Sealing ring used for tieback plug

A technology of sealing rings and connectors, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as increasing operating costs, increasing downhole operation risks, and sealing failure, so as to improve construction efficiency, reduce construction risks, The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

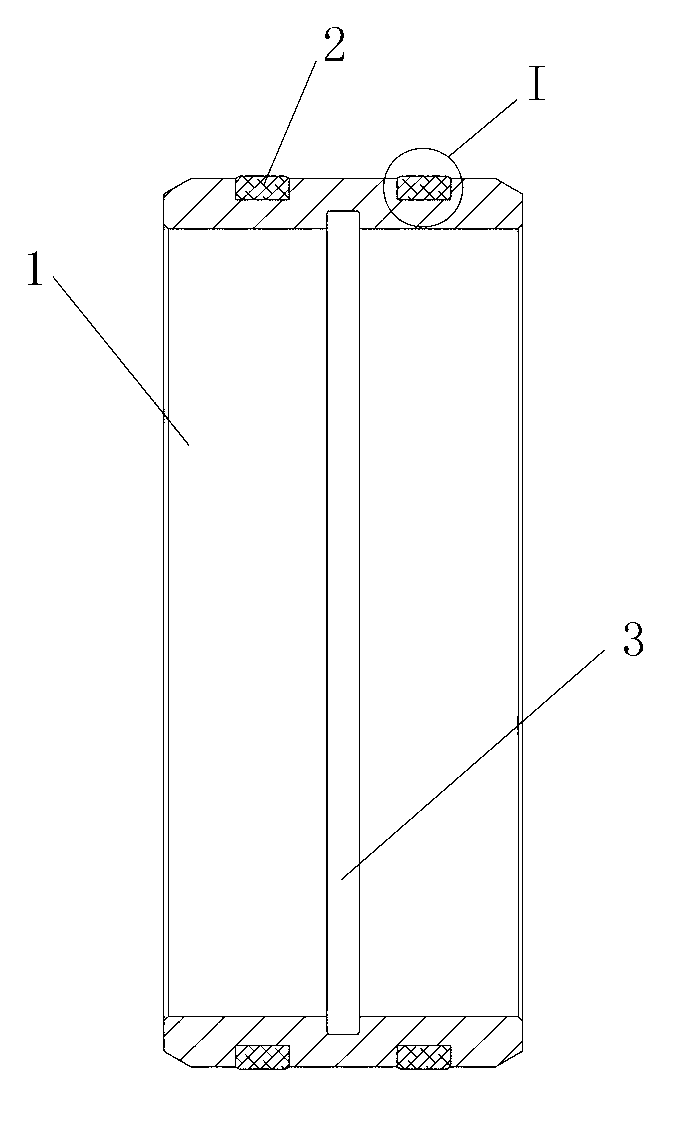

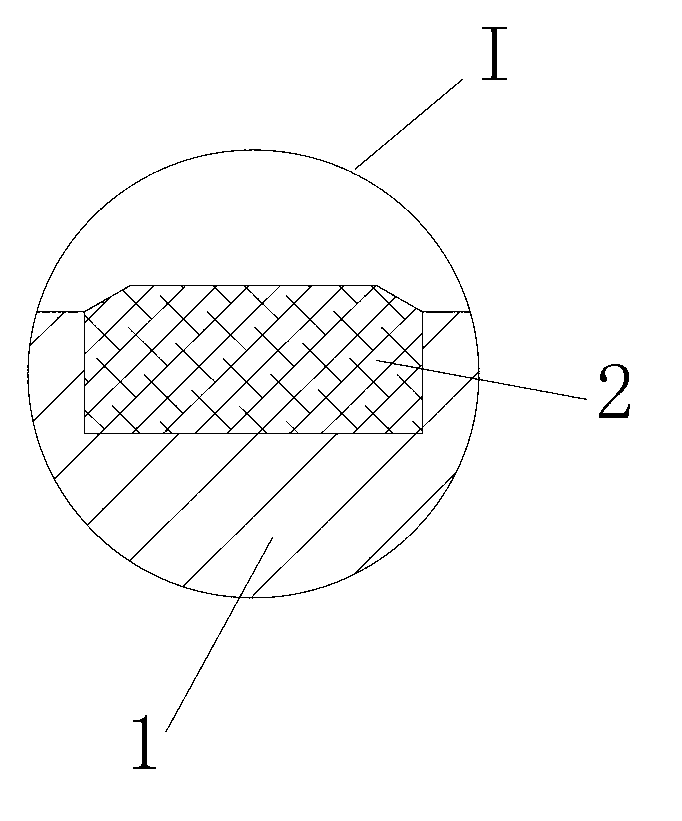

[0017] figure 1 It is a structural sectional view of the sealing ring for the tieback plug of the present invention. Such as figure 1 As shown, the sealing ring for the tie-back plug includes a sealing ring body 1, and two sealing grooves are arranged in parallel on the sealing ring body. Sealing rings 2 are respectively arranged in the sealing grooves, and the sealing rings 2 are fixedly connected with the sealing ring body 1 as a whole. The sealing ring 2 is vulcanized nitrile rubber filled in the sealing groove through the mold. The inside and outside of both ends of the sealing ring body 1 have chamfers respectively. The inner wall of the sealing ring body 1 has an annular groove 3 for arranging the sealing ring in the circumferential direction. When the sealing ring is assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com