Method for extracting angelica oil from angelica

A technology of angelica oil and angelica, applied in the direction of fat oil/fat production, fat generation, etc., can solve the problem of extracting angelica oil that has not yet been seen, and achieve the effect of easy industrial control, good solvent characteristics, and easy volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

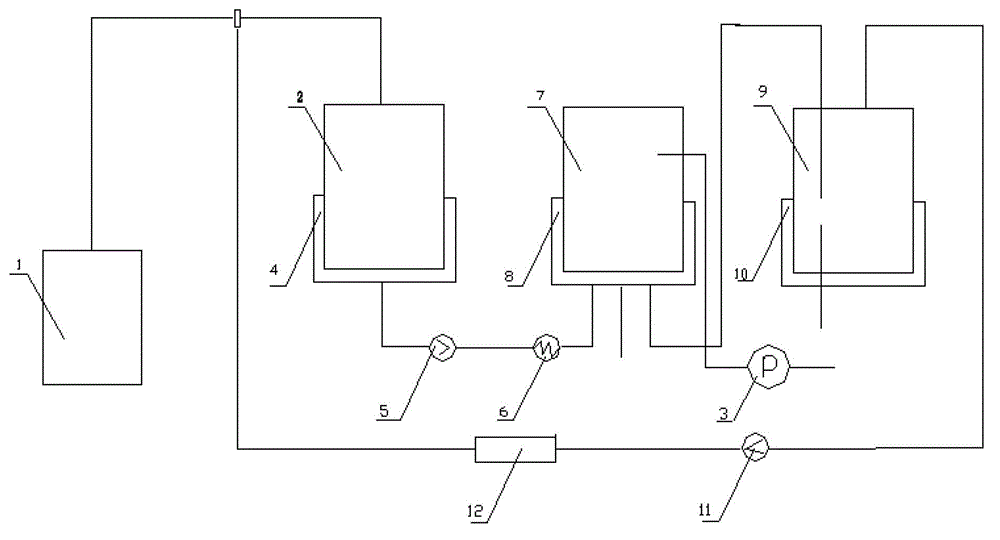

[0026] Example 1: see figure 1 , screening, cleaning, and drying the raw materials of Angelica sinensis to a water content of ≤13%, weighing 10kg, pulverizing to 40-60 mesh through a pulverizer, putting it into the extraction kettle 7, closing the feed valve, and vacuuming with a vacuum pump 3. to 1×10 4 Below Pa, the air in the extraction kettle is discharged to prevent the extraction solvent tetrafluoroethane from being mixed with air, which affects the extraction pressure in the system; then the tetrafluoroethane solvent gas in the solvent gas tank 1 is introduced into the solvent liquefaction storage tank 2 through a conduit, Condensate into a liquid solvent through the condensation jacket 4; the tetrafluoroethane liquid solvent stored in the storage tank 2 is introduced into the extraction kettle through the plunger pump 5, and the liquid level is observed through the sight glass until the angelica raw material is submerged; heated by the heater 6, The heating jacket 8 i...

Embodiment 2

[0027] Example 2: see figure 1 , screening, cleaning, and drying the raw materials of Angelica sinensis to a water content of ≤13%, weighing 10kg, pulverizing to 40-60 mesh through a pulverizer, putting it into the extraction kettle 7, closing the feed valve, and vacuuming with a vacuum pump 3. to 1×10 4Below Pa, the air in the extraction kettle is discharged to prevent the extraction solvent tetrafluoroethane from being mixed with air, which affects the extraction pressure in the system; then the tetrafluoroethane solvent gas in the solvent gas tank 1 is introduced into the solvent liquefaction storage tank 2 through a conduit, Condensate into a liquid solvent through the condensation jacket 4; the tetrafluoroethane liquid solvent stored in the storage tank 2 is introduced into the extraction kettle through the plunger pump 5, and the liquid level is observed through the sight glass until the angelica raw material is submerged; heated by the heater 6, The heating jacket 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com