Patents

Literature

34results about How to "Easy to control industrially" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method and device for extracting peony seed oil from peony seeds

InactiveCN101812370ANon-combustible explosiveVolatileFatty-oils/fats refiningFatty-oils/fats productionEcologyWater content

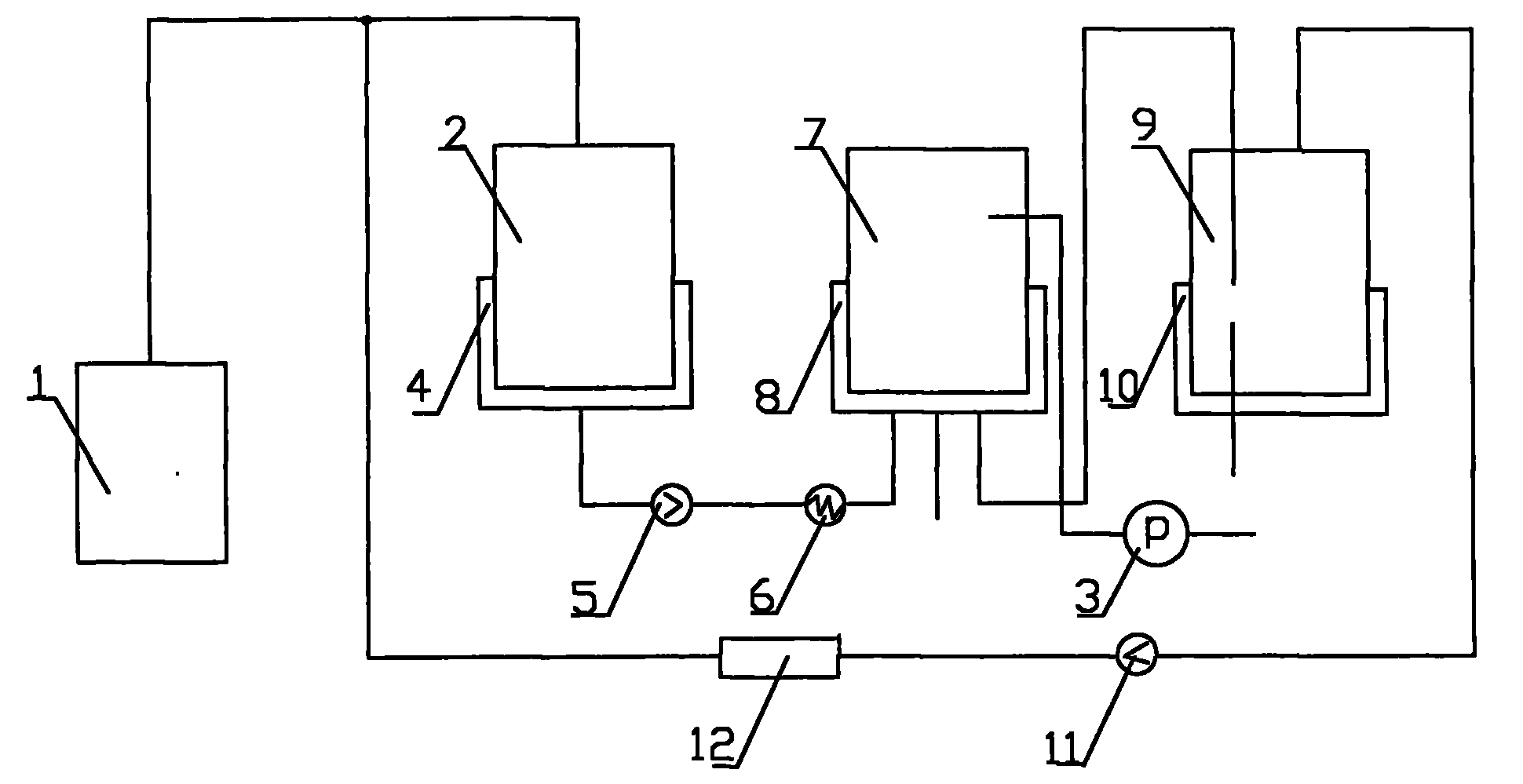

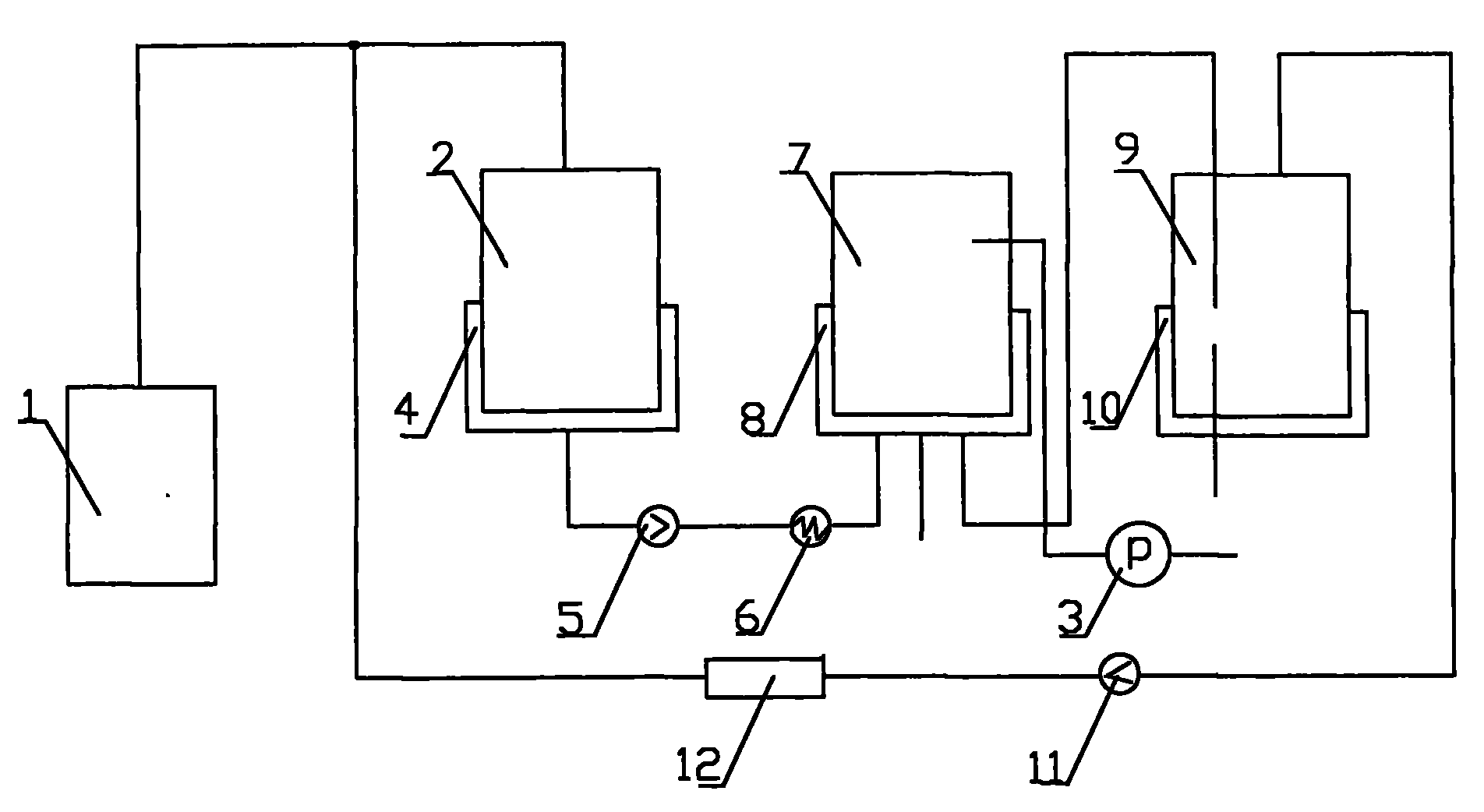

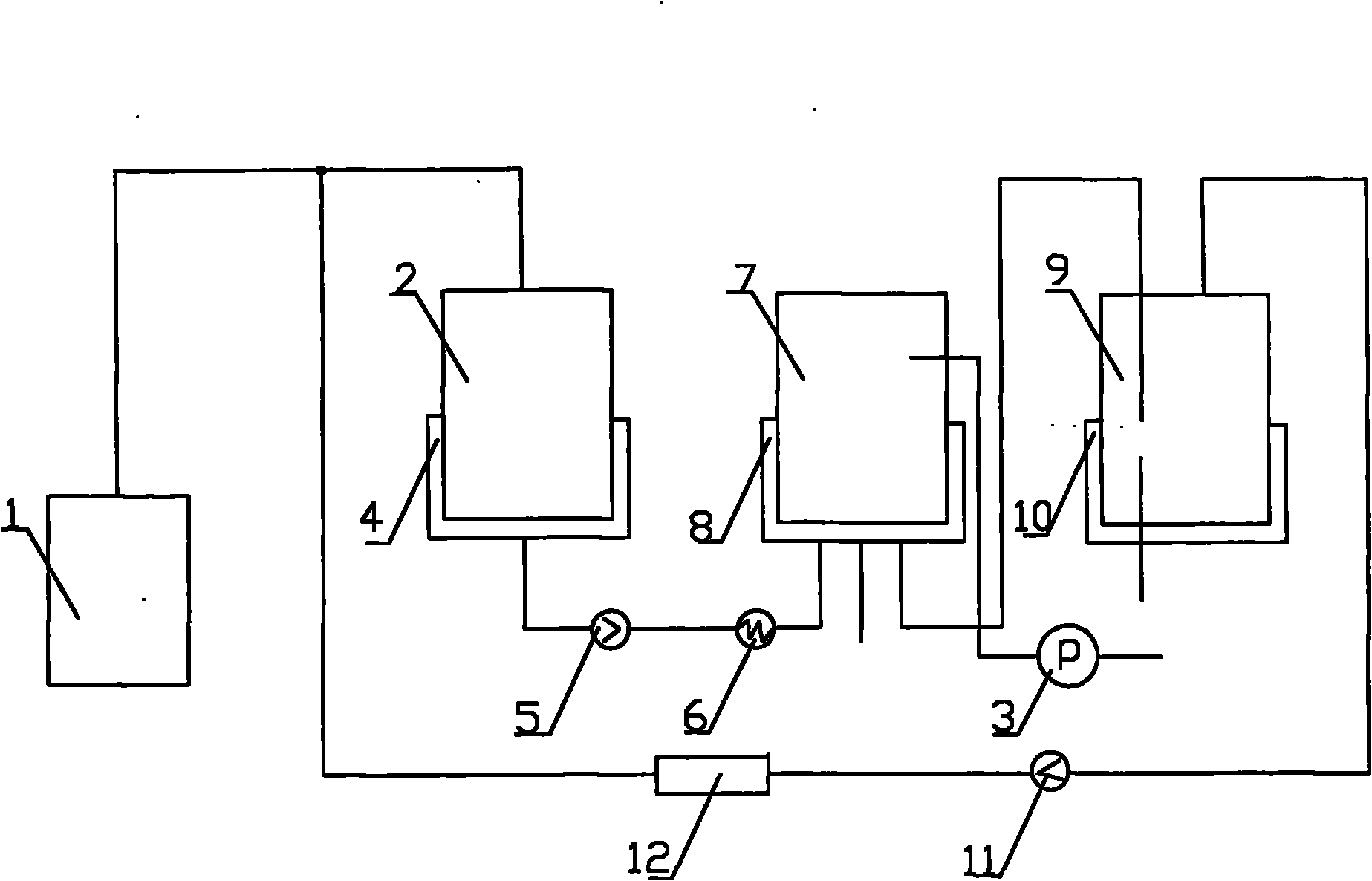

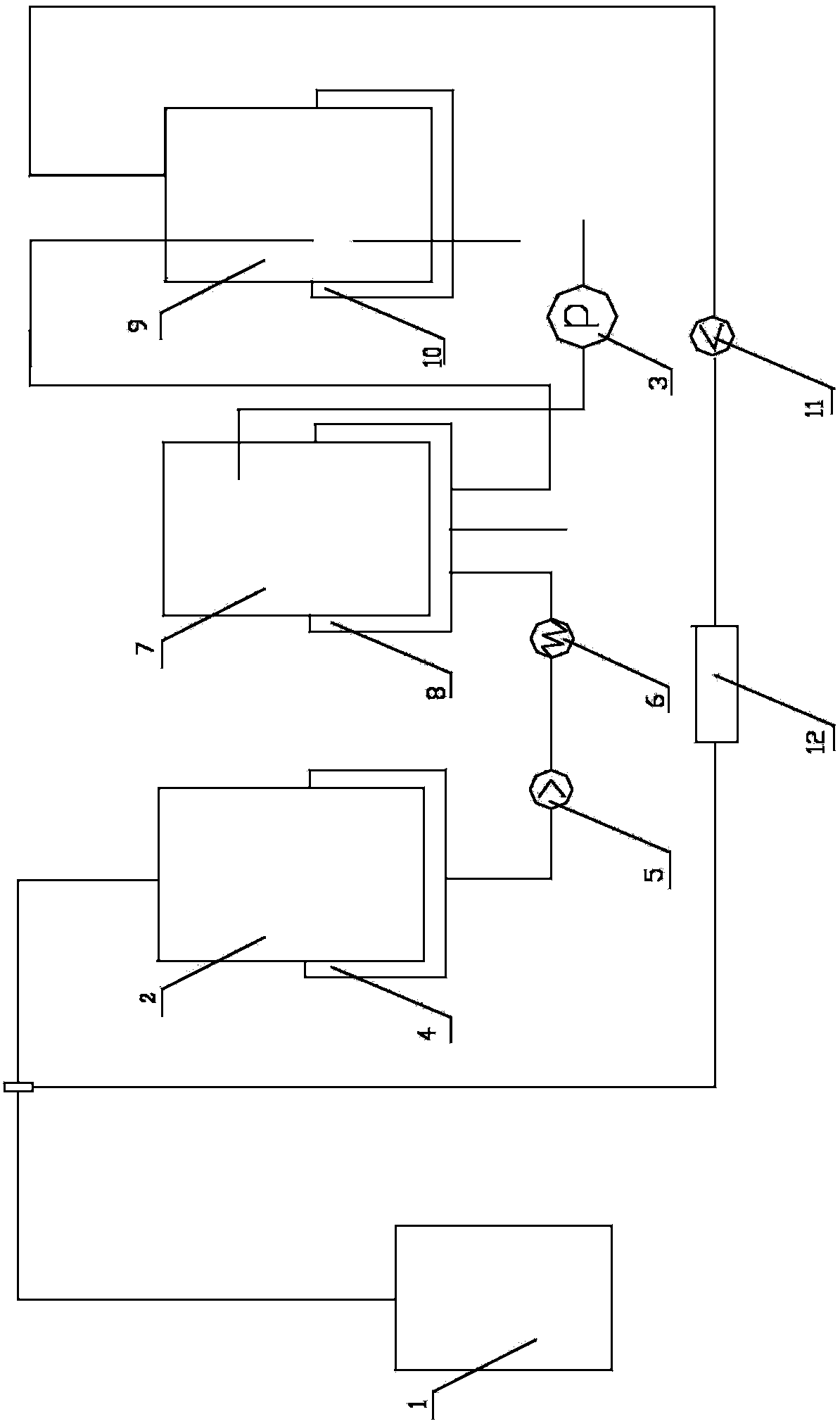

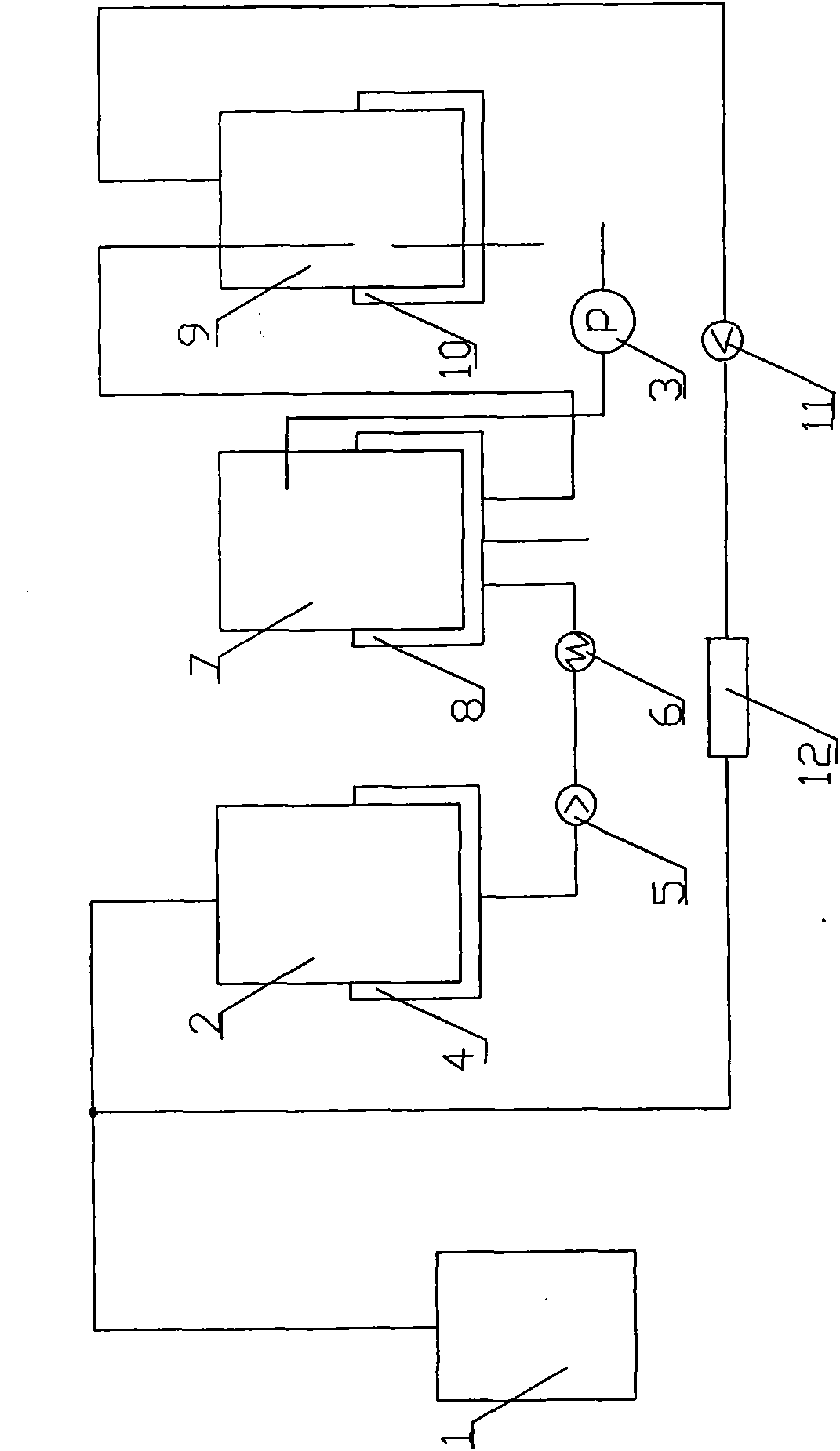

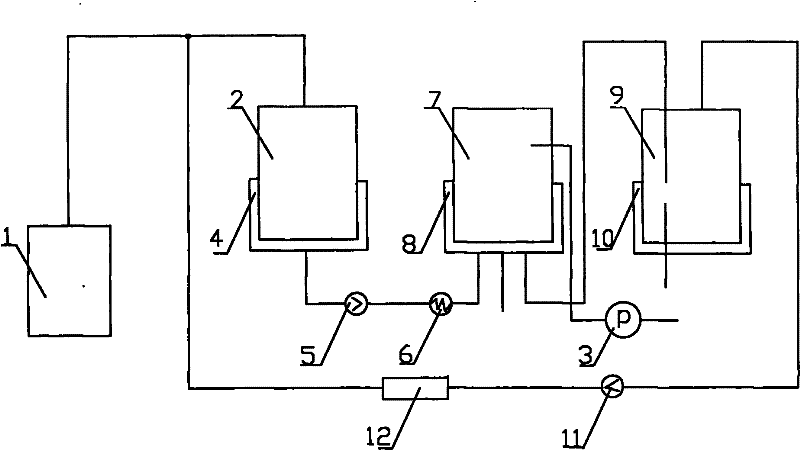

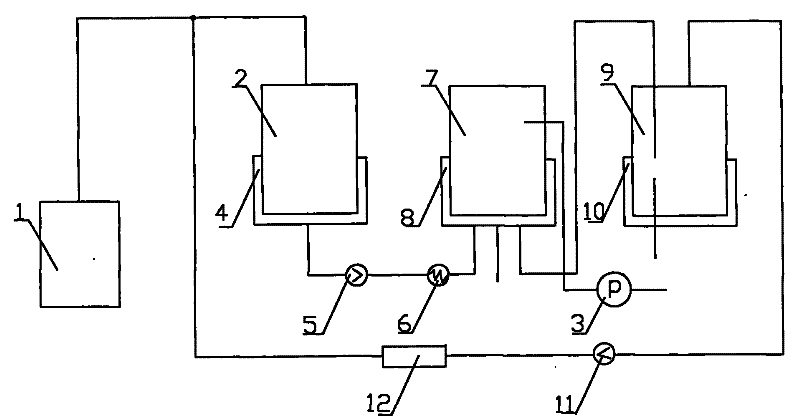

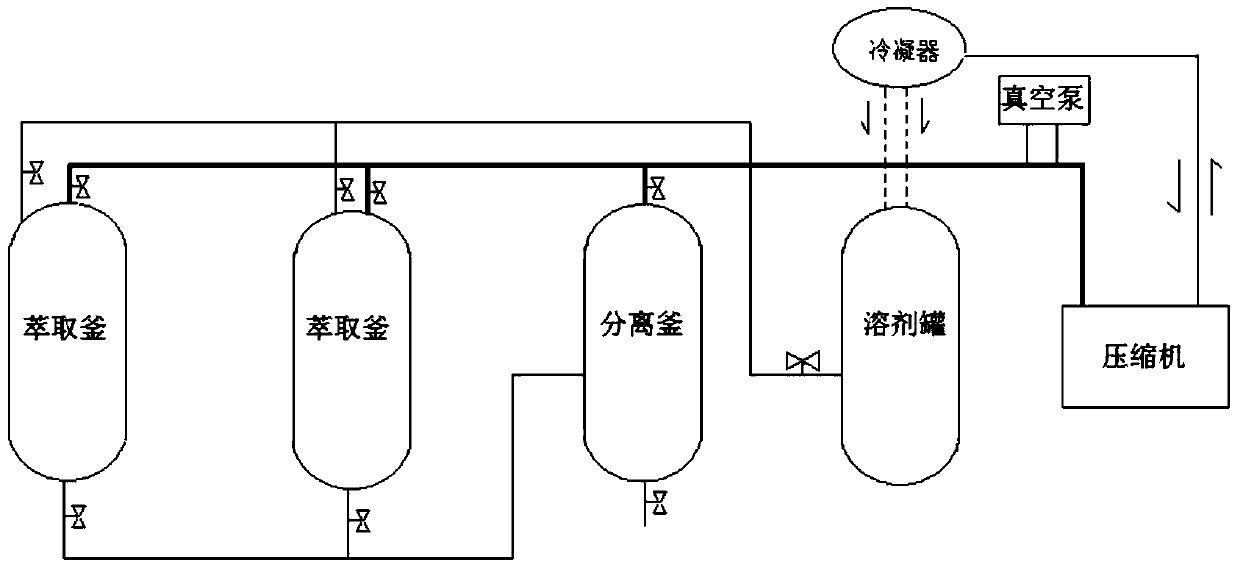

The invention relates to a method for extracting grease from oil material, in particular to a method for extracting peony seed oil from peony seeds. The method for extracting peony seed oil from peony seeds is characterized by comprising the following steps of: (1) firstly, drying the peony seeds until the water content is smaller than 13%, and crushing to 40-80 meshes by using a crusher; (2) delivering the dried and crushed peony seeds into an extracting kettle, pumping the vacuum to the pressure below 1*10<4>Pa, and evacuating air in the extracting kettle; (3) then, pumping a tetrafluoroethane solution into the extracting kettle by using a plunger pump until the peony seeds are emerged under the liquid level under the observation of a sight glass; (4) stirring, and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature range is 40-50 DEG C, and the extraction time is 30-45 min each time; (5) depressurizing and raising temperature to evaporate and separate in a separating kettle, wherein the separation pressure range is 0.5-0.1MPa, and the temperature range is 45-50 DEG C; (6) after subcritical extraction, centrifugally separating and filtering the crude oil through a high-speed centrifuge to obtain the final peony seed oil.

Owner:甘肃省轻工研究院有限责任公司

Method and device for extracting prickly ash seed oil from prickly ash seeds

ActiveCN101812369ANon-combustible explosiveVolatileFatty-oils/fats refiningFatty-oils/fats productionCrusherPlunger pump

The invention relates to a method for extracting grease from oil material, in particular to a method for extracting prickly ash seed oil from prickly ash seeds. The method for extracting prickly ash seed oil from prickly ash seeds is characterized by comprising the following steps of: (1) firstly, drying the prickly ash seeds until the water content is smaller than 13%, and crushing to 40-80 meshes by using a crusher; (2) delivering the dried and crushed prickly ash seeds into an extracting kettle, pumping the vacuum to the pressure below 1*10<4>Pa, and evacuating air in the extracting kettle; (3) then, pumping a tetrafluoroethane solution into the extracting kettle by using a plunger pump until the prickly ash seeds are emerged under the liquid level under the observation of a sight glass; (4) stirring, and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature range is 40-50 DEG C, and the extraction time is 30-45 min each time; (5) depressurizing and raising temperature to evaporate and separate in a separating kettle, wherein the separation pressure range is 0.5-0.1MPa, and the temperature range is 45-50 DEG C; and (6) after subcritical extraction, centrifugally separating and filtering the crude oil through a high-speed centrifuge to obtain the final prickly ash seed oil.

Owner:甘肃省轻工研究院有限责任公司

Method and device for extracting olive pomace oil from olive pomace

ActiveCN101805664ANon-combustible explosiveVolatileFatty-oils/fats refiningFatty-oils/fats productionPomacePlunger pump

The invention relates to a method for extracting grease from oil seeds, in particular to a method for extracting and recycling olive pomace oil from olive pomace. The method is characterized by comprising the following steps of: (1) drying the olive pomace until the water content is less than 13%, and crushing to 40-80 meshes by a crusher; (2) putting the dried and crushed olive pomace into an extraction kettle, vacuumizing until the pressure is less than 1*10<4>pa, and discharging air in the extraction kettle; (3) injecting a tetrafluoroethane solution into the extraction kettle by a plunger pump until the level of the solution submerges raw materials of the olive pomace by using a sight glass for observation; (4) starting stirring and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature is 40-50 DEG C, and the extraction time is 45min; (5) decompressing, raising temperature, evaporating and separating in a separation kettle, wherein the extraction pressure is 0.1-0.5Mpa, and the temperature is 40-50 DEG C; and (6) after subcritical extraction, centrifuging to separate crude oil by a high-speed centrifuge, and filtering to obtain the final olive pomace oil.

Owner:LONGNAN XIANGYU OIL OLIVES DEV

High-temperature biomass micron fuel

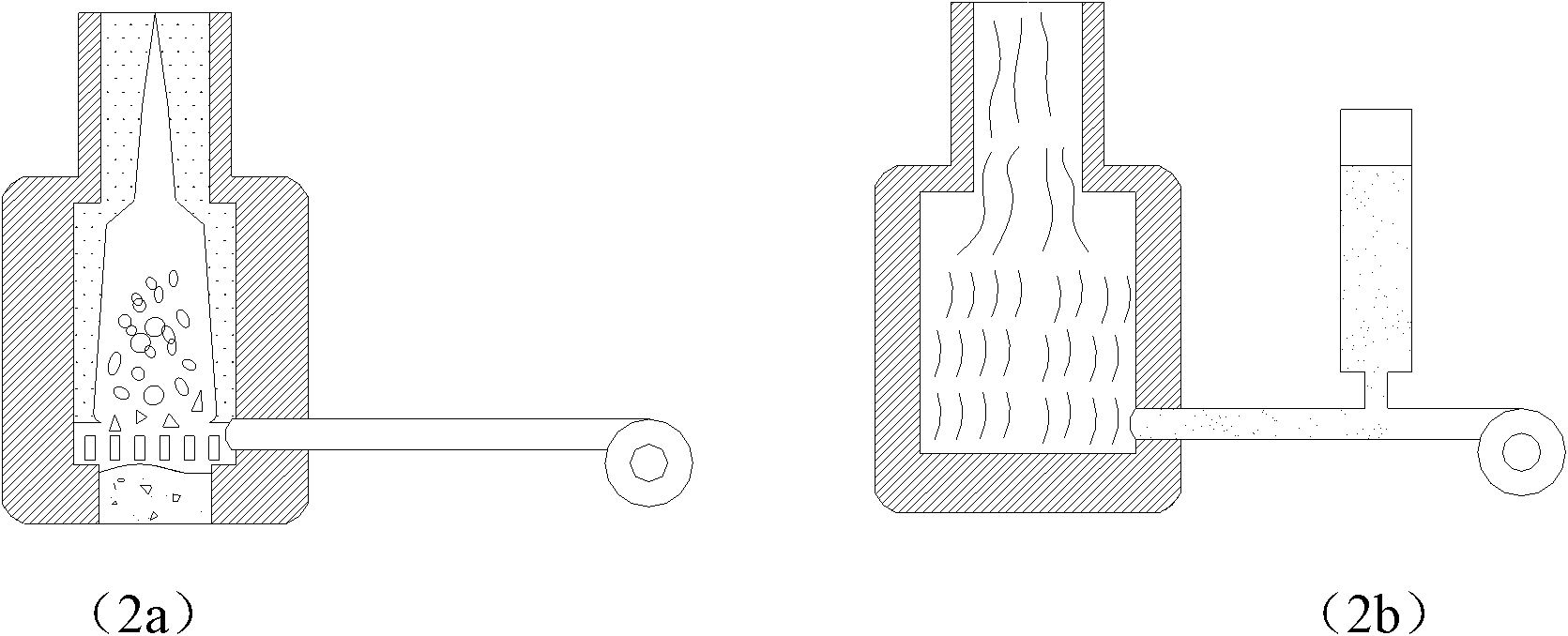

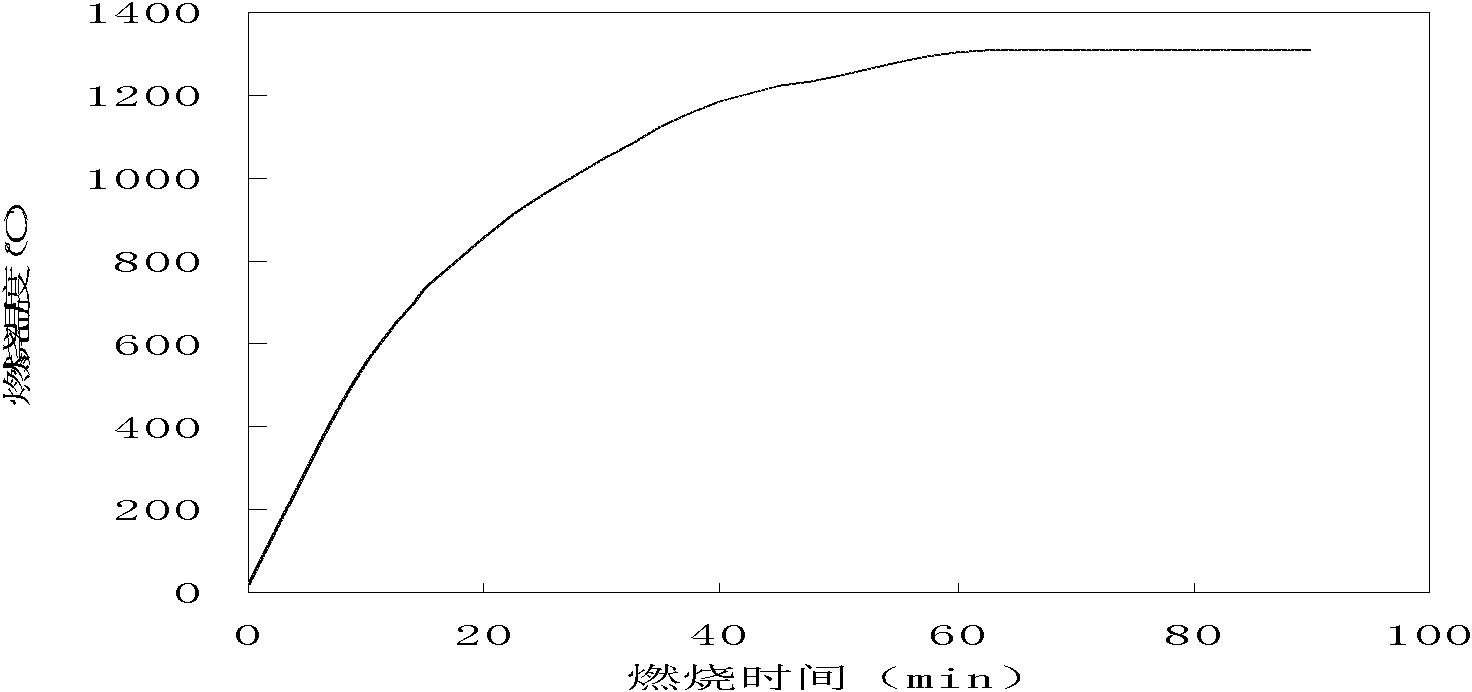

ActiveCN101935568ARaise the combustion temperatureEasy to control industriallyBiofuelsSolid fuelsVegetable fibersBiomass

The invention discloses a high-temperature biomass micron fuel. The high-temperature biomass micron fuel comprises 75 to 100 mass percent of vegetable fiber powder and the balance of additive, wherein the additive is at least one of coal powder, lime powder and red mud; and more than 70 percent of the vegetable fiber powder has the grain diameter of less than 250 mu m. Because the specific surface area of the biomass micron fuel is large, the biomass micron fuel can finish solid-gas conversion instantly under the action of the high temperature of a hearth and is decomposed to be combustible gases such as hydrogen (H2), carbon monoxide, methane and the like; the combustible gases combust with oxygen rapidly and vigorously; the energy is released in an explosive model; a high-temperature effect is formed; and the combustion temperature can reach over 1,300 DEG C and the fuel efficiency is over 96 percent. Compared with the traditional method, the method using the high-temperature biomass micron fuel has the advantages that the combustion temperature is increased by about one time and the combustion efficiency is increased by more than one time. The common biomass fiber material can perform fluidization transportation by a micron technique so as to form a high-grade fluid fuel near the grade of fuel oil and fuel gas. The high-temperature biomass micron fuel can be widely applied to thermal power generation, metal melting, the desalination of sea water, urban heating, lime burning, heating air conditioners, industrial heating and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

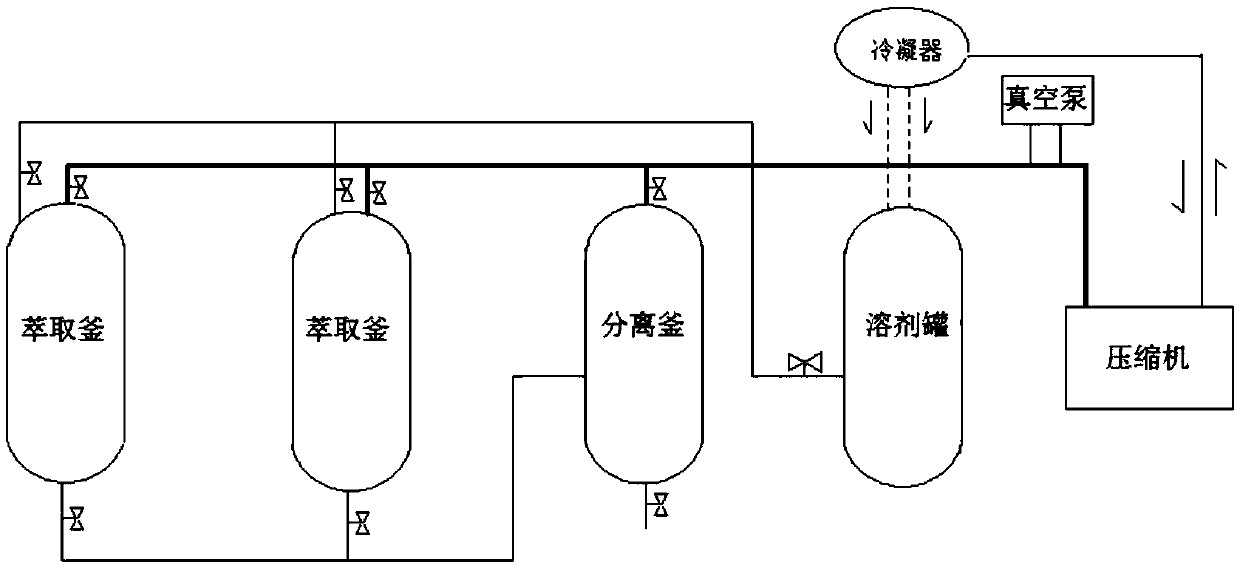

A method of extracting bay leaf oil from bay leaves with subcritical n-butane fluid

The invention relates to a method of extracting bay leaf oil from bay leaves with subcritical n-butane fluid. The method includes smashing, adding into a tank, dipping with an n-butane solvent, extracting, distilling, and the like. Extraction temperature and pressure can be accurately controlled by utilization of a subcritical extraction device. The method is high in extraction efficiency, low in device manufacturing cost, high in raw material treating amount, simple in process, low in production cost and free of solvent residue. A whole process of the method is performed at low temperature under an oxygen-free state. Extraction and separation are performed at the same time. The extraction speed is high. Recovery and reutilization of the solvent can be achieved.

Owner:郑州雪麦龙食品香料有限公司

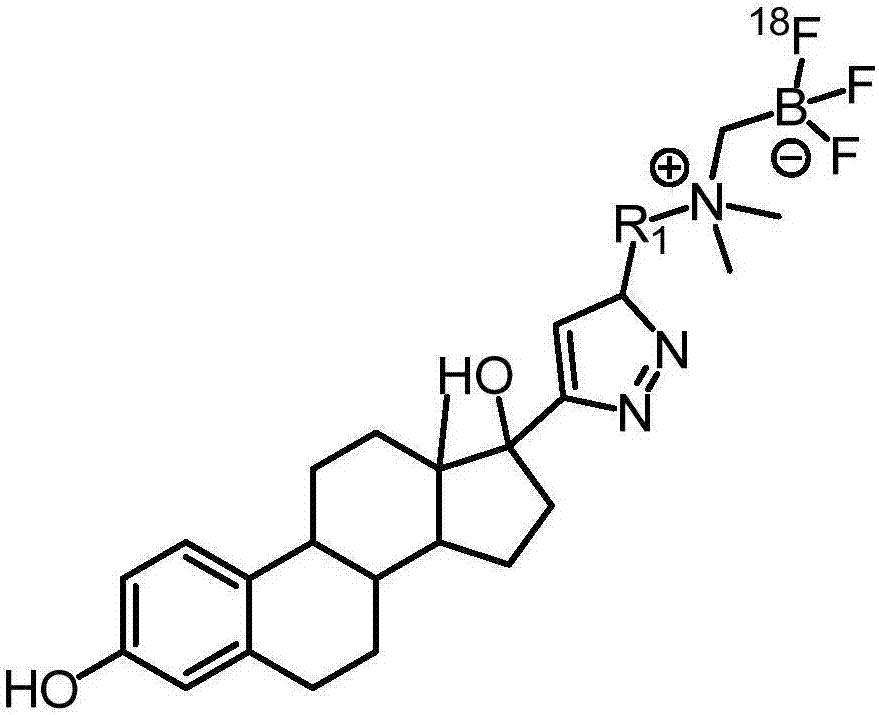

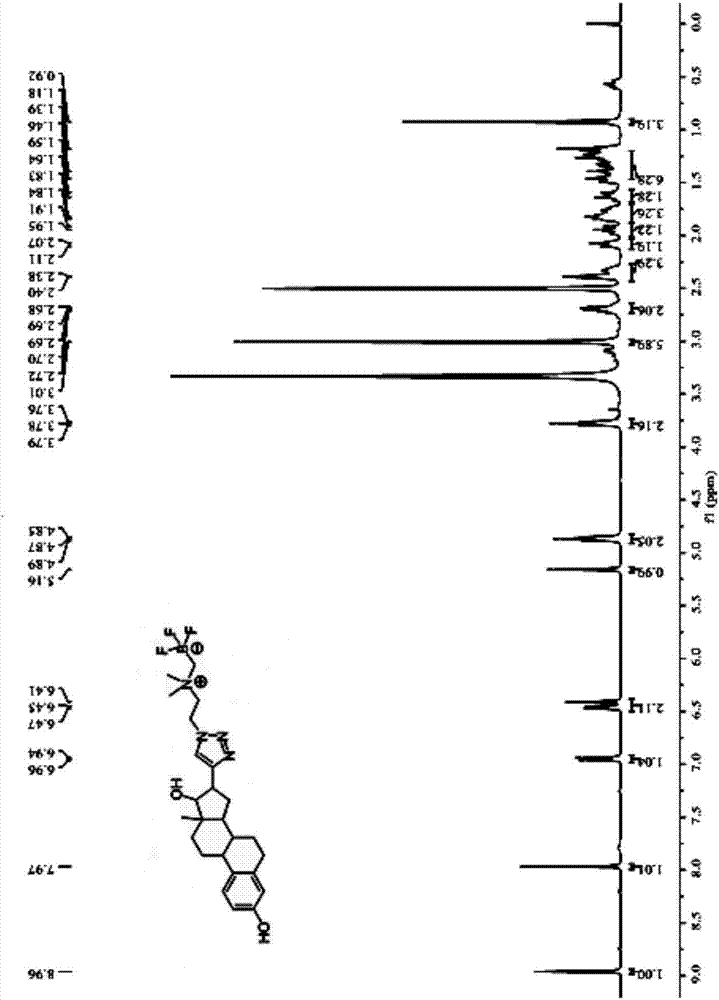

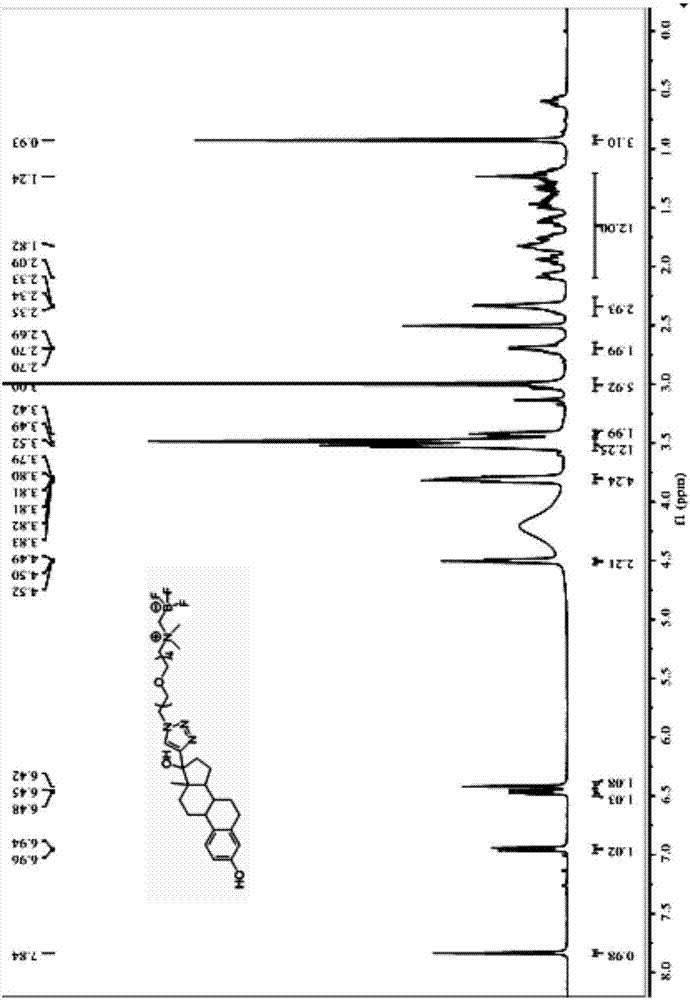

18F-labeled ethinyloestradiol and preparation method and application thereof

ActiveCN106977576AImprove biological activityImprove pharmacokinetic propertiesOrganic active ingredientsOrganic chemistry methodsMedicineCurative effect

The present invention relates to the field of medicinal chemistry, and in particular relates to 18F-labeled ethinyloestradiol and a preparation method and application thereof, a modifying group is introduced into ethinylestradiol, and the ethinylestradiol is labeled by 18F, and the 18F-labeled ethinyloestradiol has good bioactivity, excellent pharmacokinetic properties and good stability in vitro, can be better targeting to breast cancer ER + cells, and can be used as a PET tracer for early diagnosis or therapeutic effect evaluation of high metastatic breast cancer ER + cells. The invention also provides the preparation method of the 18F labeled ethinylestradiol, a labeling group is introduced into the ethinylestradiol as a raw material by Click reaction, and heated for being exchanged with 18F<-> under relatively mild conditions, a labeling step and purification time are simplified, the radiochemical yield of the 18F-labeled ethinyloestradiol is high, and commercial application and clinical promotion of radiolabeled compounds are facilitated.

Owner:JIANGSU INST OF NUCLEAR MEDICINE

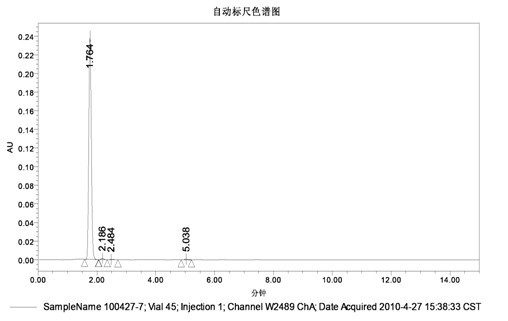

Polymer containing duel-tracer group and preparation method thereof

ActiveCN101381431AImprove hydrophilicityImprove adsorption capacityScale removal and water softeningMaterial analysis by optical meansPolymer scienceSide chain

The invention relates to the fields of industrial cooling water treating agent and water circular treatment, which provides a polymer containing a double-tracing group and a method for preparing the same. In the polymer, mixed water solution of an unsaturated fluorescence monomer containing trisulfonic acid, maleic anhydride, acrylic acid or itaconic acid, acrylamide or substituted acrylamide, an unsaturated monomer containing sulfonic acid and a non-ion monomer is subjected to copolymerization at a temperature of between 70 and 90 DEG C for 5 to 7 hours so as to obtain a single tracing copolymer with the side chain containing a trisulfonic acid tracing group; and the single tracing copolymer is added with 9-hydroxyxanthene and stirred under the conditions of avoiding light and room temperature for 40 and 60 hours, and is added with methanol for deposition, filtering and refinement, and the polymer containing the double-tracing group is obtained. Because the polymer contains two different structures of fluorescence groups, if the fluorescent background interference exists in the system, the concentration of the polymer can also be detected by another fluorescence group, and the concentration of the polymer in water can be quickly and accurately measured by the fluorescence or spectrophotometry, thereby improving the application range of the polymer.

Owner:JIANGSU JIANGHAI CHEM

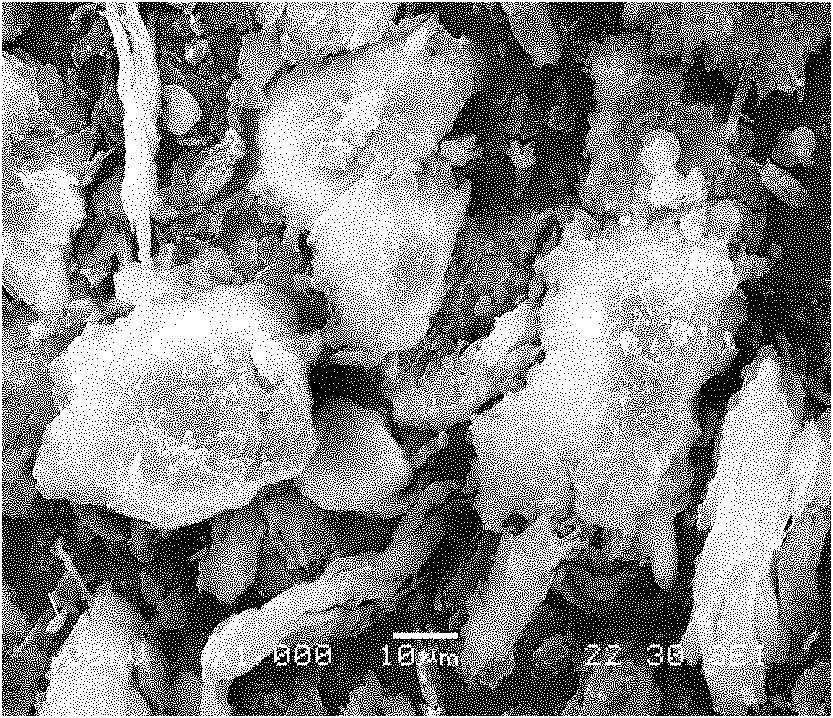

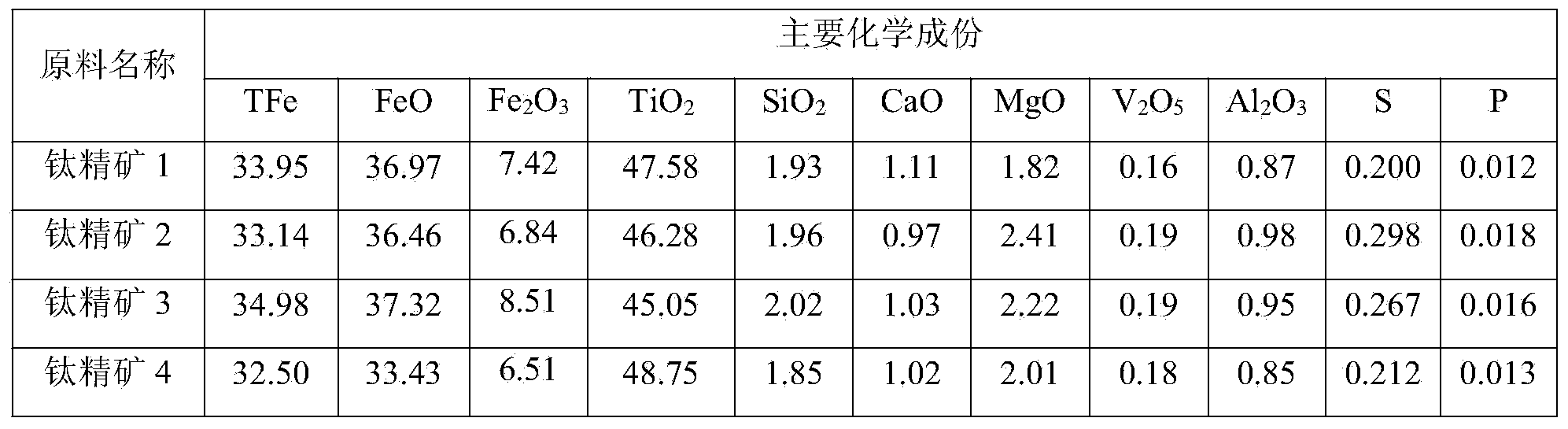

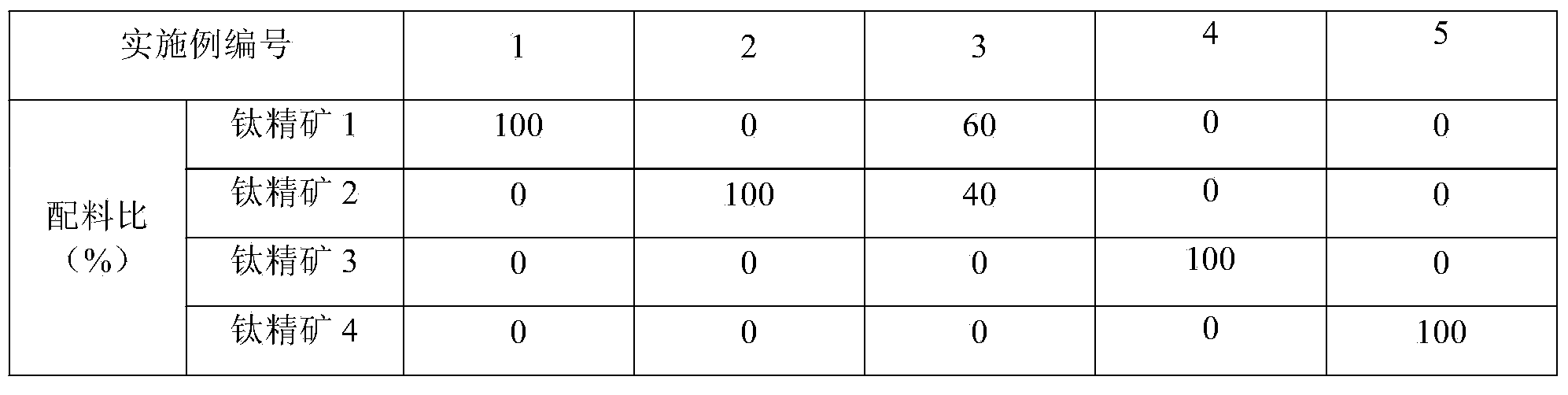

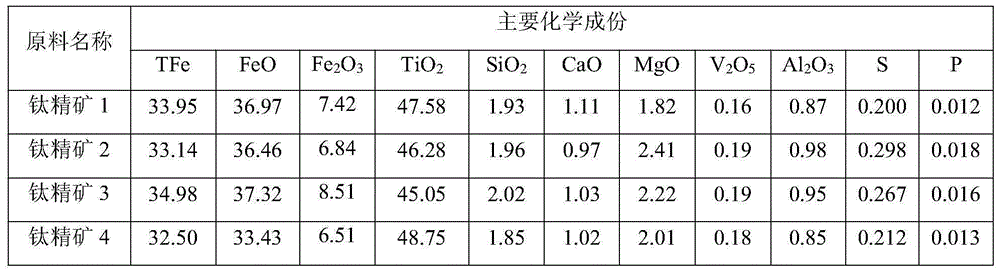

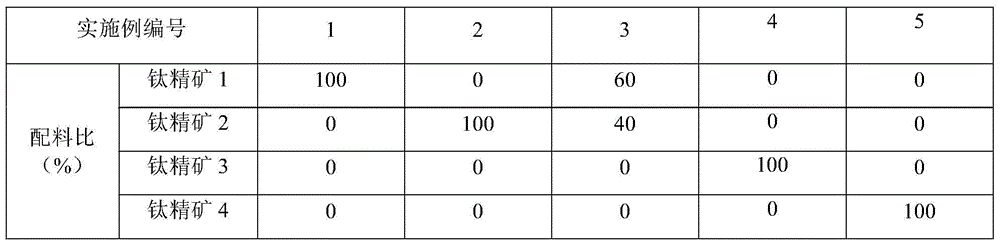

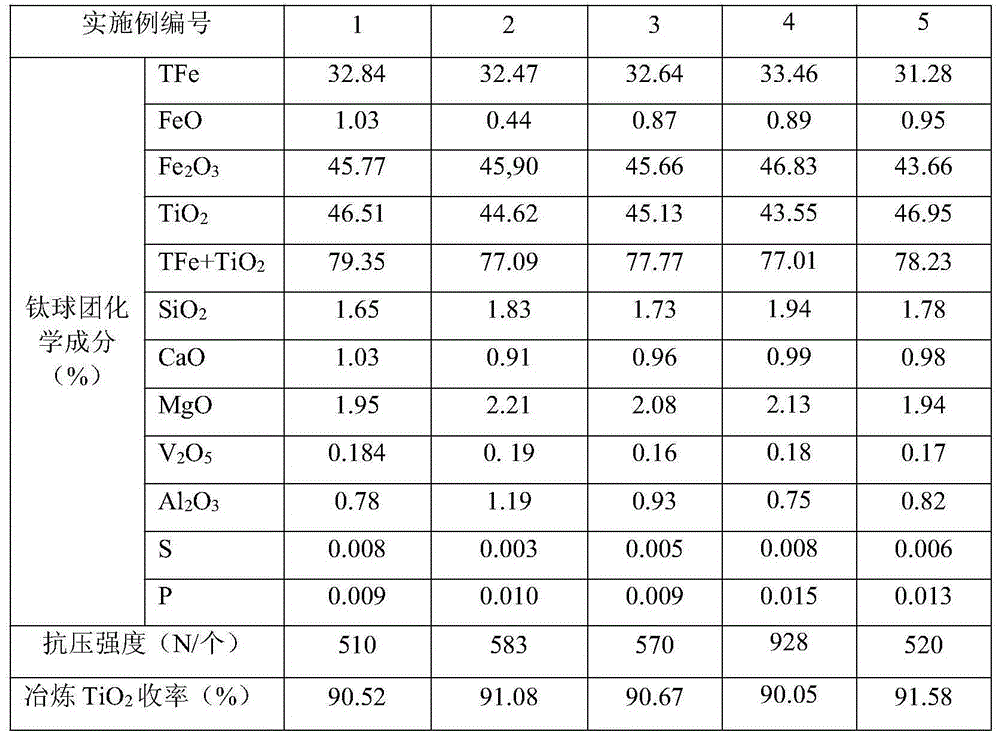

Titanium pellet for smelting high titanium slag and preparation method thereof

The invention belongs to the field of metallurgy, and particularly relates to a titanium pellet for smelting high titanium slag and a preparation method thereof. The titanium pellet for smelting high titanium slag comprises following main components: 41%-49% of TiO2, 31%-34% of TFe, 0.3-2% of FeO, and 42%-47% of Fe2O3, wherein the mass percent of the titanium pellet with particle size of 5mm-20mm is greater than 90%, the main raw material comprises titanium concentrate and an organic molding additive formed by mixing polyacrylamide and calcium oxide, and the organic molding additive accounts for 0.5%-1.0% the total mass of the titanium concentrate. The invention also provides the preparation method for the titanium pellet for smelting high titanium slag. The method comprises following steps of burdening, drying, finely grinding uniformly, rolling to mold, oxidizing roasting, and cooling. The titanium pellet prepared by the method is used for smelting high titanium slag.

Owner:攀枝花一立矿业股份有限公司

Tea alcoholization method

InactiveCN102823693AFast agingFlow balance breakPre-extraction tea treatmentTea flavoringVacuum pumpingHigh pressure

The invention discloses a tea alcoholization method and belongs to the technical field of tea processing methods. The tea alcoholization method comprises the following steps of 1, packaging fresh tea leaves, and carrying out vacuum-pumping until the pressure is in a range of 0.08 to 0.09MPa, 2, putting the packaged tea leaves into a cold isostatic high-pressure processor, raising pressure to 300-1000MPa at a pressure-raising rate of 250-350MPa / min in the presence of purified water as a cooling and pressure-transmitting medium having a temperature of 15 to 25 DEG C, keeping for 5-30min under the condition of static pressure, and fast releasing pressure, 3, after pressure releasing, taking out the treated tea leaf package, opening the treated tea leaf package, carrying out alcoholization of the tea leaves at a temperature of 18 to 35 DEG C for 0.5 to 10 hours, wherein laying thickness is in a range of 2 to 25cm, and 4, after the alcoholization, treating the tea leaves until water content of the tea leaves is below 10%. The tea alcoholization method has a reasonable design and simple processes, can effectively improve tea quality and can satisfy industrial production requirements.

Owner:TEA RES INST CHINESE ACAD OF AGRI SCI

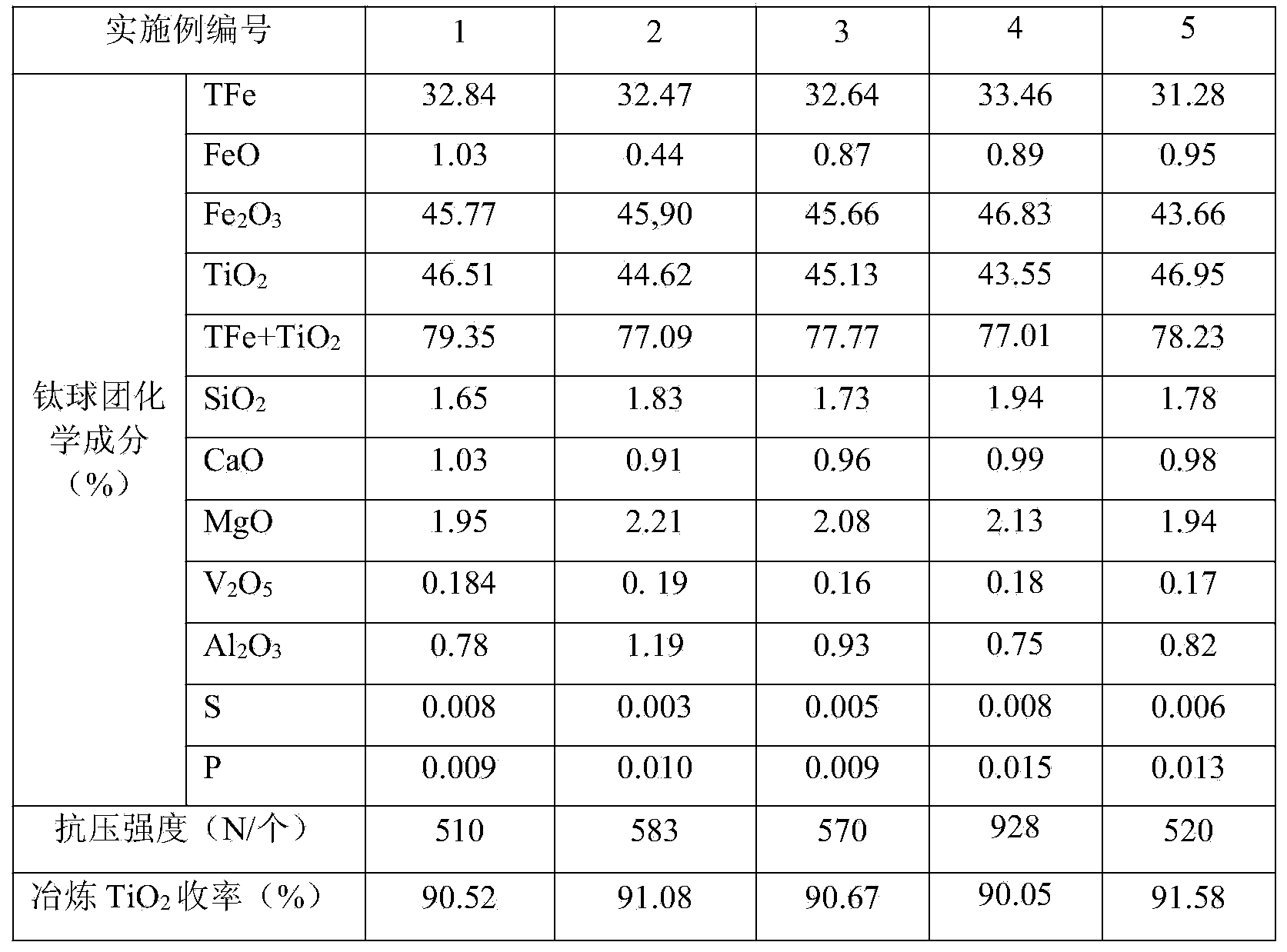

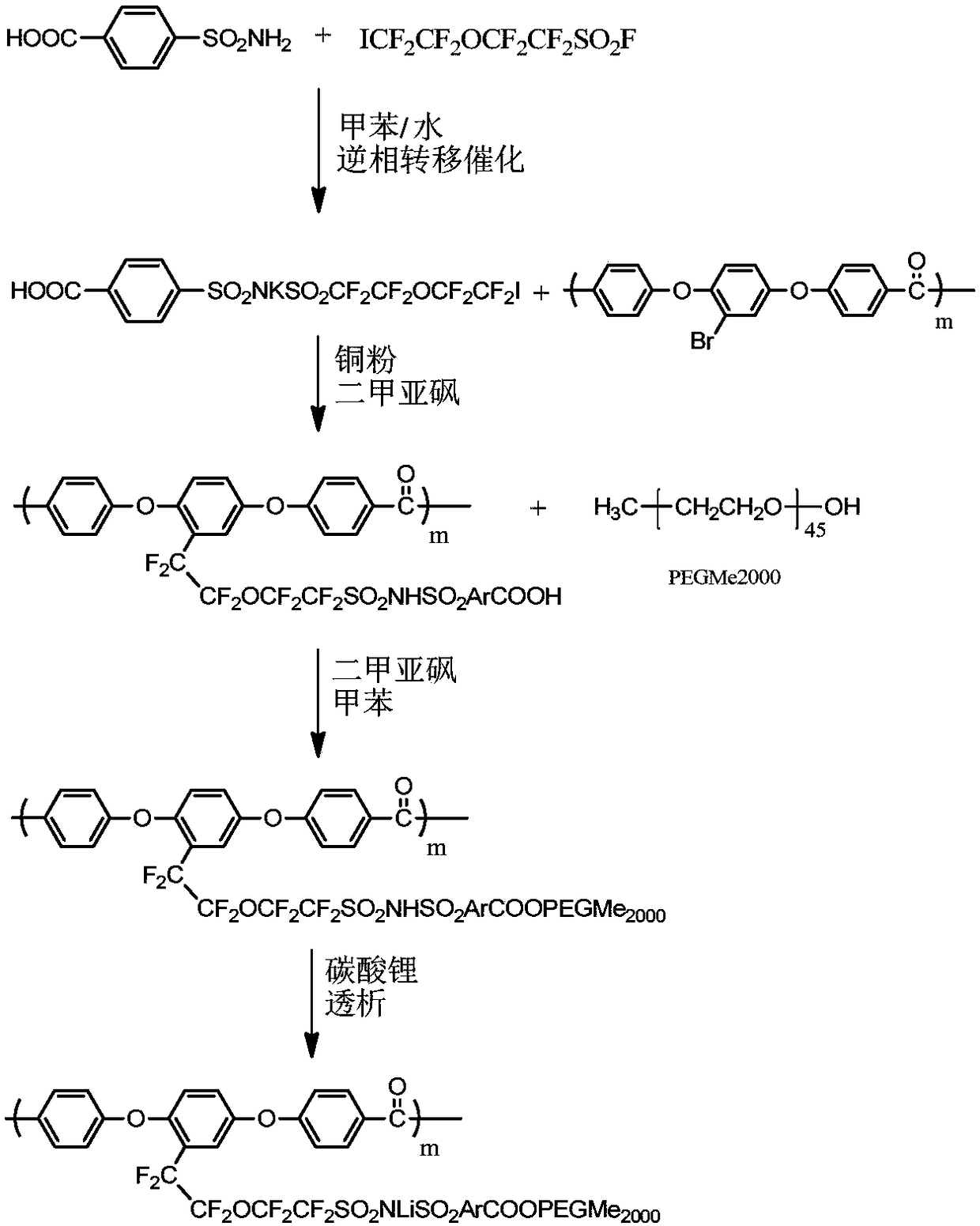

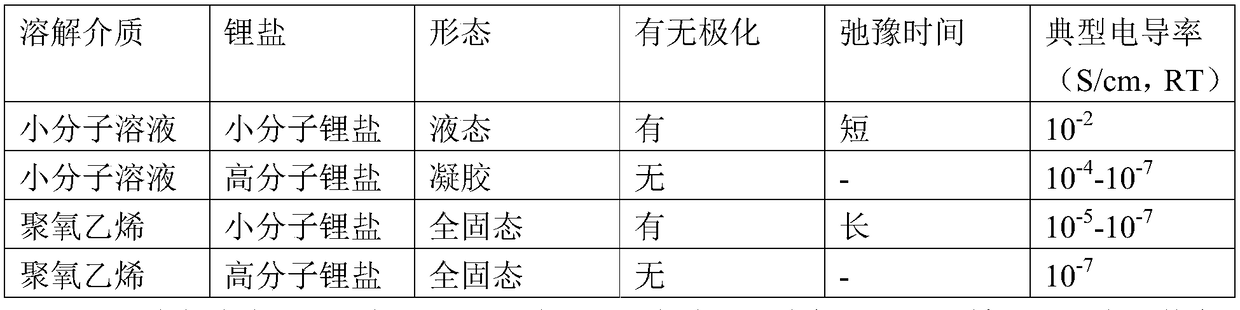

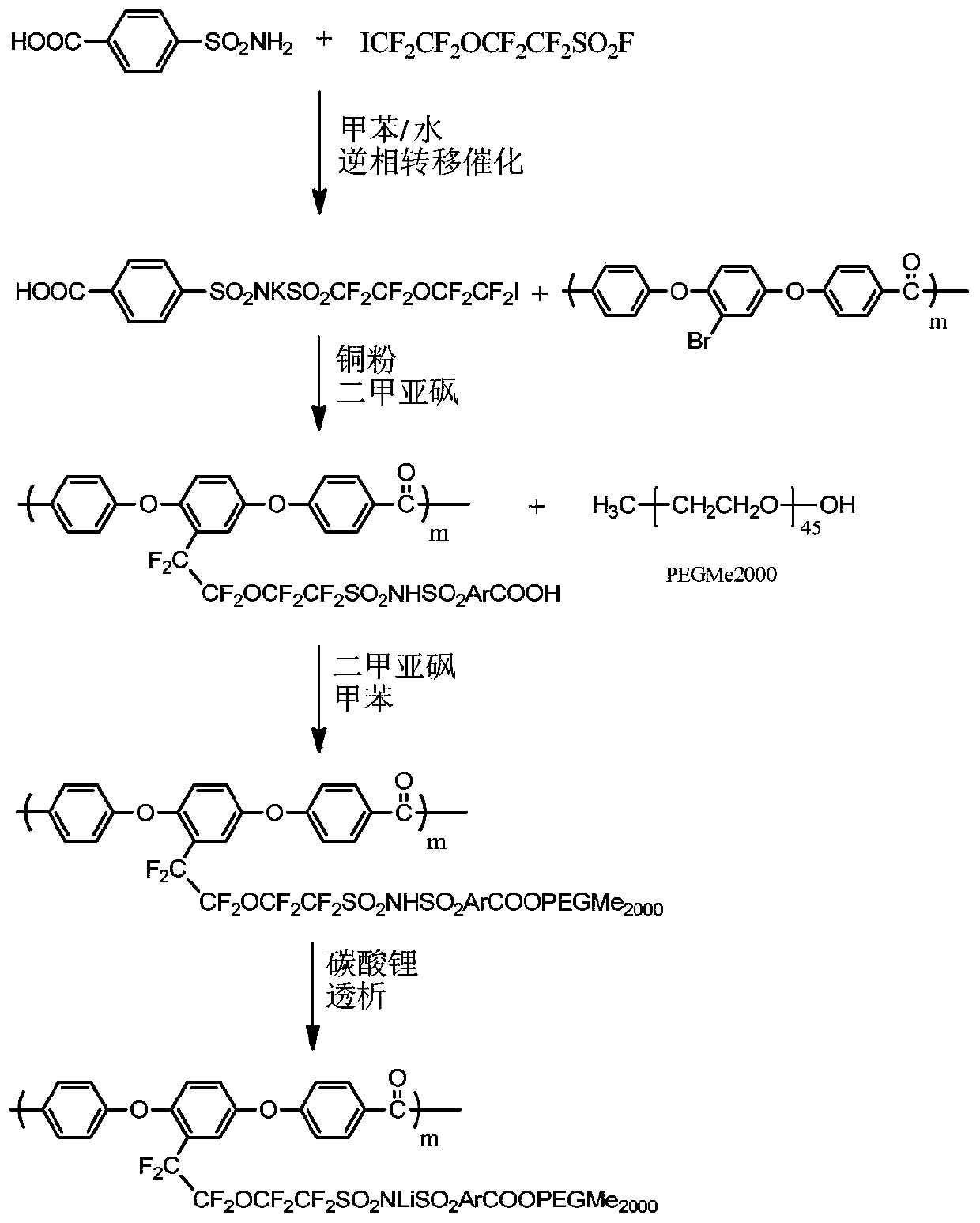

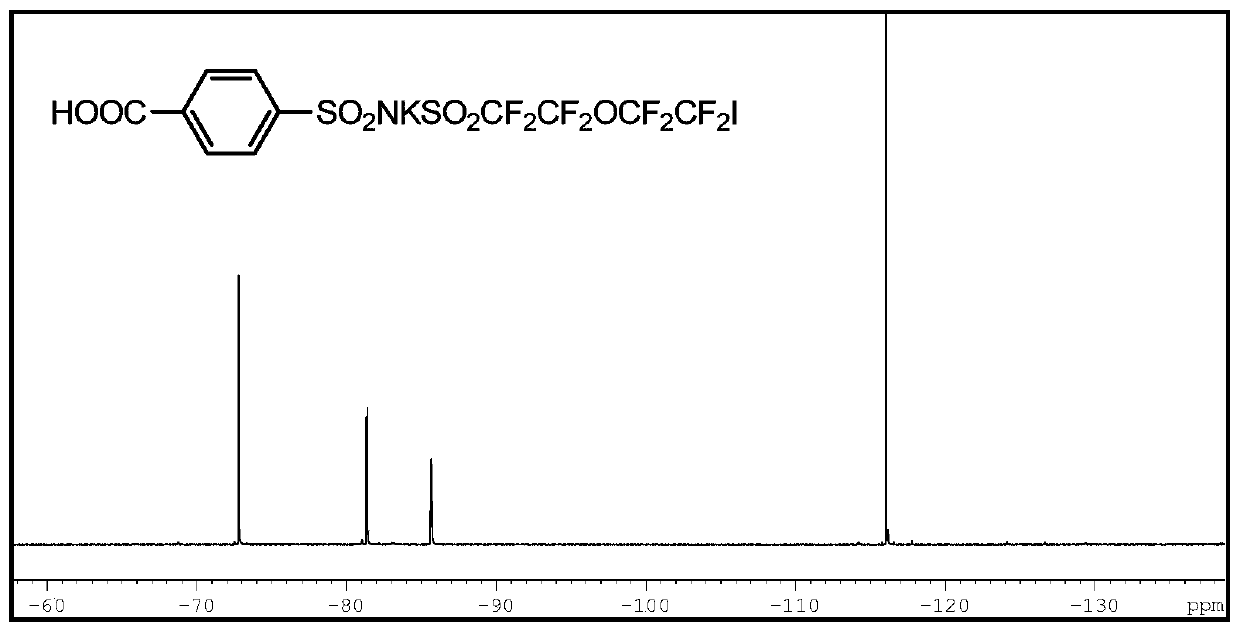

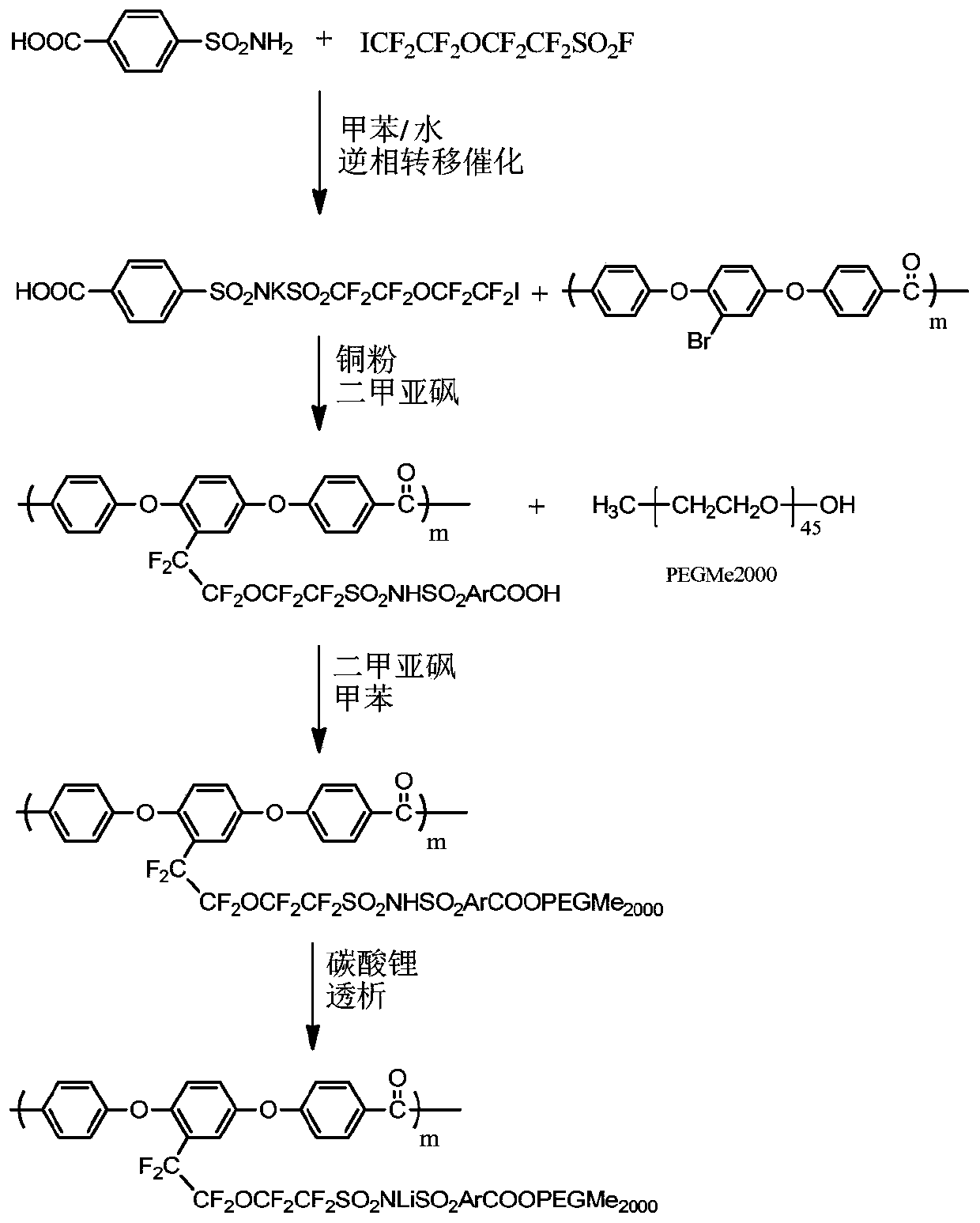

Self-plasticizing fluorine-containing polymer lithium ion conductor, preparation method and application thereof

ActiveCN108155414AFully contactedResolving Insufficient DissociationSolid electrolytesSecondary cellsElectrical conductorSide chain

The invention provides a self-plasticizing fluorine-containing polymer lithium ion conductor. The conductor comprises an aromatic polymer main chain and side chain fluorine-containing organic lithiumsalt, and a chain polyoxyethylene derivative tail end connected with the organic lithium salt, and as a polymer framework, lithium salt and a polyether chain segment serving as a dissolving medium arecombined in a chemical bond manner, and the lithium salt and the dissolving medium are in sufficient contact with each other and are interacted, the lithium salt can be furthest dissociated, and theconductivity is improved. The conductor can serve as novel all-solid-state polymer electrolyte to be applied to a lithium ion battery, so as to solve the problem that the current all-solid-state lithium ion battery cannot be applied at a room temperature because the conductivity is too low.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method and device for extracting tomato seed oil from tomato seeds

InactiveCN101812371AImprove solubilityGood solvent propertiesFatty-oils/fats refiningFatty-oils/fats productionOil and greaseSight glass

The invention relates to a method for extracting grease from oil material, in particular to a method for extracting tomato seed oil from tomato seeds. The method for extracting tomato seed oil from tomato seeds is characterized by comprising the following steps of: (1) firstly, drying the tomato seeds until the water content is smaller than 13%, and crushing to 40-80 meshes by using a crusher; (2) delivering the dried and crushed tomato seeds into an extracting kettle, pumping the vacuum to the pressure below to 1*10<4>Pa, and evacuating air in the extracting kettle; (3) then, pumping a tetrafluoroethane solution into the extracting kettle by using a plunger pump until the tomato seeds are emerged under the liquid level under the observation of a sight glass; (4) stirring, and extracting, wherein the extraction pressure is 1.0-1.2Mpa, the temperature range is 40-45DEG C, and the extraction time is 40-50min each time; (5) depressurizing and raising temperature to evaporate and separate in a separating kettle, wherein the separation pressure range is 0.5-0.1MPa, and the temperature range is 45-50DEG C; and (6) after subcritical extraction, centrifugally separating and filtering the crude oil through a high-speed centrifuge to obtain the final tomato seed oil.

Owner:甘肃省轻工研究院有限责任公司

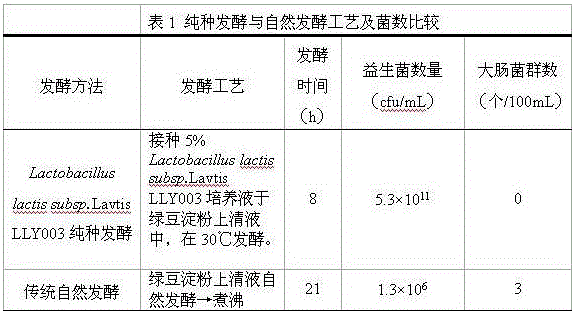

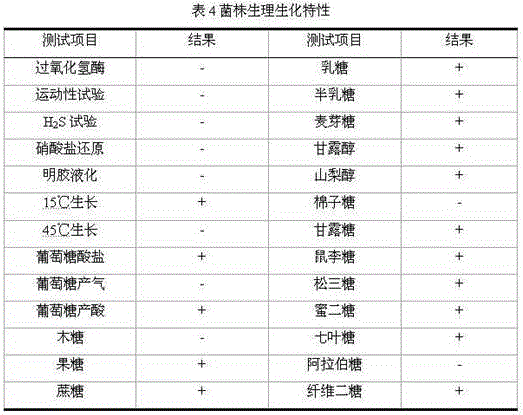

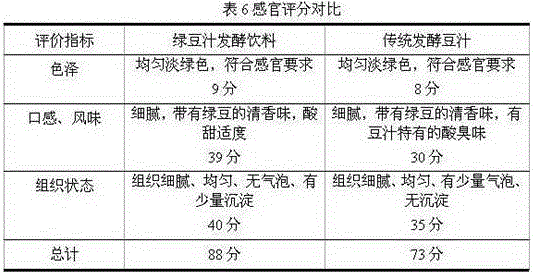

Lactobacillus lactis subsp.Lavtis LLY003, and applications thereof in living bacterium-type mung bean juice fermented beverage

ActiveCN106399164AGrow fastIncrease acidityBacteriaMicroorganism based processesNutritionFood flavor

The invention discloses Lactobacillus lactis subsp.Lavtis LLY003. Nutritional requirement of Lactobacillus lactis subsp.Lavtis LLY003 is simple, it is suitable for Lactobacillus lactis subsp.Lavtis LLY003 to grow in mung bean starch supernate prepared via only adding of a carbon source, and Lactobacillus lactis subsp.Lavtis LLY003 is capable of achieving key effects in bean juice fermentation. Lactobacillus lactis subsp.Lavtis LLY003 is capable of growing rapidly in bean juice fermentation, generating acid, and simplifying fermentation process, is suitable for production under existing conditions of the domestic manufacturers, and is capable of shortening production period. Pure bacterium fermentation of bean juice is capable of increasing safety factor and nutritional value of bean juice greatly; and flavor substances generated via lactobacillus metabolism are capable of improving the flavor of bean juice. Lactobacillus lactis subsp.Lavtis LLY003 is capable of maintaining the natural faint scent of mung bean; and the obtained living bacterium-type mung bean juice fermented beverage is a functional beverage high in nutritional value.

Owner:JINZHOU MEDICAL UNIV

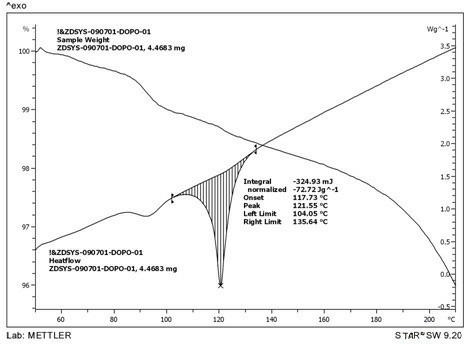

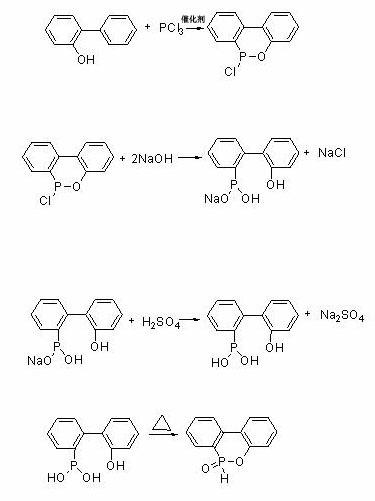

Method for preparing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide

InactiveCN102146097AReduce pollutionHigh yieldGroup 5/15 element organic compoundsPhosphoric acidAlkaline hydrolysis

The invention discloses a method for preparing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide. The method comprises the following steps: using phosphorus trichloride and o-phenylphenol to react and prepare an intermediate product 6-chloro-(6-hydro)-diphenyl[C,E][1,2]phosphaphenanthrene; (2) performing alkaline hydrolysis on the intermediate product to obtain a saline solution of the intermediate product, and filtering the saline solution to obtain filtrate; (3) acidizing the filtrate to obtain a crystal-solution mixture, filtering the crystal-solution mixture to obtain 2-hydroxybiphenyl-2-hypophosphorous acid crystal powder; and (4) heating the crystal powder to dewater, and then stirring and cooling to crystallize, thus obtaining a block material which is the target product. The method disclosed by the invention has the advantages of simplified technological conditions, low equipment investment, good production stability and suitability for industrialized production; and the prepared product has higher purity and yield.

Owner:SHANDONG TIANYI CHEM

Manufacturing method of gold plated and silvered ornament

The invention discloses a manufacturing method of a gold plated and silvered ornament. The manufacturing method comprises the following steps: substrate preparation, caulking groove processing, filling of metal materials in other colors and surface polishing and coloring. By adopting the methods such as machining, chemical corrosion and the like, a groove is machined at the substrate of the ornament, the ornament materials are molten at high temperature and then used to fill in the groove, and polishing is carried out to obtain the finished product; the manufacturing method is good in binding force, the finished product is firm and reliable, and not liable to fall off, and batch ornament production is easy to realize through the manufacturing process.

Owner:李泽琨 +2

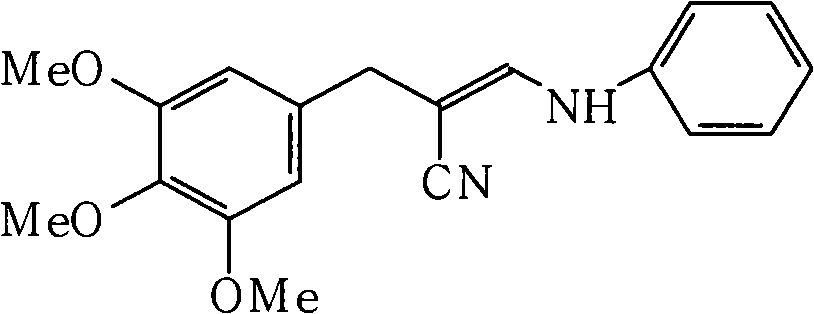

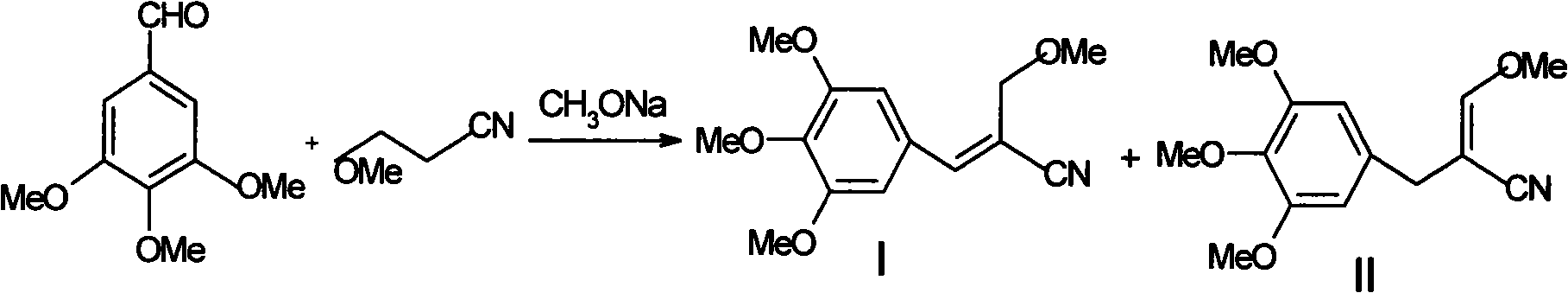

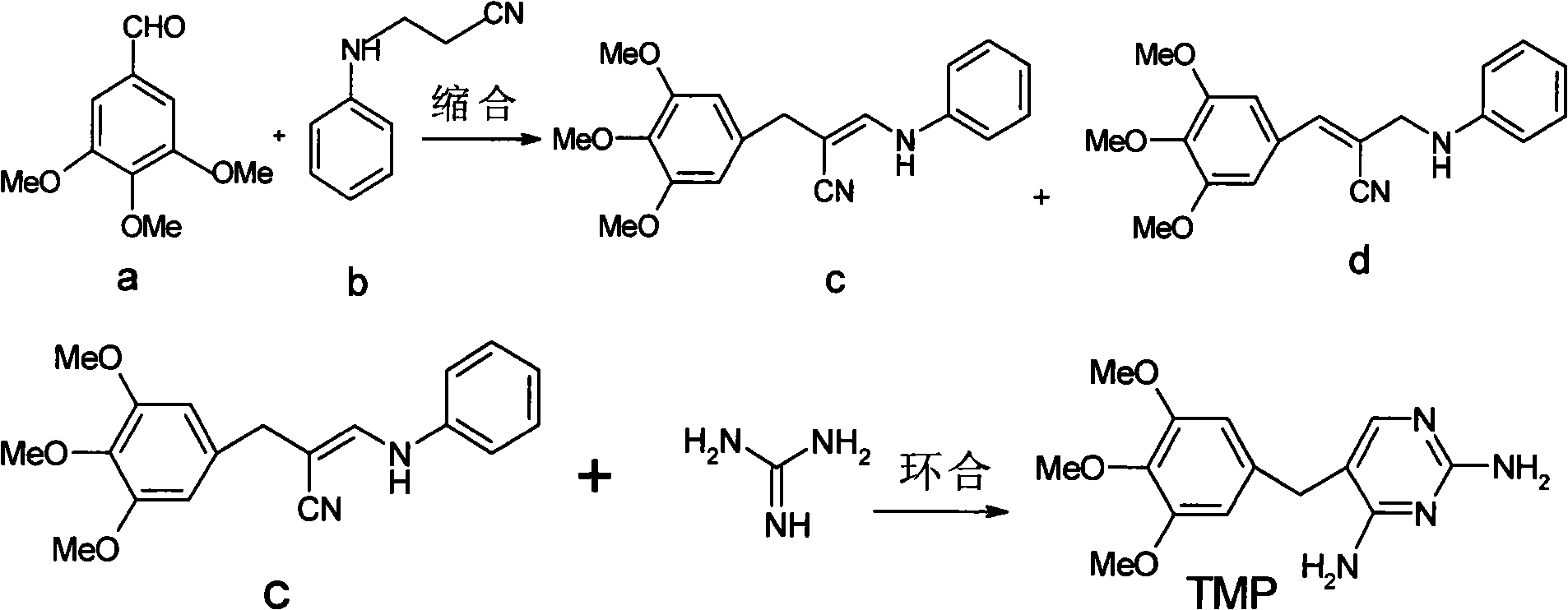

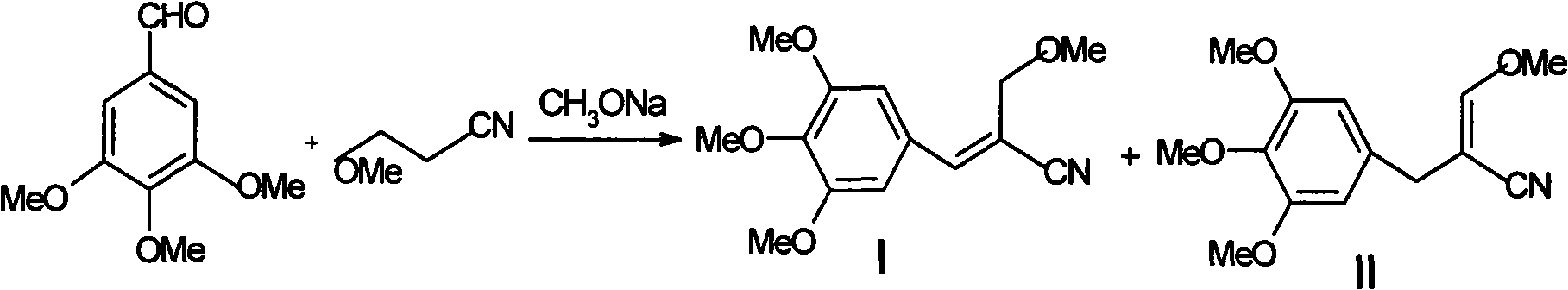

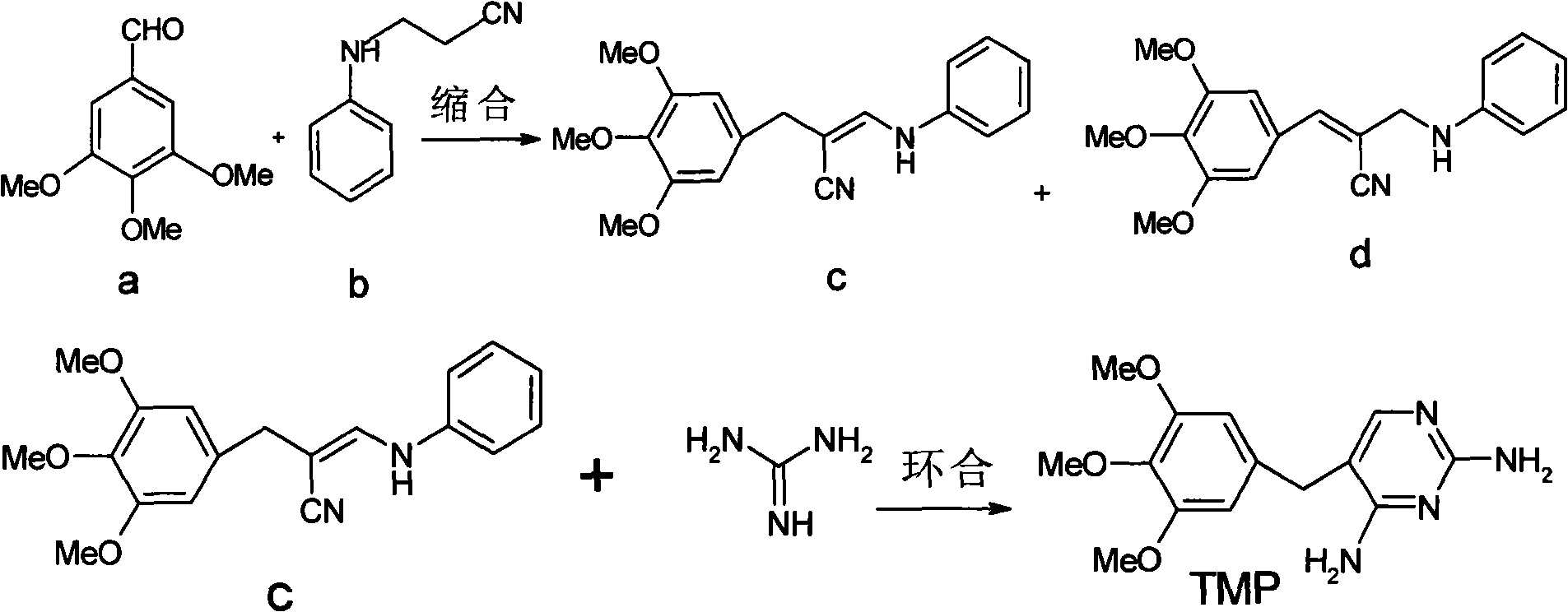

Preparation of trimethoprim and intermediate

The invention provides a method for preparing trimethoprim, comprising the following steps: (1) performing a condensation reaction by using 3,4,5-trimethoxybenzaldehyde and aniline propionitrile as raw materials; (2) performing a cyclization reaction among condensation reaction products and guanidine compounds; wherein an inertia solution is added in a reaction system in the step (1), in a reflux reaction water is brought to a water knockout vessel; and in the step (2) the condensation compound and the guanidine compounds are dissolved in ethanol, and are heated and reflowed. The preparation method of the invention is convenient in operation, high in yield low in cost and is easy to controlled in industry.

Owner:SHOUGUANG FUKANG PHARMA

Method of extracting shiny-leaf yellowhorn oil from shiny-leaved yellowhorn seeds

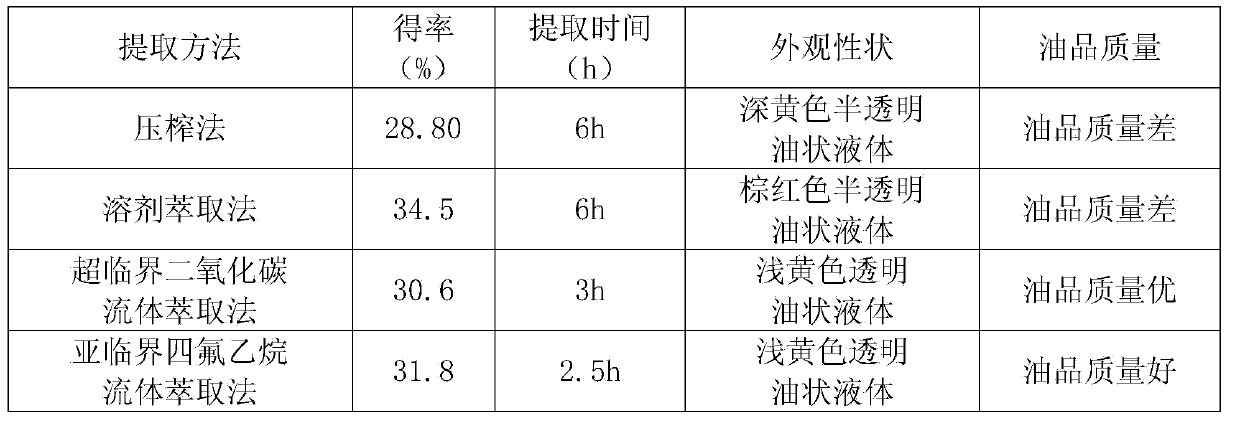

InactiveCN104212631AKeep natural colorBig investmentFatty-oils/fats productionFiltrationProcess conditions

The invention belongs to the field of plant grease extraction and particularly relates to a method for extracting shiny-leaf yellowhorn oil from shiny-leaved yellowhorn seeds by adopting a supercritical tetrafluoroethane fluid. The method for extracting shiny-leaf yellowhorn oil from shiny-leaved yellowhorn seeds comprises the following steps: crushing the shiny-leaf yellowhorn seed raw material to 40-60 meshes, and repeatedly extracting three times at 30-40 DEG C and 1.0-1.2MPa, wherein the extraction time every time is 30-40 minutes; pumping negative pressure by using a diagram compressor at the separating temperature of 45-55 DEG C and gradually reducing the pressure to 5*10<-2>Pa, and repeatedly separating three times, 20-30 minutes per time; and finally, carrying out centrifugal separation and filtration on the crude shiny-leaf yellowhorn oil by a high speed refrigerated centrifuge to obtain a shiny-leaf yellowhorn oil product. Experiments verify that the yield of the shiny-leaf yellowhorn oil under the above process conditions is 31.8%, and the product quality is good.

Owner:甘肃省轻工研究院有限责任公司

Chemical nickel phosphor plating solution for surface acidity of sintered NdFeB magnet, and nickel phosphor plating process

InactiveCN105369226AUniform thicknessReduce porosityLiquid/solution decomposition chemical coatingNickel saltMetallurgy

The invention relates to a chemical nickel phosphor plating solution for surface acidity of a sintered NdFeB magnet. The pH value of the chemical nickel phosphor plating solution is 4.5 to 5.0, and the chemical nickel phosphor plating solution comprises dissoluble nickel salt, a reducing agent, a composite complex agent, a buffer agent, a promoter and a stabilizer. The nickel phosphor plating process comprises the following steps: (1), carrying out ultrasonic acid pickling on the sintered NdFeB magnet for 20 to 40s, then carrying out ultrasonic water washing and regular water washing; (2), under a temperature of 55 to 60 DEG C, carrying out ultrasonic alkaline washing for 5 to 12 min, then carrying out ultrasonic water washing and regular water washing; (3), carrying out ultrasonic activation for 20 to 40s at a room temperature; and (4), placing into the nickel phosphor plating solution, carrying out ultrasonic plating for 60 to 180 min, and then carrying out water washing and drying. The nickel phosphor plating solution is environment friendly and has less pollution to the environment, an obtained clad layer is even in thickness, the porosity is low, magnetism loss is avoided, and corrosion resistance is excellent; and the nickel phosphor plating process is simple, the cost is low, and the binding force of the clad layer and a basal body is strong.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

Method and device for extracting olive pomace oil from olive pomace

ActiveCN101805664BImprove solubilityGood solvent propertiesFatty-oils/fats refiningFatty-oils/fats productionOil and greaseCrusher

Owner:LONGNAN XIANGYU OIL OLIVES DEV

Process for enriching high-purity catechin

A process for enriching high-purity catechin includes such steps as dissolving tea extract in solvent, filtering, slowly adding crystallizing solvent at 4-6 deg.C until the catechin is fully separated out, stirring, standing, filling nitrogen gas, vacuum filtering, dissolving the dregs in same solvent, precipitation, filling nitrogen gas, repeating same steps at least 3 times, dissolving filter residue in distilled water, and freeze drying. Its advantages are high yield and low cost.

Owner:ZHEJIANG UNIV

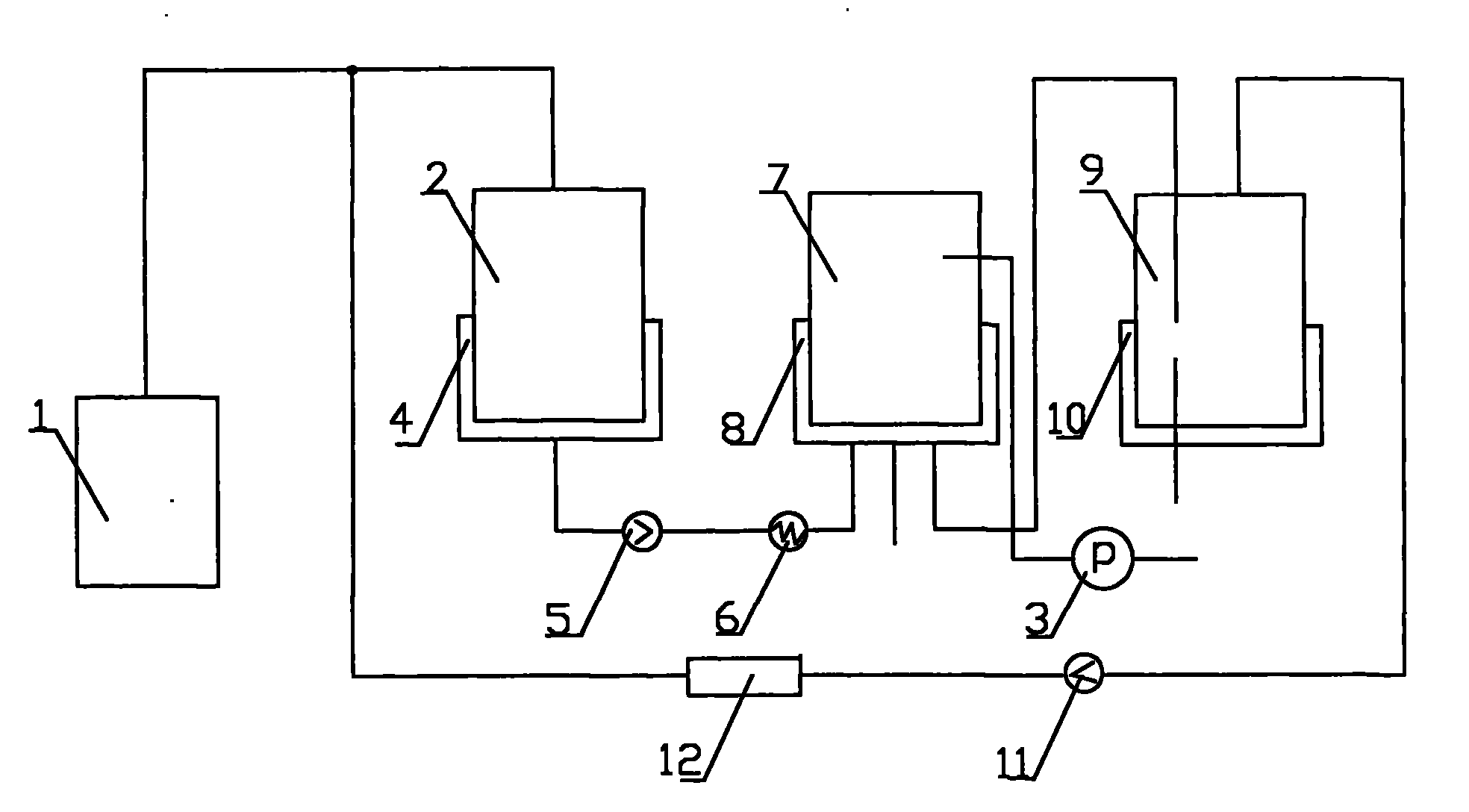

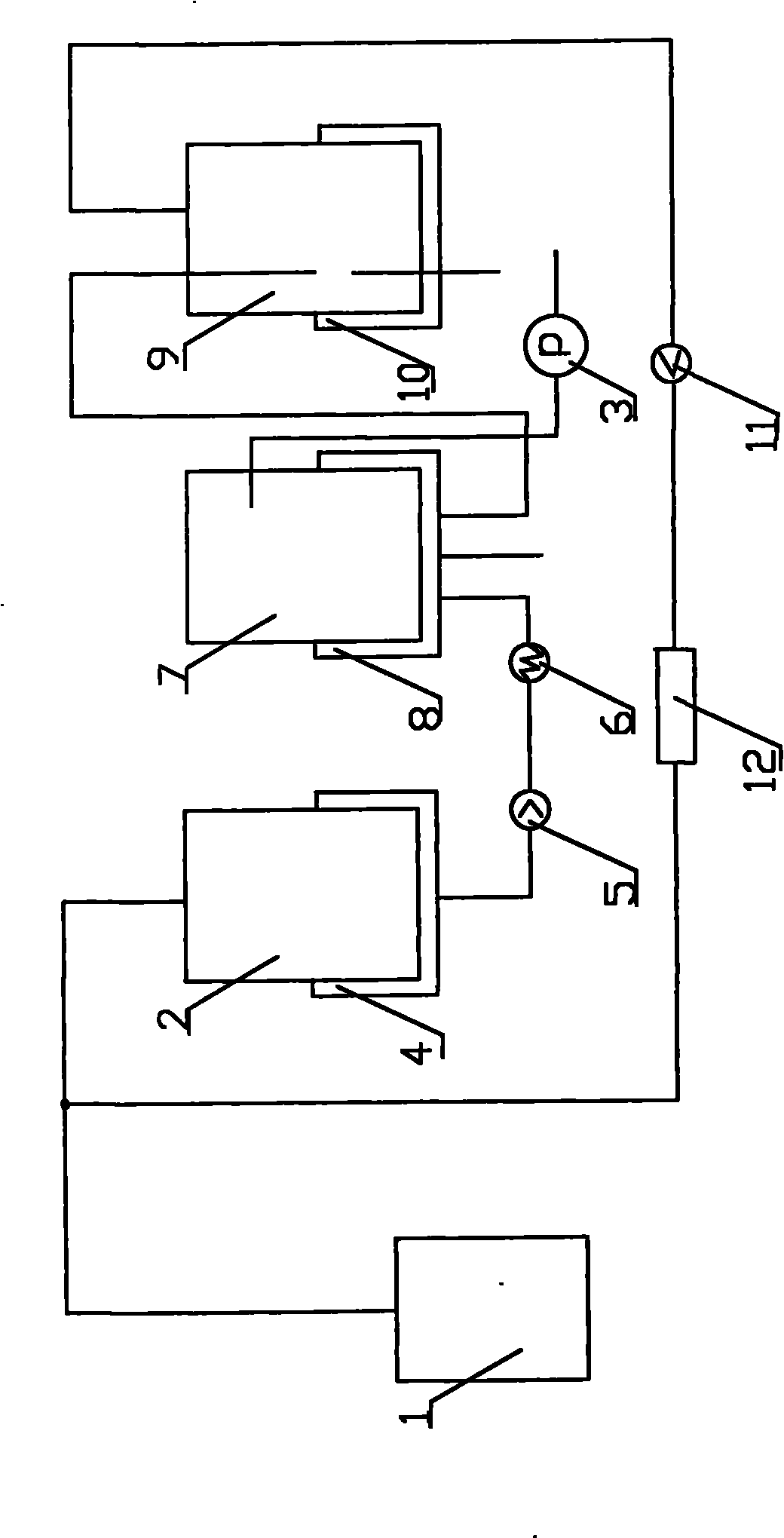

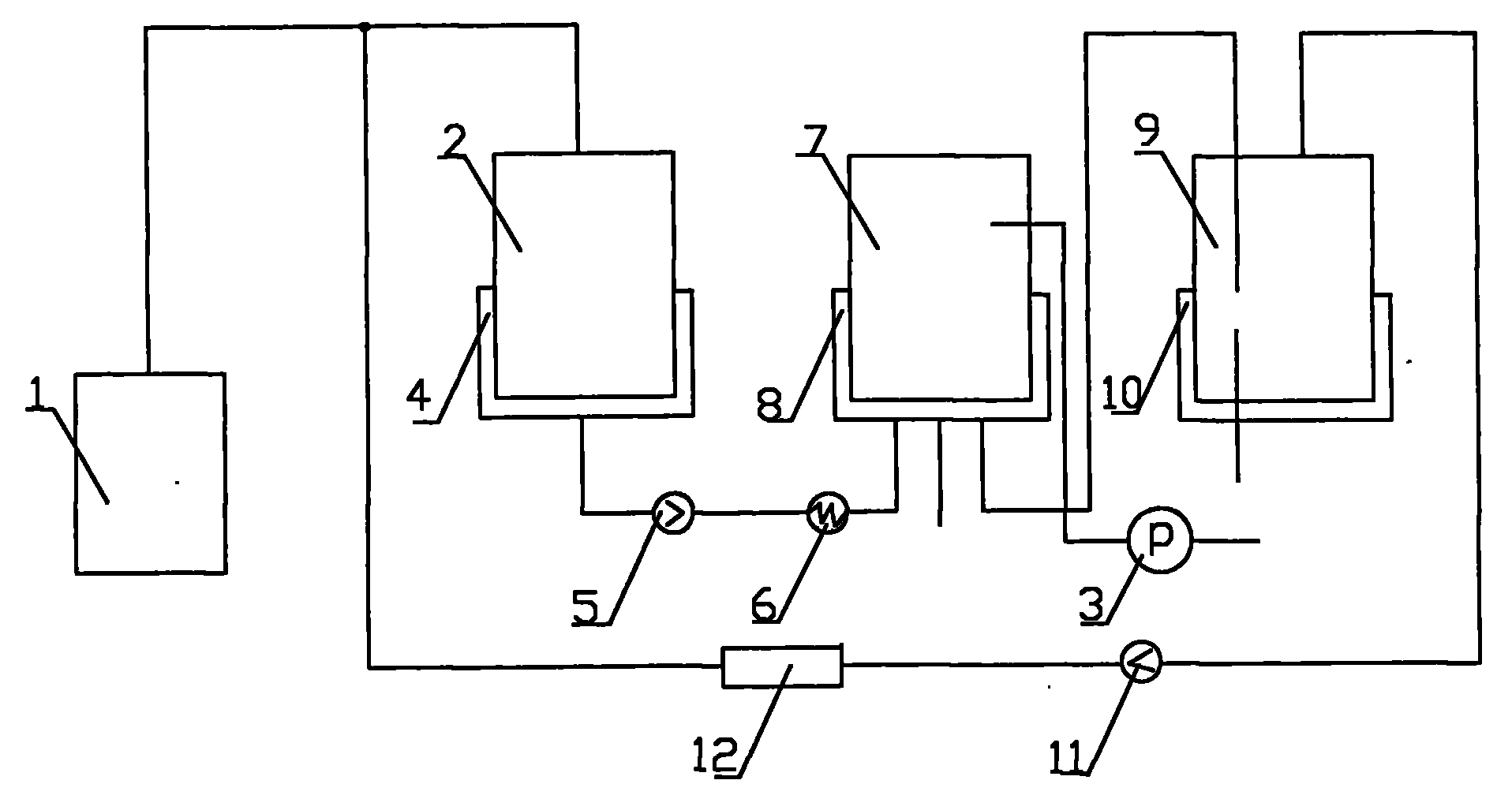

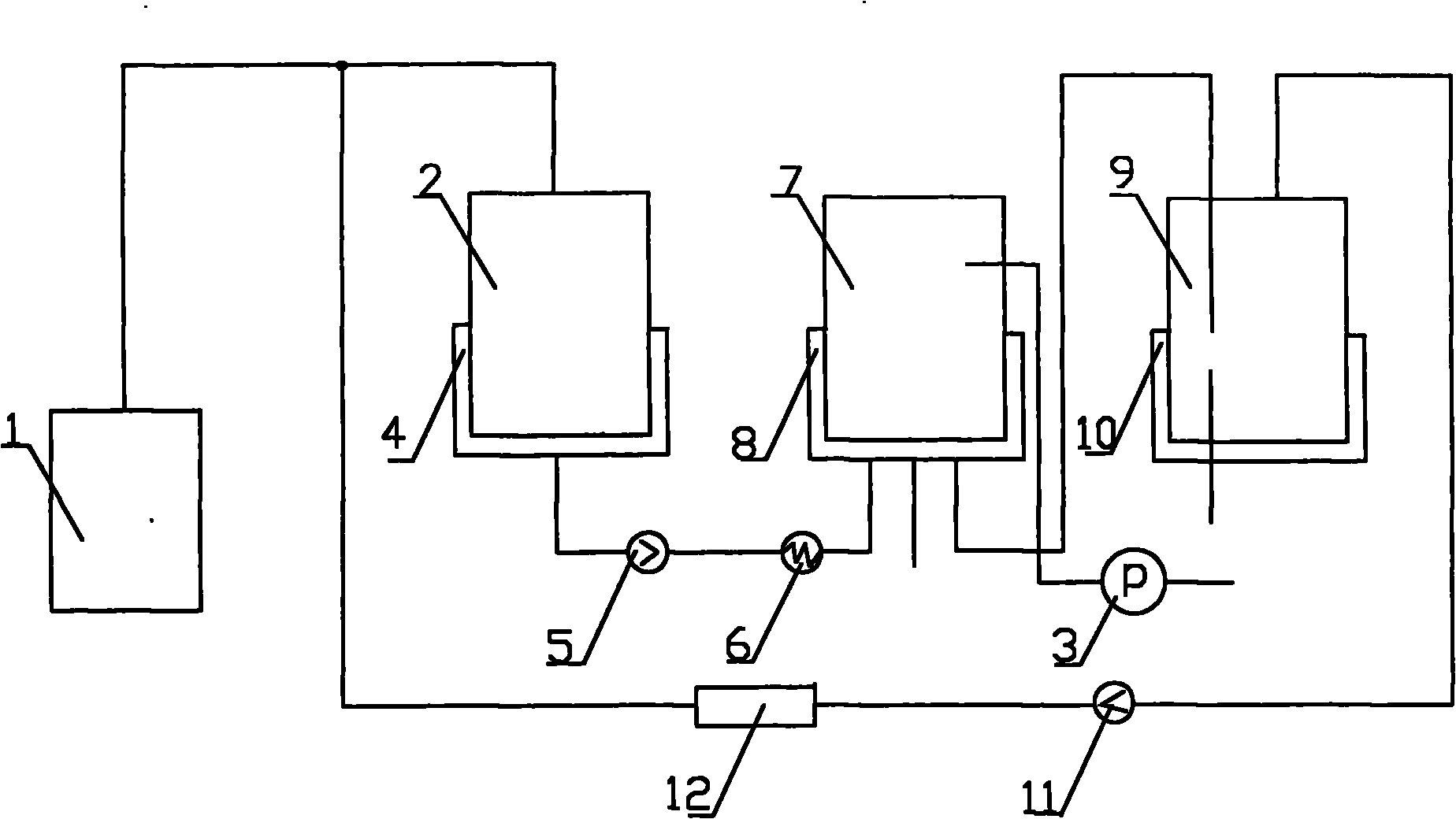

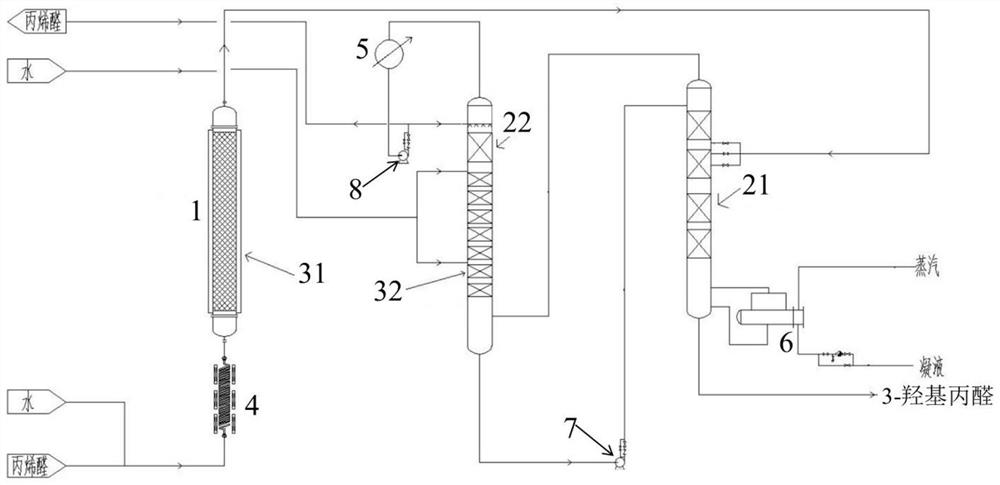

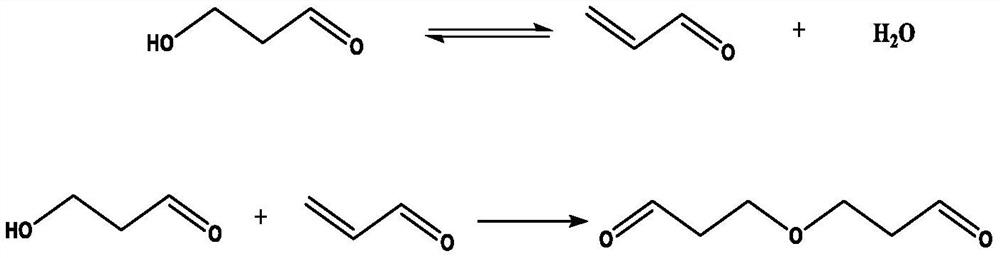

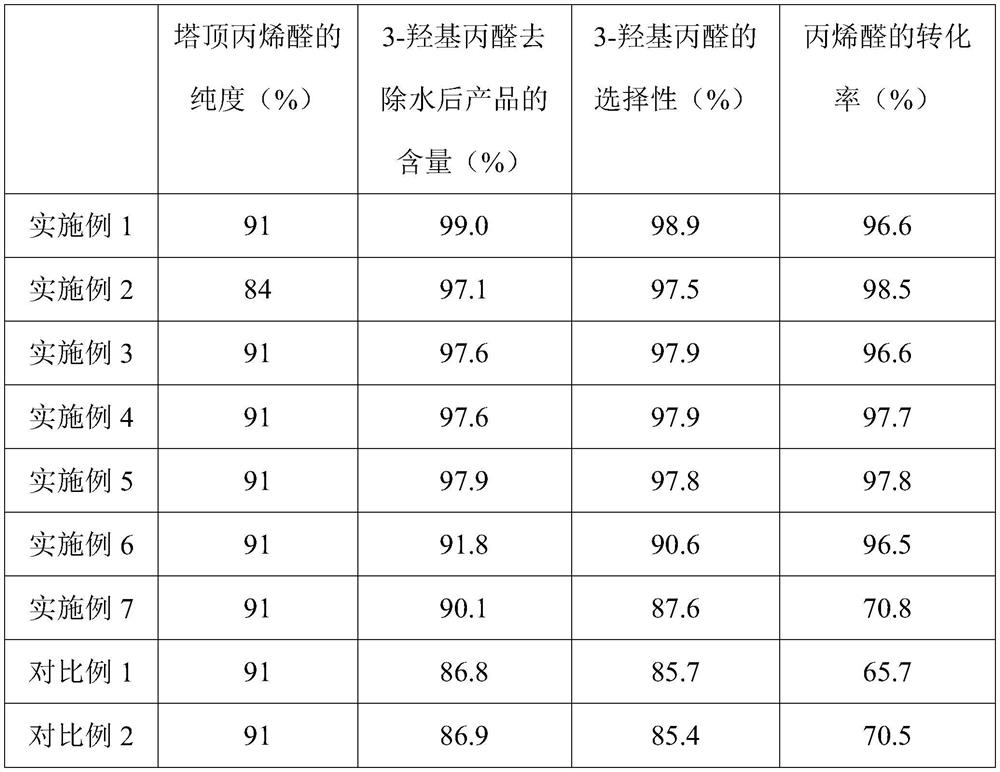

Method and device for preparing 3-hydroxypropionaldehyde through continuous catalytic rectification

ActiveCN113277933AImprove conversion rateResolve recovery rateOrganic compound preparationChemical industryHydration reactionPtru catalyst

The invention provides a method and device for preparing 3-hydroxypropionaldehyde through continuous catalytic rectification. The method comprises the steps of (1) mixing acrolein and water, and carrying out a hydration reaction on the obtained mixed solution under the action of a first catalyst to obtain a hydration reaction product; and (2) carrying out continuous catalytic rectification on the hydration reaction product obtained in the step (1), upwards conveying acrolein, continuously carrying out hydration reaction under the action of a second catalyst, and downwards conveying 3-hydroxypropionaldehyde generated by the hydration reaction in the steps (1) and (2) to realize separation of 3-hydroxypropionaldehyde and acrolein, thereby obtaining the 3-hydroxypropionaldehyde product. According to the method, reaction and rectification are coupled together, the conversion rate of acrolein can be increased to be greater than or equal to 96%, the selectivity of 3-hydroxypropionaldehyde is increased to be greater than or equal to 90%, and meanwhile, the content of 3, 3 '-oxybis-1-propionaldehyde by-products in the hydration process is effectively reduced through the method.

Owner:JIANGSU YANGNONG CHEM GROUP

Polymer containing duel-tracer group and preparation method thereof

ActiveCN101381431BImprove hydrophilicityImprove adsorption capacityScale removal and water softeningMaterial analysis by optical meansPolymer scienceFluorescence

Owner:JIANGSU JIANGHAI CHEM

A kind of preparation method of cyclohexane-1,2-dicarboxylate plasticizer

ActiveCN107417523BEasy to manufactureExtended service lifeOrganic compound preparationCarboxylic acid esters preparationPtru catalystAlcohol

The invention discloses a production method of cyclohexane-1,2-dicarboxylate plasticizer, which proceeds through the following steps: 1. Preparation of composite catalyst: hydrogen sulfate and metal powder with a particle size of 40 to 100 mesh According to the mass ratio of 2~5:1, the composite catalyst is obtained; 2. Use the molar ratio of: cyclohexane-1,2-dicarboxylic acid:alcohol = 1:2~3 as the material, which will account for the total mass of the material Add 0.1% to 1% of the composite catalyst to the reactor, stir under normal pressure, react at 140 to 170°C for 3 to 5 hours, cool down, and separate to obtain cyclohexane-1,2-dicarboxylate plasticizer. The catalyst is environmentally friendly and economical, easy to prepare, does not produce waste acid, has a long service life, flexible mass composition ratio, moderate catalytic activity, pure product and easy separation; low equipment requirements; cyclohexane-1,2 of the invention -The synthesis method of diformate plasticizer is simple, no other by-products are produced, and no complex product separation device is required. It greatly reduces energy consumption and investment costs, is easy to operate, and is easy to industrialize control.

Owner:HENAN VOCATIONAL COLLEGE OF APPLIED TECH

A kind of preparation method of titanium pellets for refining high titanium slag

The invention belongs to the field of metallurgy, and particularly relates to a titanium pellet for smelting high titanium slag and a preparation method thereof. The titanium pellet for smelting high titanium slag comprises following main components: 41%-49% of TiO2, 31%-34% of TFe, 0.3-2% of FeO, and 42%-47% of Fe2O3, wherein the mass percent of the titanium pellet with particle size of 5mm-20mm is greater than 90%, the main raw material comprises titanium concentrate and an organic molding additive formed by mixing polyacrylamide and calcium oxide, and the organic molding additive accounts for 0.5%-1.0% the total mass of the titanium concentrate. The invention also provides the preparation method for the titanium pellet for smelting high titanium slag. The method comprises following steps of burdening, drying, finely grinding uniformly, rolling to mold, oxidizing roasting, and cooling. The titanium pellet prepared by the method is used for smelting high titanium slag.

Owner:攀枝花一立矿业股份有限公司

The synthetic method of isopropylamine

ActiveCN103965055BHigh selectivityLow reaction temperaturePreparation by reductive alkylationSynthesis methodsFixed bed

The invention discloses a synthesis method of isopropyl amine. A preheater is arranged in front of a fixed-bed reactor, and a gas-liquid separator is arranged behind the fixed-bed reactor; a middle section of the fixed-bed reactor is filled with a mixed catalyst; acetone, hydrogen and ammonia are taken as raw materials, acetone is reduced and ammoniated into isopropyl amine, and the reaction conditions are as follows: the reaction pressure is between atmospheric pressure and 0.5MPa, the reaction temperature is 70-130 DEG C, the molar ratio of the acetone to the hydrogen to the ammonia is 1:1-4:2-6, and the liquid space velocity of acetone is 0.1-0.5h<-1>; the mixed catalyst is obtained by evenly mixing a nickel-based catalyst and quartz sand according to the mass ratio of 2:0.8-1.2. By adopting the method disclosed by the invention, the selectivity of the isopropyl amine is as high as 100%.

Owner:ZHEJIANG JIANYE CHEM +1

Self-plasticized fluoropolymer lithium ion conductor, its preparation method and application

ActiveCN108155414BFully contactedResolving Insufficient DissociationSolid electrolytesSecondary cellsSide chainFluoropolymer

The invention provides a self-plasticizing fluorine-containing polymer lithium ion conductor. The conductor comprises an aromatic polymer main chain and side chain fluorine-containing organic lithiumsalt, and a chain polyoxyethylene derivative tail end connected with the organic lithium salt, and as a polymer framework, lithium salt and a polyether chain segment serving as a dissolving medium arecombined in a chemical bond manner, and the lithium salt and the dissolving medium are in sufficient contact with each other and are interacted, the lithium salt can be furthest dissociated, and theconductivity is improved. The conductor can serve as novel all-solid-state polymer electrolyte to be applied to a lithium ion battery, so as to solve the problem that the current all-solid-state lithium ion battery cannot be applied at a room temperature because the conductivity is too low.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Fast aging processing method for tea

InactiveCN106578159AImprove sensory qualityProduct quality and stable qualityPre-extraction tea treatmentHigh pressureRefrigeration

The invention discloses a fast aging processing method for tea. The method includes the steps of: (1) subjecting fresh tea to grading treatment to remove non tea impurities, and then conducting withering spreading on fresh tea till a water content of 70-75%; (2) conducting deactivation treatment on the withering treated tea, then performing moisture regain treatment, subjecting the moisture regain treated tea leaves to rolling treatment, and finally carrying out secondary drying on the rolled tea leaves to a water content of 18-25%; (3) transferring the treated tea into a refrigeration high-pressure processor, adopting 18-25DEG C purified water as the cooling and pressure transmitting medium, conducting pressure raising at a speed of 180-240MPa / min to 600-900MPa, then maintaining the state for 5-15min, and then conducting quick pressure relief; and (4) aging the obtained tea at 22-36DEG C for 4-6h, controlling the spreading thickness at 8-14cm, and at the end of aging, treating the tea to a water content of less than 10%, thus obtaining a finished product.

Owner:潜山县彭河幸福茶场

Method and device for extracting pepper seed oil from pepper seeds

ActiveCN101812369BImprove solubilityGood solvent propertiesFatty-oils/fats refiningFatty-oils/fats productionFiltrationEvaporation

The invention relates to a method for extracting oil from oil plants, in particular to a method for extracting pepper seed oil from pepper seeds. A method for extracting Zanthoxylum bungeanum oil from Zanthoxylum bungeanum, the main features of which include the following steps: (1) first drying the Zanthoxylum bungeanum seeds until the water content is less than 13%, and pulverizing them to 40-80 meshes by a pulverizer; (2) drying Put the pulverized Zanthoxylum bungeanum seeds into the extraction kettle, vacuum down to below 1×104pa, and discharge the air in the extraction kettle; (3) Then use a plunger pump to inject tetrafluoroethane solution into the extraction kettle, and observe the liquid through the sight glass. (4) start stirring and start extraction, the extraction pressure range is 1.0-1.2Mpa, the temperature range is 40-50°C, each extraction time is 30-45min, a total of 3 extractions; (5) then Evaporation separation is carried out in the separation tank under reduced pressure and temperature rise. The separation pressure range is 0.5-0.1Mpa, the temperature range is 40-50°C, and the separation time is 15-25min; (6) After subcritical extraction, the crude oil is centrifuged in a high-speed centrifuge Separate and filter to obtain the final pepper seed oil.

Owner:甘肃省轻工研究院有限责任公司

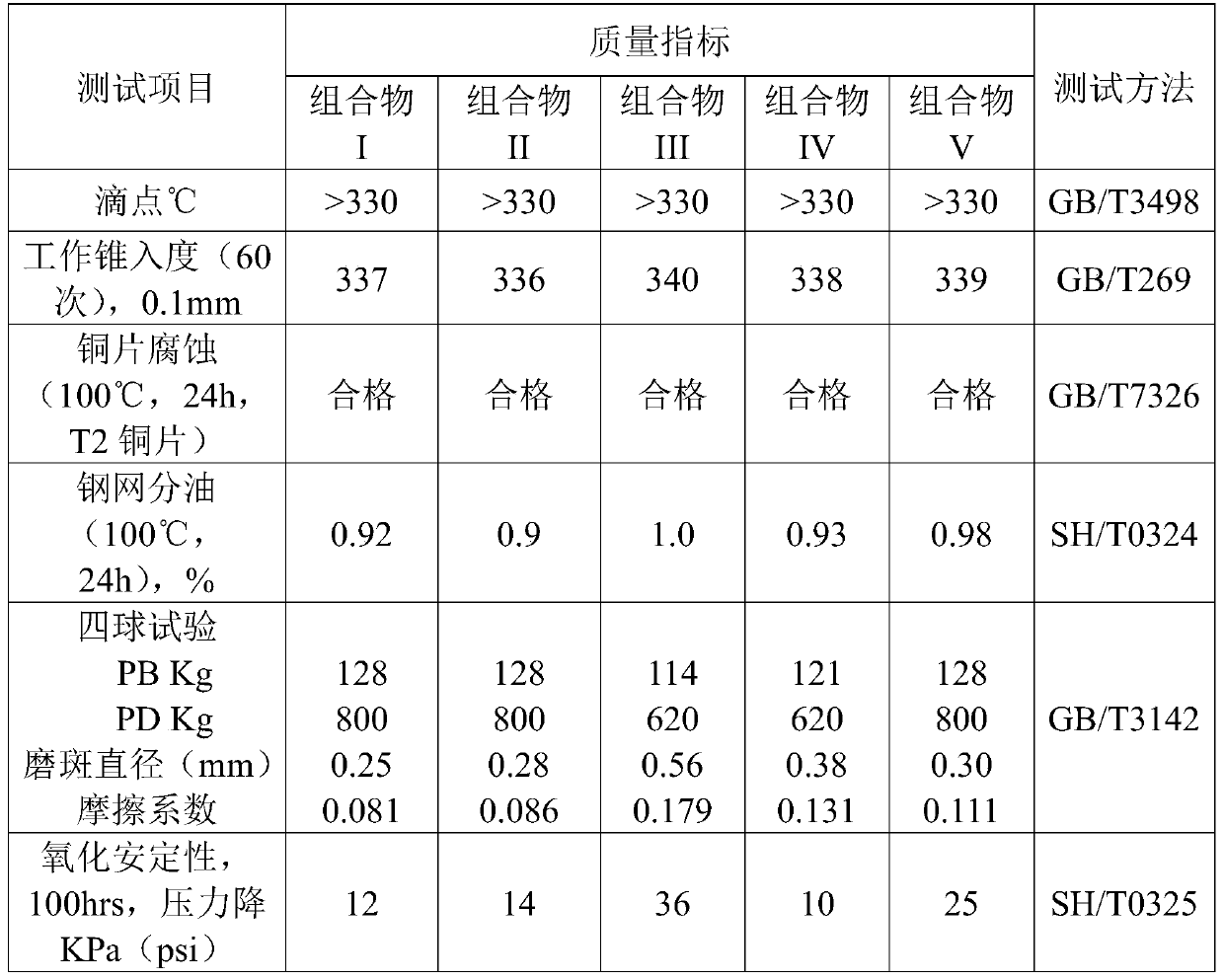

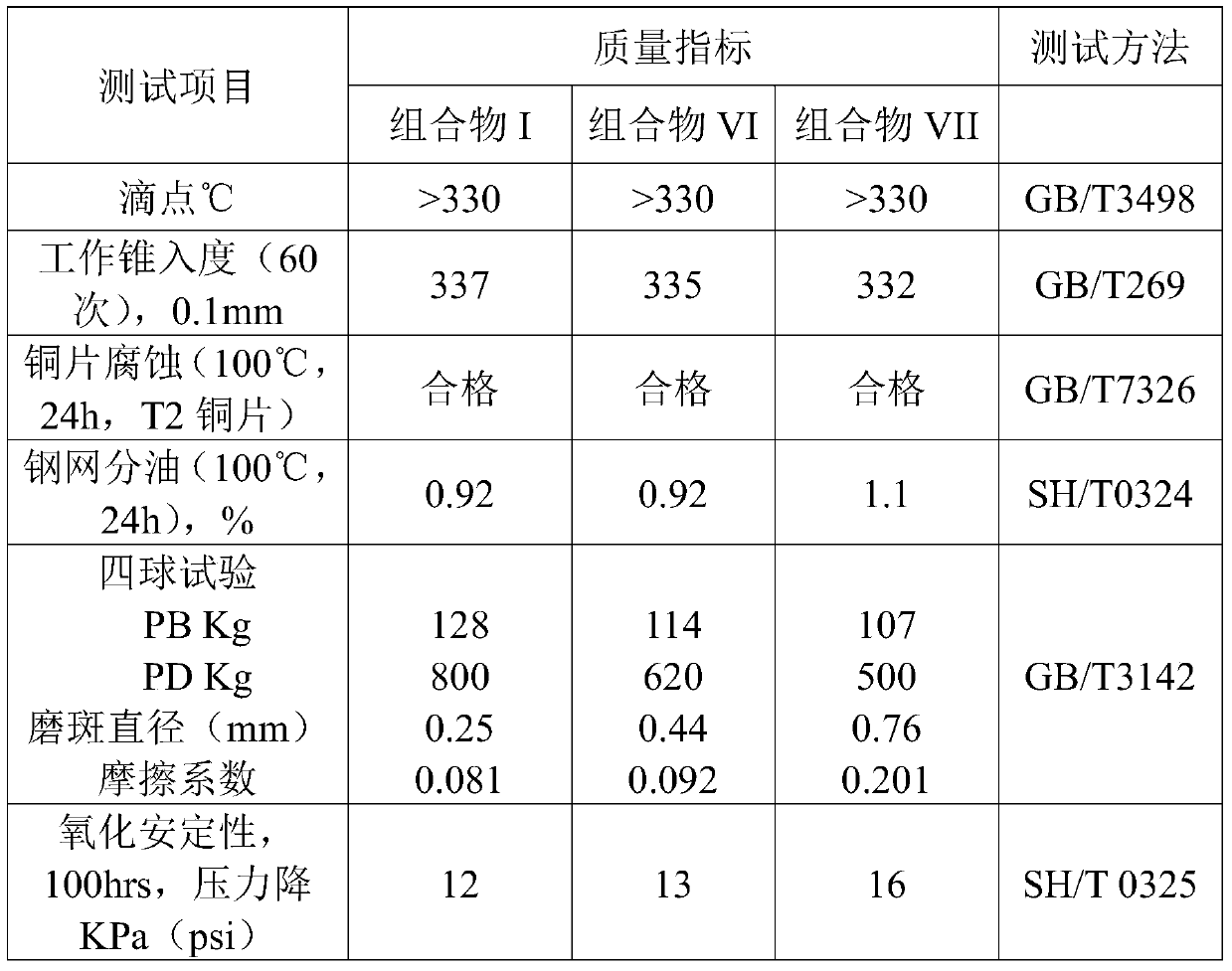

Antifriction agent and its preparation method

ActiveCN104531306BReduce coefficient of frictionGood extreme pressure and anti-wear propertiesLubricant compositionSulfonateAntioxidant

The invention provides an antifriction agent and a preparation method thereof. The antifriction agent comprises the following components: (a) complex calcium sulfonate grease; (b) extreme pressure antiwear agent; (c) antioxidant; (d) ) solid additive; with the mass of composite calcium sulfonate grease (a) as 100%, the addition amount of extreme pressure antiwear agent (b) is 0.5-5 mass %; the addition amount of antioxidant (c) is 0.1 ‑3% by mass, and the amount of the solid additive (d) is 1‑10% by mass. The friction reducing agent of the present invention has a low friction coefficient and outstanding extreme pressure and anti-wear properties, has strong wide temperature adaptability, oxidation stability, colloid stability and anti-corrosion performance, excellent comprehensive performance, and is suitable for modern rail transit Lubrication; and the preparation process is simple, easy to industrial control.

Owner:SHANGHAI HITECRUN SPECIAL LUBRICATE SCI & TECH

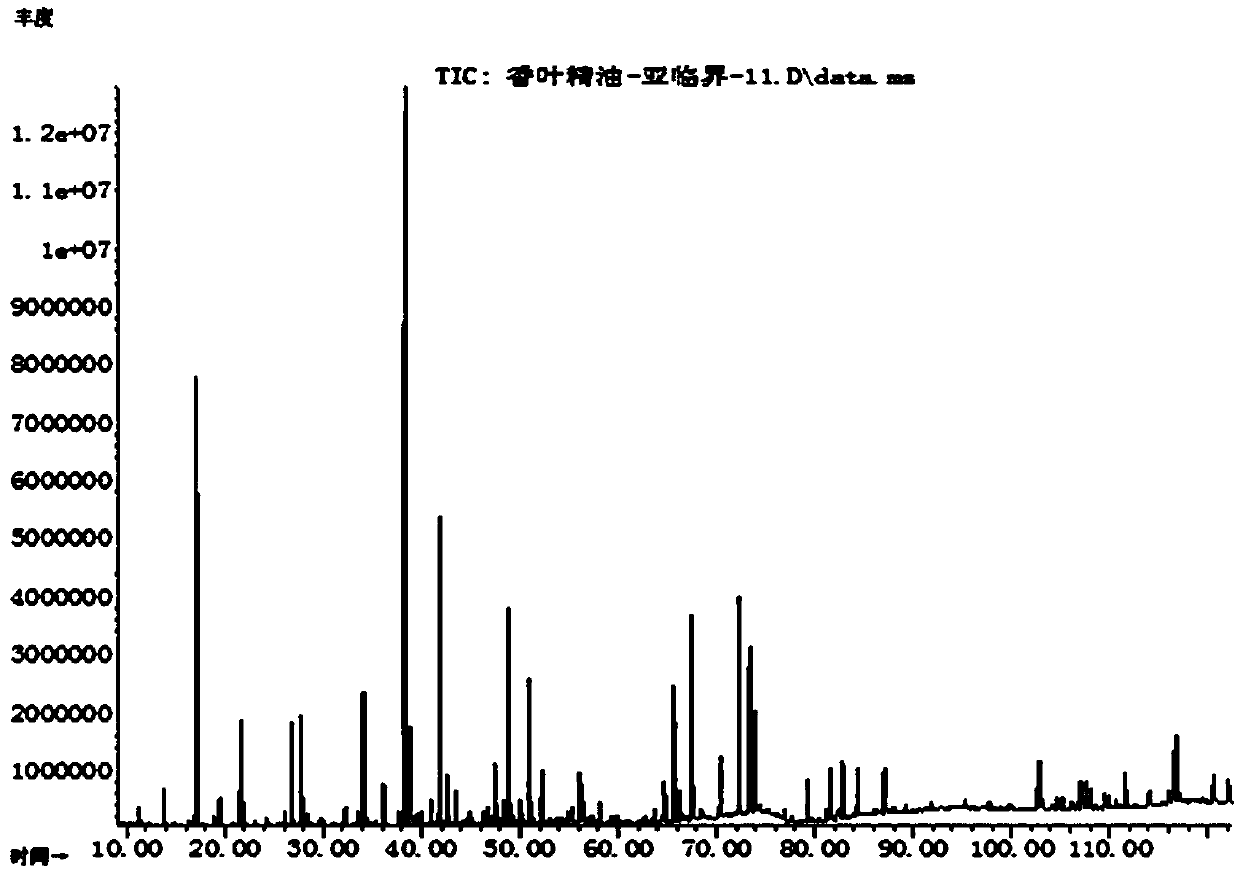

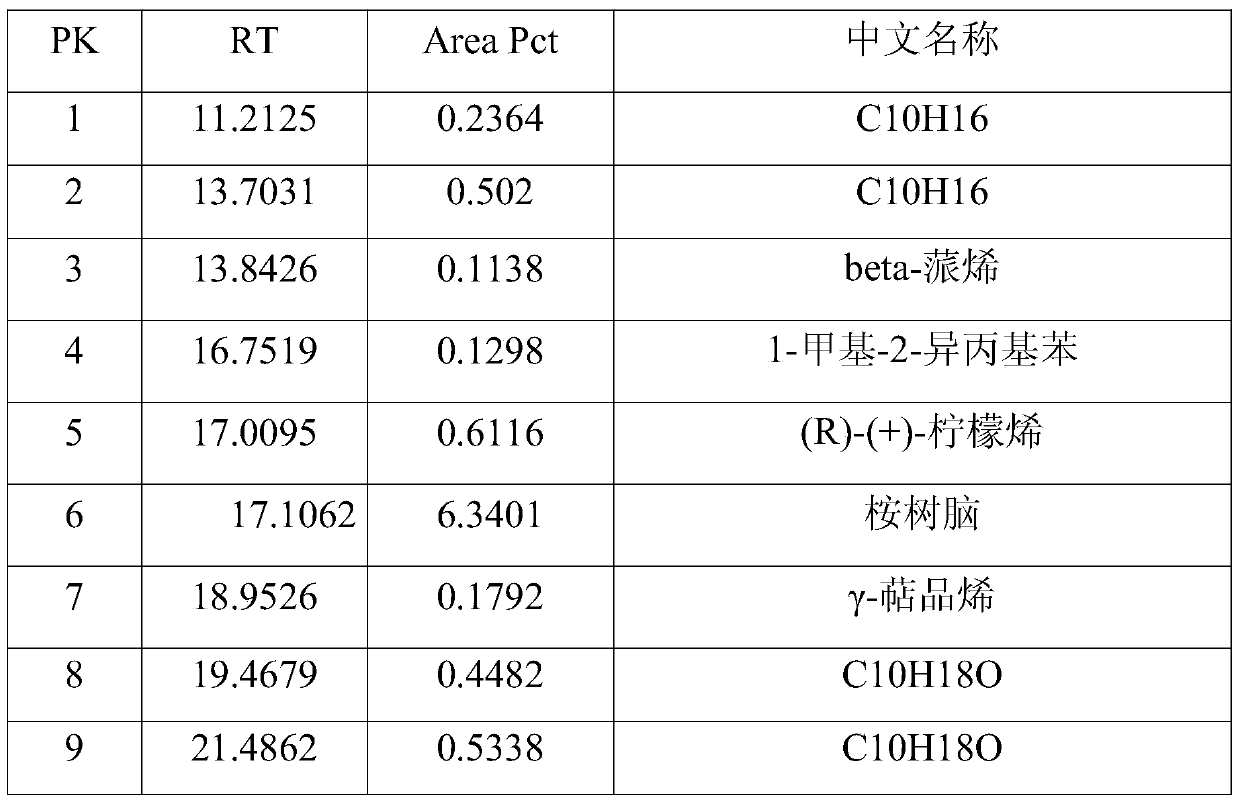

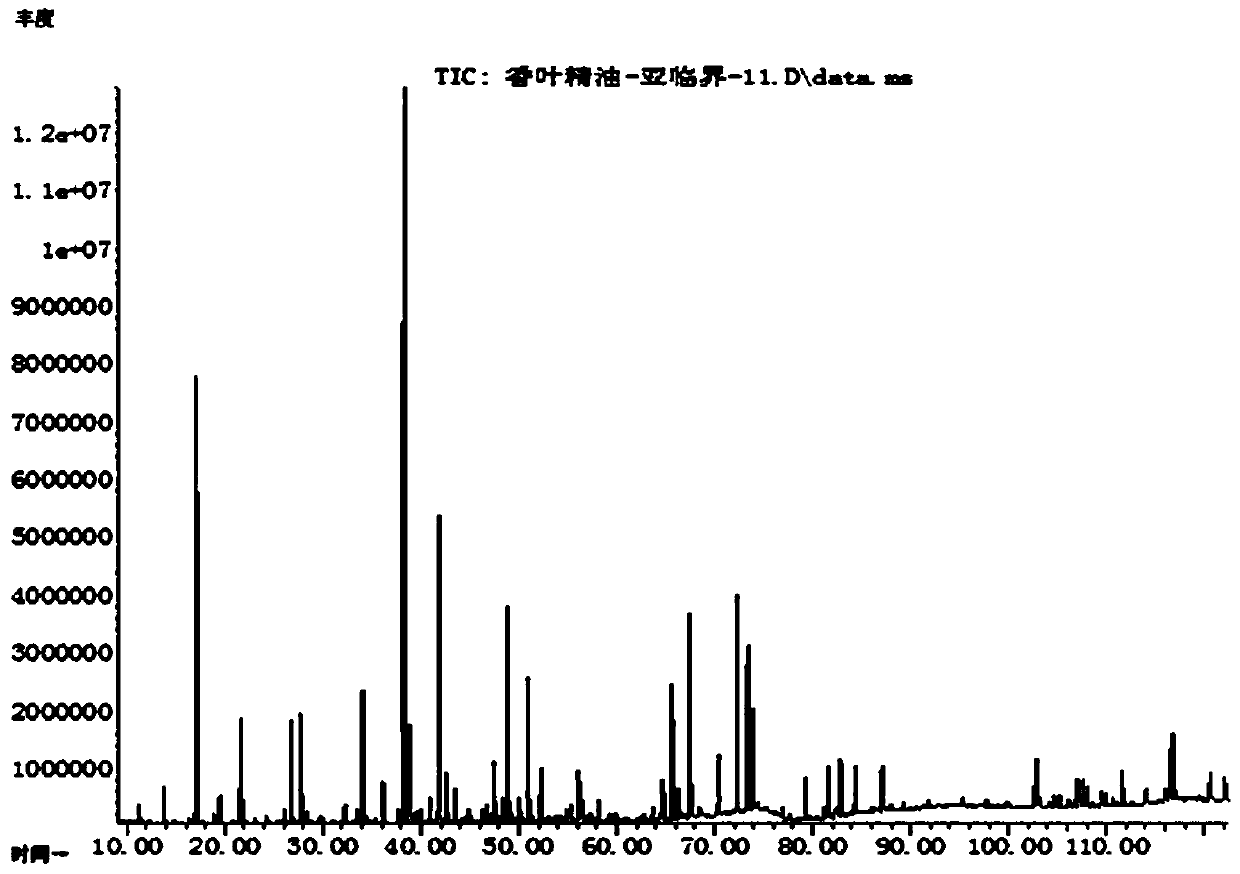

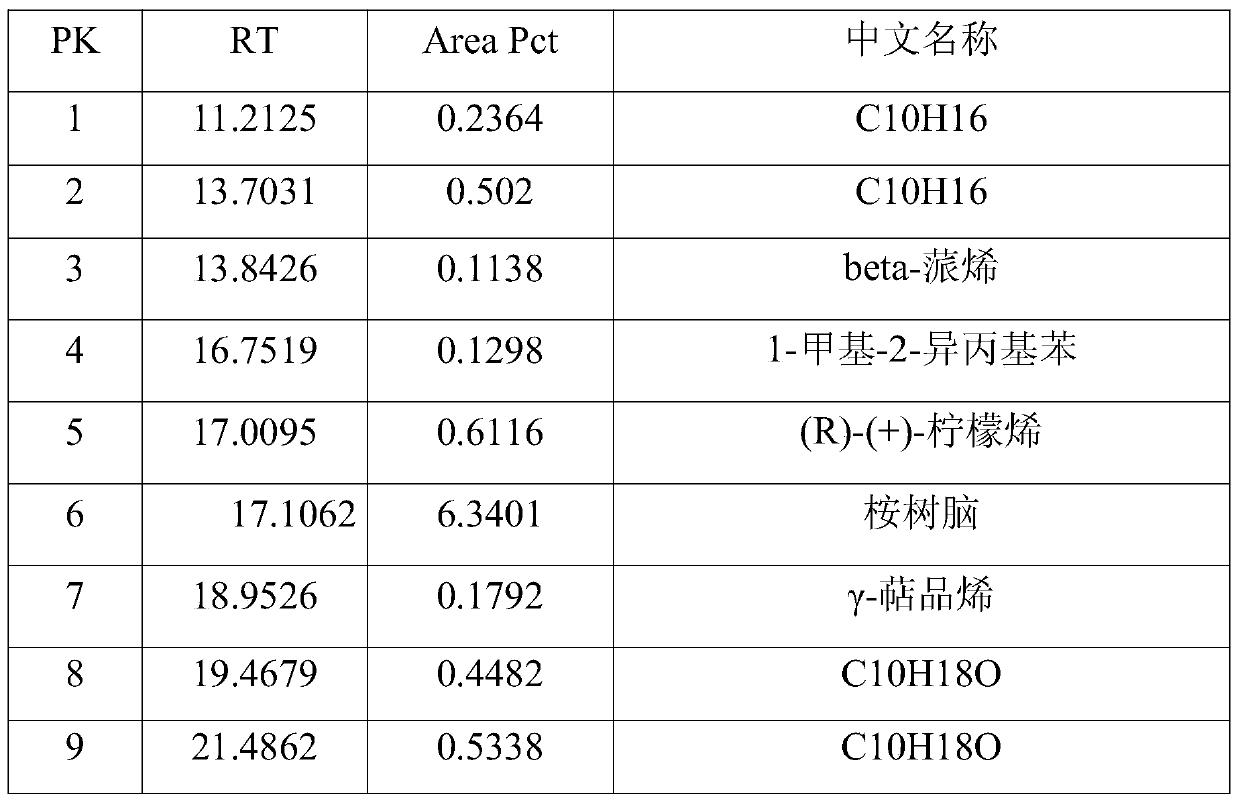

A method for extracting geranium oil from geranium leaves with subcritical n-butane fluid

ActiveCN105505583BGood solvent propertiesEasy to separateEssential-oils/perfumesProcess engineeringSolvent

The invention relates to a method of extracting bay leaf oil from bay leaves with subcritical n-butane fluid. The method includes smashing, adding into a tank, dipping with an n-butane solvent, extracting, distilling, and the like. Extraction temperature and pressure can be accurately controlled by utilization of a subcritical extraction device. The method is high in extraction efficiency, low in device manufacturing cost, high in raw material treating amount, simple in process, low in production cost and free of solvent residue. A whole process of the method is performed at low temperature under an oxygen-free state. Extraction and separation are performed at the same time. The extraction speed is high. Recovery and reutilization of the solvent can be achieved.

Owner:郑州雪麦龙食品香料有限公司

Preparation of trimethoprim

Owner:SHOUGUANG FUKANG PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com