Device for detecting abnormality in construction machine

A technology for construction machinery and anomaly detection, which is used in measurement devices, testing of machinery/structural components, mechanical equipment, etc., and can solve problems such as false detection and complex control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (Example (1) about the pump)

[0057] Regarding an embodiment of the present invention, taking engineering machinery, that is, a hydraulic excavator as an example, using Figure 1 to Figure 12 Be explained. This embodiment is an embodiment in the case where a plurality of sensors detects three or more identical physical states as a plurality of related physical states. In addition, the present invention is not limited to hydraulic excavators, and can be applied to other construction machines such as cranes, wheel loaders, and bulldozers.

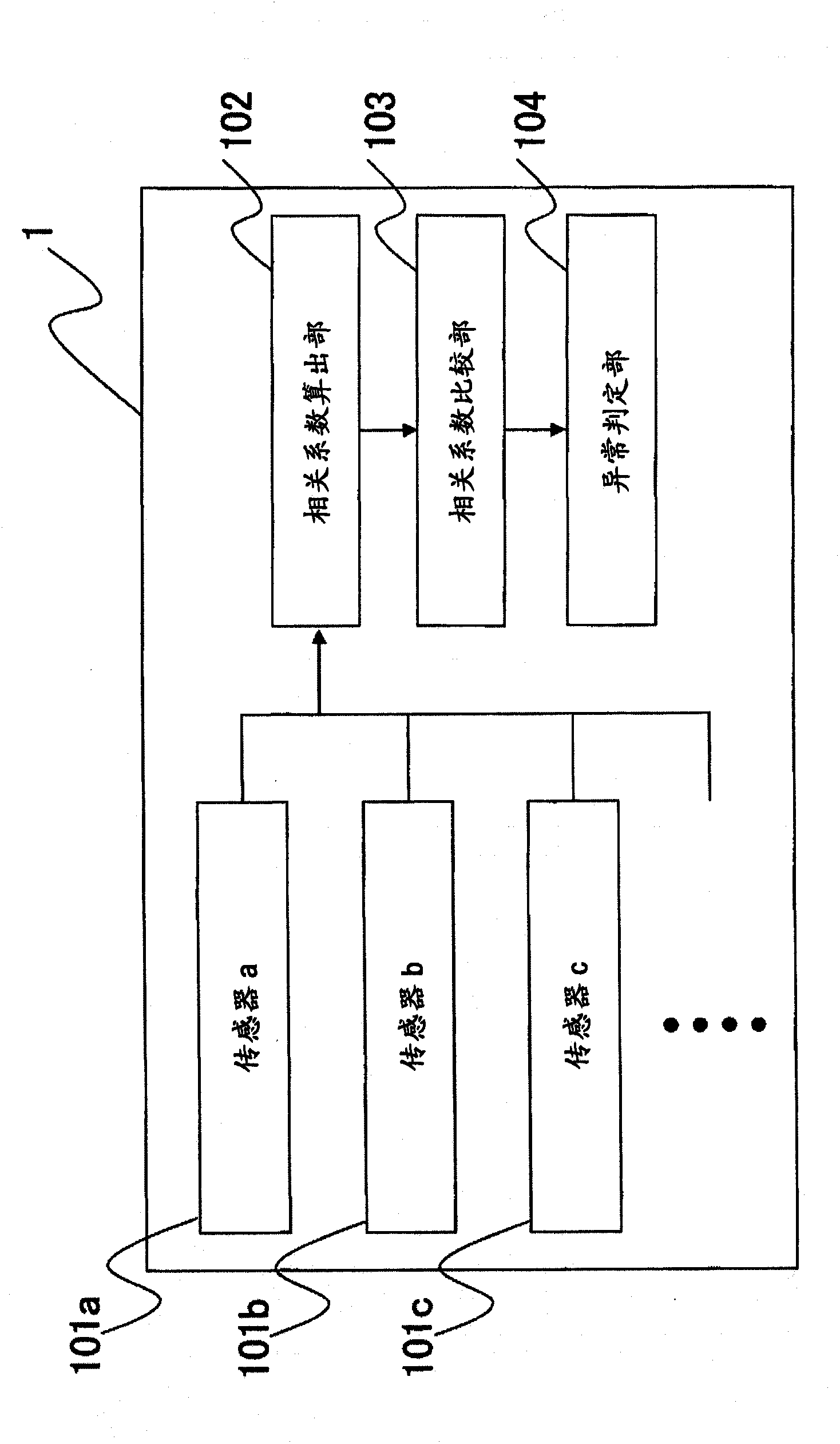

[0058] figure 1 It is a configuration diagram showing the overall system of the abnormality detection device of the present invention.

[0059] The abnormality detection device 1 of the present invention has a configuration including a plurality of sensors 101a, 101b, 101c, . . . Then, sensor signals (sensor information) from the plurality of sensors 101a, 101b, 101c, . In the correlation coefficient calculation unit 102, a plura...

Embodiment 2

[0087] (Example (2) about pumps)

[0088] Using the above examples and Figure 13 Other embodiments of the present invention will be described. This embodiment is a modified example of Embodiment 1.

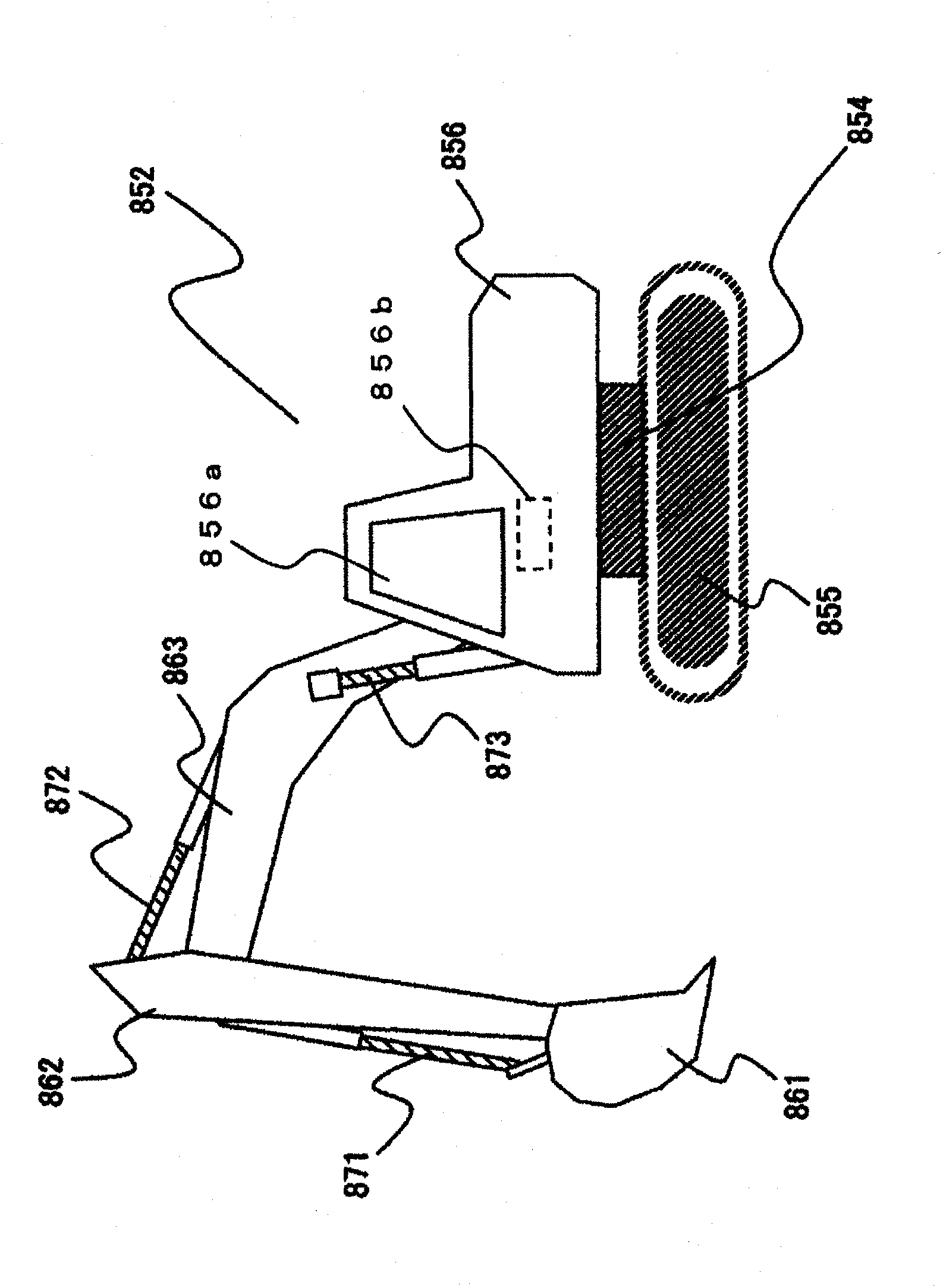

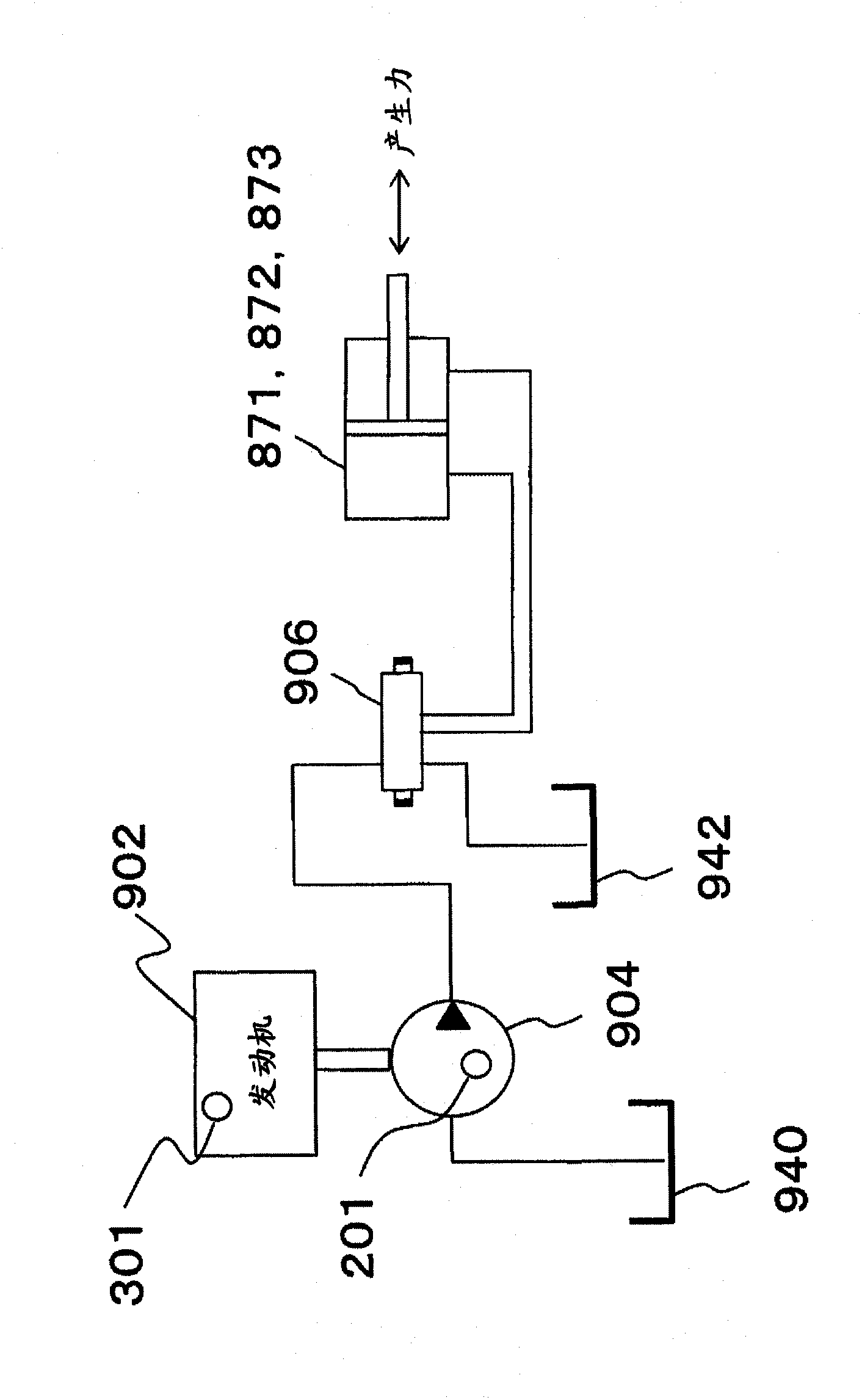

[0089] Figure 13 In the abnormality detection device 1 in this embodiment, except figure 2 In addition to the shown structure, it also has: for the hydraulic excavator 852 (refer to Figure 18 ) operation information detection unit 202; pump operation determination unit 203 for determining the operation state of each hydraulic pump 904 based on the operation information. The hydraulic excavator 852 has a control lever device as an operating mechanism, and the control lever device generates an operation pilot pressure corresponding to a lever operation amount, and drives the control valve 906 by the operation pilot pressure. The operation information detection unit 202 is, for example, a pressure sensor that detects the operation pilot pressure. In this case, when the oper...

Embodiment 3

[0093] (Example (1) about the engine)

[0094] Regarding other embodiments of the present invention, taking engineering machinery, that is, a hydraulic excavator as an example, using the above-mentioned embodiments and Figure 14 to Figure 17 Be explained. This embodiment is also an embodiment in a case where a plurality of sensors detect three or more identical physical states as a plurality of associated physical states.

[0095] Figure 14 is said to be figure 1 The sensor 101 in the figure is replaced by the engine cylinder temperature sensor 301. As mentioned above, the engine 902 of the hydraulic excavator 852 has 16 cylinders, and the temperature of each cylinder is measured by the 16 engine cylinder temperature sensors 301a to 301p (not shown), so that the temperature of the engine can be known. action state.

[0096] Figure 15 It is a graph showing the engine cylinder temperature measured by the engine cylinder temperature sensor 301a to the engine cylinder tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com