Solid particle medium thermal expansion forming method for light alloy tubular component

A technology of solid particles and tubular components, which is applied in the field of solid particle medium thermal expansion forming of light alloy tubular components, can solve the problems of restricting wide application and difficulty in applying the forming temperature range, and achieve simple process control, good chemical stability and mechanical properties , The effect of improving the forming limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

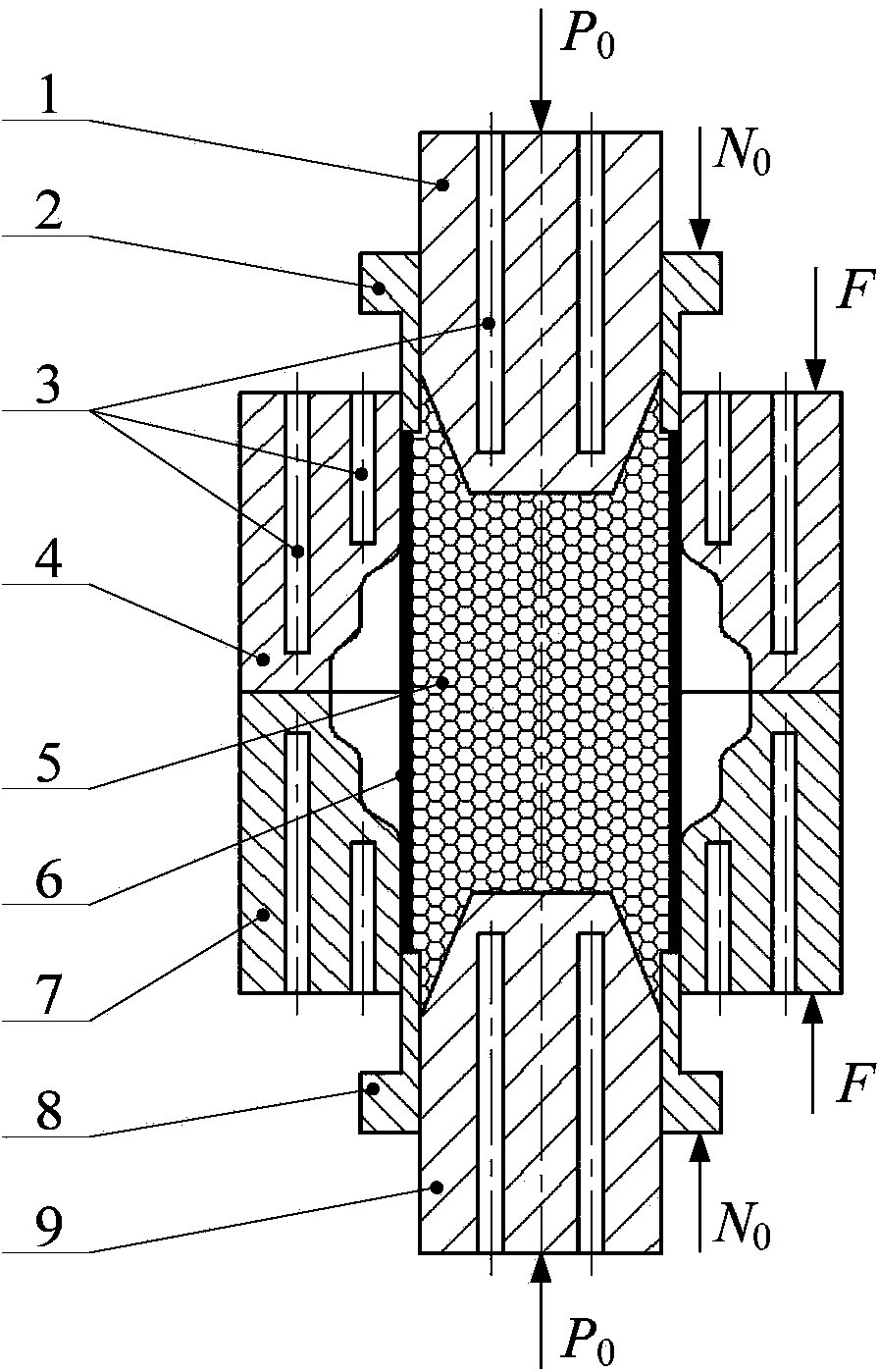

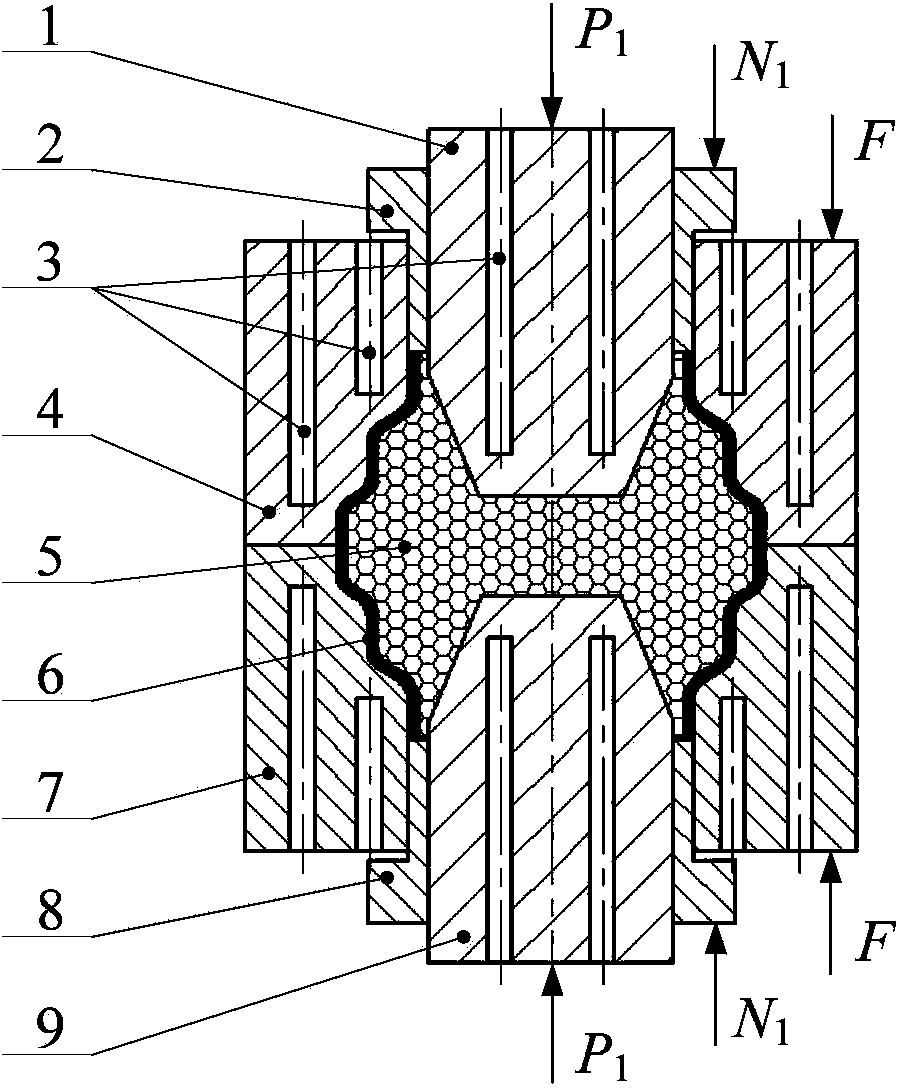

Embodiment 1

[0018] First, the upper pressing head 1, the upper pressing cover 2, the upper die 4, the lower die 7, the lower pressing head 8, and the lower pressing head 9 in the mold device are closed and preheated to the process setting temperature of AA5052 aluminum alloy pipe 6 forming 270 ℃, the heating device 3 adopts resistance heating and a closed-loop temperature control system, and at the same time, the steel ball particle medium 5 is heated externally by a heating furnace, and preheated to a process setting temperature of 270°C; the mold is closed, and the lower gland and the lower pressure head are moved To the set position, the moving positions of the lower gland and the lower pressure head are respectively set according to the length of the tube blank and the filling volume of the heat-resistant solid granular medium. Put the AA5052 aluminum alloy tube blank into the cavity of the above-mentioned heated mold, and fill the above-mentioned heated heat-resistant solid particle m...

Embodiment 2

[0020] First, close and preheat the upper pressing head, upper gland, upper mold, lower mold, lower gland, and lower pressing head in the mold device to the process setting temperature of TC4 titanium alloy pipe forming at 850°C. The heating device adopts intermediate frequency heating and Closed-loop temperature control system. At the same time, the heat-resistant ceramic granular medium is heated externally by the heating furnace, and preheated to the process setting temperature of 850°C; the mold is closed, and the lower gland and the lower pressure head are moved to the set position, and the lower gland and the moving position of the lower pressure head are respectively set according to the length of the tube blank and the filling volume of the heat-resistant solid granular medium. Put the TC4 titanium alloy tube blank into the cavity of the above-mentioned heated mold, and fill the above-mentioned heated heat-resistant solid particle medium into the cavity formed by the tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com