Method and device for extracting pepper seed oil from pepper seeds

A technology of prickly ash seed oil and prickly ash seed is applied in the directions of fat oil/fat production, fat oil/fat refining, fat production, etc., and can solve the problems of low oil yield, influence, high manufacturing cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1. Dry the pepper seeds to a water content of ≤13%, and analyze and detect that the oil content is 27.5%; weigh 10 kg of pre-dried pepper seeds, crush them to 40-80 mesh through a pulverizer, put them into the extraction kettle 7, and close Feed valve, use vacuum pump 3 to evacuate down to 1×10 4 below pa, discharge the air in the extraction kettle; then pass the R134A gas in the gas tank 1 into the liquefaction storage tank 2, and condense it into a liquid solvent through the condensation jacket 4; the R134A solution stored in the storage tank 2 is pumped into In the extraction kettle, observe the liquid level through the sight glass until the raw material of prickly ash is submerged; it is heated by the heater 6, and the heating jacket 8 is kept warm to form R134A subcritical fluid, which is stirred at 1.0-1.2Mpa and 40-45°C for extraction and co-extraction 3 times, 45min for the first time, 30min for the 2nd and 3rd times; after the extraction is completed...

Embodiment 2

[0027] Embodiment 2. What is different from Example 1 is that the pepper seeds are dried at a temperature of 50-60 degrees; each extraction time is 35-40min, and the separation time is 20-25min; the remaining steps are the same as in Example 1.

Embodiment 3

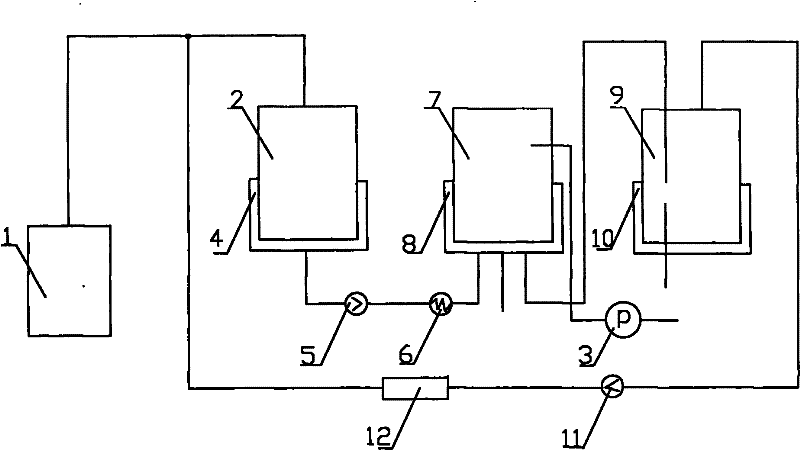

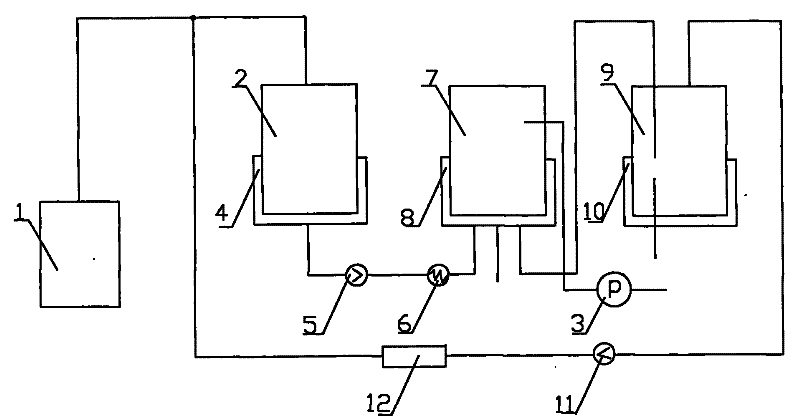

[0028] Embodiment 3. A device for extracting pepper seed oil from Zanthoxylum bungeanum, the output end of the tetrafluoroethane gas tank 1 is connected with the input end of the tetrafluoroethane liquefaction storage tank 2 through a pipeline; the tetrafluoroethane liquefaction storage tank The output end of 2 is connected with extraction kettle 7 through plunger pump 5, heater 6, and the output end of extraction kettle 7 is connected with the input end of separation kettle 9 by pipeline; Separator 9 is connected compressor 11, condenser 12 sequentially through pipeline , and connected between the tetrafluoroethane gas tank 1 and the tetrafluoroethane liquefaction storage tank 2; a vacuum pump 3 is provided on the extraction kettle 7; a condensation jacket 4 is provided on the tetrafluoroethane liquefaction storage tank 2; A heating insulation jacket 8 is arranged on the extraction kettle 7; a heating jacket 10 is arranged on the separation kettle 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com