Liquid chlorine delivery system for producing chlorinated polyethylene

A chlorinated polyethylene and conveying system technology, applied in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of wasting manpower and material resources, affecting the chlorination reaction, affecting the continuous and stable output of liquid chlorine, etc. cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

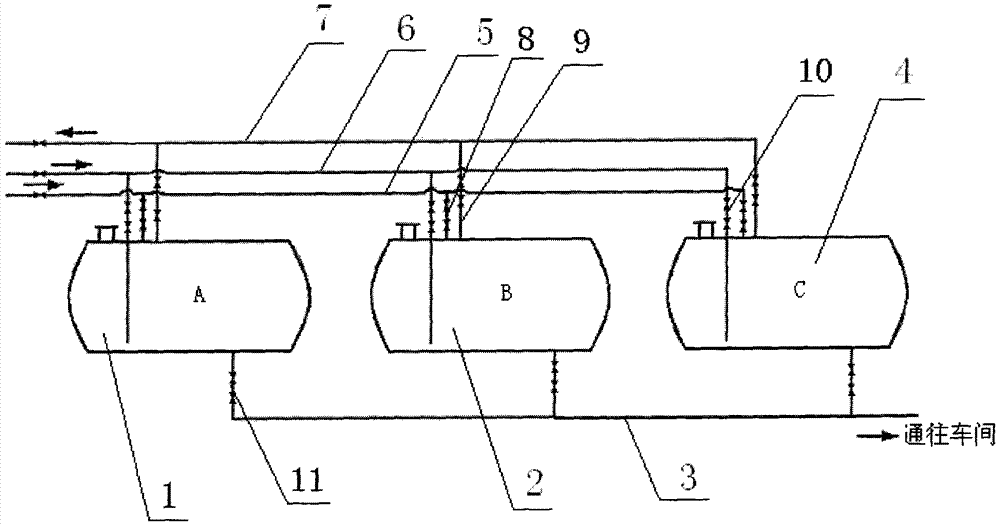

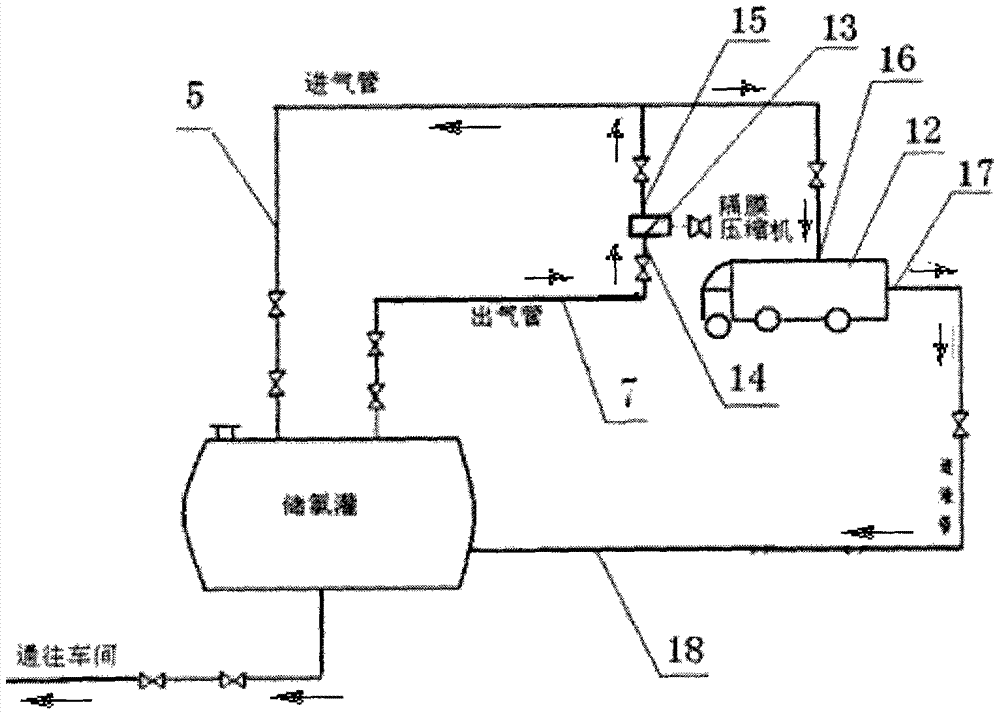

[0013] as attached figure 1 , 2 A liquid chlorine delivery system for the production of chlorinated polyethylene is shown, which includes three chlorine storage tanks A1, B2, and C4, a diaphragm air compressor 13, and the tops of the three chlorine storage tanks A1, B2, and C4. Air intake pipe 8, air outlet pipe 9, liquid chlorine inlet pipe 10 are respectively arranged on the surface, liquid chlorine outlet pipe 11 is respectively arranged on the bottom surface of each chlorine storage tank, and the air outlet pipe of each chlorine storage tank is connected on a total air outlet pipe 7, each The air inlet pipe is connected to a total air intake pipe 5, each liquid chlorine inlet pipe is connected to a total liquid chlorine inlet pipe 6, each liquid chlorine outlet pipe is connected to a total liquid chlorine outlet pipe 3, each tank Each pipe is provided with valve control; when producing chlorinated polyethylene, connect the total outlet pipe 7 with the air inlet 14 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com