Labyrinth and fingertip combined type seal structure

A sealing structure and fingertip sealing technology, which is applied to engine sealing, leakage prevention, engine components, etc., can solve problems such as unbearable pressure difference, unsuitable for high pressure ratio axial sealing, etc., to prevent gas leakage and reduce manufacturing Cost, make up for the effect of large leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

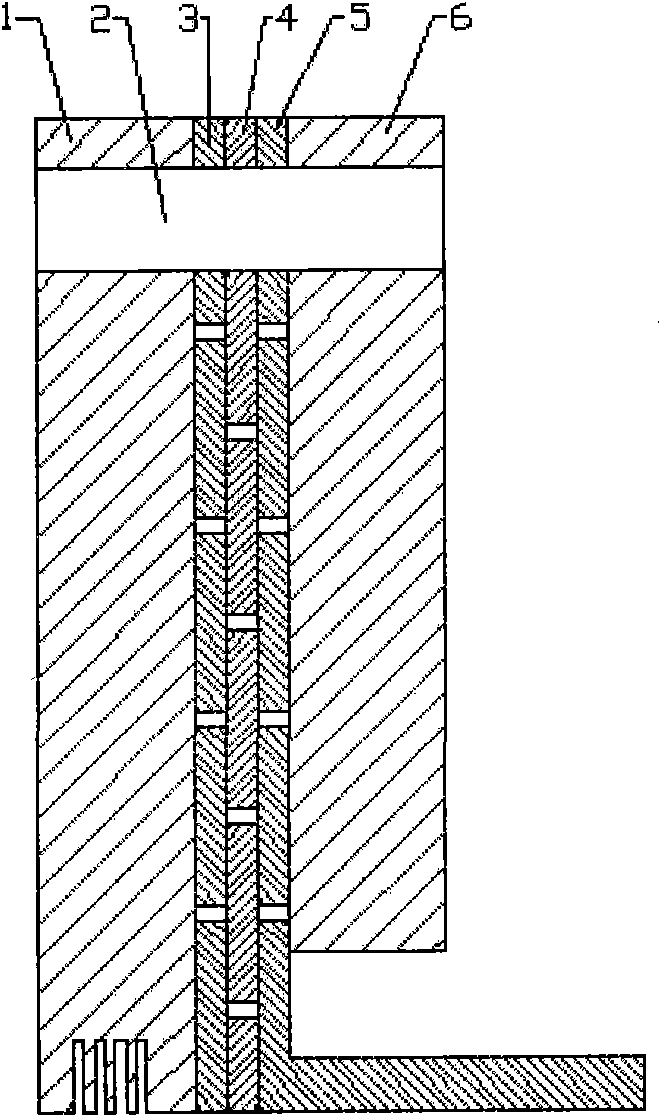

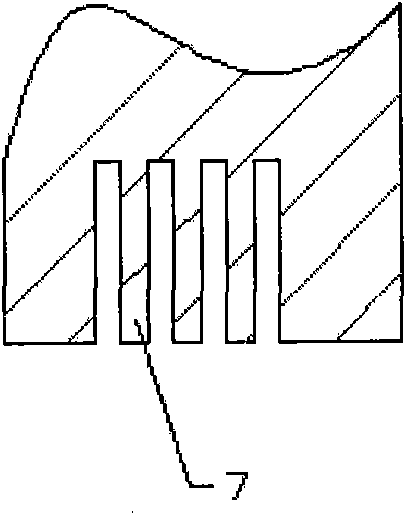

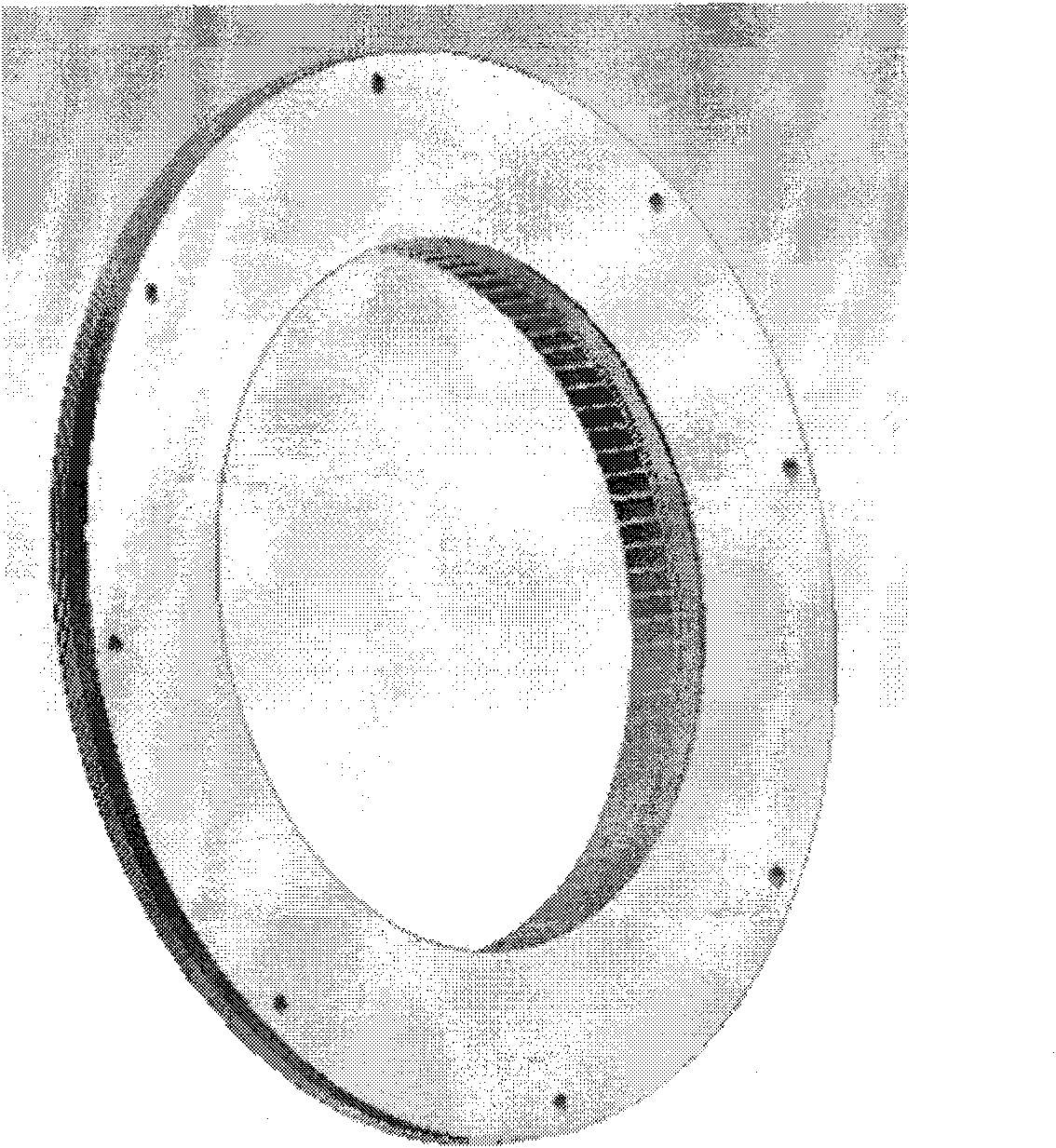

[0023] combine figure 1 and figure 2 . The sealing structure of the present invention includes a labyrinth seal and a fingertip seal; the fingertip seal includes a first high-pressure sealing fingertip 3, a second high-pressure sealing fingertip 4, and a low-pressure sealing fingertip 5 with a fingertip shoe , there is an arc-shaped gap on the fingertip piece, the three fingertip pieces are fixed together, a front baffle 1 is set in front of the high-pressure sealing level fingertip piece, and a rear baffle is set behind the low-pressure sealing level fingertip piece with fingertip boots Plate 6; labyrinth seal is the seal tooth 7 that is inlaid on the front baffle. There are bolt holes 2 on the periphery of the fingertip sheet and the front and rear baffles to fix the fingertip sheet and connect it to the receiver. The number of the sealing teeth is selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com