Charging equipment for heptafluoropropane firefighting gas and technology thereof

A technology for heptafluoropropane and fire-fighting gas, which is applied in the field of filling equipment for heptafluoropropane fire-fighting gas, can solve the problems of low production efficiency, large maintenance, inability to apply heptafluoropropane fire-fighting gas, etc., and achieves the effects of good sealing and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described now in conjunction with accompanying drawing.

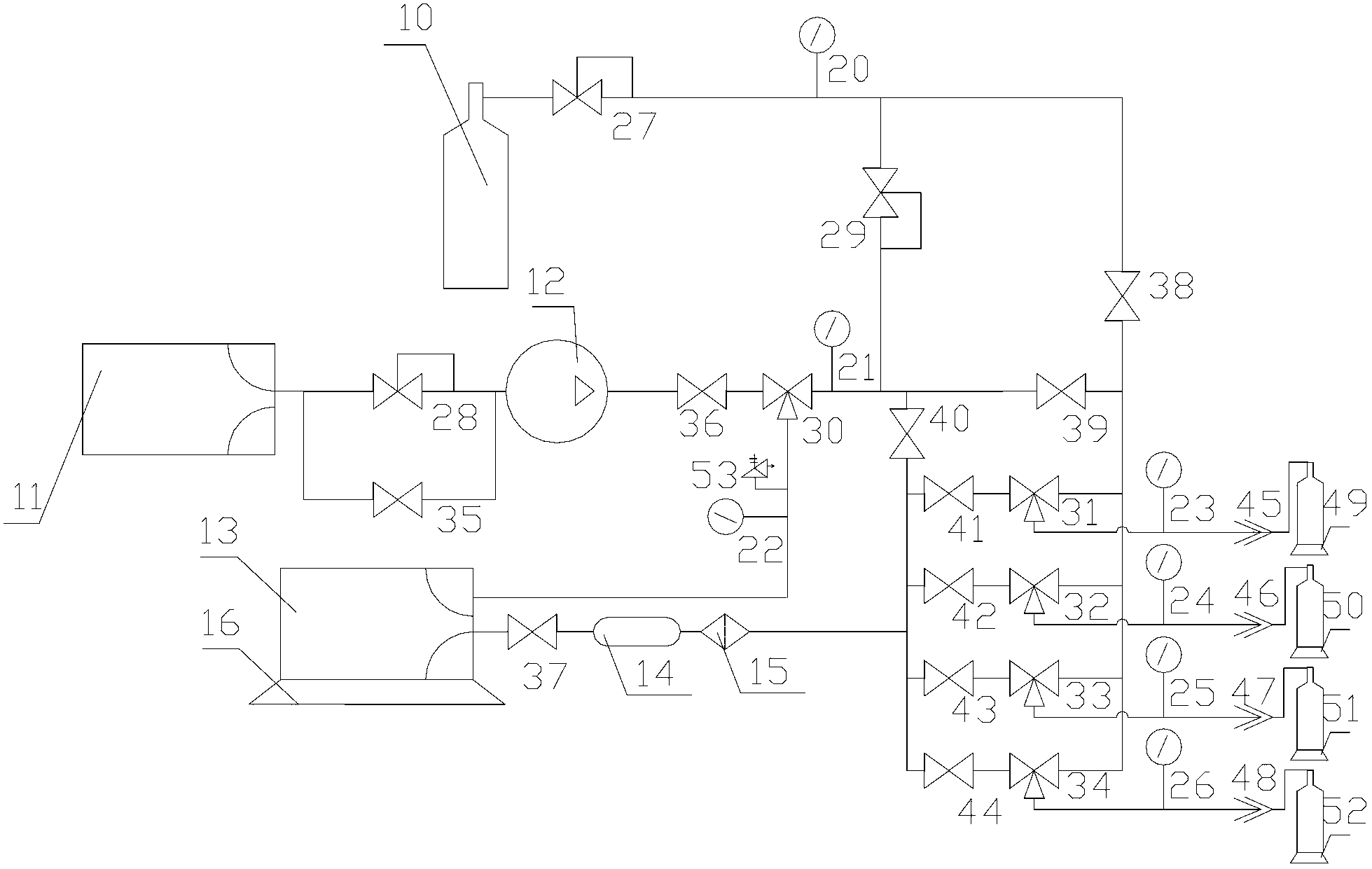

[0019] see figure 2 , the present invention has designed a kind of filling equipment of heptafluoropropane fire-fighting gas. Nitrogen cylinder 10 is connected with one end of pressure reducing valve one 27, and the other end of pressure reducing valve one 27 is divided into three ways to connect with pressure gauge one 20, one end of pressure reducing valve three 29 and one end of valve four 38 respectively, and pressure reducing valve three The other end of 29 is connected with pressure gauge two 21, the right end of selection valve one 30, one end of valve six 40 and one end of valve five 39 respectively in four ways, and the left end of selection valve one 30 is connected with one end of valve two 36; valve two The other end of 36 is connected with one end of diaphragm compressor 12, and the other end of diaphragm compressor 12 is divided into two paths and connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com