Method for preparing 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide

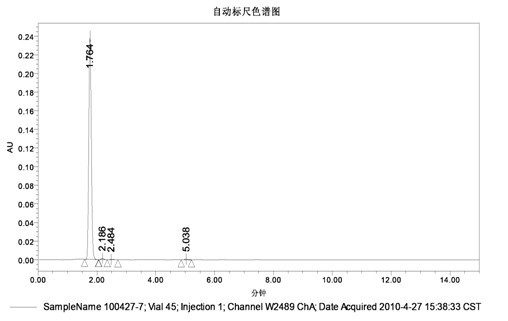

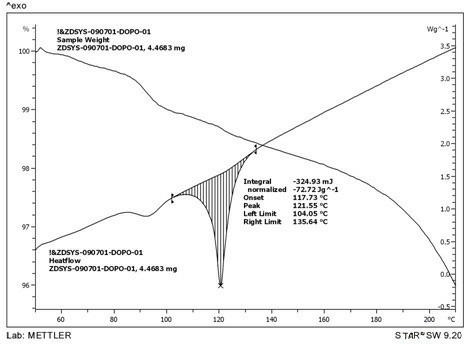

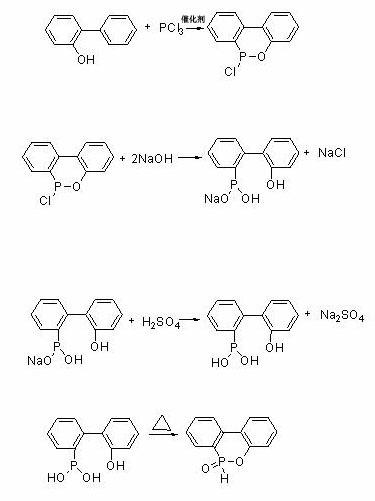

A phosphaphenanthrene and oxide technology is applied in the field of preparation of phosphorus-containing reactive flame retardant intermediates, which can solve the problems of poor product purity, complicated production process, and excessively long synthesis time, and achieves high product yield and high product quality. High-purity, easy-to-use results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Add 170g of OPP and 1.7g of anhydrous zinc chloride to a 1000ml four-necked flask equipped with a thermometer, a magnetic stirrer, a reflux condenser, and a constant pressure dropping funnel, stir and raise the temperature to 140°C to melt the OPP, and continue to raise the temperature to 160°C , Began to add 164.4g of phosphorus trichloride dropwise, after 8 hours of dropping, keep the reaction at 160-165°C for 2 hours; after the reaction is completed, distill out excess phosphorus trichloride at a temperature of 120°C to prepare intermediate The product 6-chloro-(6hydro)-diphenyl[C,E][1,2]-phosphaphenanthrene (CDOP); under stirring and reaction conditions of 50℃, drop the obtained CDOP into a concentration of 25% In the sodium hydroxide solution containing 80g of sodium hydroxide, drip in 1 hour and maintain the reaction for 2 hours to obtain the sodium salt solution of CDOP; let the sodium salt solution of CDOP stand for 30 minutes, and then filter the sodium salt solu...

Embodiment 2

[0031] Add 170g of OPP and 3.4g of FeCl to a 1000ml four-necked flask equipped with a thermometer, a magnetic stirrer, a reflux condenser, and a constant pressure dropping funnel 3 , Stir and raise the temperature to 140°C to melt the OPP, continue heating to 165°C, start adding 219.2g of phosphorus trichloride dropwise, the addition is completed in 10 hours, and keep the reaction at 165~170°C for 4 hours; after the reaction is completed, the temperature Excess phosphorus trichloride was distilled out at 130℃ to obtain the intermediate product 6-chloro-(6hydro)-diphenyl[C,E][1,2]-phosphaphenanthrene (CDOP); Under the reaction conditions of ℃, drop the obtained CDOP into a 30% concentration of sodium hydroxide 100g sodium hydroxide solution, drop in 1.5 hours, maintain the reaction for 3 hours, obtain the sodium salt solution of CDOP; leave the CDOP to stand still The sodium salt solution of CDOP is filtered for 40 minutes, and then the catalyst iron and impurities in the sodium ...

Embodiment 3

[0033] Add 170g of OPP and 5.1g of TiCl to a 1000ml four-necked flask equipped with a thermometer, a magnetic stirrer, a reflux condenser, and a constant pressure dropping funnel 4 , Stir and raise the temperature to 140℃ to melt the OPP, continue heating to 170℃, start to add 274g phosphorus trichloride dropwise, 12 hours to complete the dropwise addition, 170~175℃ to continue to react for 4 hours; after the reaction is completed, the temperature is 140 Excess phosphorus trichloride was distilled out at ℃ to obtain the intermediate product 6-chloro-(6hydro)-diphenyl[C,E][1,2]-phosphaphenanthrene (CDOP); under stirring and 95℃ Under the reaction conditions, the obtained CDOP was dropped into a 10% concentration of sodium hydroxide 120g sodium hydroxide solution, after 2 hours of dripping, after maintaining the reaction for 4 hours, the sodium salt solution of CDOP was obtained; Sodium salt solution for 60 minutes, and then filter the catalyst titanium and impurities in the CDOP ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com