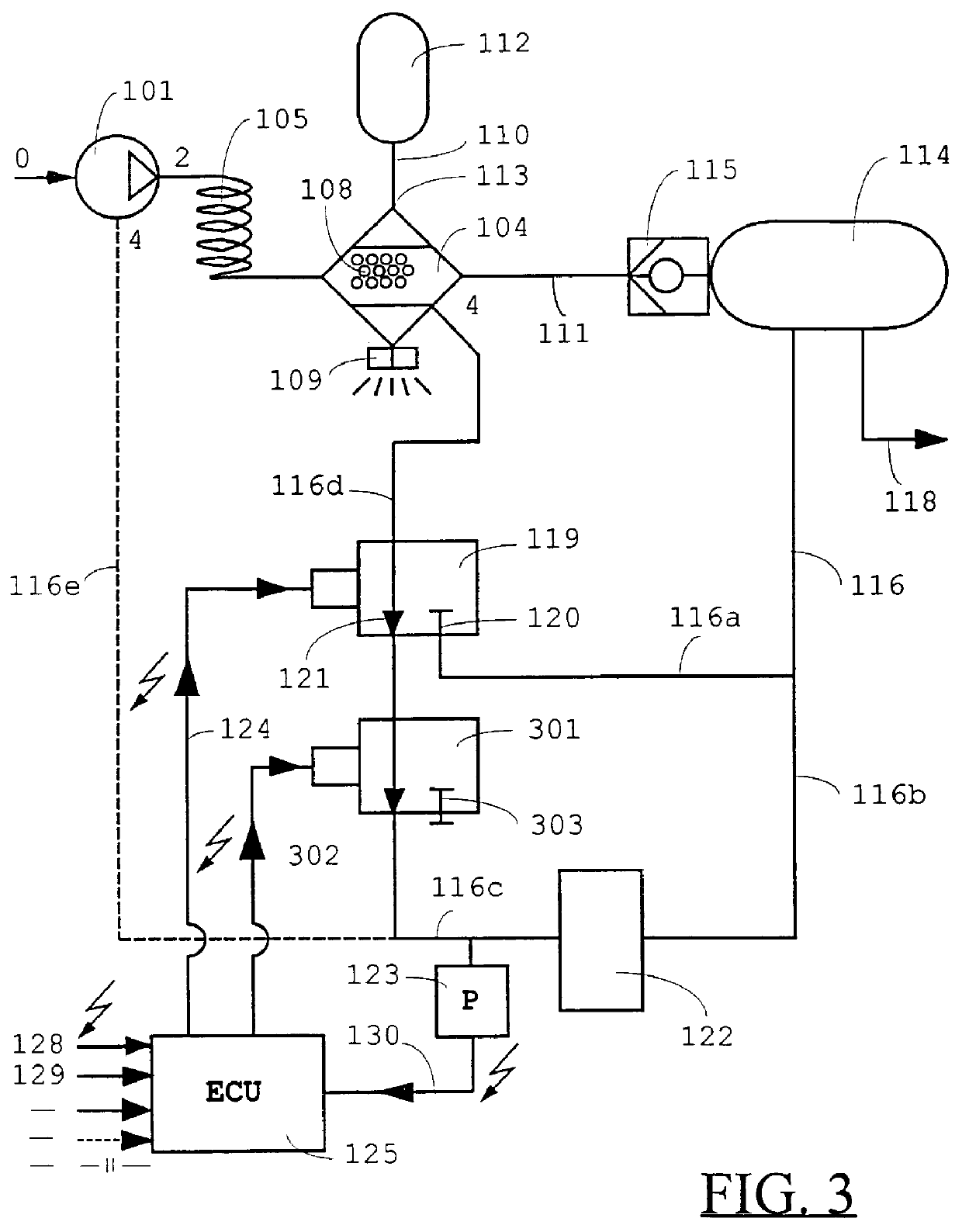

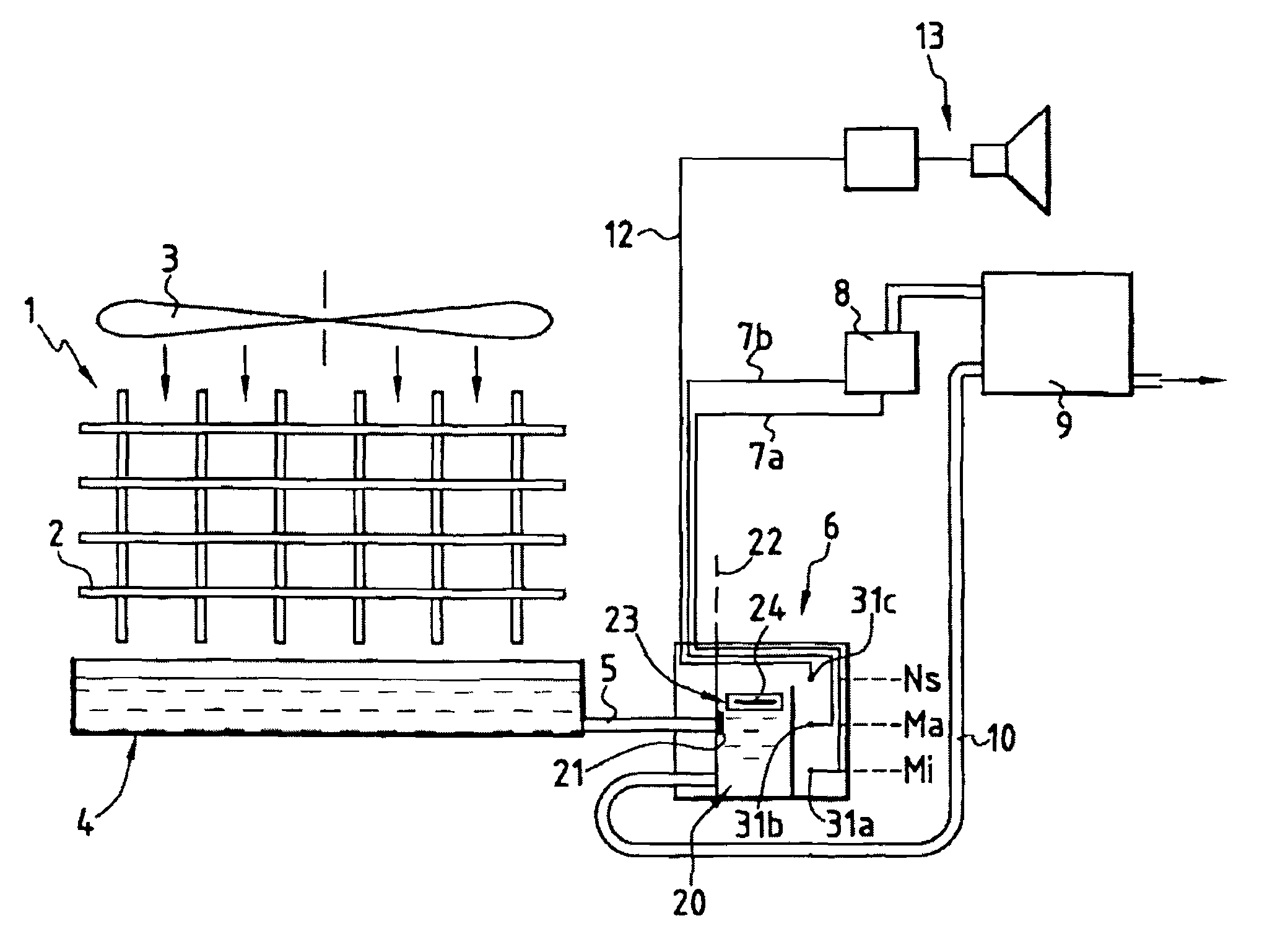

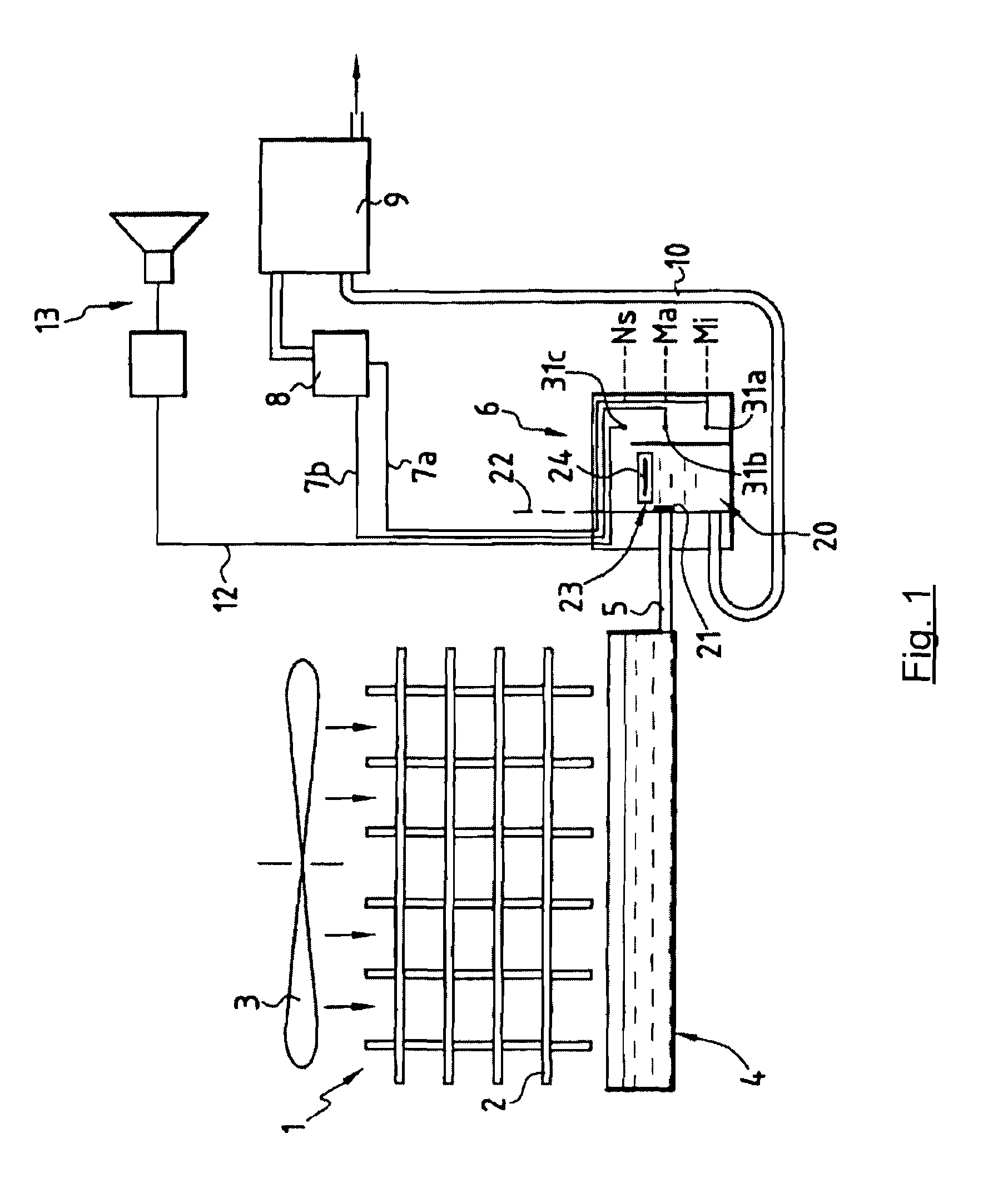

Air drying device for a pneumatic system

PCT No. PCT / SE96 / 01162 Sec. 371 Date Jun. 10, 1998 Sec. 102(e) Date Jun. 10, 1998 PCT Filed Sep. 20, 1996 PCT Pub. No. WO97 / 11274 PCT Pub. Date Mar. 27, 1997Device and method for the regeneration of a drying agent in compressed air system. The wetting degree of the drying agent is estimated and recorded by a control unit. The control unit ensures that the drying agent is dehumidified as soon as the wetting degree has reached a certain wetting degree. This certain wetting degree may be set to different levels for different operational condition.

Owner:AB VOLVO

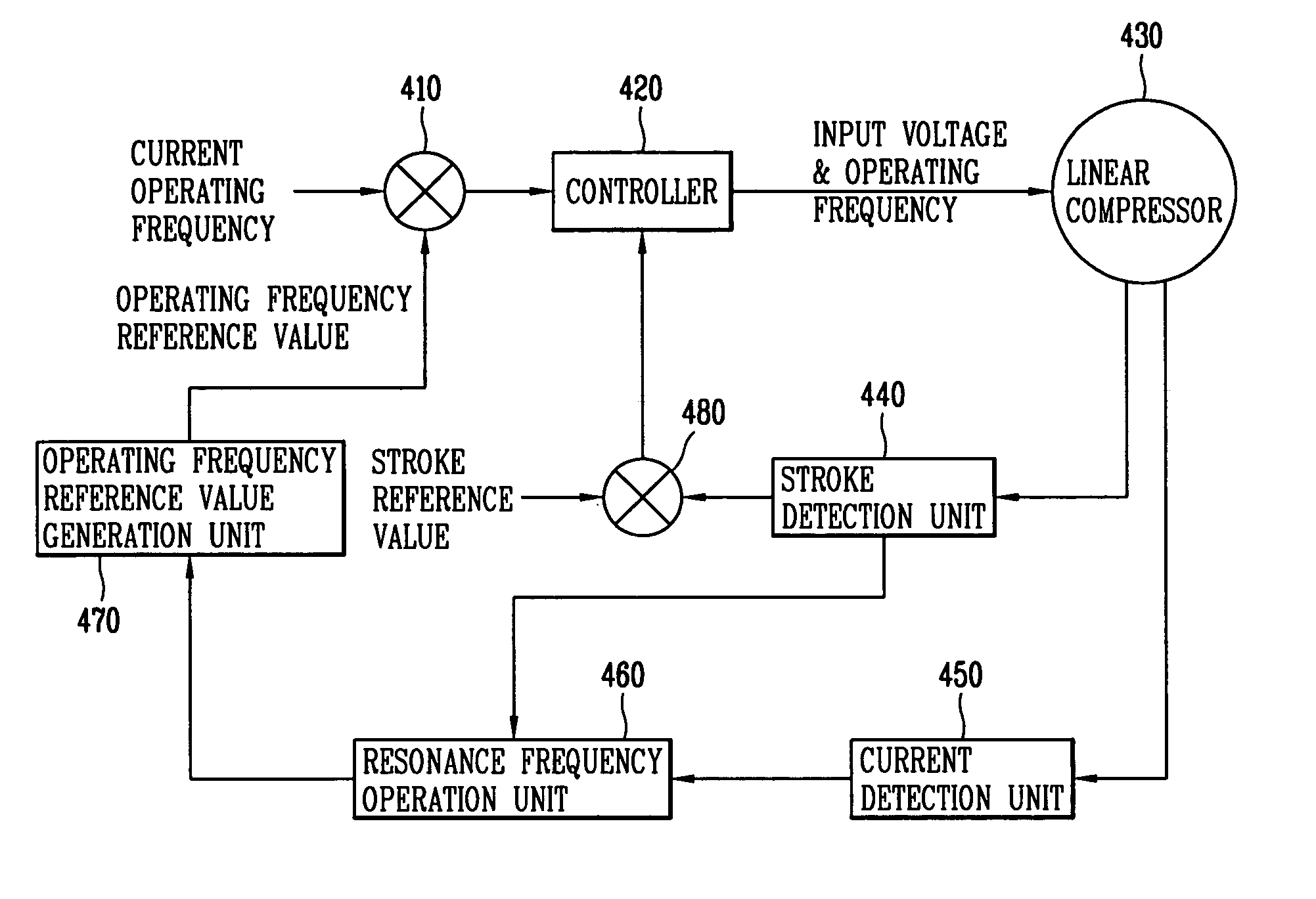

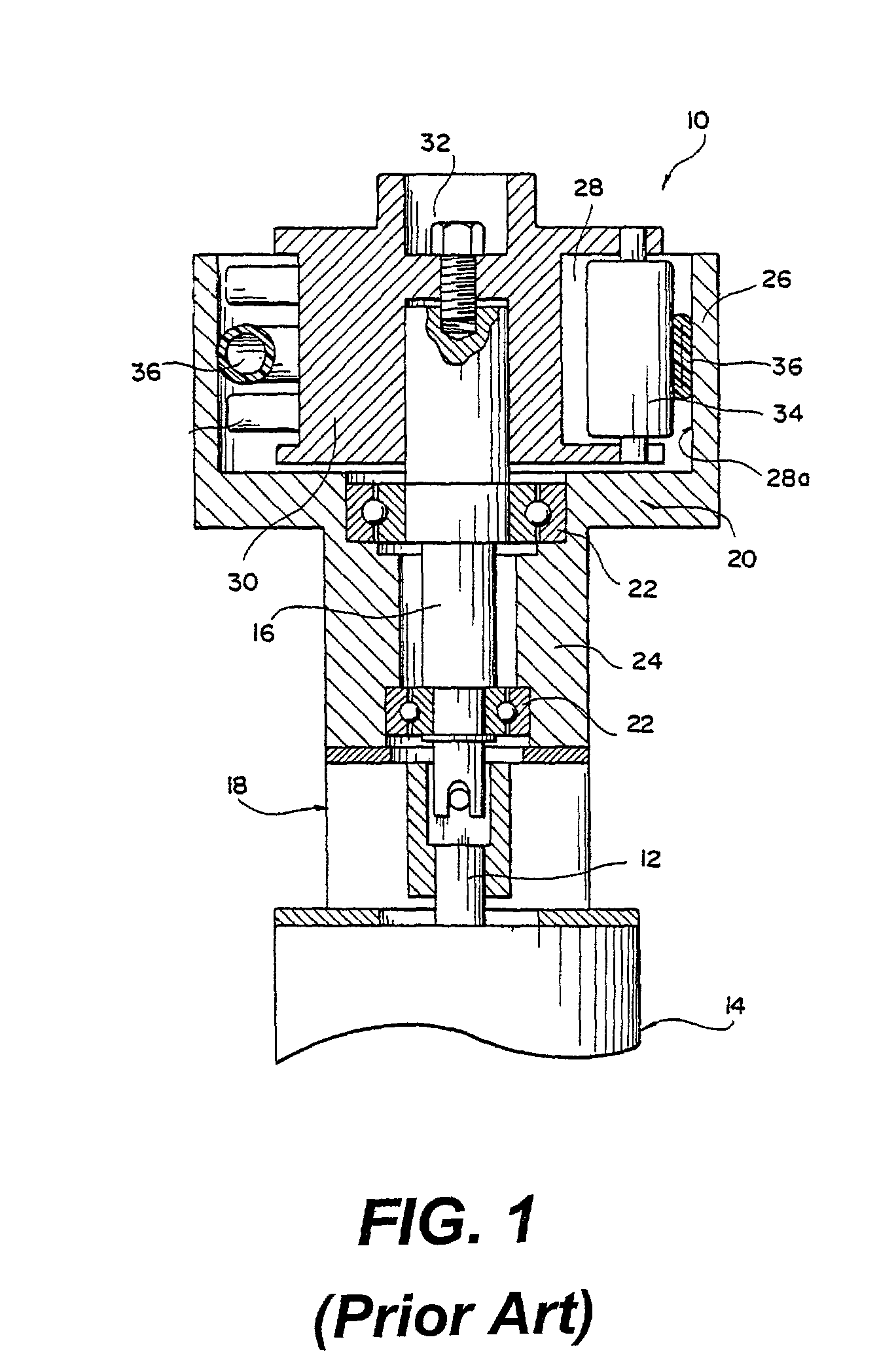

Apparatus and method for controlling operation of reciprocating compressor

InactiveUS20050158178A1Operation efficiency can be improvedCompressorExternal parameterMechanical resonanceOperating frequency

Disclosed are an apparatus and a method for controlling an operation of a reciprocating compressor which can improve operational efficiency of the reciprocating compressor. The apparatus for controlling the operation of the reciprocating compressor includes a resonance frequency operation unit for operating a mechanical resonance frequency of the reciprocating compressor, an operating frequency reference value generation unit for comparing the operated mechanical resonance frequency with a current operating frequency of the reciprocating compressor, and generating an operating frequency reference value according to the comparison result, and a controller for controlling a motor of the reciprocating compressor according to the generated operating frequency reference value.

Owner:LG ELECTRONICS INC +1

Dynamic brake with backlash control for peristaltic pump

InactiveUS20020127115A1Prevent reboundMechanical/radiation/invasive therapiesOther blood circulation devicesPeristaltic pumpBrief periods

The present invention involves a dynamic brake for use in a peristaltic (i.e., roller) pump. The dynamic brake avoids backlash, due to counter rotation. In addition, it does not preclude the option of hand operating the roller pump. This is achieved by initiating the braking operation after the roller pump set-point has been set to zero and only after the roller pump has decelerated below a predefined speed (e.g., 20 rpm). In addition, the braking operation is activated for only a very brief period of time (i.e., a period of time required for the pressure in the roller pump fluid conduit to subside).

Owner:TERUMO CARDIOVASCULAR SYST CORP

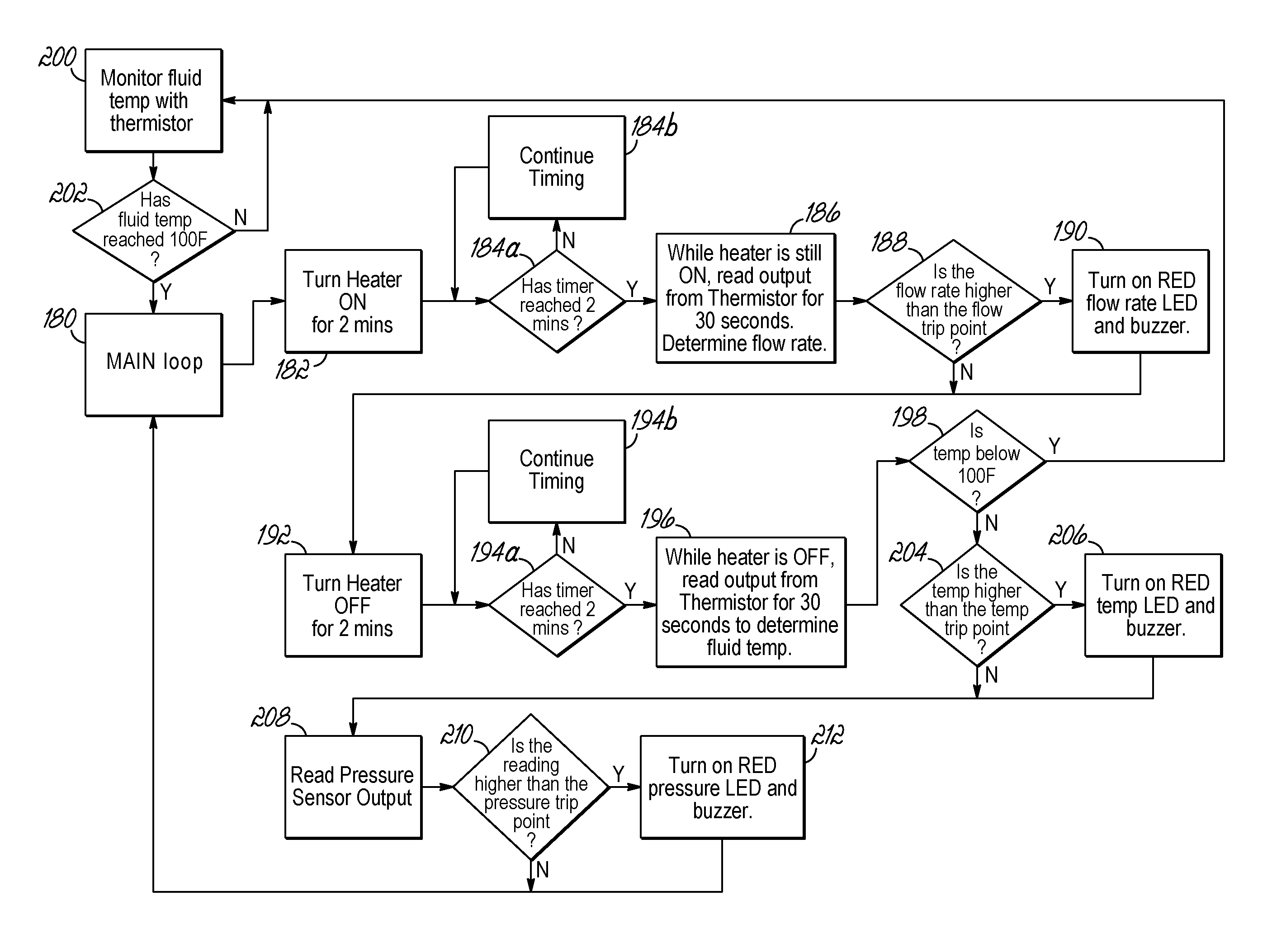

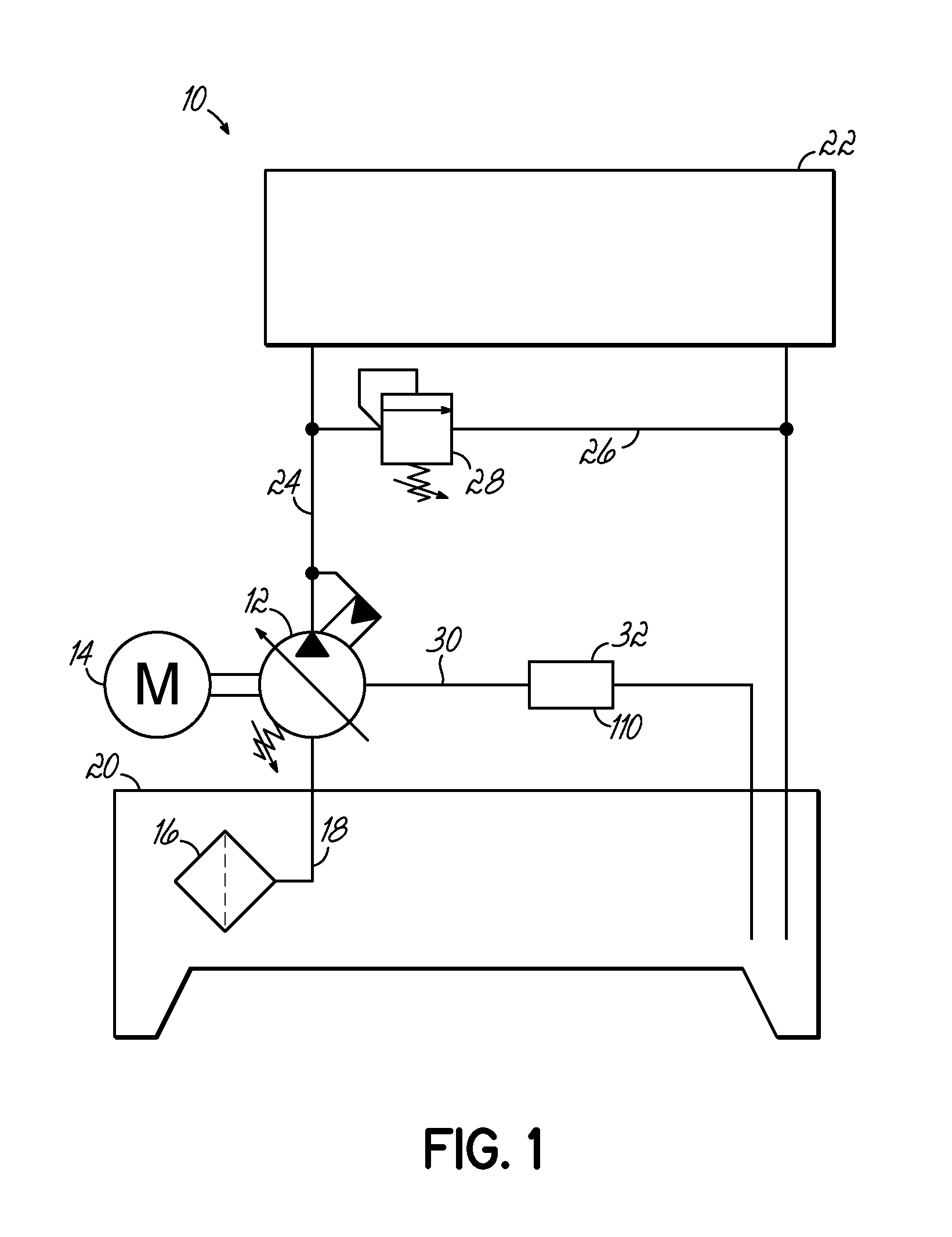

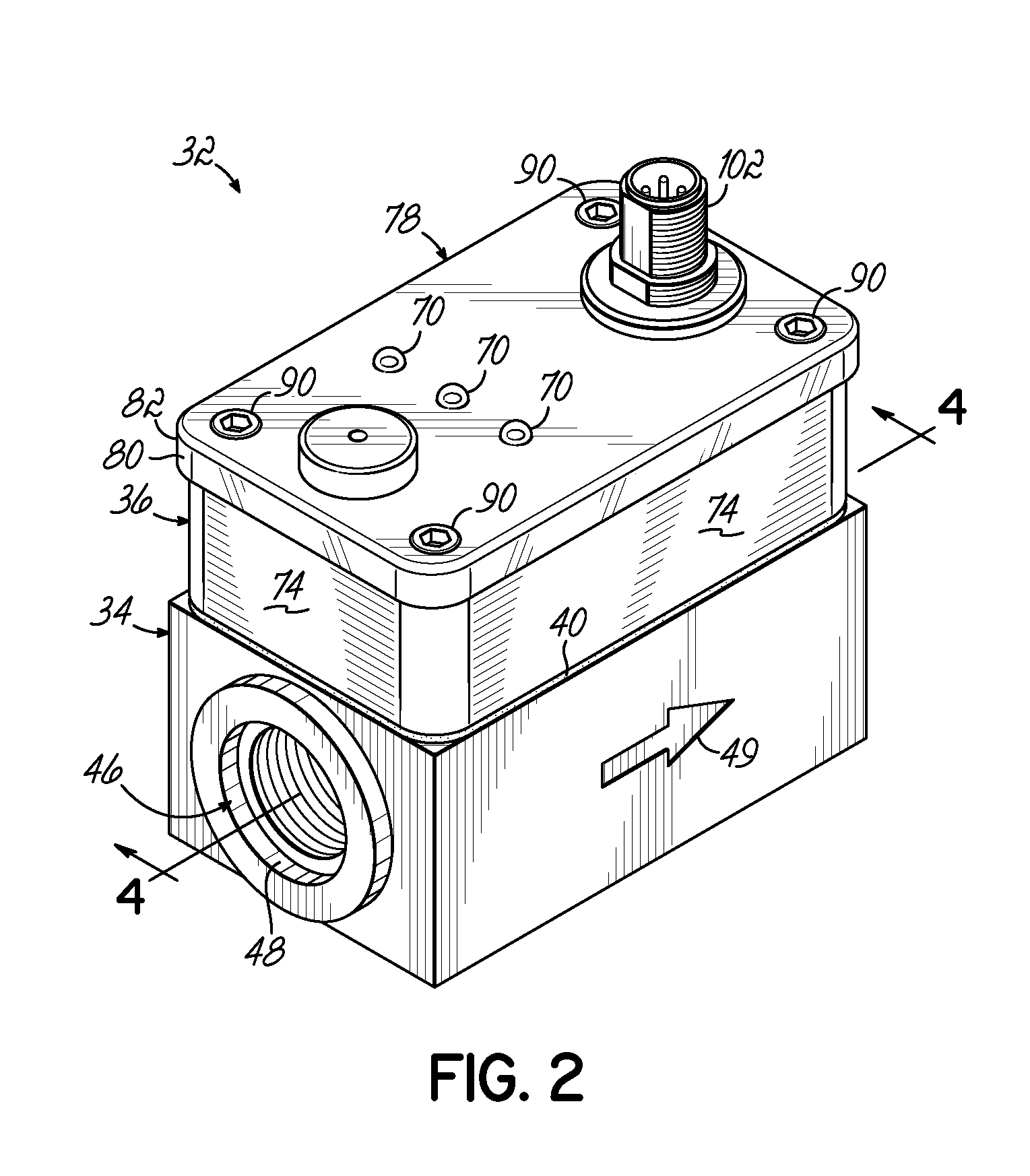

Pump monitoring device

A pump monitoring device is configured to be connected to a case drain of a pump. The device includes a manifold having an inlet for connection to the case drain. A flow rate sensor generates a signal indicative of a flow rate of fluid in a fluid path. The flow rate sensor includes a temperature sensor, a heater, and a sensor barrel. The heater heats the sensor barrel while in fluid communication with the fluid. A pressure sensor generates a signal indicative of a pressure of the fluid. There is at least one fault indicator operatively coupled to at least one of the flow rate sensor, the temperature sensor, and the pressure sensor. The fault indicator provides a human perceptible indication that at least one of a sensed flow rate, a sensed temperature, or a sensed pressure of the fluid flowing in the fluid path exceeds a predetermined threshold value.

Owner:IOT DIAGNOSTICS LLC

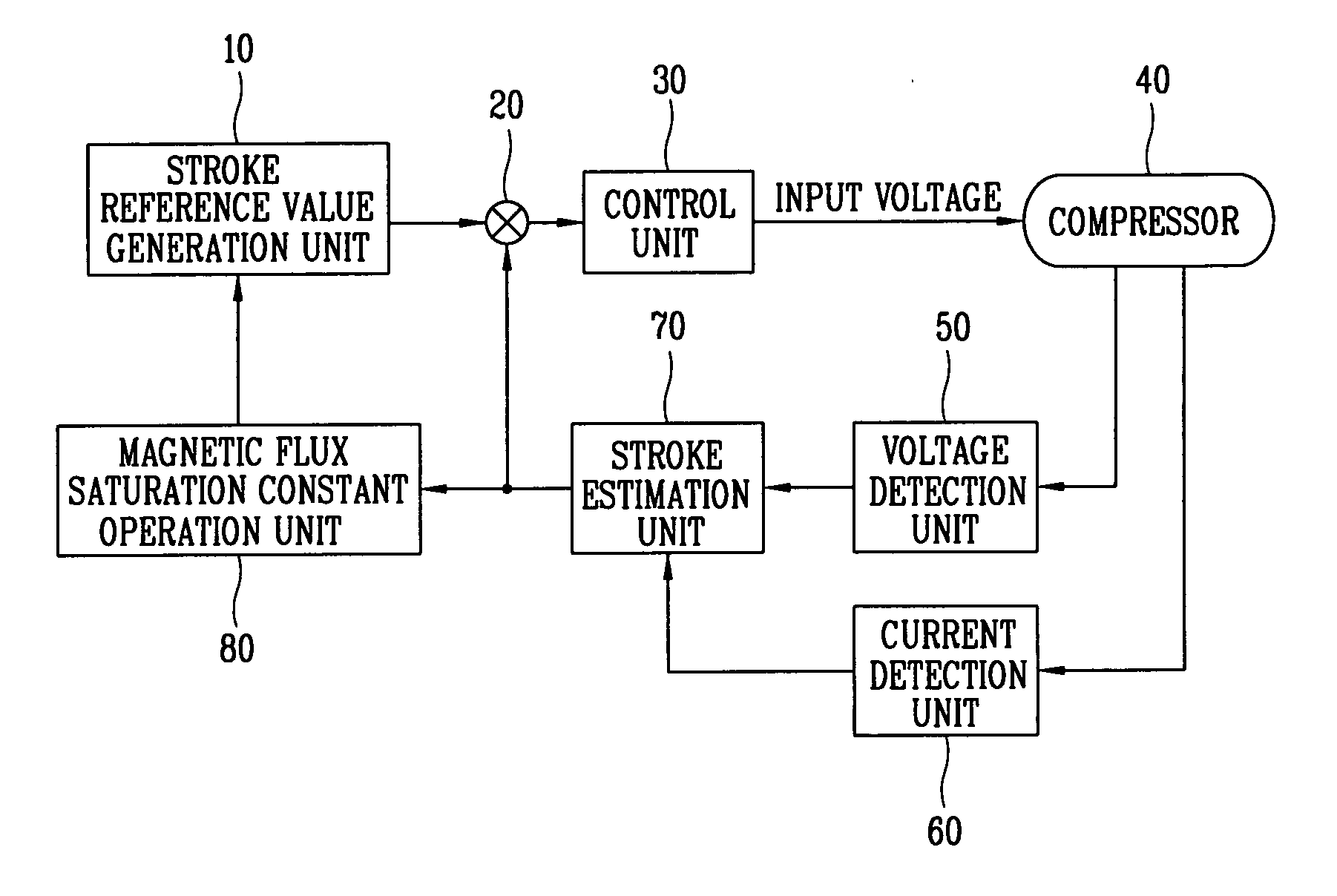

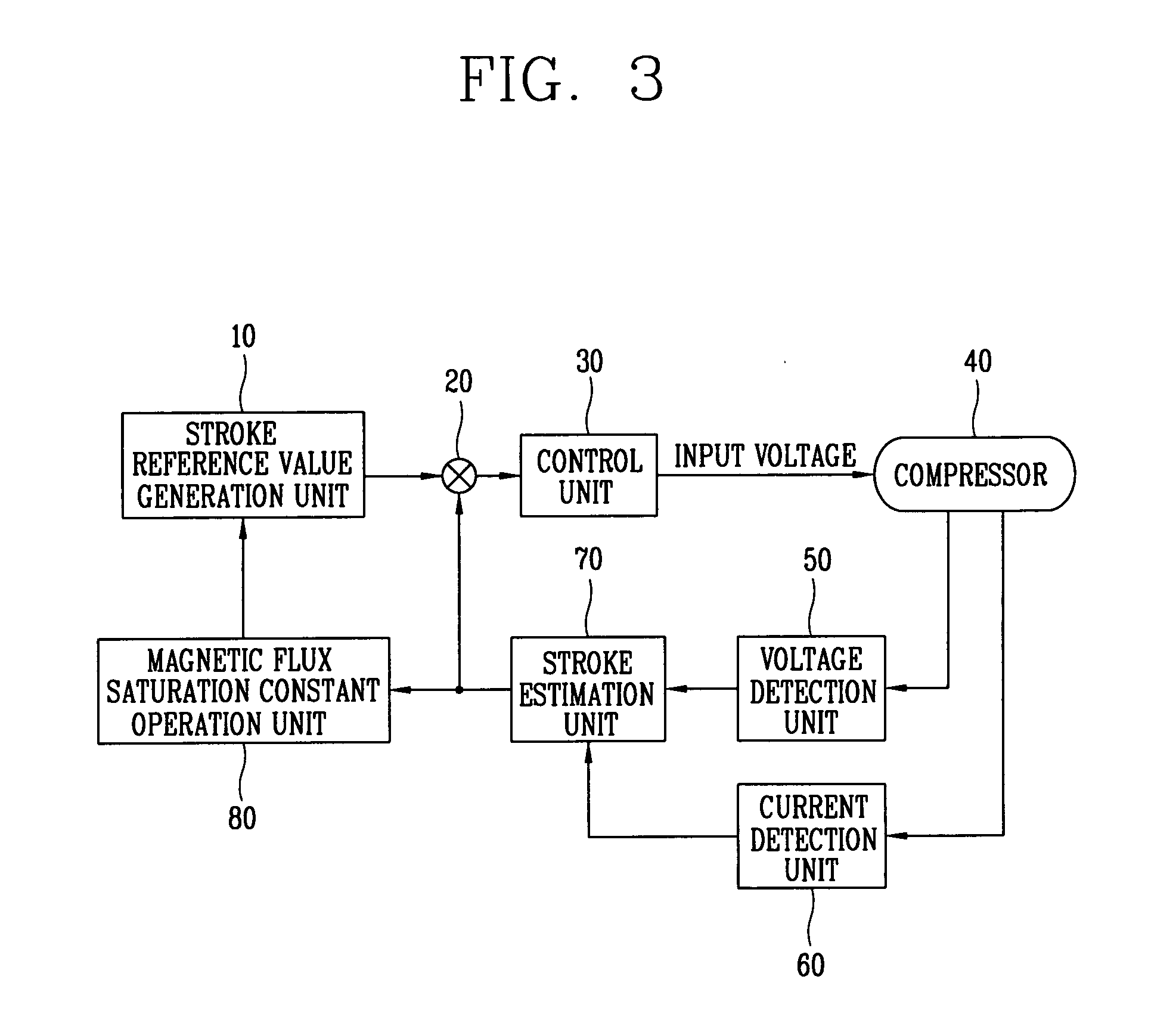

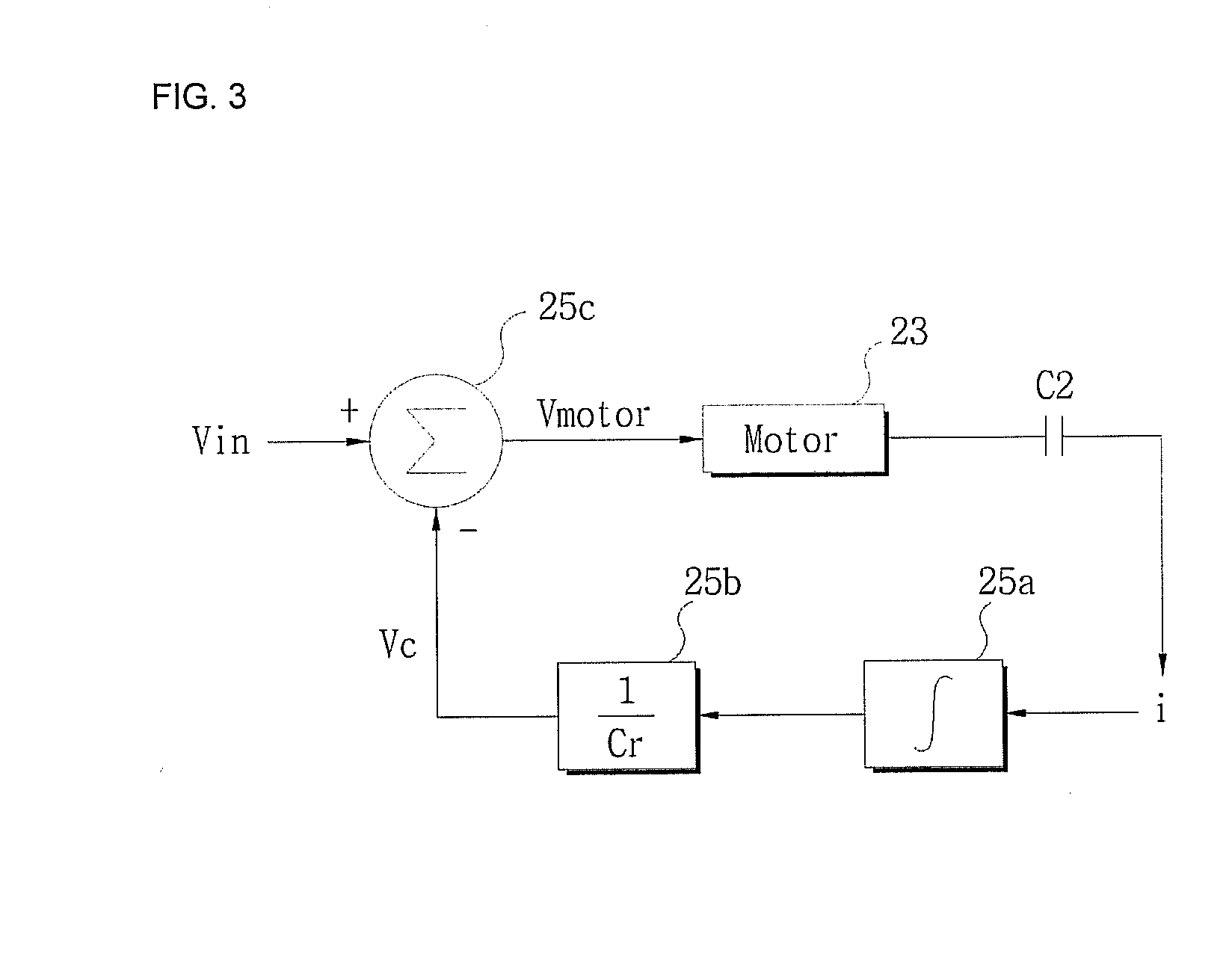

Apparatus for controlling operation of reciprocating compressor, and method therefor

ActiveUS20050141998A1Reduce errorsAvoid oversaturationDC motor speed/torque controlTemperatue controlMagnetic fluxVoltage

The present invention discloses an apparatus for controlling an operation of a reciprocating compressor and a method therefor which can reduce errors in an operation of a stroke estimated value of the reciprocating compressor, by previously preventing over-saturation of a magnetic flux density generated in a coil of a motor. The apparatus for controlling the operation of the reciprocating compressor includes a magnetic flux saturation constant operation unit for operating a magnetic flux saturation constant of a motor of the reciprocating compressor on the basis of a stroke estimated value of the reciprocating compressor, a stroke reference value generation unit for generating an increased or decreased stroke reference value by increasing or decreasing a predetermined stroke reference value on the basis of the magnetic flux saturation constant, and a control unit for controlling a voltage applied to the motor of the reciprocating compressor on the basis of the generated stroke reference value.

Owner:LG ELECTRONICS INC

Device for controlling a condensate lift pump, and corresponding capacitive detector and system

ActiveUS20100064705A1Simple and effective and inexpensive to implementLow implementation costExternal parameterResistance/reactance/impedenceCapacitanceEngineering

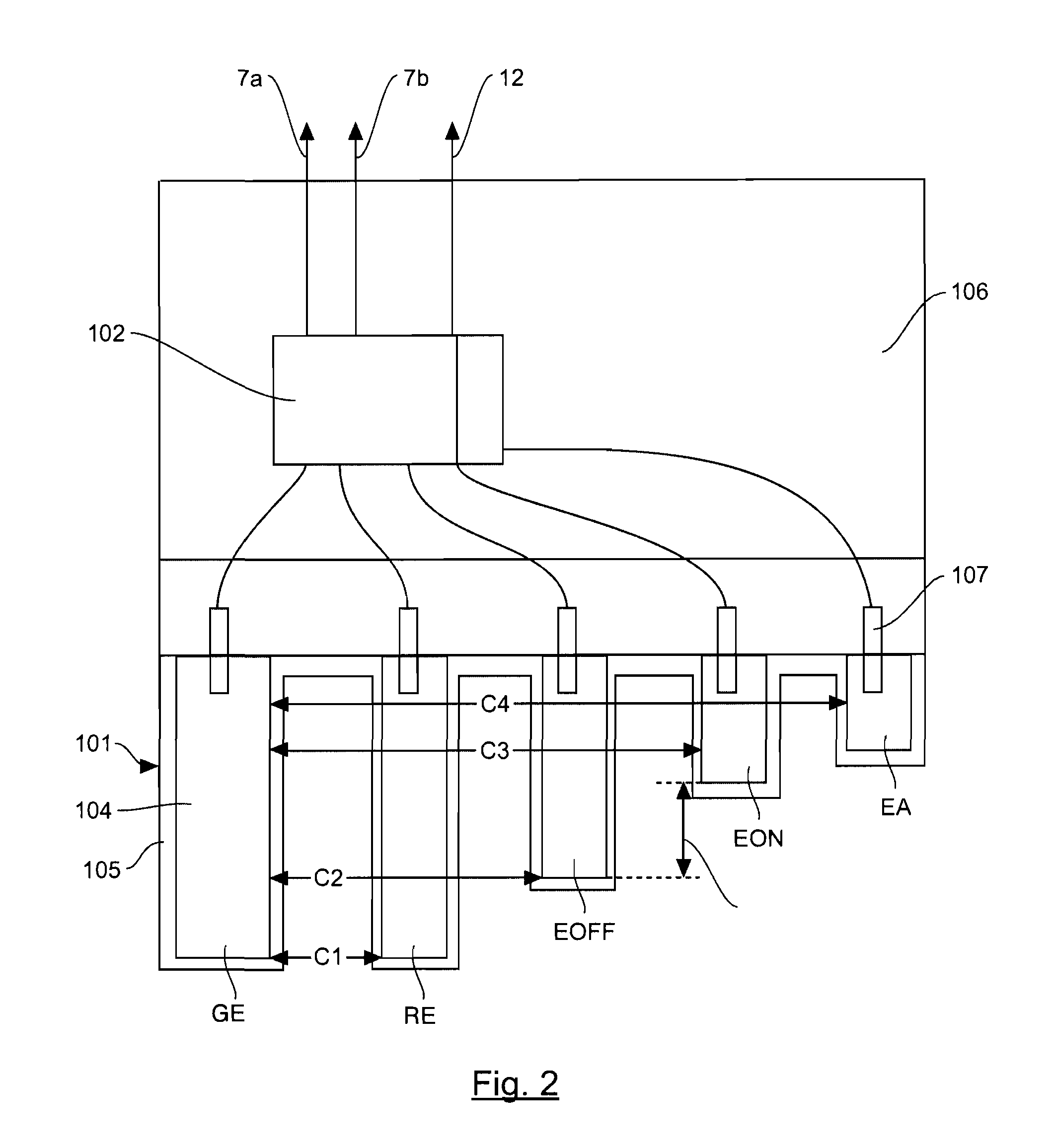

The invention relates to a device for controlling a condensate lift pump (9), comprising a means for detecting at least two condensate levels in a container (20), and a means for activating and for stopping said pump (9) according to said levels, in which said detection means comprises a capacitive detector (101) comprising at least three electrodes (GE, RE, EOFF, EON, EA):a ground electrode (GE);a first level detection electrode (EOFF); anda second level detection electrode (EON),and a processing means (102) comprising a means for measuring the capacitance (C2, C3) between the electrodes.According to the invention, the lengths of said first level detection electrode (EOFF) and second level detection electrode (EON) are defined so as to come into contact with said condensates, when the condensates respectively reach said first level and said second level in said container (20); these electrodes are produced on distinct supports not having a submergible physical continuity between them.

Owner:SAUERMANN IND

Billing method for pump usage

InactiveUS20080005000A1Mechanical/radiation/invasive therapiesMedical devicesPayment scheduleUnit of time

Disclosed are methods of leasing or billing for the usage of a portable suction pump adapted for use in a suction-assisted would treatment system. The pump has means for recording time units corresponding to periods of time when the pump is operating and for providing reports of usage time. The pump further has means for detecting that the wound treatment system is operating normally so as to be compliant with standards for suction wound treatment, and for recording and reporting time of normal operation or compliant usage. The methods include leasing the pump at a payment schedule that is based upon the amount of actual usage time or the amount of compliant usage time. The lease payment may include an amount of pre-paid time units such that unused time units can be credited to a new or renewed lease for a replacement pump. The billing methods can also be based in whole or in part on a planned maintenance schedule for the pump.

Owner:BOEHRINGER TECH

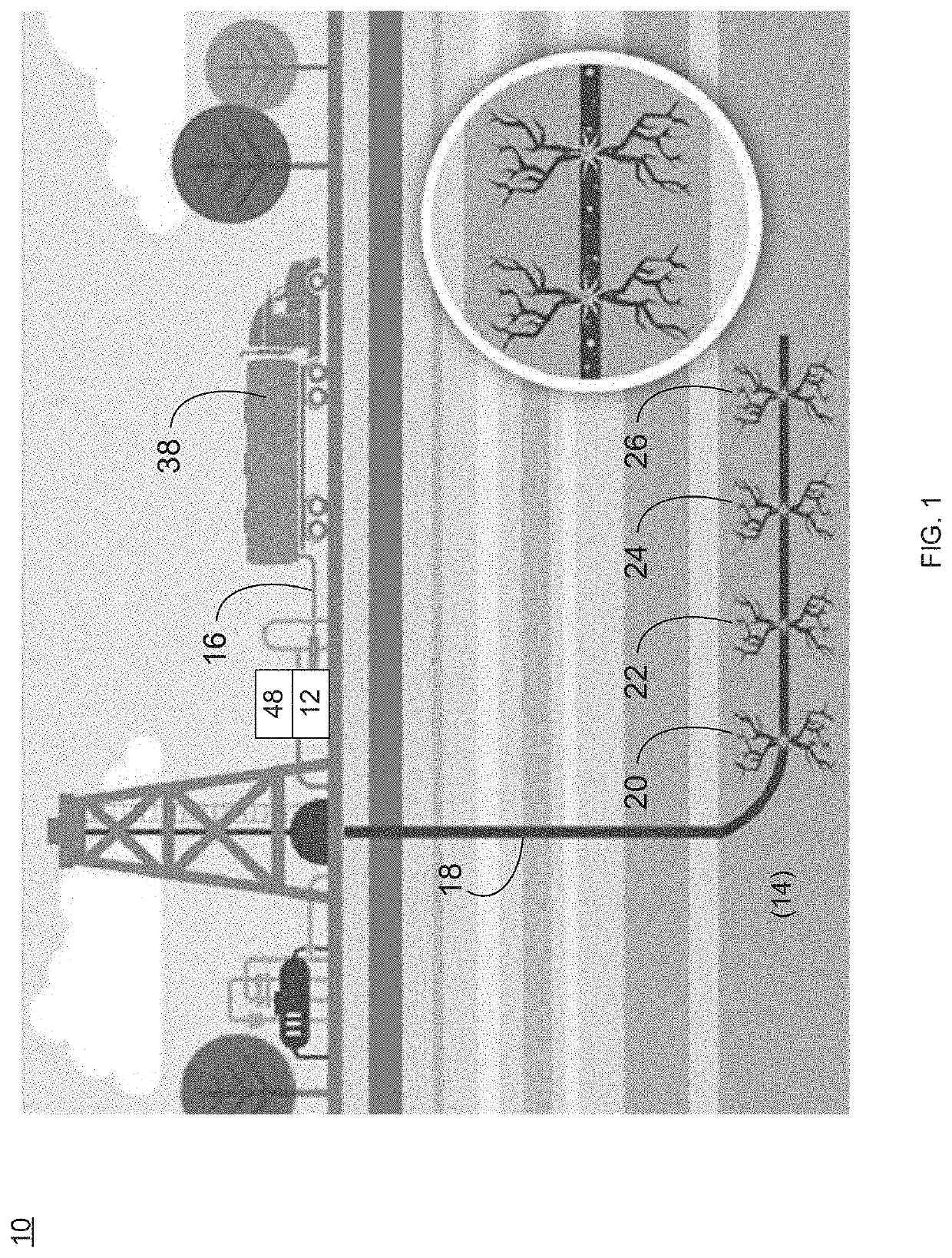

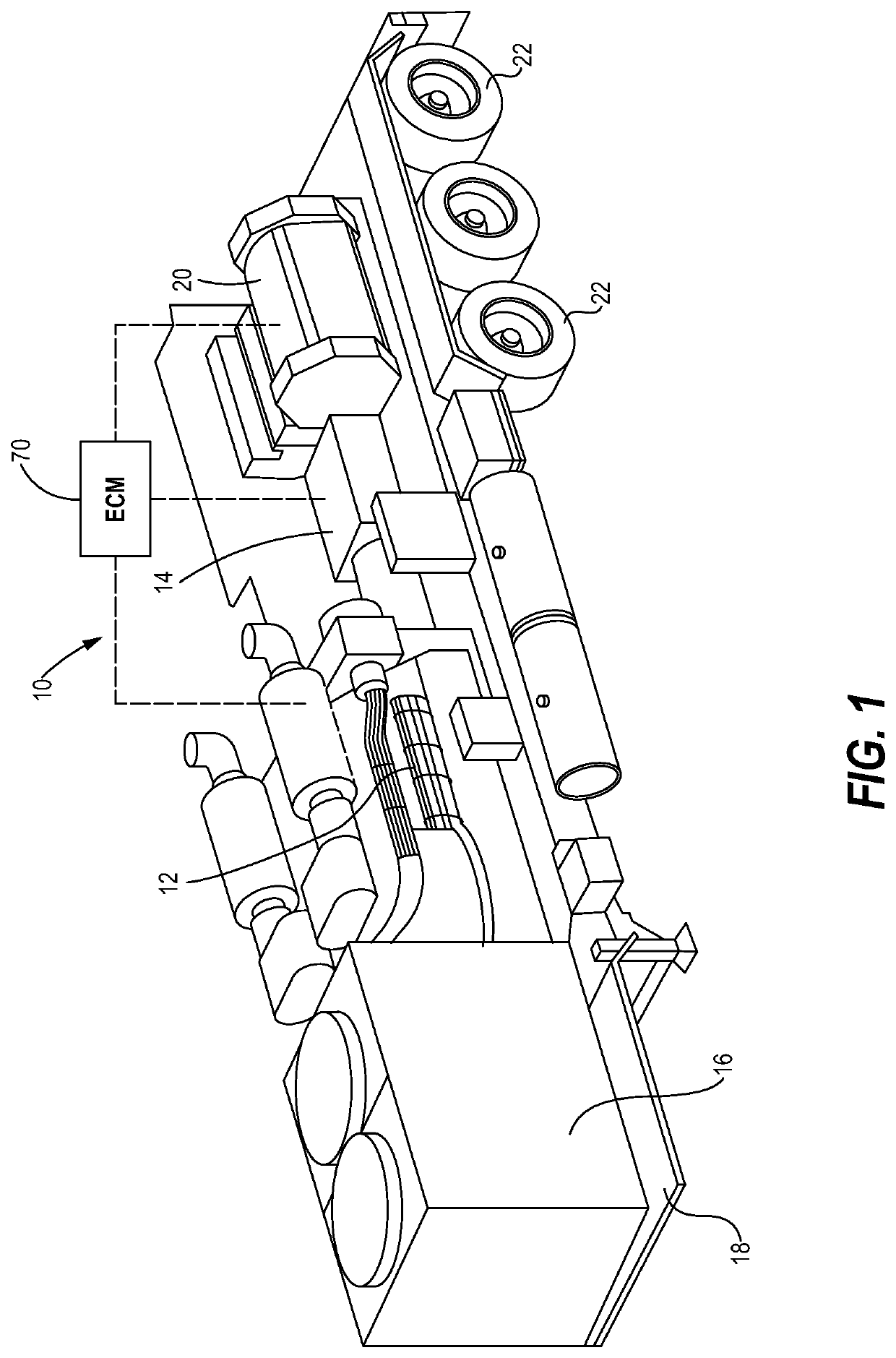

Hydraulic fracturing pump health monitor

A hydraulic fracturing machine includes a pump failure detection system. The hydraulic fracturing machine includes a hydraulic fracturing pump with a power end and a fluid end. The power end includes a plurality of roller bearings, and the fluid end includes a flow of fluid. A particle sensor coupled to the power end is configured to transmit particle information regarding a quantity of particles in the fluid. A temperature sensor, also coupled to the power end, is configured to transmit temperature information regarding a temperature of the fluid. A vibration sensor coupled to the power end is configured to transmit vibration information regarding a vibration of each of the plurality of roller bearings. An electronic control module analyzes the particle information, the temperature information and the vibration information, and calculates a failure warning level based on the analysis.

Owner:CATERPILLAR INC

Actuator system comprising detector means

The invention provides an actuator system comprising an actuator member having first and second positions. The system further comprises actuating means for moving the actuator member between the first and second positions and detection means for detecting the first respectively the second position and supplying time signals indicative thereof. A controller determines on the basis of supplied time signals the time lapsed when the actuator member is moved between the first and second positions in a given direction, the controller comprising information representing at least one defined time range, each time range being associated with movement of the actuator member in a given direction between the first and second positions and a given actuation force, the controller being adapted to compare the determined time lapsed with the defined time range(s) and perform an action corresponding to the time range associated with the determined time lapsed.

Owner:NOVO NORDISK AS

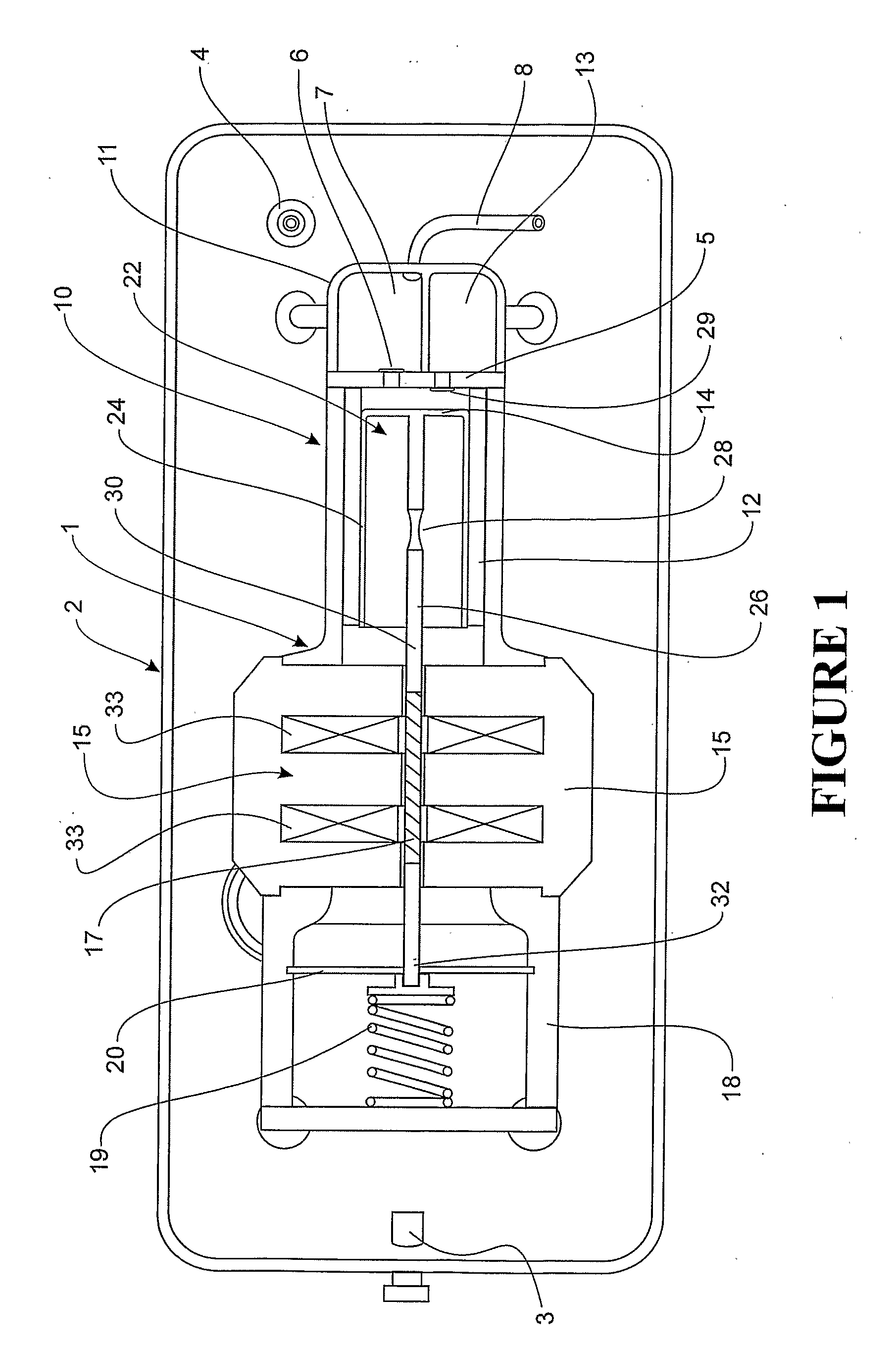

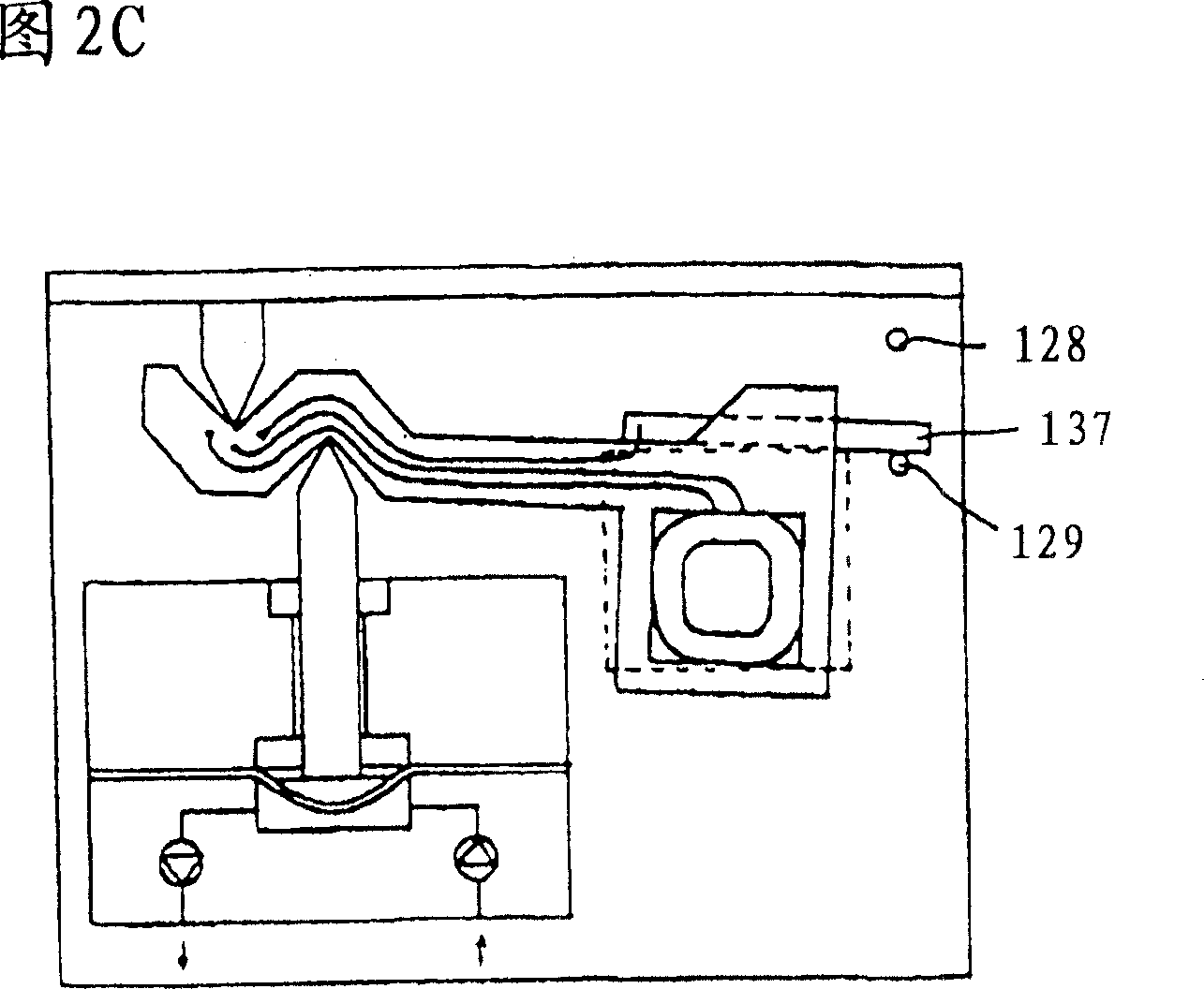

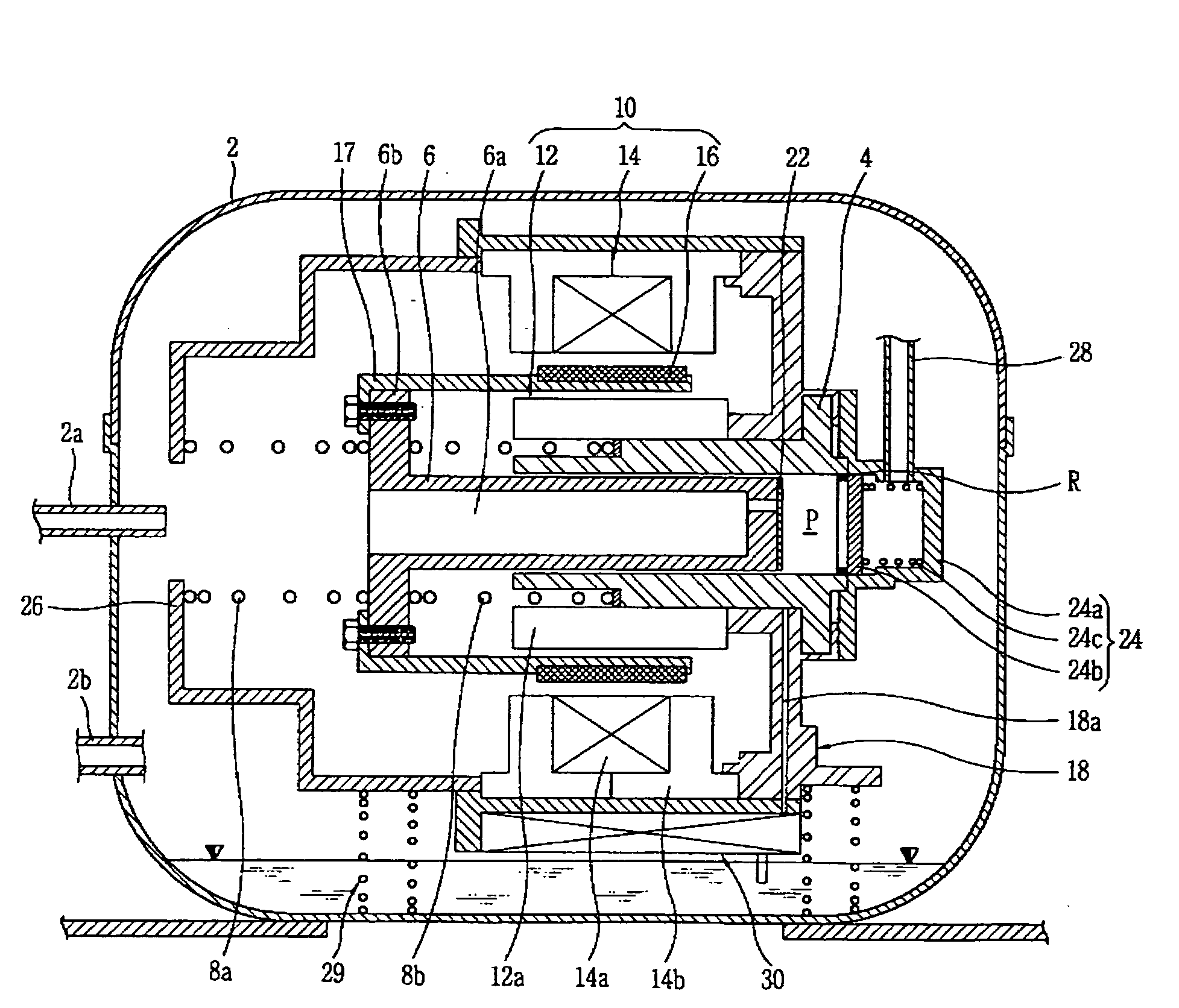

Linear compressor

InactiveUS20110318193A1External parameterPositive displacement pump componentsReciprocating motionLinear compressor

The present invention discloses a linear compressor which makes it possible to adjust a variable rate of a cooling capacity. The linear compressor includes a fixed member having a compression space therein, a movable member linearly reciprocated in the fixed member to compress a refrigerant sucked into the compression space, one or more springs provided to elastically support the movable member in the motion direction of the movable member, a motor unit including a motor connected to the movable member to linearly reciprocate the movable member in the axial direction and a capacitor connected in series to the motor, and a motor control unit controlling an AC voltage applied to the motor to adjust a variable rate of a cooling capacity by the reciprocation of the movable member.

Owner:LG ELECTRONICS INC

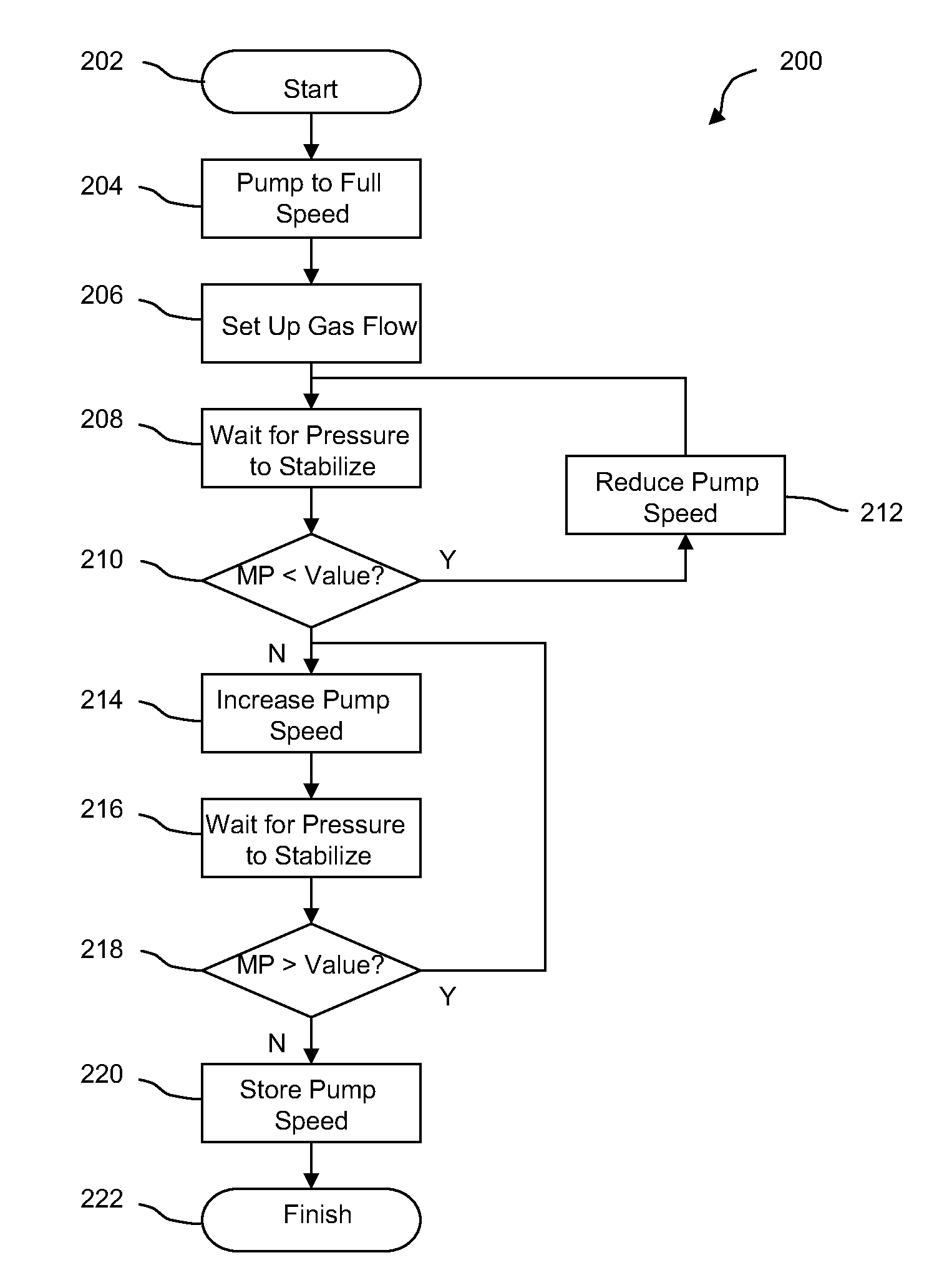

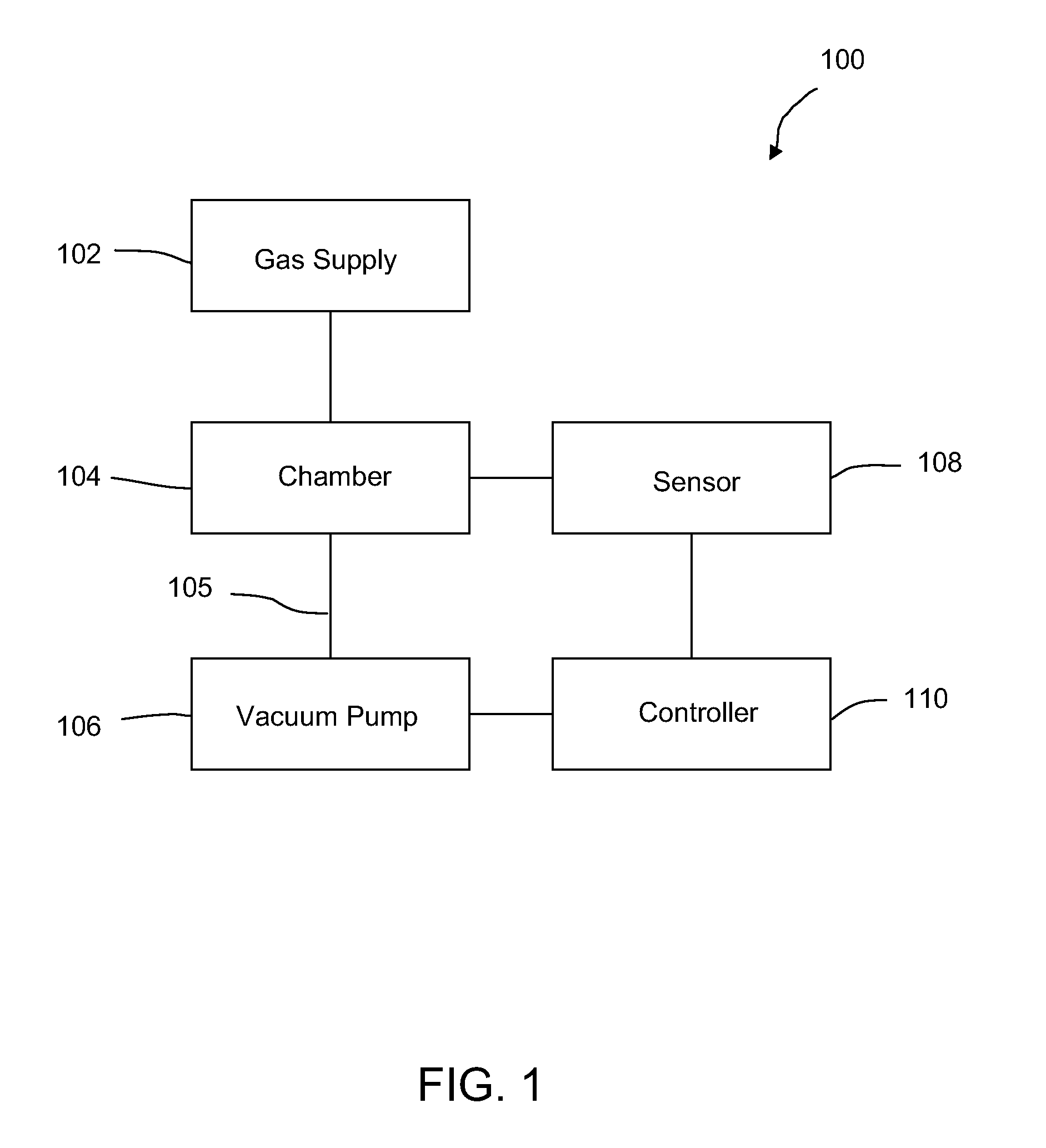

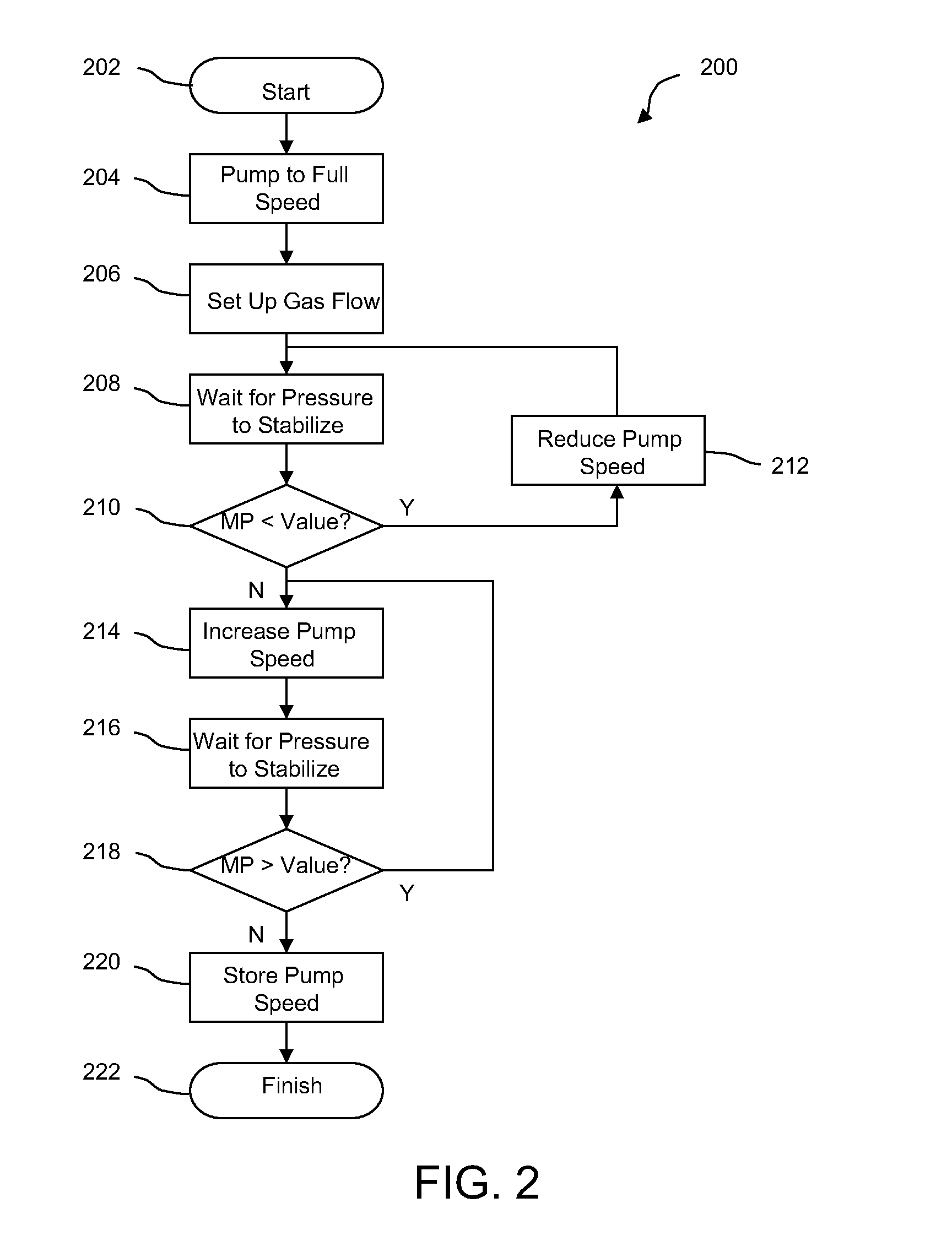

Apparatus and method for tuning pump speed

ActiveUS20110200450A1Consumes less energyEliminate spaceExternal parameterWorking fluid for enginesEngineeringVacuum pump

An apparatus for tuning pump speed at an optimal or desired speed using an automated method is disclosed. The apparatus includes a vacuum pump connected to a chamber for evacuating gas from the chamber. A sensor measures one or more characteristics, such as pressure, of the gas in the chamber. The measured characteristic is compared to a predetermined value. The speed of vacuum pump is adjusted based on the comparison until it falls in a desired range.

Owner:EDWARDS LTD

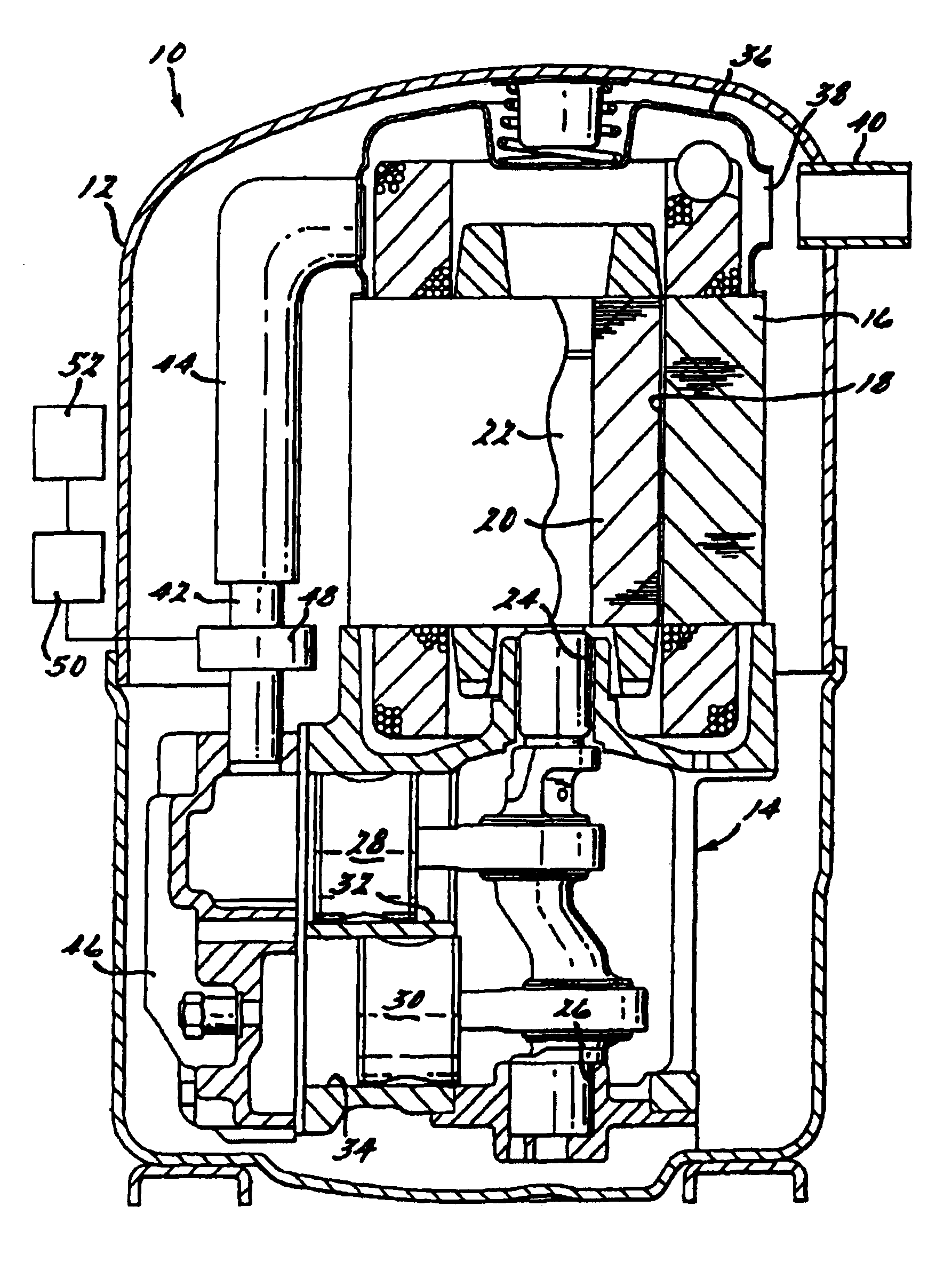

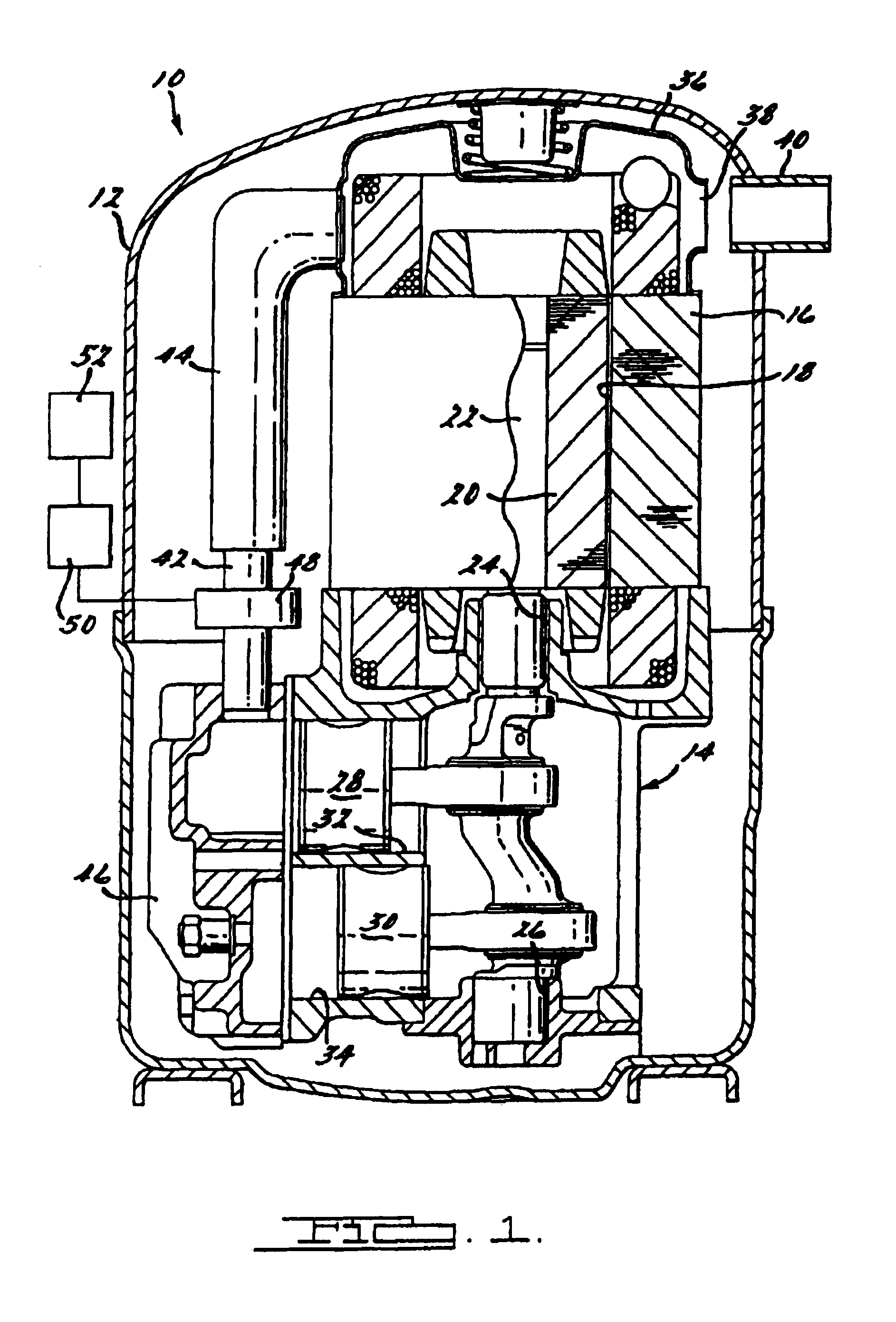

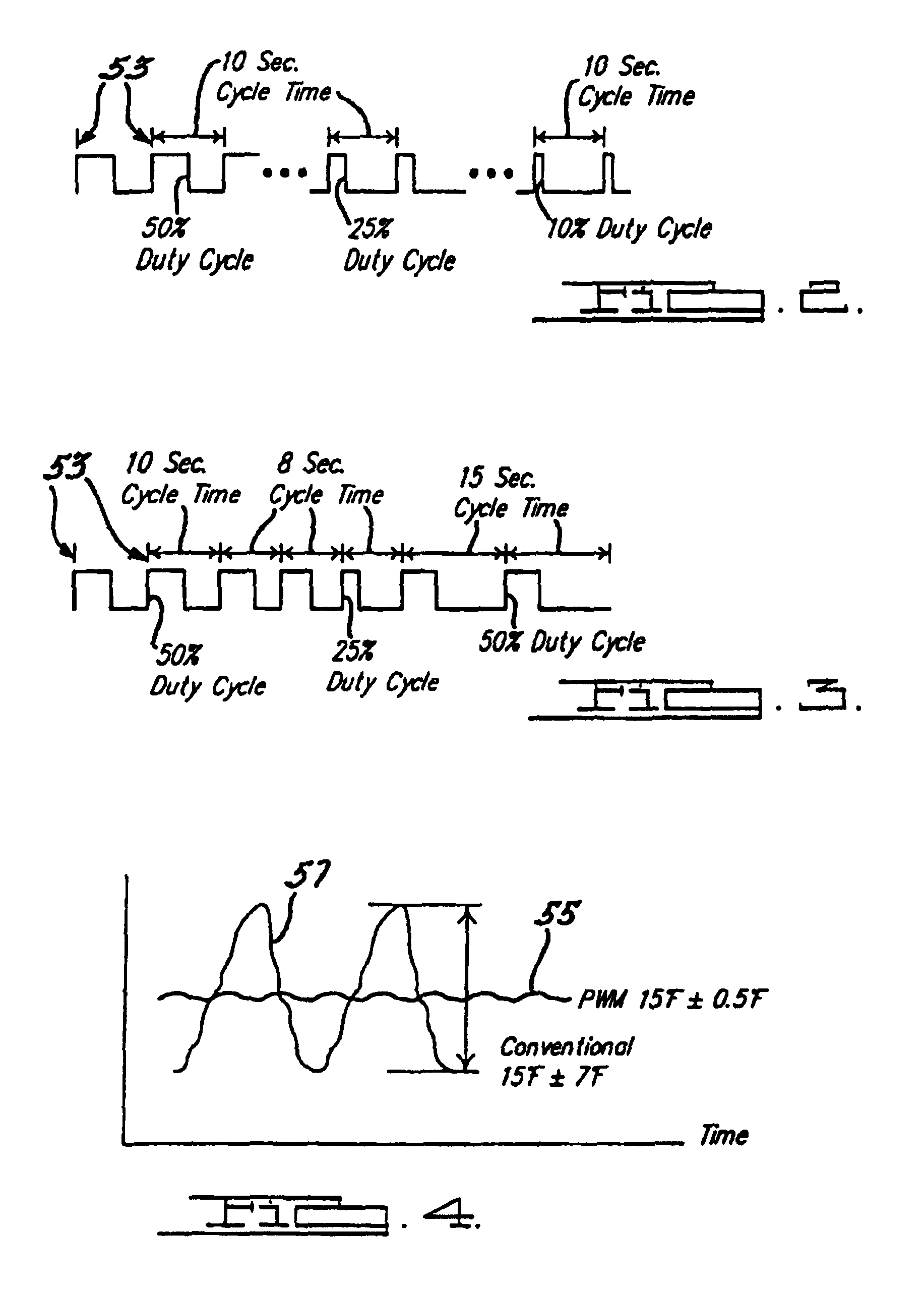

Compressor capacity modulation

InactiveUSRE40830E1Eliminate unbalanced operation of compressorMinimizes pressure fluctuationRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsRC time constantControl system

A pulsed modulated capacity modulation system for refrigeration, air conditioning or other types of compressors is disclosed in which suitable valving is provided which operates to cyclically block flow of suction gas to a compressor. A control system is provided which is adapted to control both the frequency of cycling as well as the relative duration of the on and off time periods of each cycle in accordance with sensed system operating conditions so as to maximize the efficiency of the system. Preferably the cycle time will be substantially less than the time constant of the load and will enable substantially continuously variable capacity modulation from substantially zero capacity to the full capacity of the compressor. Additional controls may be incorporated to modify one or more of the motor operating parameters to improve the efficiency of the motor during periods of reduced load.

Owner:EMERSON CLIMATE TECH INC

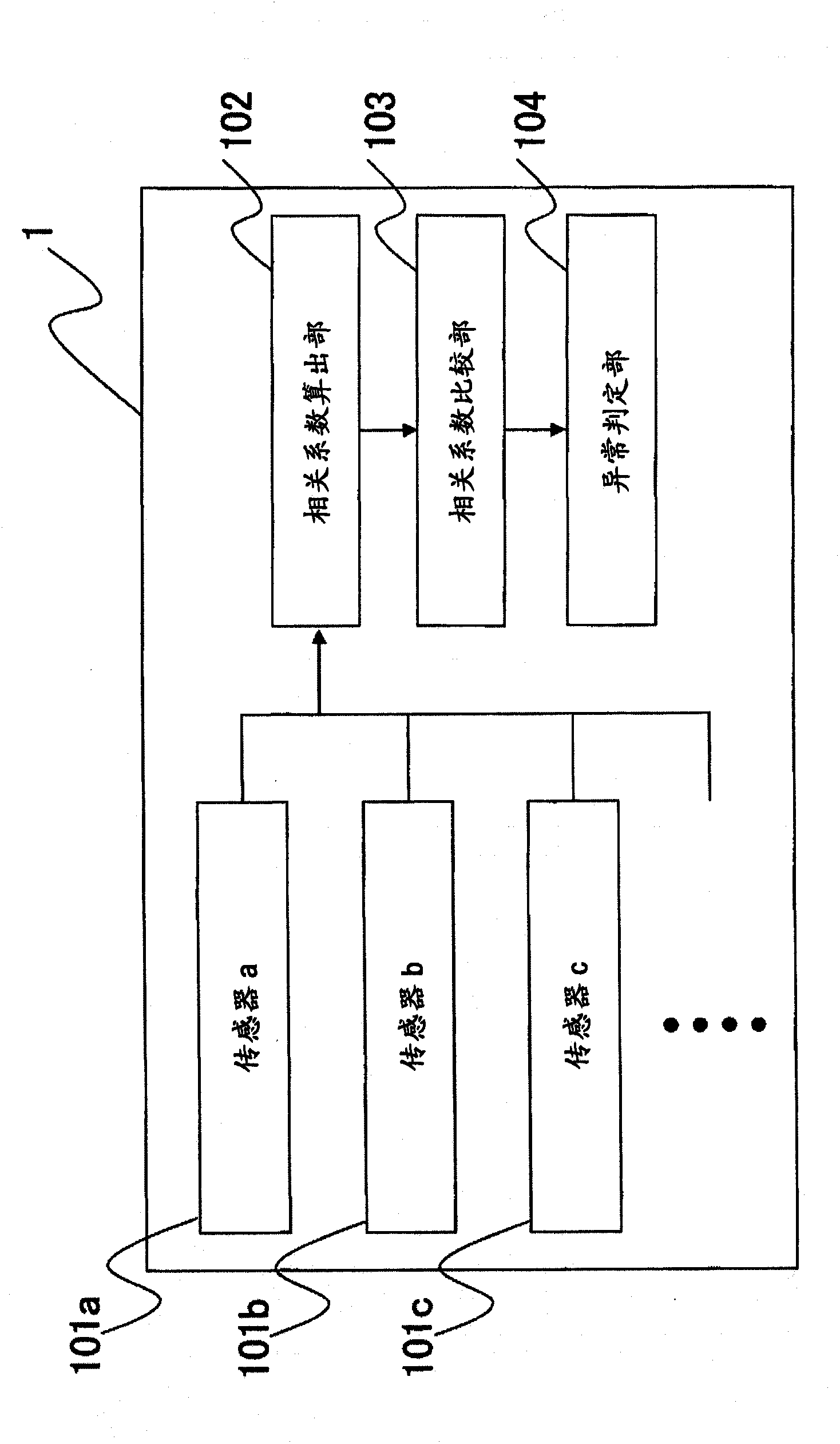

Device for detecting abnormality in construction machine

Provided is a device for detecting an abnormality in a construction machine, which can estimate an abnormality in mechanism parts such as an engine and a pump of a construction machine on the basis of the relationship among a plurality of pieces of sensor information, thereby preventing the machine from occurrence of any failure. From time-series sensor values obtained by a plurality of sensors (101), a correlation coefficient calculation unit (102) calculates respective correlation coefficients, a correlation coefficient comparison unit (103) compares the correlation coefficients and calculates the degree of the difference between the correlation coefficients, and when the calculated degree of the difference exceeds a predetermined value, an abnormality determination unit (104) determines that there is an abnormality in a part associated with the corresponding sensor.

Owner:NIHON KENKI CO LTD

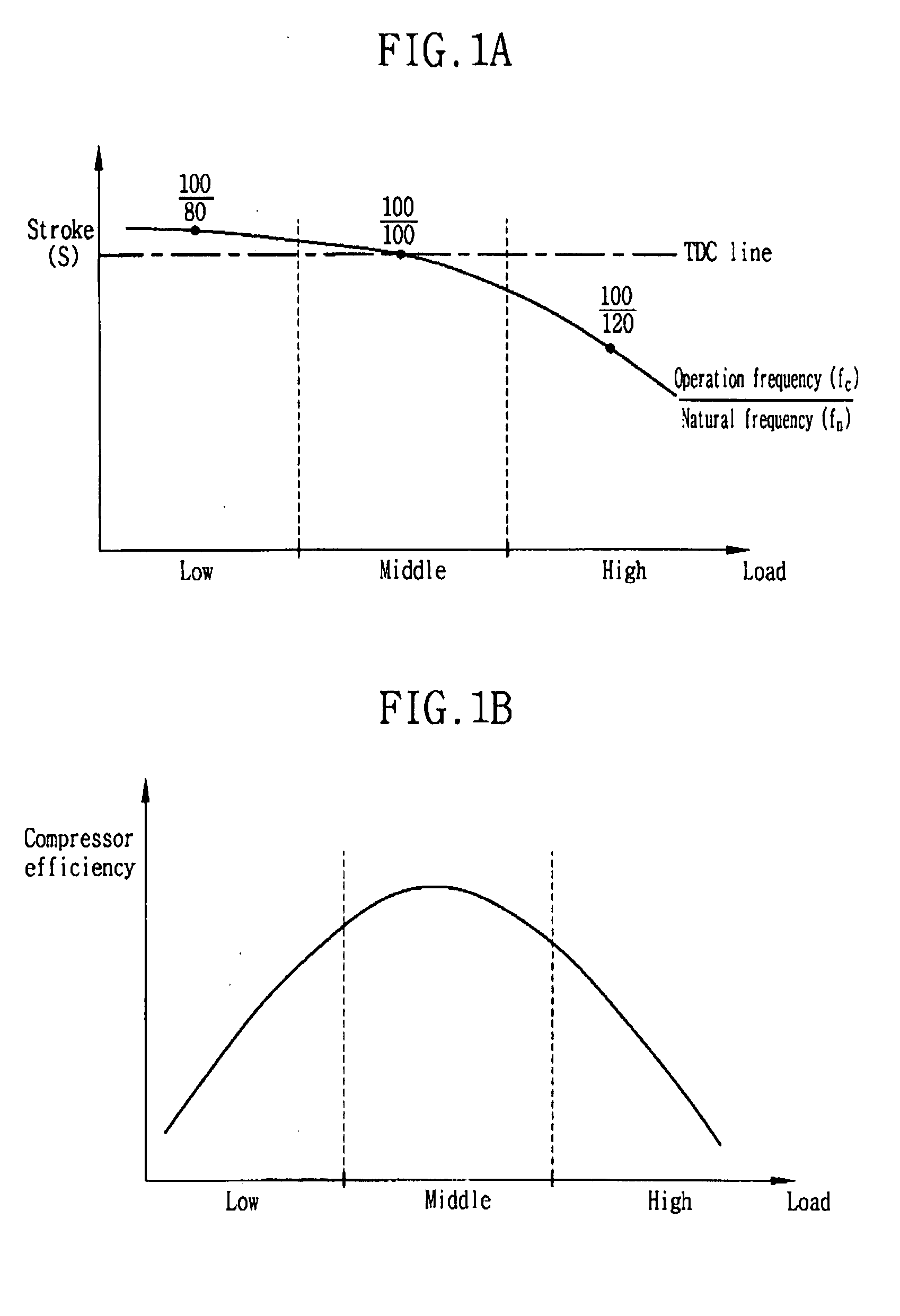

Linear Compressor

ActiveUS20090047154A1Efficiency sometimes variesMost efficientExternal parameterMotor parameterTop dead centerReciprocating motion

The present invention discloses a linear compressor which can rapidly overcome load and improve compression efficiency, by synchronizing an operation frequency of a linear motor with a natural frequency of a movable member varied by the load and varying a stroke of the movable member according to the load. The linear compressor includes a fixed member having a compression space inside, a movable member linearly reciprocated in the fixed member in the axial direction, for compressing refrigerants sucked into the compression space, one or more springs installed to elastically support the movable member in the motion direction of the movable member, spring constants of which being varied by load, and a linear motor installed to be connected to the movable member, for linearly reciprocating the movable member in the axial direction, and varying a stroke of the movable member according to a predetermined refrigeration force, so that the movable member can be linearly reciprocated to reach a top dead center.

Owner:LG ELECTRONICS INC

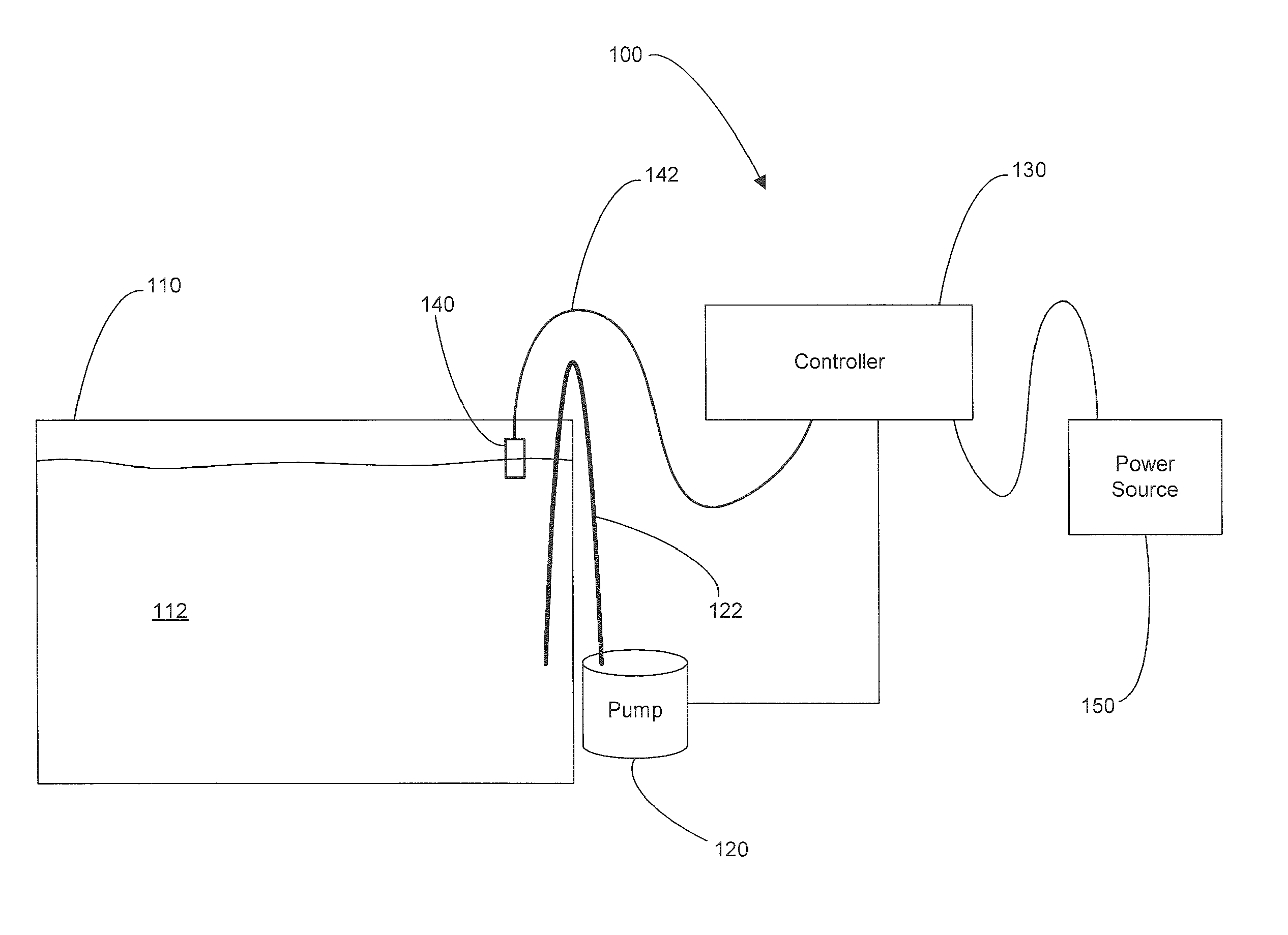

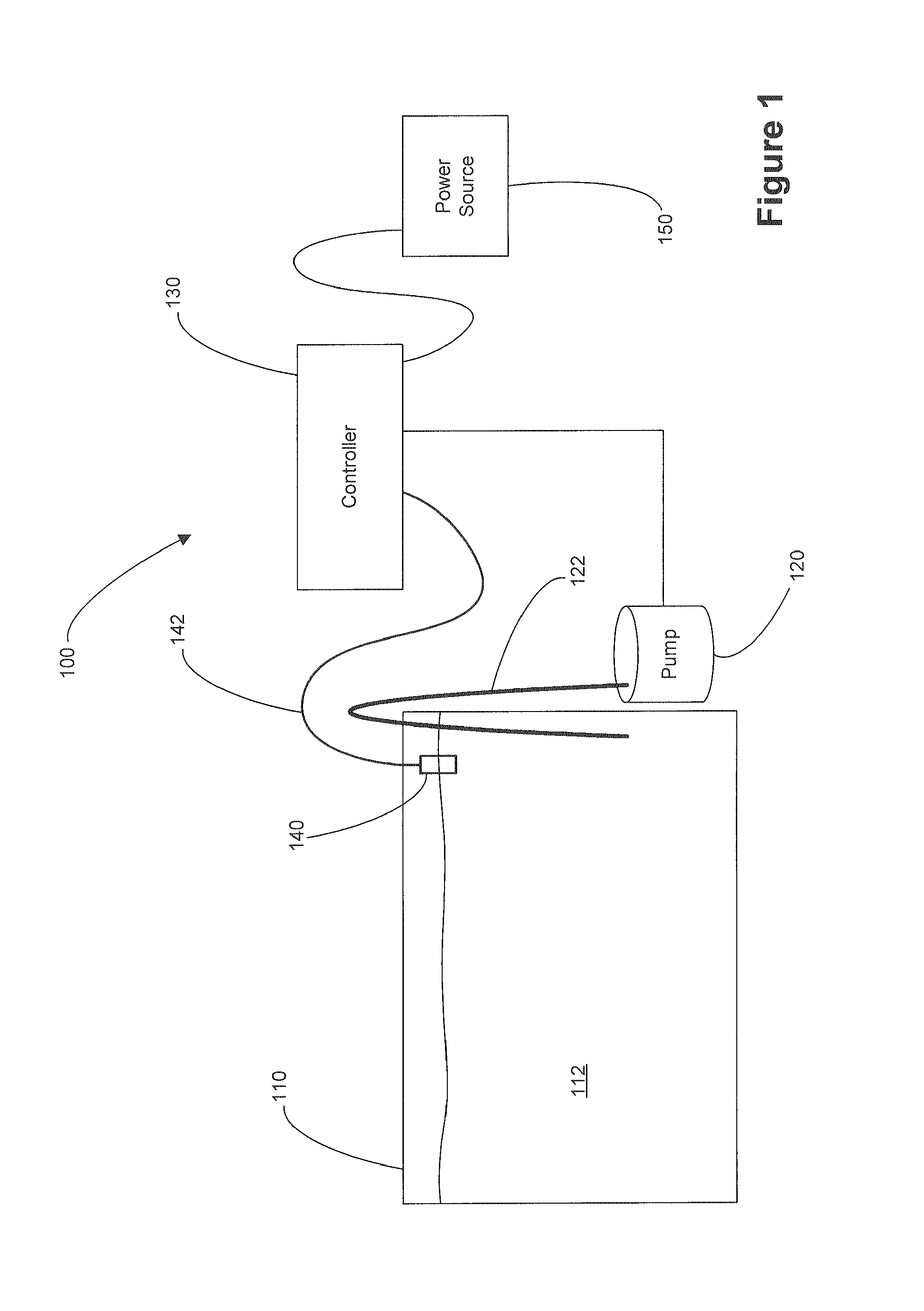

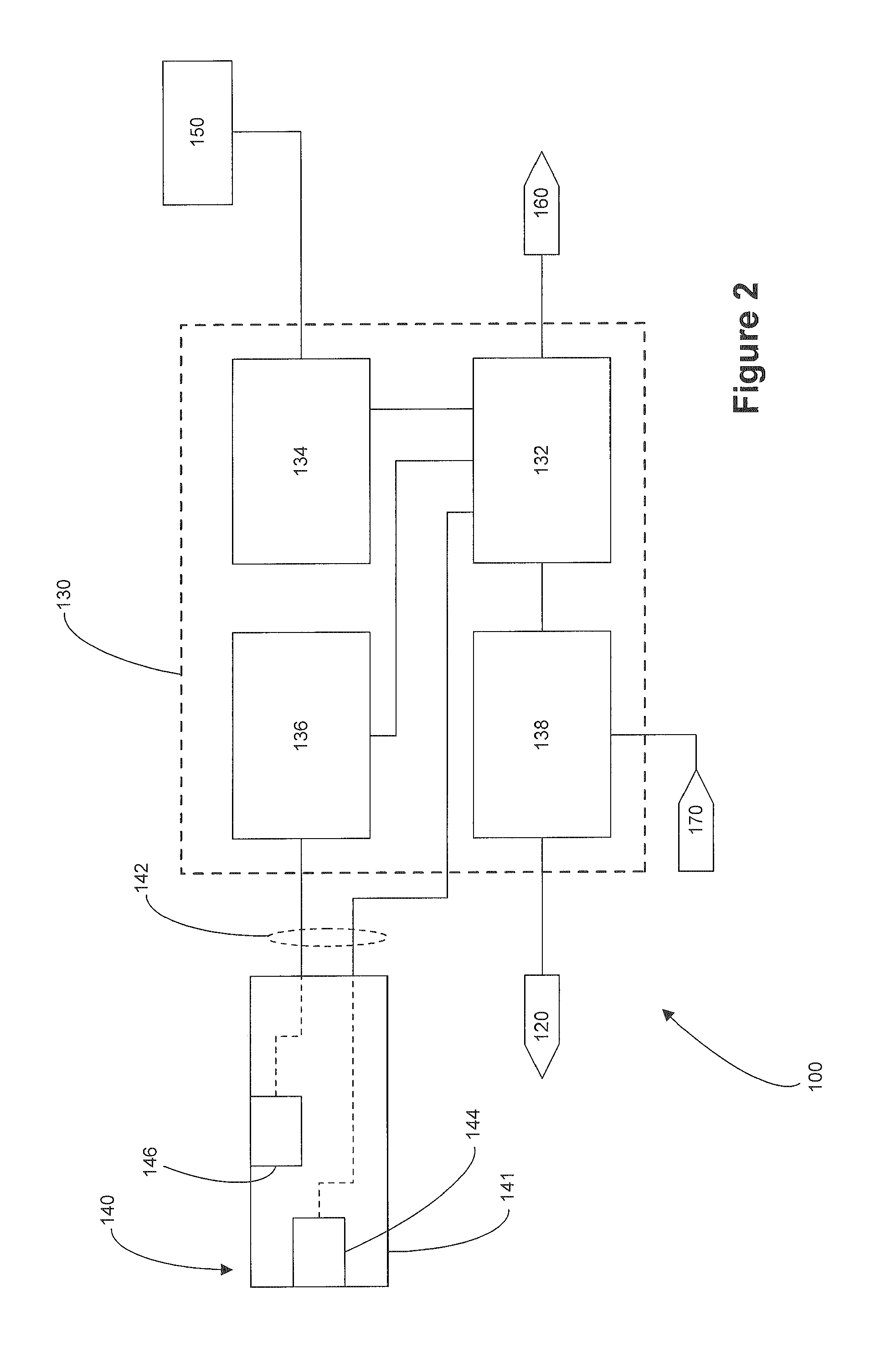

Fluid level management

Fluid level in an aquarium or other container containing a fluid is managed using a mounted fluid level sensor that includes a heating element mounted to a heat conductive sensor housing and a temperature sensor mounted to the housing at a location spaced from the heating element. A controller collects temperature readings from the temperature sensor and operates a pump to add fluid to the container when temperature readings from the fluid level sensor housing exceed a threshold temperature for a prescribed period of time, representing a drop in fluid level in the container. The controller can include a pump control unit that controls operation of the pump and a microprocessor configured to receive temperature readings from the temperature sensor, control the temperature of the heating element, and control the pump control unit based on the temperature readings received from the temperature sensor.

Owner:GANDINI NICOLA

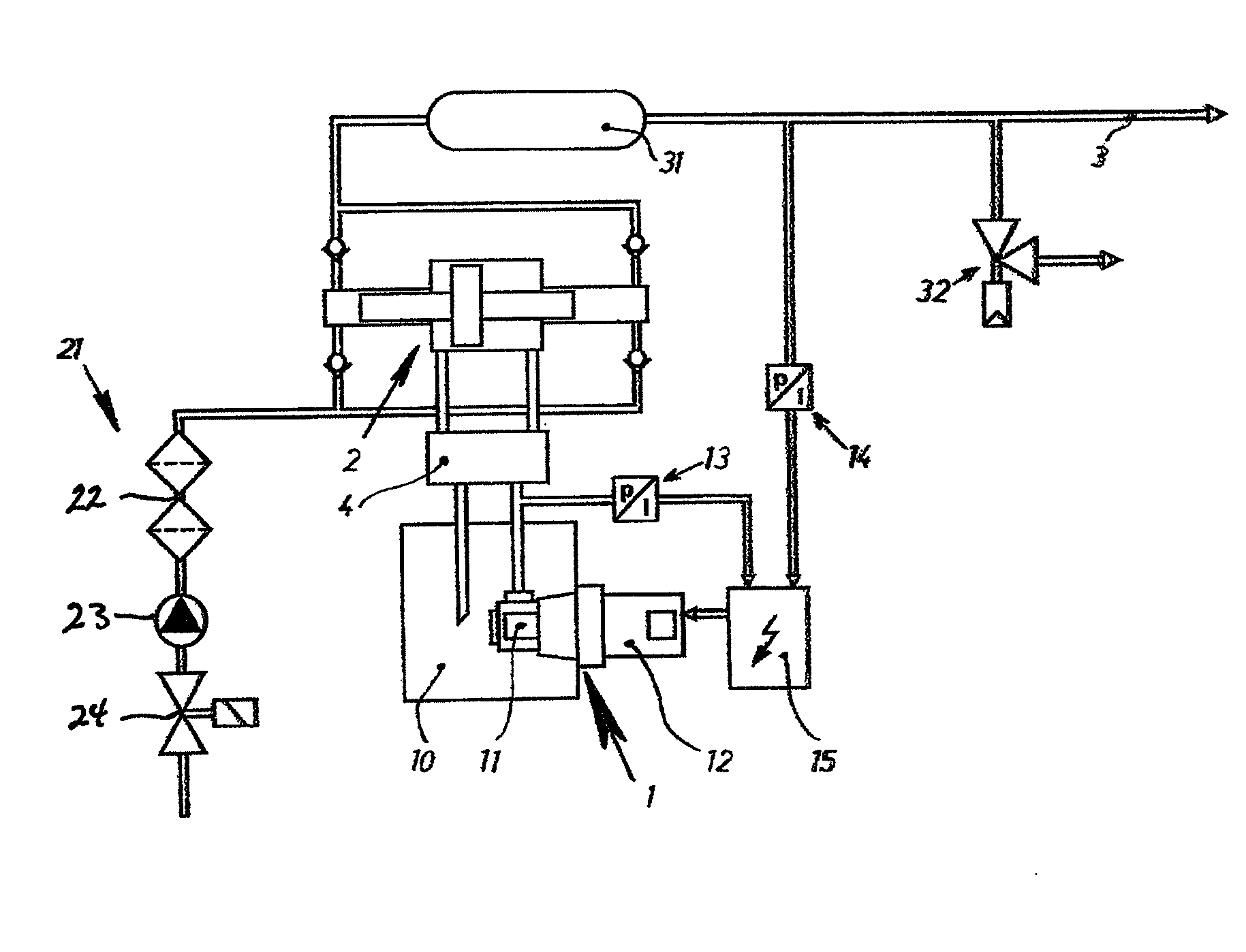

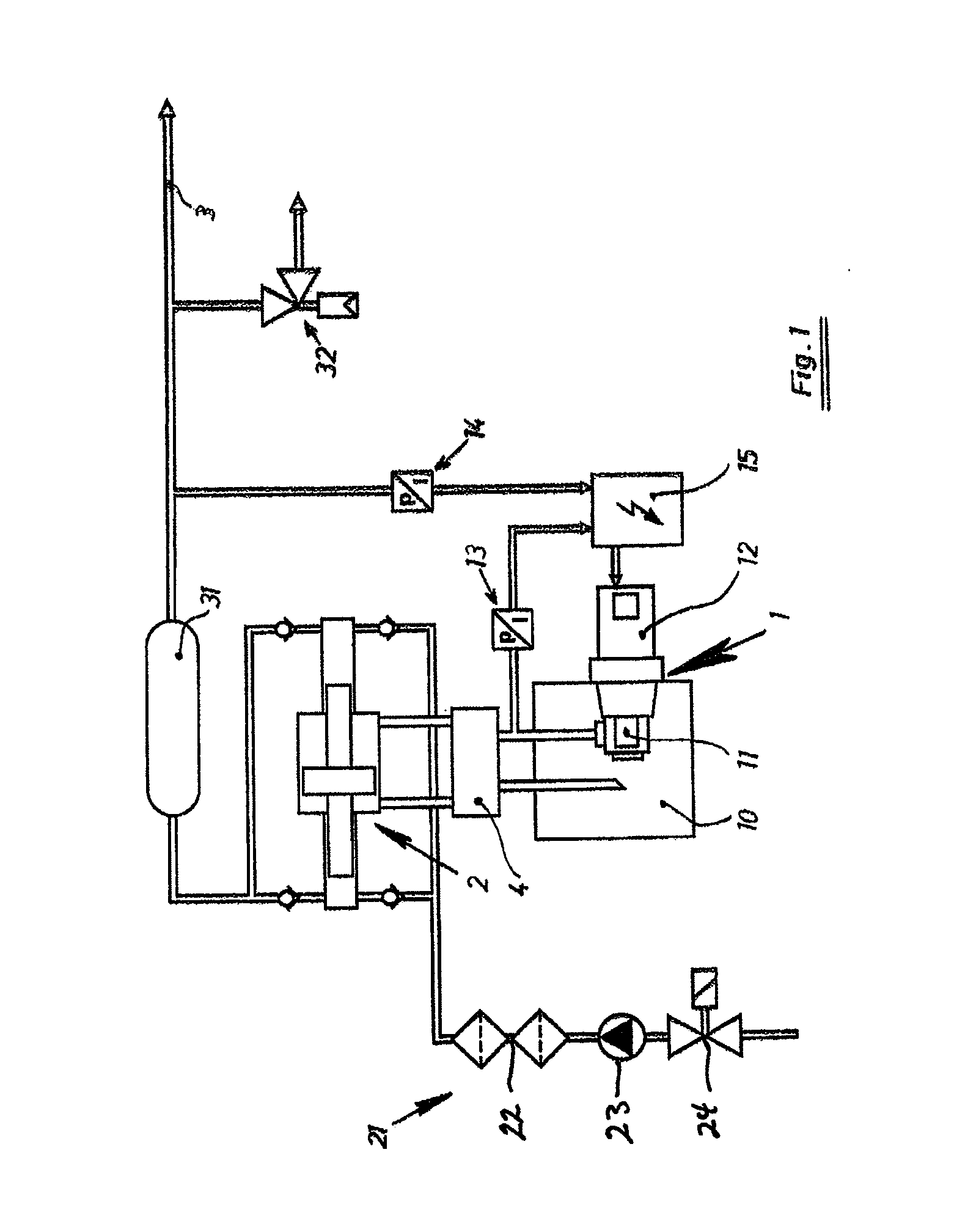

Hydraulic drive for a pressure booster

ActiveUS20130167951A1Extended service lifeReduce power consumptionExternal parameterOperating means/releasing devices for valvesHigh pressureControl theory

Hydraulic drive and method for driving a pressure booster of a high-pressure apparatus. The hydraulic drive includes a pressure medium pump having one of a constant displacement pump and a pump conveying a constant volume per revolution, a servo motor coupled to drive the pump, and a controller structured to at least one of electrically control, regulate and switch the servo motor, which is arranged on at least one of a low pressure side and a high pressure side of the pressure booster.

Owner:BFT

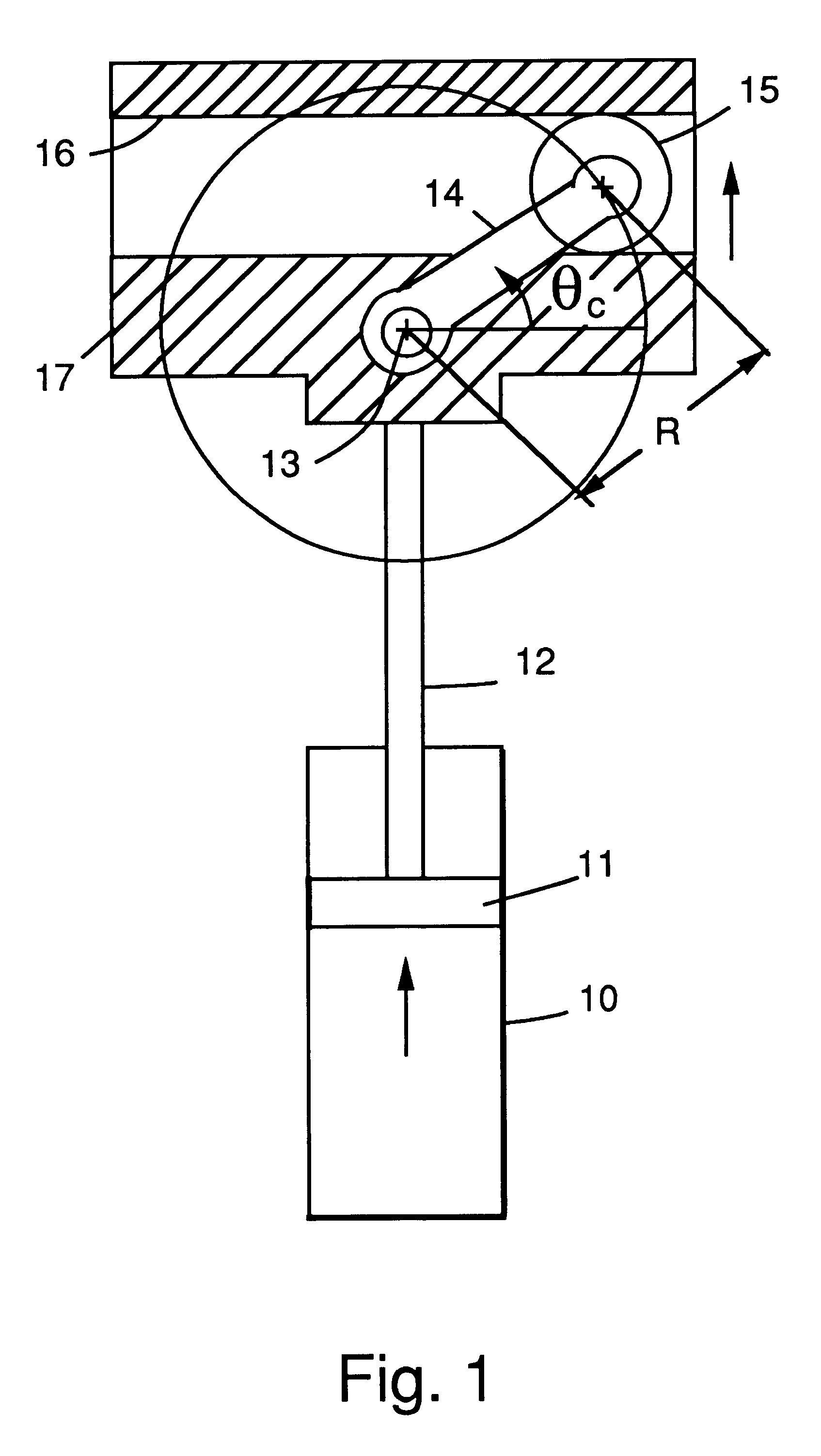

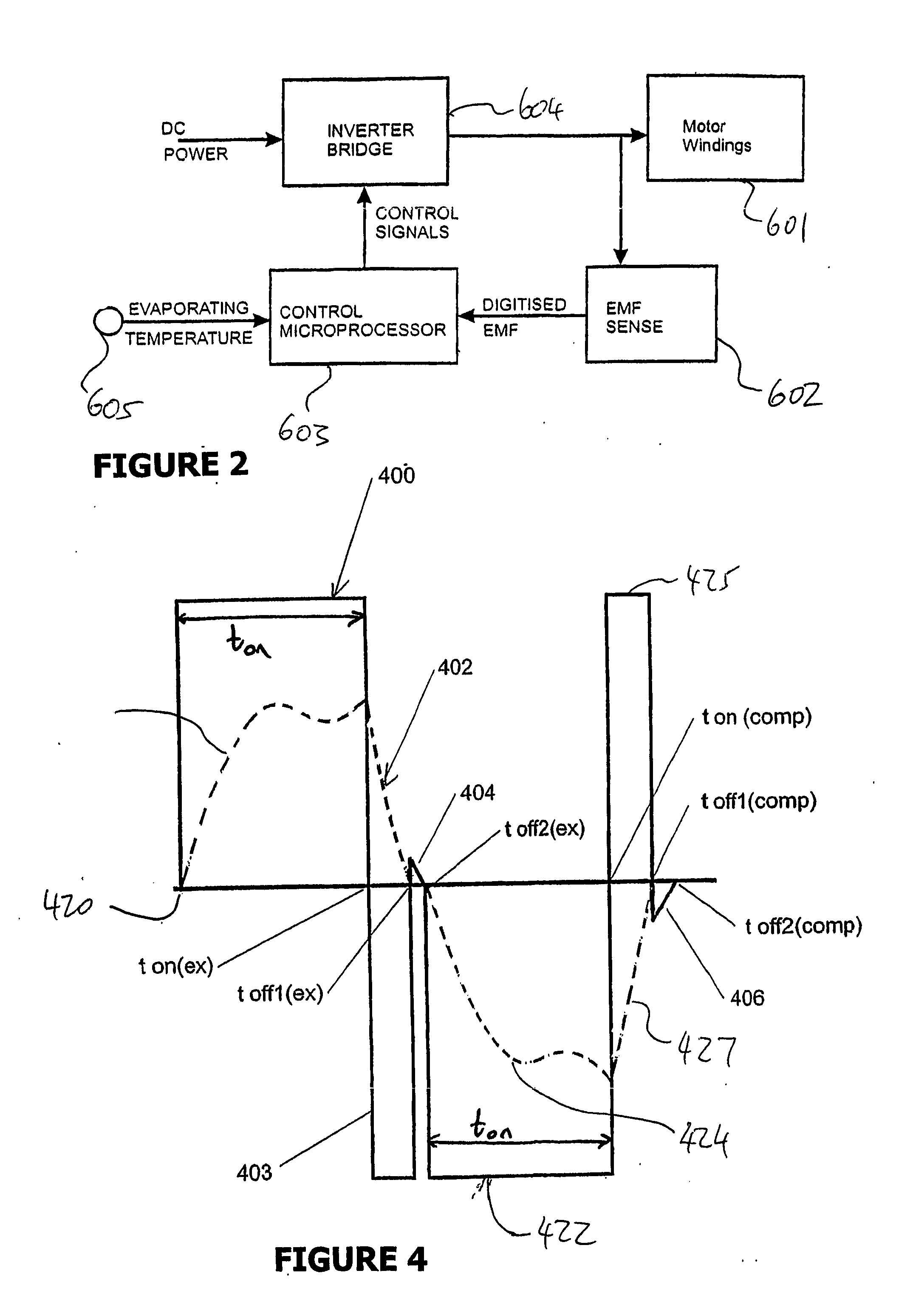

Linear motor controller improvements

ActiveUS20070152512A1Reduced risk of collisionTotal current dropDC motor speed/torque controlAC motor controlReciprocating motionGas compressor

A free piston gas compressor has a cylinder, a piston, the piston reciprocable within the cylinder in alternating compression and expansion strokes. A reciprocating linear electric motor is drivably coupled to the piston. A controller is programmed to control or adjust power input to the linear motor on the basis of a relationship including at least one of the present compression stroke or expansion stroke durations, the relationship being indicative of the top dead centre (TDC) position of the piston, including in the absence of any collision. In the preferred embodiment the controller obtains a measure reflecting the difference between the compression stroke duration and the expansion stroke duration and adjusts the power input in response to the obtained measure.

Owner:FISHER & PAYKEL APPLIANCES LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com