Method for evaluating reliability of stepping stress quickened degradation experiment based on time sequence

An accelerated degradation test and time series technology, applied in the direction of strength characteristics, measuring devices, instruments, etc., can solve the problems of being unable to describe the randomness information of the statistical data of the accelerated degradation test, and difficult to apply the reliability evaluation of the accelerated degradation test, etc.

Inactive Publication Date: 2010-01-06

BEIHANG UNIV

View PDF0 Cites 57 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

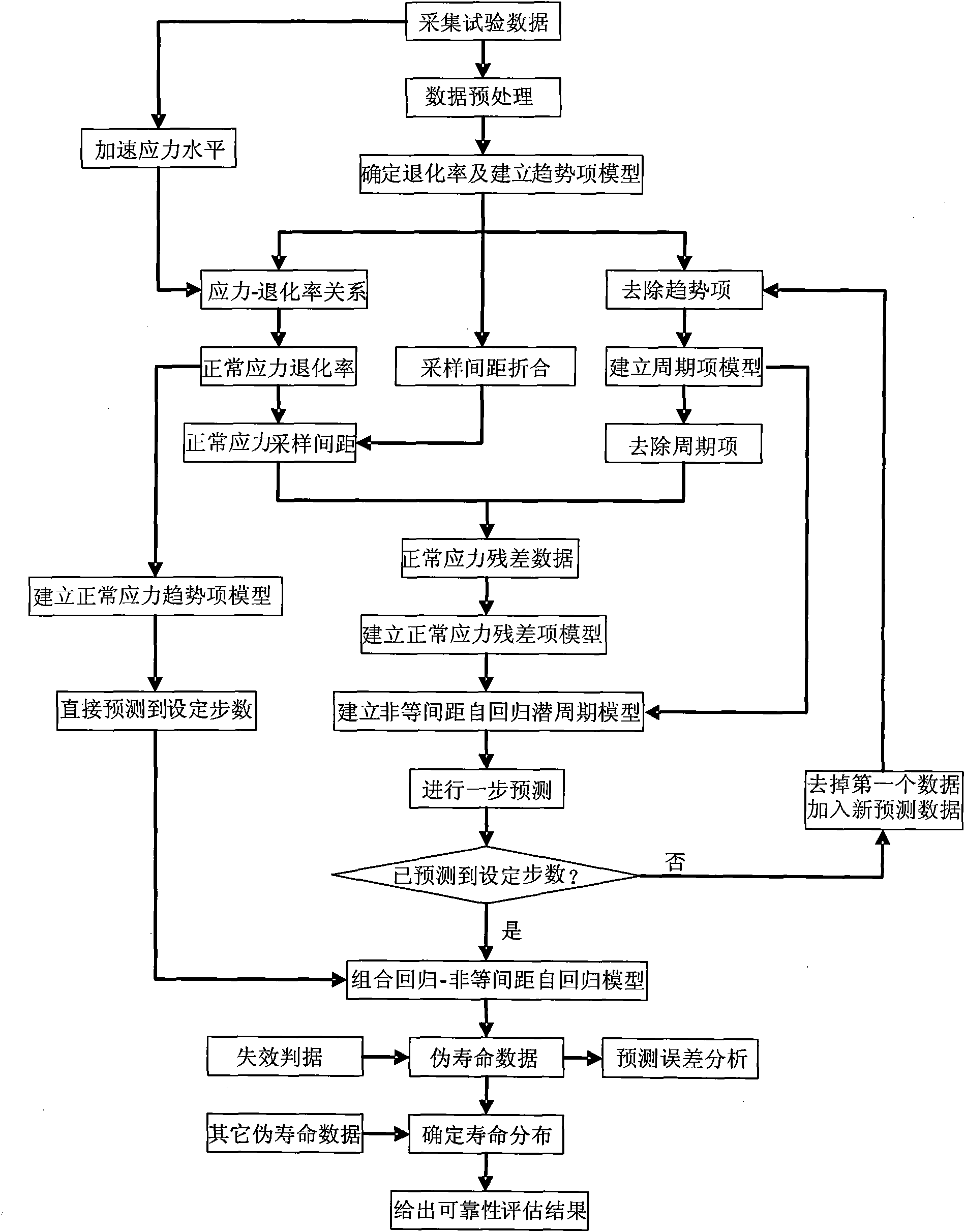

[0012] The purpose of the present invention is to solve the problem that the traditional accelerated degradation model cannot describe the randomness information in the statistical data of the accelerated degradation test, and the existing accelerated degradation test reliability assessment method is difficult to apply to the accelerated degradation test reliability assessment of the step stress level To solve the problem, time series analysis and modeling techniques are adopted to achieve the technical effect of reasonably predicting product life and reliability evaluation based on step stress accelerated degradation test data

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

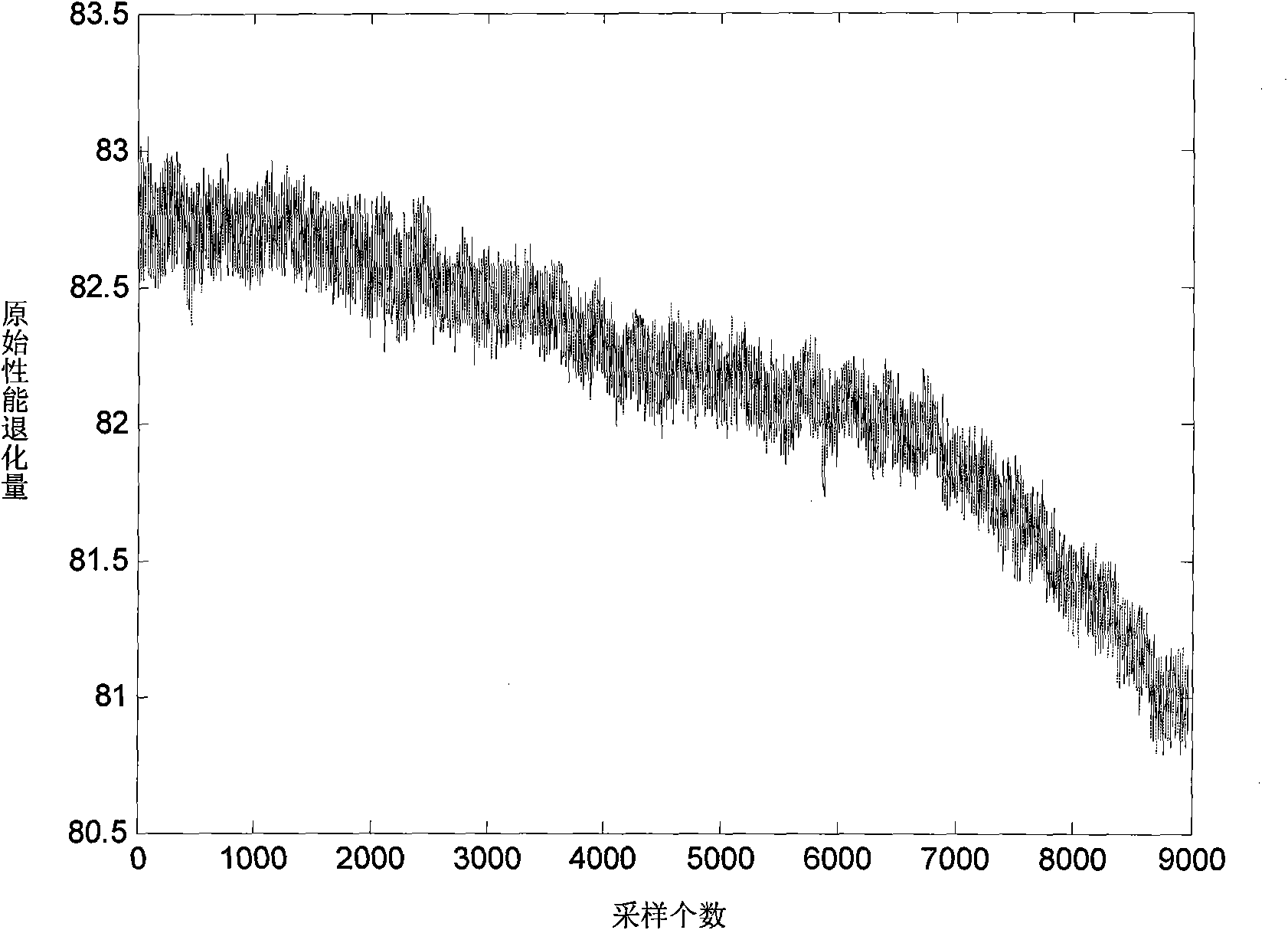

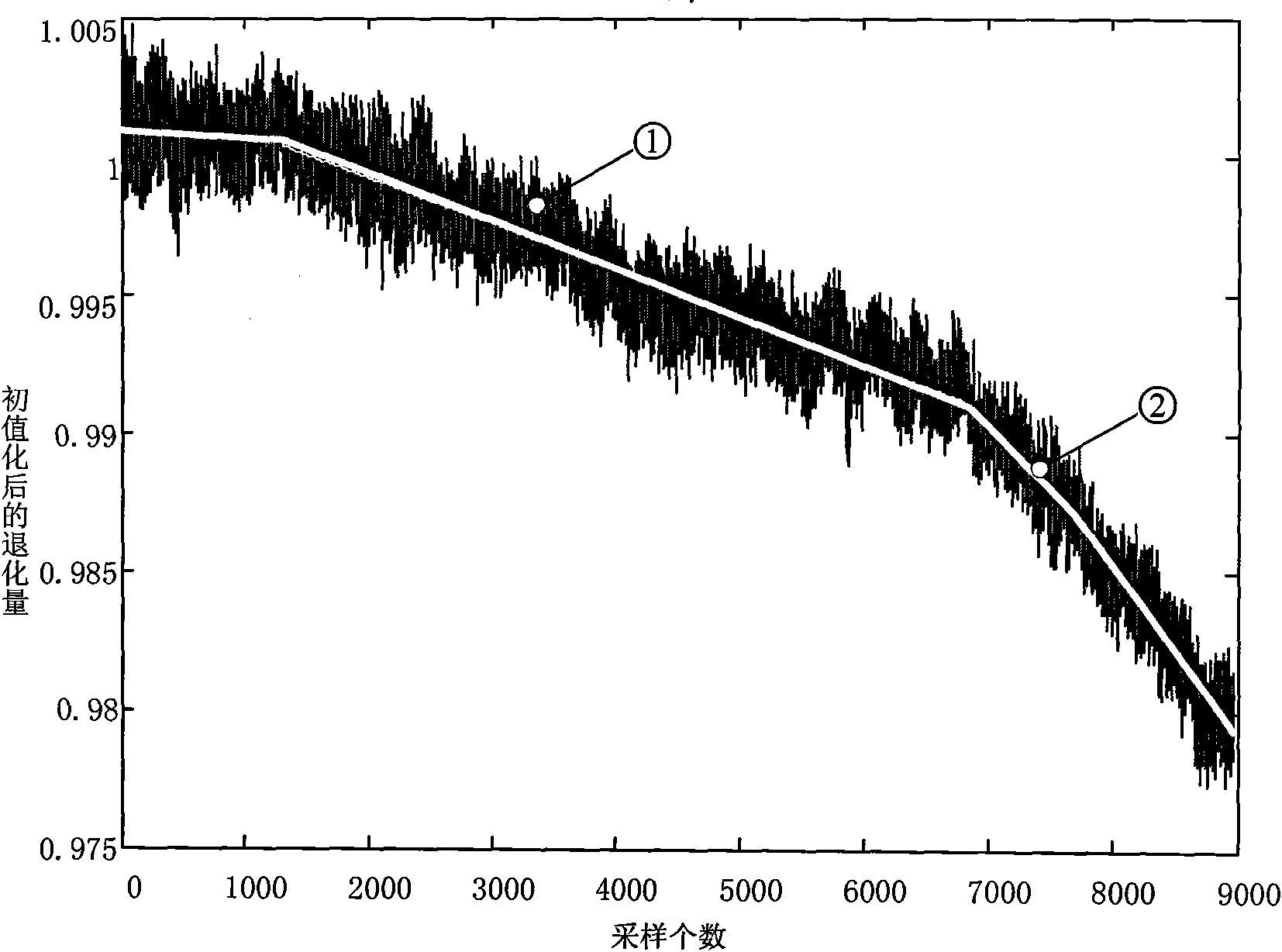

[0198] Taking the step stress accelerated degradation test of a certain type of electronic product as an example, the reliability evaluation method of the step stress accelerated degradation test based on time series is introduced in detail.

[0199] Step 1. Collect test data and perform data preprocessing.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a method for evaluating the reliability of a stepping stress quickened degradation experiment based on a time sequence. The method utilizes a correlation coefficient stationary sequence analytical method to describe non-equidistant stochastic information in stepping stress quickened degradation experiment data, establishes a regressive-non-equidistant autoregression degradation model on the basis of obtaining the respective advantages of a deterministic regression model and a stochastic correlation coefficient stationary sequence autoregression model, combines a grey theory to predict a product degradation trend and forms a function and a curve for predicting the life and evaluating the reliability of the stepping stress quickened degradation experiment based on the time sequence. The method obviously decreases the sample quantity of a product and shortens the time of the degradation experiment, thereby saving a large amount of expenses and resources, enhancing the fitting accuracy of the degradation model and enhancing the reliability of a reliability evaluating result.

Description

technical field [0001] The invention relates to an accelerated degradation test life prediction and reliability evaluation method, belonging to the technical field of accelerated test evaluation. Background technique [0002] For products with high reliability and long life, it is often difficult to observe product failure in a short period of time, and analyzing product reliability based on product performance degradation data has become an effective way. In order to evaluate the reliability of these products whose failure data are difficult to obtain but performance degradation data can be obtained, the method of accelerated degradation test came into being. [0003] To study accelerated degradation failure, the key is to establish an accelerated degradation model in which the characteristic parameters of product performance degradation change with time. Accelerated degradation models are generally divided into two types based on degradation mechanism and statistical data...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/00G01M19/00

Inventor 王立李晓阳姜同敏

Owner BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com