Anti-explosion multi-component dynamic air distribution device and method

A dynamic gas distribution, multi-component technology, used in mixing methods, chemical instruments and methods, mixer accessories, etc., can solve the problems of reduced purity of mixed standard gas, poor airtightness, discounted gas distribution accuracy, etc., to reduce equipment. Dosage, good sealing performance, and the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples.

[0036]This embodiment provides a multi-component dynamic gas distribution device and method for dynamically configuring multi-component gas. The component gas includes raw material gas and diluent gas. For example, if 1.4% methane in air is configured, the raw material gas is methane, and the air is diluent gas.

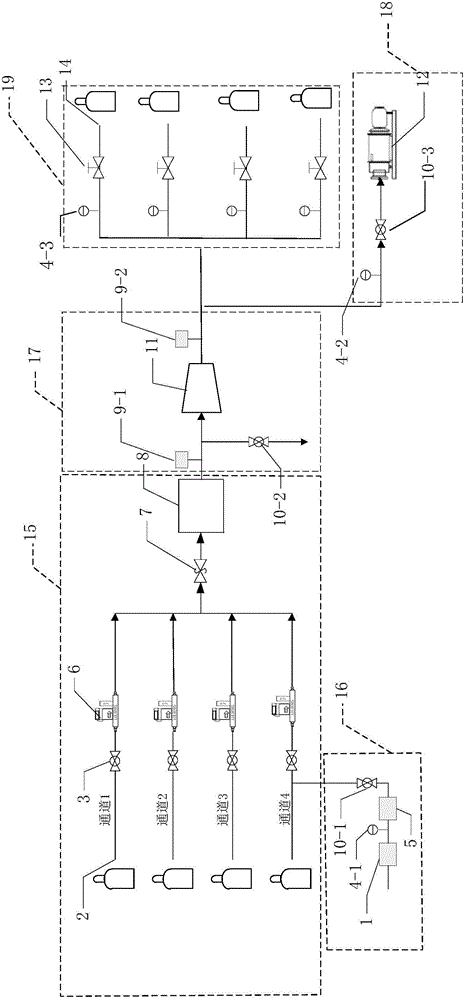

[0037] see figure 1 , An explosion-proof multi-component dynamic gas distribution device in a preferred embodiment of the present invention includes: a low-pressure gas distribution system 15 , an air compression generator 16 , a booster system 17 , a vacuum system 18 , and a filling system 19 .

[0038] The low-pressure gas distribution system 15 is composed of n low-pressure gas distribution channels, a back pressure valve 7, a gas mixer 8 and an air compression generating device 16, and each low-pressure gas distribu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com