Active electromagnetic bearing impeller pump

A technology of active electromagnetic bearings and impeller pumps, applied to pumps, pump devices, pump components, etc., can solve problems such as life safety issues, mechanical bearing seals, and overall system failures, achieving simple functions and overcoming easy wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

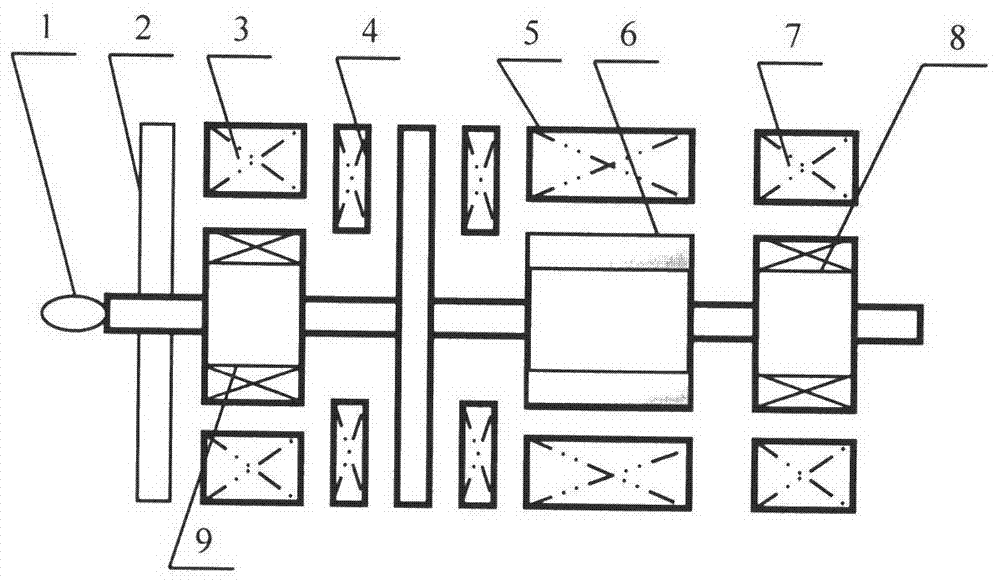

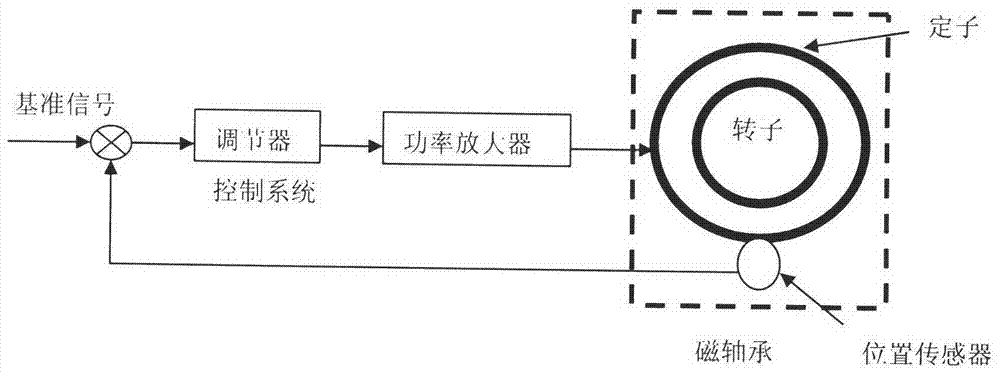

[0009] figure 1 As shown, the active electromagnetic bearing impeller pump consists of an axial displacement sensor (1), a radial displacement sensor (2), a radial magnetic bearing stator (3) (7), an axial magnetic bearing stator (4), and a stator coil (5 ), impeller rotor magnetic steel (6), radial magnetic bearing rotor (8) (9) and other components. figure 2 As shown, a typical active magnetic bearing system is composed of rotor, electromagnet, sensor, control circuit and power amplifier. Bearings consist of a rotor and a stator. The eccentricity of the rotor is detected by the sensor, and compared with the reference signal (the ideal position of the rotor) through feedback, the regulator adjusts according to the deviation signal, and sends the adjustment signal to the power amplifier to change the current of the electromagnet (stator) , so that the electromagnet current on one side of the air gap increases, and the electromagnet current on the other side decreases, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com