Antifriction agent and its preparation method

A technology of wear reducer and extreme pressure antiwear agent, which is applied in the field of lubricants, can solve limitations and other problems, and achieve the effects of strong wide temperature adaptability, reduced locomotive running friction, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Compared with the preparation process of other composite calcium sulfonate greases, the present invention omits the saponification process in the preparation process of calcium sulfonate greases, reduces the cost of raw materials and energy consumption, and shortens the production process, which is very easy for industrial production and control , and the prepared lubricating grease still has good comprehensive properties, which can fully meet the requirements of the lubrication conditions of modern rail transit.

[0032] In the wear reducer of the present invention, the amount of the extreme pressure antiwear agent added is 0.5-5 mass%, preferably 1-3 mass%, based on the calculation that the mass of the complex calcium sulfonate lubricating grease is 100%.

[0033] The present invention preferably adopts borate extreme pressure antiwear agent, preferably potassium triborate neutral dispersion liquid. Its oil film thickness is more than 10 times that of sulfur phosphoru...

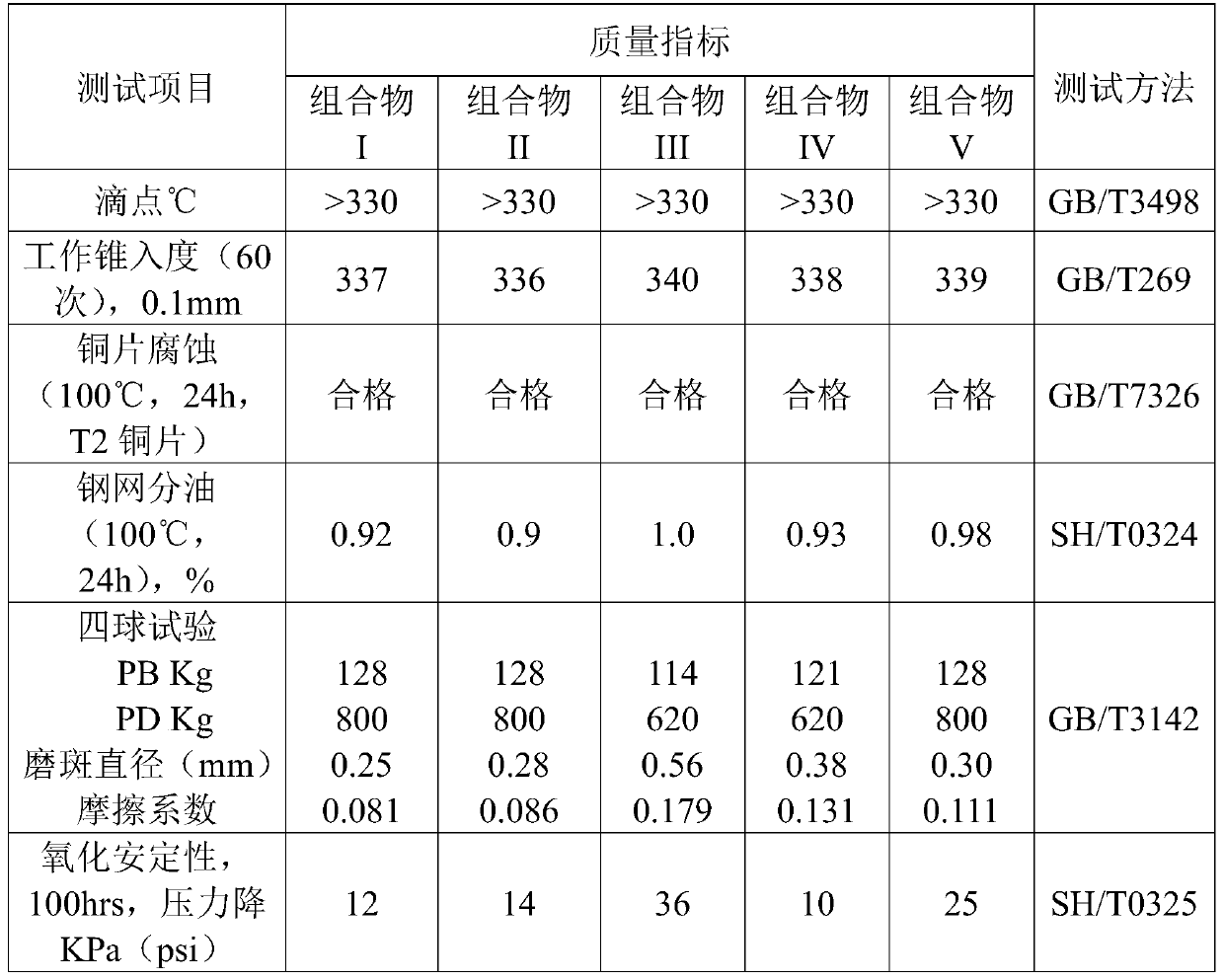

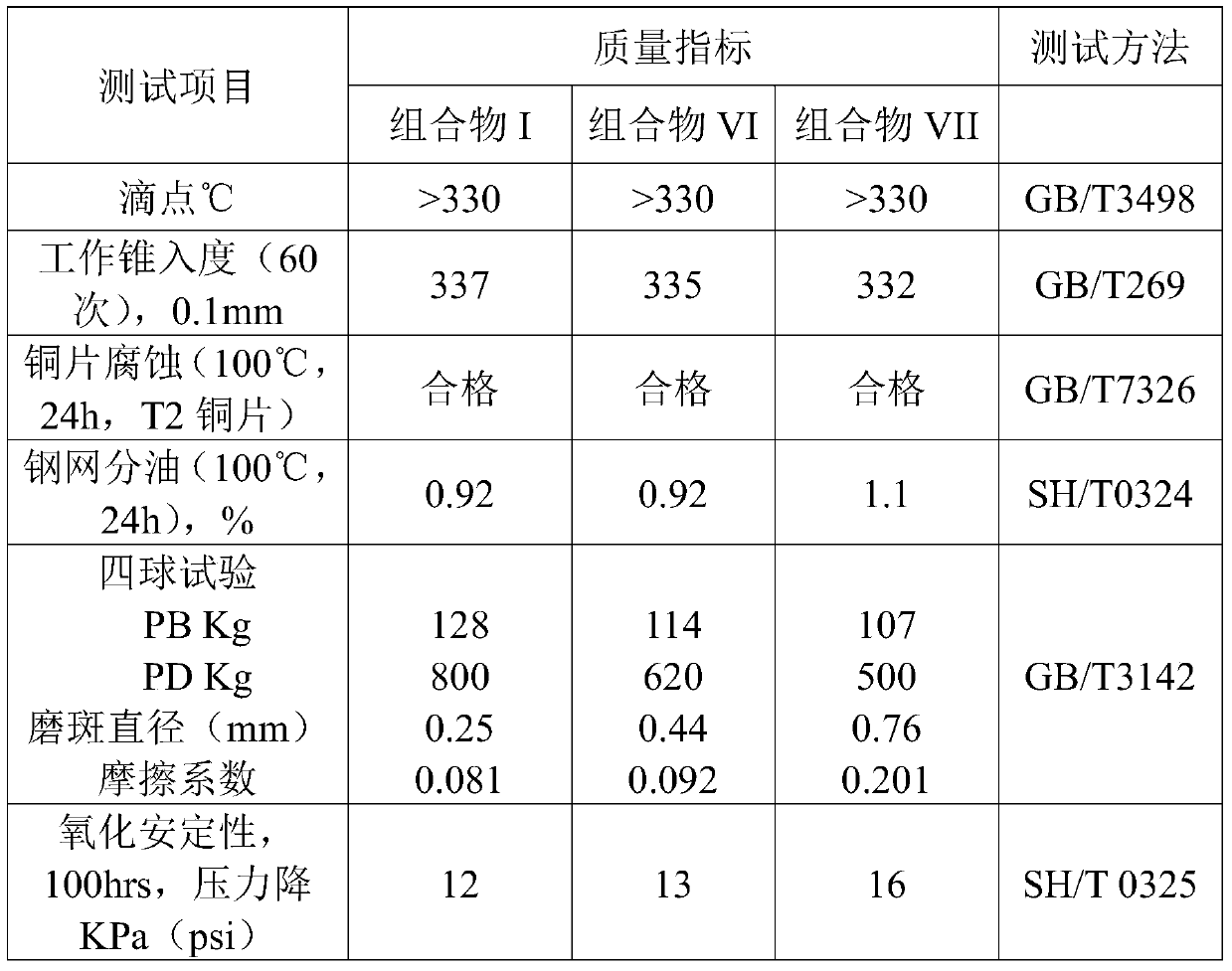

Embodiment 1

[0045] Add 220 parts of 150BS base oil and 12 parts of lauryl hydroxystearic acid into the reaction kettle, heat and stir to 80°C to fully dissolve, then add 200 parts of high alkali value calcium sulfonate, 10 parts of dodecylbenzene Add sulfonic acid and 30 parts of water to the above mixture in turn, keep stirring at 80°C for 10 minutes; 2) Add 5 parts of glacial acetic acid, heat up to 100°C, the system gradually becomes viscous, and finally becomes semi-fluid fat; stir and heat up to Dehydrate at 120°C for 40 minutes, add 553 parts of 150BS, cool, grind, homogenize and degas to obtain complex calcium sulfonate grease.

[0046] Add 100 parts of the above-mentioned complex calcium sulfonate grease into the pre-cleaned normal pressure reactor, heat up and stir, add 2 parts of potassium triborate neutral oil dispersion Octopol PTB (Tiarco Chemical Company, Inc. the same below), 0.5 Part butyl / octyl diphenylamine Vanlube 961 (R.T.Vanderbilt Company, Inc, the same below), 3 par...

Embodiment 2

[0048] Add 100 parts of the above-mentioned complex calcium sulfonate grease to the pre-cleaned normal pressure reactor, heat up and stir, add 1 part of potassium triborate neutral oil dispersion Octopol PTB, 0.5 parts of butyl / octyl diphenylamine Vanlube 961 , 4 parts of polytetrafluoroethylene and 2 parts of nano-calcium carbonate, mixed and stirred, then heated to 90 ° C, stirred at a constant temperature for 40 minutes, cooled out of the kettle, homogeneously ground and packaged to obtain the friction reducing agent composition II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| cone penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com