Novel pressurizing sealing ball valve

A sealed ball valve, a new type of technology, applied in valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of leaking sealing rings, affecting service life, and ring damage, ensuring clean opening and closing reversing, and overcoming difficult problems. The effect of adjusting and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

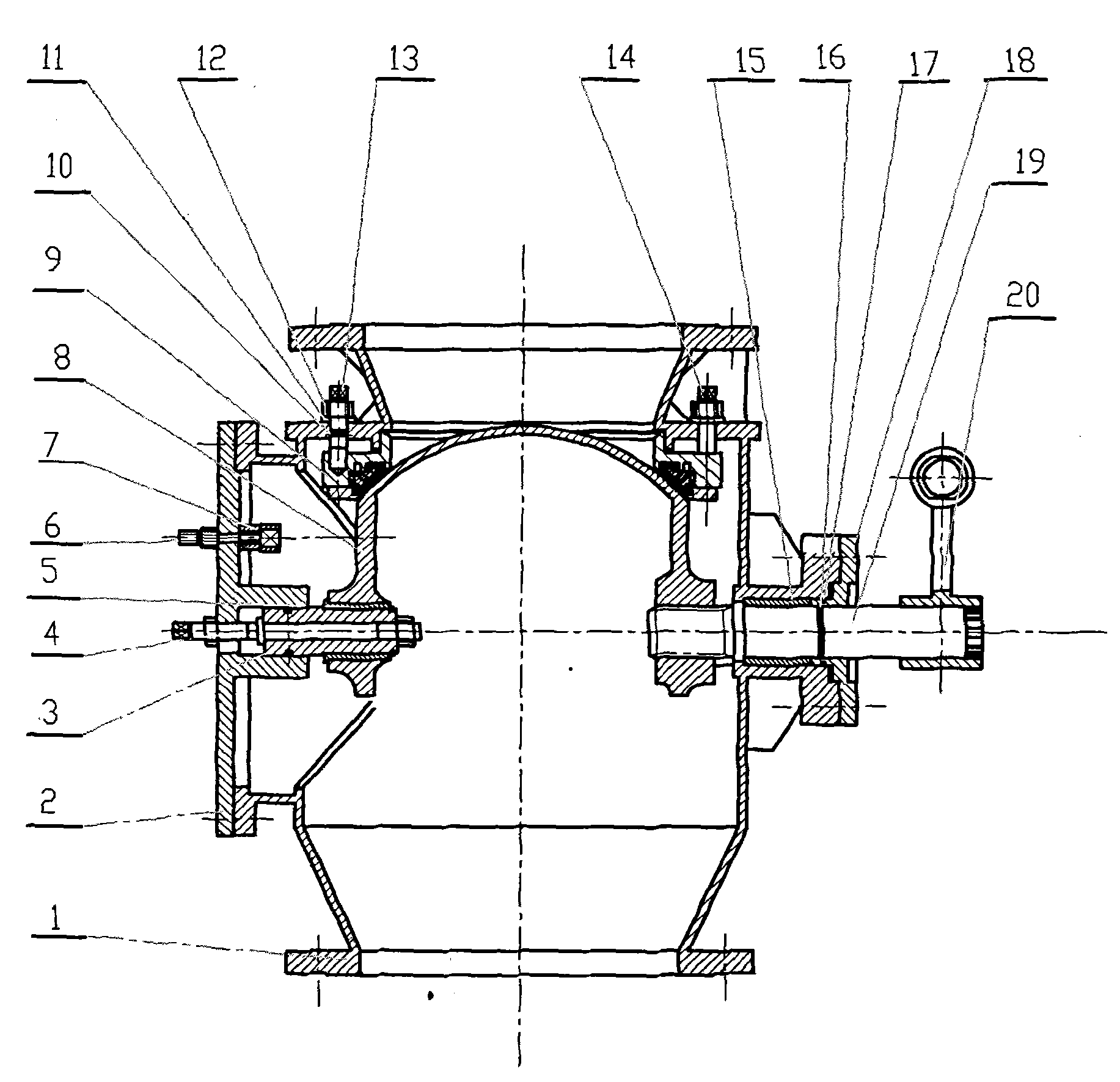

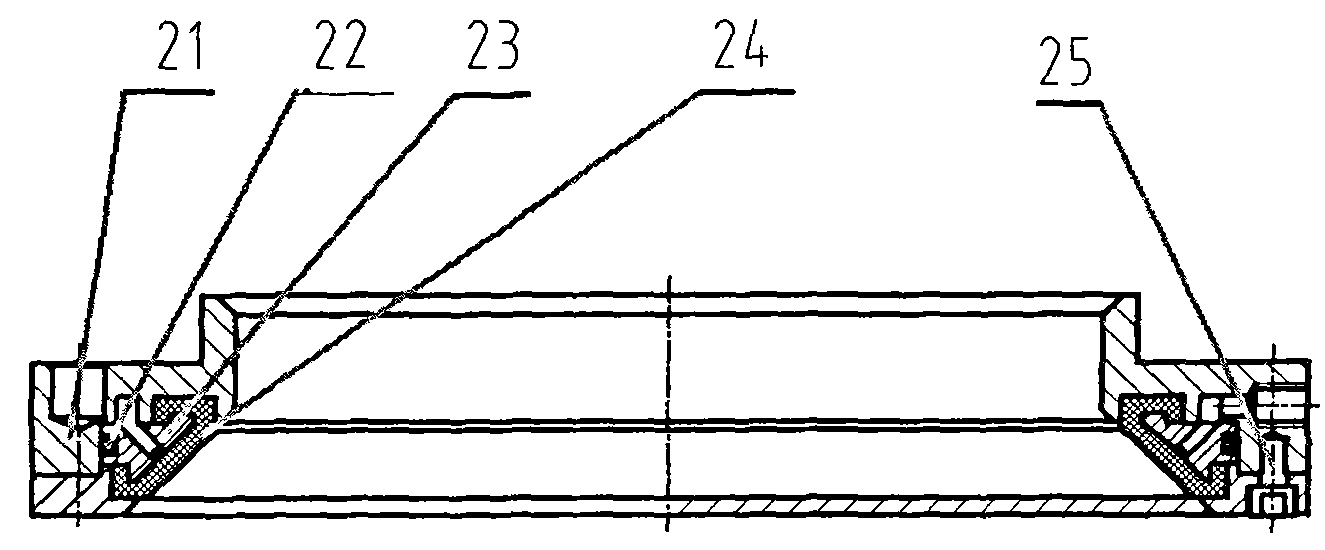

[0013] like figure 1 and figure 2 As shown, the novel pressurized sealing ball valve of the present invention includes a sealing gap adjustment device, a valve core hemispherical adjustment mechanism and a dust removal device. The sealing gap adjustment device is composed of a valve body 1, a sealing assembly 9, a tension bolt 13, a compression bolt 14, an O-ring 10, a washer 11 and a nut 12. The sealing assembly 9 is formed by connecting the sealing body 21, the O-ring 22, the positioning ring 23 and the sealing ring 24 with hexagonal bolts. The valve body 1 is welded with steel plates, and there are 4-6 M16 screw holes and 4-6 φ16 through holes corresponding to the sealing body 21 on the upper end surface of the valve body 1, and the compression bolts 14 are installed in the M16 holes, and the compression The bolt head bears against the sealing body 21, and the tension bolt 13 is installed in φ16, the tension bolt is connected with the sealing body, the sealing assembly i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com