Single-stage multi-head diaphragm type gas pump

A diaphragm type, multi-head technology, applied in the direction of variable displacement pump components, pumps, pump components, etc., can solve the problem of unable to meet the requirements of spray gun use, and achieve the effect of light weight, high purity and wide pressure range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

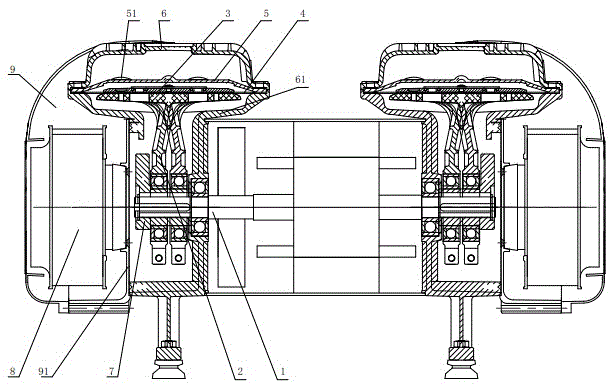

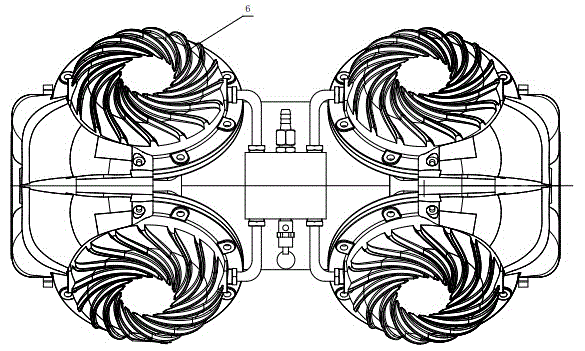

[0035] Such as Figure 1 to Figure 3 As shown, the single-stage multi-head diaphragm air pump of the present invention includes a main shaft 1, and four connecting rods 2 are arranged on the main shaft 1; the four connecting rods 2 are divided into two groups and arranged at both ends of the main shaft, between the two main shafts at the same end. form an angle of 90°;

[0036] The two ends of the main shaft 1 are respectively connected to one end of the connecting rod 2 through the eccentric wheel 7; a bearing is arranged between the eccentric wheel 7 and the connecting rod 2;

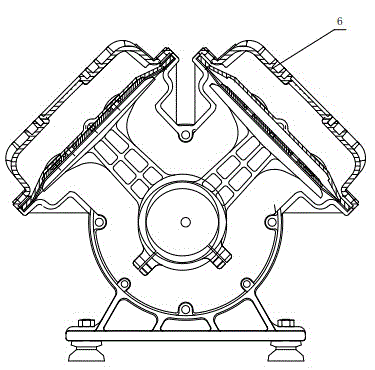

[0037] Such as Figure 4 As shown, the other end of the connecting rod 2 is provided with a diaphragm pressure plate, and the connecting rod 2 is fixedly connected to the valve pressure plate 3 through the diaphragm pressure plate, and a diaphragm is fixed between the valve pressure plate 3 and the diaphragm pressure plate. 4. The top of the valve platen 3 is fixed with a sealing plate 31 by screws ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com