Method and device for extracting olive pomace oil from olive pomace

A technology of olive pomace oil and olive fruit, which is applied in the direction of fat oil/fat production, fat oil/fat refining, fat production, etc. It can solve the problems of solvent residue, flammable and explosive solvent, poor production safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

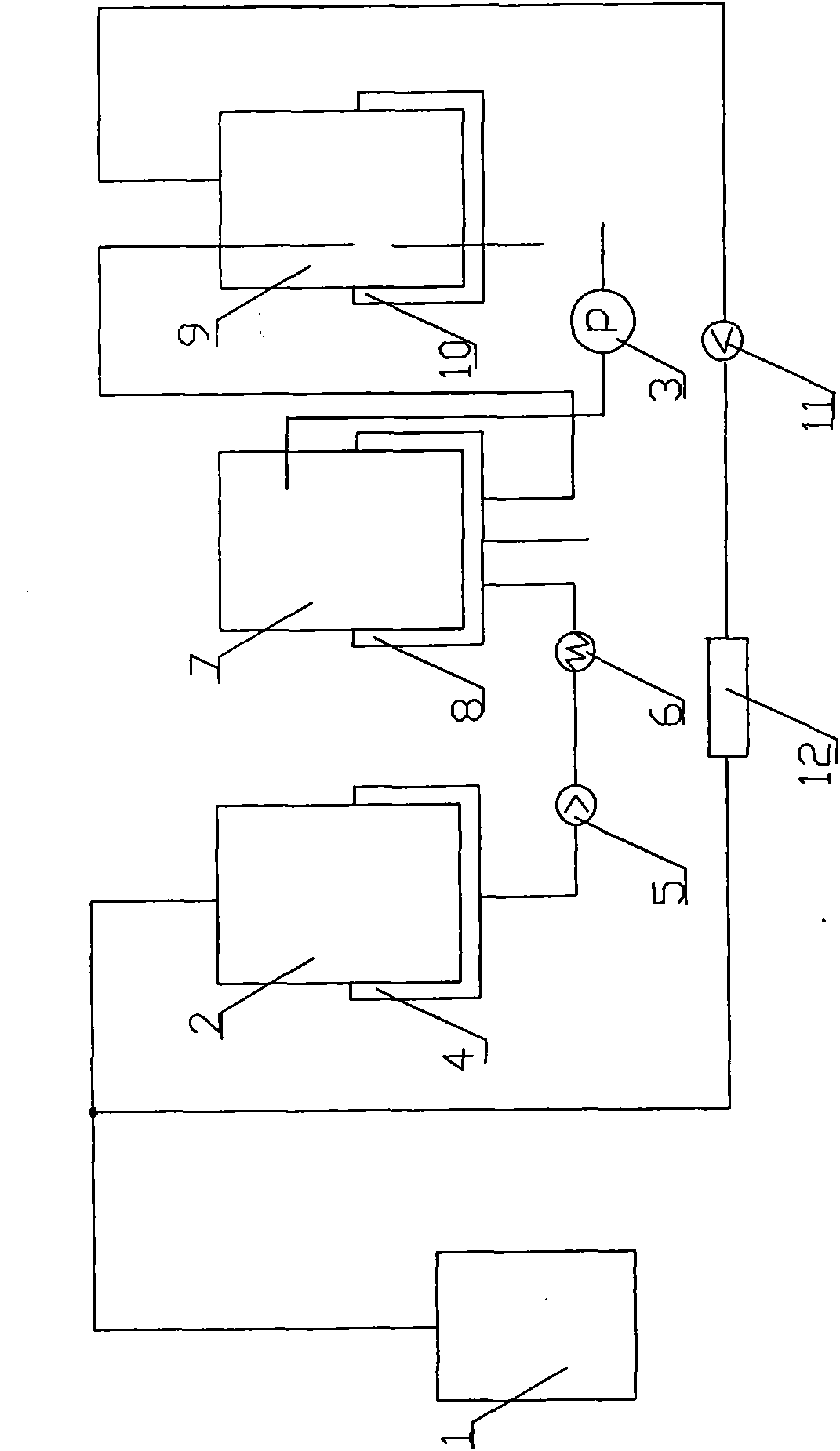

[0025] Embodiment 1. The olive pomace is dried to a moisture content≤13%, and the oil content is 8% after analysis; 10kg of pre-dried olive pomace is weighed, crushed to 40-80 mesh by a pulverizer, and loaded into an extraction kettle 7 , close the feed valve, and use the vacuum pump 3 to evacuate to 1×10 4 below pa, discharge the air in the extraction kettle system; then pass the R134A gas in the gas tank 1 into the liquefaction storage tank 2, and condense it into a liquid solvent through the condensation jacket 4; Put it into the extraction kettle, and observe the liquid level through the sight glass until the pomace raw material is submerged; it is heated by the heater 6, and the heating jacket 8 is kept warm to form a R134A subcritical fluid, which is stirred at 1.0-1.2Mpa and 40-45°C for extraction. The extraction time is 1 time, and the extraction time is 45 minutes; after the extraction is completed, the extract enters the separation kettle 9, reduces the pressure, rai...

Embodiment 2

[0026] Embodiment 2. What is different from Example 1 is that the olive pomace is dried at a drying temperature of 50-60 degrees; each extraction time is 35-40min, and the separation time is 20-25min; all the other steps are the same as in Example 1.

Embodiment 3

[0027] Embodiment 3 A device for extracting olive pomace oil from olive pomace is that the output end of the tetrafluoroethane gas tank 1 is connected to the input end of the tetrafluoroethane liquefaction storage tank 2 through a pipeline; the tetrafluoroethane liquefaction storage tank The output end of tank 2 is connected with extraction kettle 7 through plunger pump 5, heater 6, and the output end of extraction kettle 7 is connected with the input end of separation kettle 9 through pipeline; 12, and connected between the tetrafluoroethane gas tank 1 and the tetrafluoroethane liquefaction storage tank 2; a vacuum pump 3 is provided on the extraction kettle 7; a condensation jacket 4 is provided on the tetrafluoroethane liquefaction storage tank 2 ; A heating insulation jacket 8 is provided on the extraction kettle 7 ; a heating jacket 10 is provided on the separation kettle 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com