Preparation of trimethoprim and intermediate

A technology of trimethoprim and trimethoxybenzaldehyde, which is applied in the field of medicine and can solve the problems of no obvious increase in yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

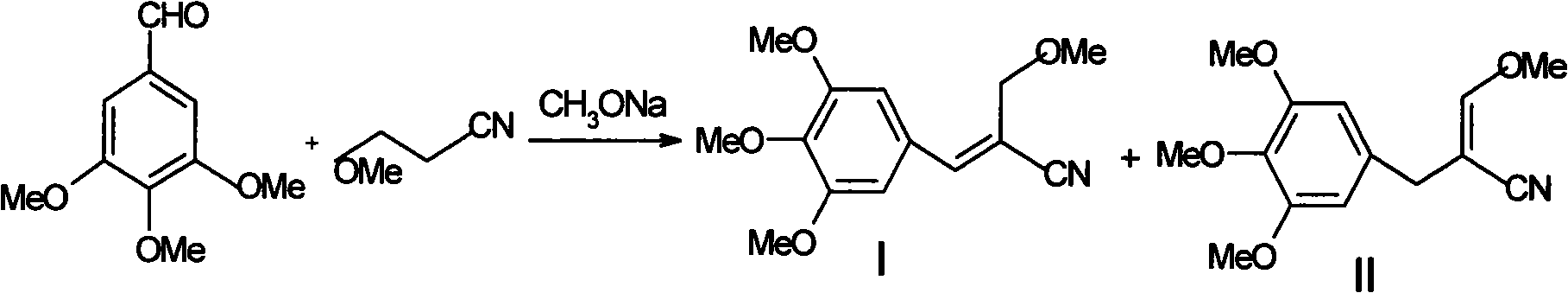

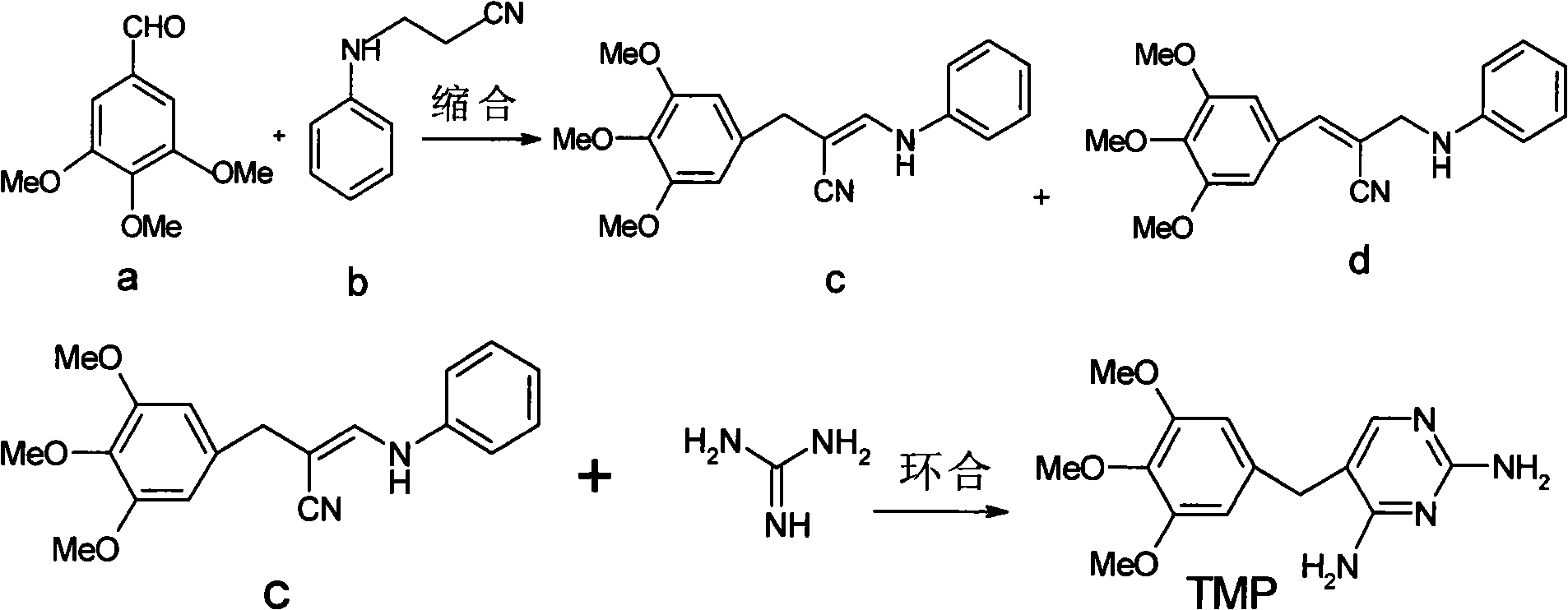

Method used

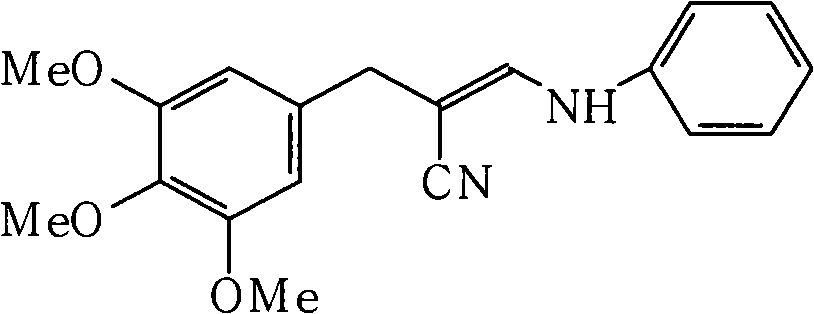

Image

Examples

Embodiment 1

[0016] In a 1000mL four-necked flask (equipped with a reflux separator), add 49g (0.25mol) of TMB, 42.5g (0.29mol) of anilinopropionitrile, 150mL of dimethylsulfoxide, 15g of sodium methoxide, and 100mL of toluene, and heat up to 110°C , when the reflux reaction brings water until no water drops are generated in the water separator, stop the reaction, distill toluene under reduced pressure, then add 400mL of water, stir and cool to 5-10°C, filter with suction, and obtain 78.5g of product after drying (yield 97%). mp: 132.5-132.5°C.

[0017] Take 32g of the above-mentioned compound, 19g of guanidine hydrochloride, and 50g of sodium methoxide into a 500mL three-necked flask, add 100mL of ethanol, heat and reflux for 1 hour, evaporate part of the solvent, add 100mL of water, stir and cool down to 5-10°C, filter with suction, and bake TMP27.5g (yield 96%) was obtained after drying. mp: 201.5-201.7°C; HPLC content: 98.7%.

Embodiment 2

[0019] In a 2000mL four-neck flask (equipped with a reflux separator), add TMB98g (0.5mol), anilinopropionitrile 85 (0.58mol)g, dimethylsulfoxide 250mL, sodium methoxide 50g, benzene 300mL, heat up to reflux at 85°C Separate the water until no water drops are formed in the water separator, stop the reaction, recover benzene under reduced pressure, then add 750mL of water, stir and cool down to 5-10°C, filter with suction, and dry to obtain 155g of the product (95.5% yield) . mp: 132.0-132.2°C.

[0020] Take 64g of the above compound, 38g of guanidine hydrochloride, and 100g of sodium methoxide into a 1000mL three-necked flask, add 200mL of ethanol, heat and reflux for 1 hour, evaporate part of the solvent, add 200mL of water, stir and cool down to 5-10°C, and suction filter to obtain the product 56g (96.1% yield). mp: 201.6-201.8°C; HPLC content: 98.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com