Method and device for preparing 3-hydroxypropionaldehyde through continuous catalytic rectification

A technology of catalytic rectification and hydroxypropionaldehyde, applied in the field of petrochemical industry, can solve the problems of low selectivity and low conversion rate, and achieve the effects of simple device process, improved selectivity and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

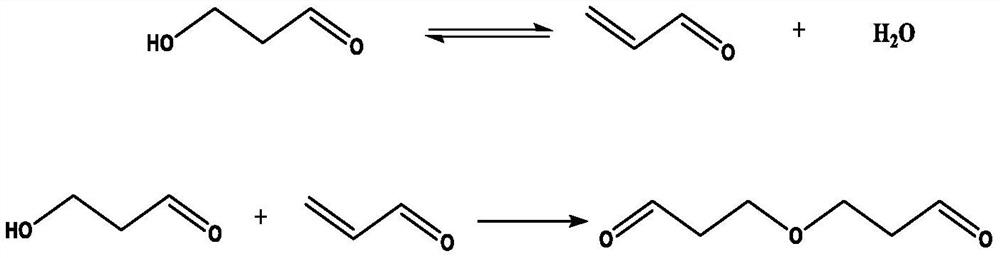

Problems solved by technology

Method used

Image

Examples

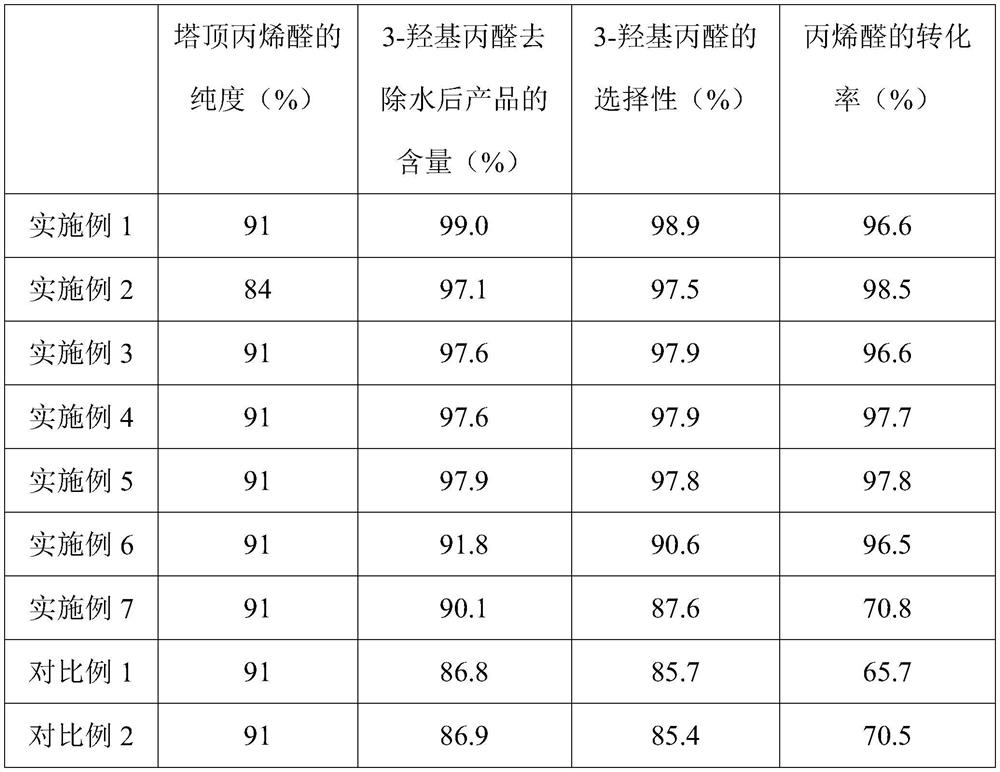

Embodiment 1

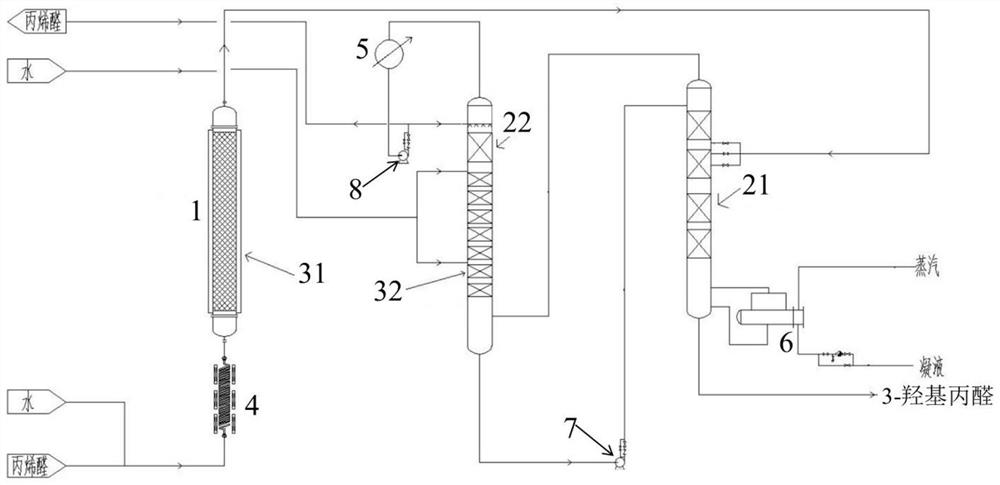

[0075] This embodiment provides a device for preparing 3-hydroxypropanal by continuous catalytic rectification, such as figure 1 As shown, the system device includes a hydration reaction device 1 and a catalytic rectification device connected in sequence, the first catalyst 31 is arranged in the hydration reaction device 1, and the second catalyst 32 is arranged in the catalytic rectification device; The hydration reaction device 1 includes a hydration reaction column; a first heat exchange device 4 is arranged before the hydration reaction device 1; the first heat exchange device 4 is a preheater; the material outlet of the hydration reaction device 1 is connected The middle part of catalytic rectification unit; Said catalytic rectification unit comprises the first catalytic rectification tower 21 and the second catalytic rectification tower 22; The material outlet of said first heat exchange device 4 connects the first catalytic rectification tower 21 Middle part; The middle...

Embodiment 2

[0080] This embodiment provides a method for preparing 3-hydroxypropanal by continuous catalytic rectification. The method is carried out using the device in Example 1, and specifically includes the following steps:

[0081] (1) Mix acrolein and water to obtain a mixed solution with a mass concentration of acrolein of 14%. The mixed solution is preheated to 50° C. by a preheater at a flow rate of 5 kg / h and then at a space velocity of 0.5 h -1Send into the hydration reactor, the hydration reactor is filled with the first catalyst, the first catalyst includes the resin (model: S957) whose surface functional group is phosphoric acid, the resin (model: CT151) of sulfonic acid and iminoacetic acid type Resin (model: S930Plus), ratio 1:1:1 (wt%), hydration reaction under the action of the first catalyst to obtain a hydration reaction product;

[0082] (2) The hydration reaction product described in step (1) is sent to the middle part of the first stage catalytic rectification, the ...

Embodiment 3

[0084] This embodiment provides a method for preparing 3-hydroxypropanal by continuous catalytic rectification. The method is carried out using the device in Example 1, and specifically includes the following steps:

[0085] (1) Mix acrolein and water to obtain a mixed solution with a mass concentration of acrolein of 18%. The mixed solution is preheated to 30°C by a preheater at a flow rate of 2kg / h and then at a space velocity of 2h -1 Send into the hydration reactor, and the hydration reactor is filled with the first catalyst, and the first catalyst includes the resin of iminoacetic acid type (model is S930Plus) and aminophosphonic acid type (model is S940), and its mass ratio is 1:1, performing a hydration reaction under the action of the first catalyst to obtain a hydration reaction product;

[0086] (2) The hydration reaction product described in step (1) is sent to the middle part of the first section catalytic rectification, the bottom temperature of the first section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com