Insulating oil volume compensation device system for oil immersed electrical device

A technology of power equipment and volume compensation, applied in the direction of transformer/inductor cooling, etc., can solve problems such as complicated maintenance and installation, hidden dangers of maintenance, poor safety, etc., achieve the effects of saving manufacturing and maintenance costs, simplifying the external structure, and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

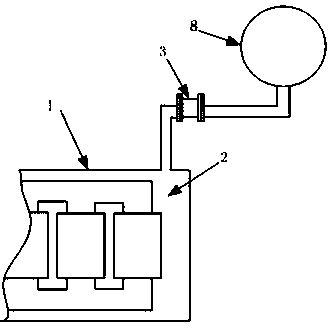

Image

Examples

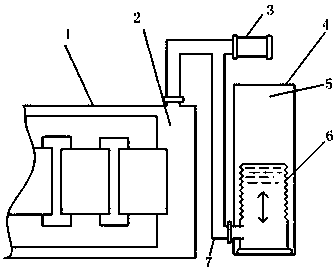

Embodiment 1

[0036] figure 2 Shown is an insulating oil volume compensation device system for oil-immersed power equipment, which is composed of power equipment 1, insulating oil 2, gas relay 3, casing 4 and elastic element 6, and the elastic element 6 is vertically arranged on the casing 4 In the inner bottom, the inside of the elastic element 6 communicates with the highest position of the insulating oil 2 in the electric equipment 1 through the oil passage system 7, the gas relay 3 is arranged on a branch of the oil passage system 7, and the housing 4 is set separately from the electric equipment 1 , wherein the space between the outside of the elastic element 6 and the casing 4 is filled with air 5 , and the air 5 communicates with the outside of the casing 4 .

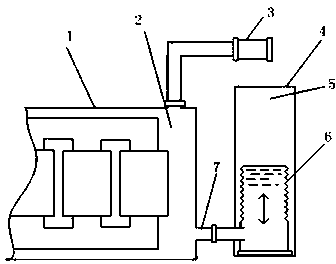

Embodiment 2

[0038] image 3 Shown is an insulating oil volume compensation device system for oil-immersed power equipment, which is composed of power equipment 1, insulating oil 2, gas relay 3, casing 4 and elastic element 6, and the elastic element 6 is vertically arranged on the casing 4 In the inner bottom, the inside of the elastic element 6 communicates with the low position of the insulating oil 2 in the electric equipment 1 through the oil circuit system 7. The gas relay 3 is arranged on the top of the electric equipment 1, and the casing 4 is separated from the electric equipment 1. The elastic element 6 The space between the outside and the casing 4 is filled with air 5 , and the air 5 communicates with the outside air of the casing 4 .

Embodiment 3

[0040] Figure 4 Shown is an insulating oil volume compensation device system for oil-immersed power equipment, which is composed of power equipment 1, insulating oil 2, gas relay 3, casing 4 and elastic element 6, and the elastic element 6 is vertically arranged on the casing 4 In the inner bottom, the inside of the elastic element 6 communicates with the low position of the insulating oil 2 in the power equipment 1 through the oil circuit system 7, the gas relay 3 is arranged on the top of the power equipment 1, and the housing 4 and the power equipment 1 are of an integrated structure, wherein Air 5 is filled between the outside of the elastic element 6 and the housing 4 , and the air 5 communicates with the outside of the housing 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com