Integrated high temperature resistant aerosol spray pipe

A spray pipe and high-temperature-resistant technology, which is applied in the spray device for cleaning and dust removal, and in the field of cooling, can solve the problems of reduced service life, complex structure, inconvenient installation and use, etc., and achieves convenient installation and use, large adjustable range, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

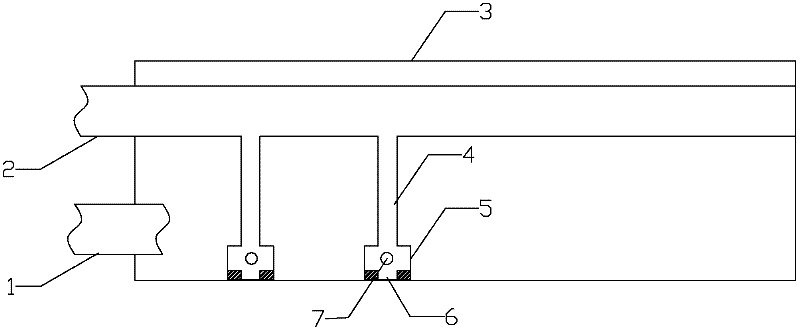

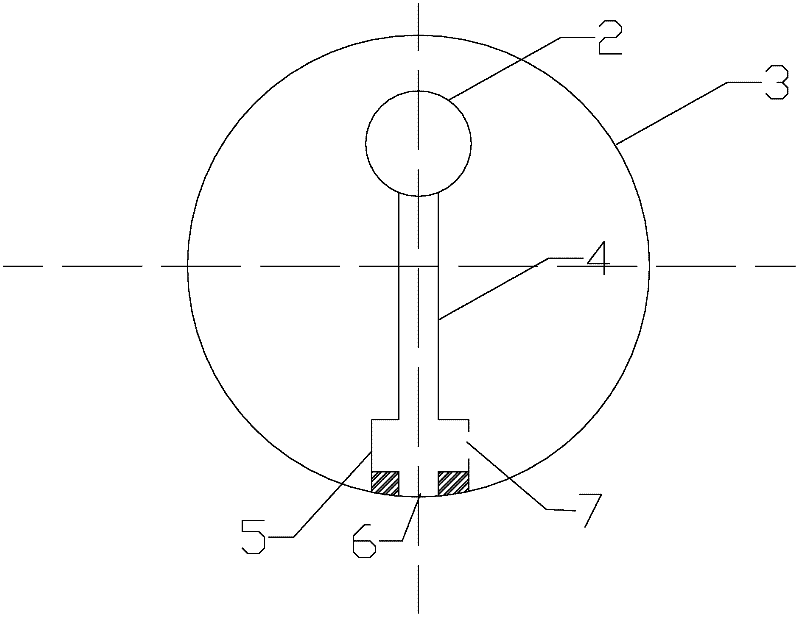

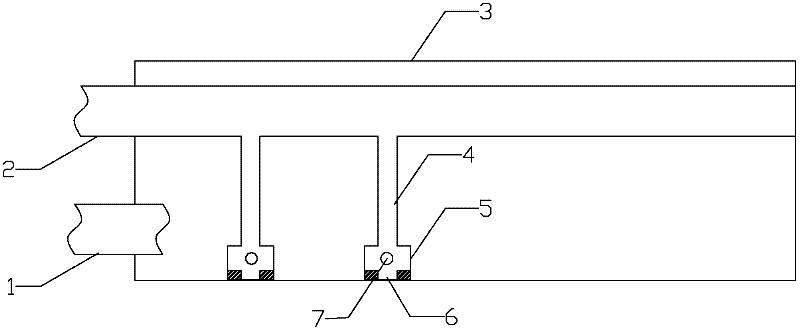

[0029] Below in conjunction with embodiment and attached Figure 1-2 The present invention is described further, but the present invention is not limited.

[0030] One-piece high-temperature-resistant aerosol spray pipe, the air pipe 2 is installed inside the water pipe 3 of the spray pipe, and then connected to the air-water mixing chamber 5 through the branch pipe 4, the gas enters the air-water mixing chamber 5 through the air pipe 2 and the branch pipe 4, and after mixing with water Spray outwards through an aerosol nozzle (not shown);

[0031] Water enters the spray pipe through the external water pipe 1 and fills the entire spray pipe water pipe 3. Under the action of pressure, it enters the air-water mixing chamber 5 through the water inlet hole 7, and finally sprays outward through the aerosol nozzle (not shown);

[0032] The outer wall of the spray pipe, that is, the water pipe 3 of the spray pipe, is self-cooled by the cooling water in the pipe to achieve the purpos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com