Patents

Literature

143results about How to "Reduce air bubble content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

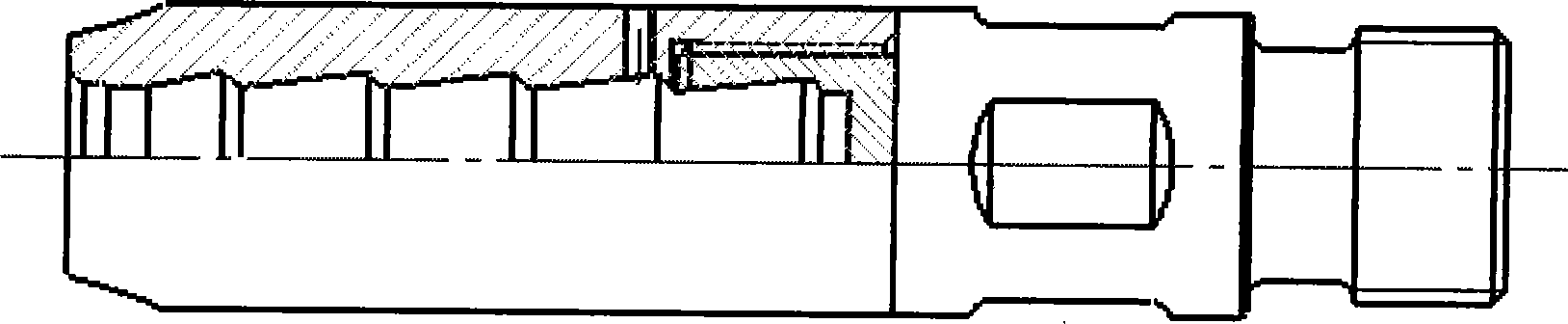

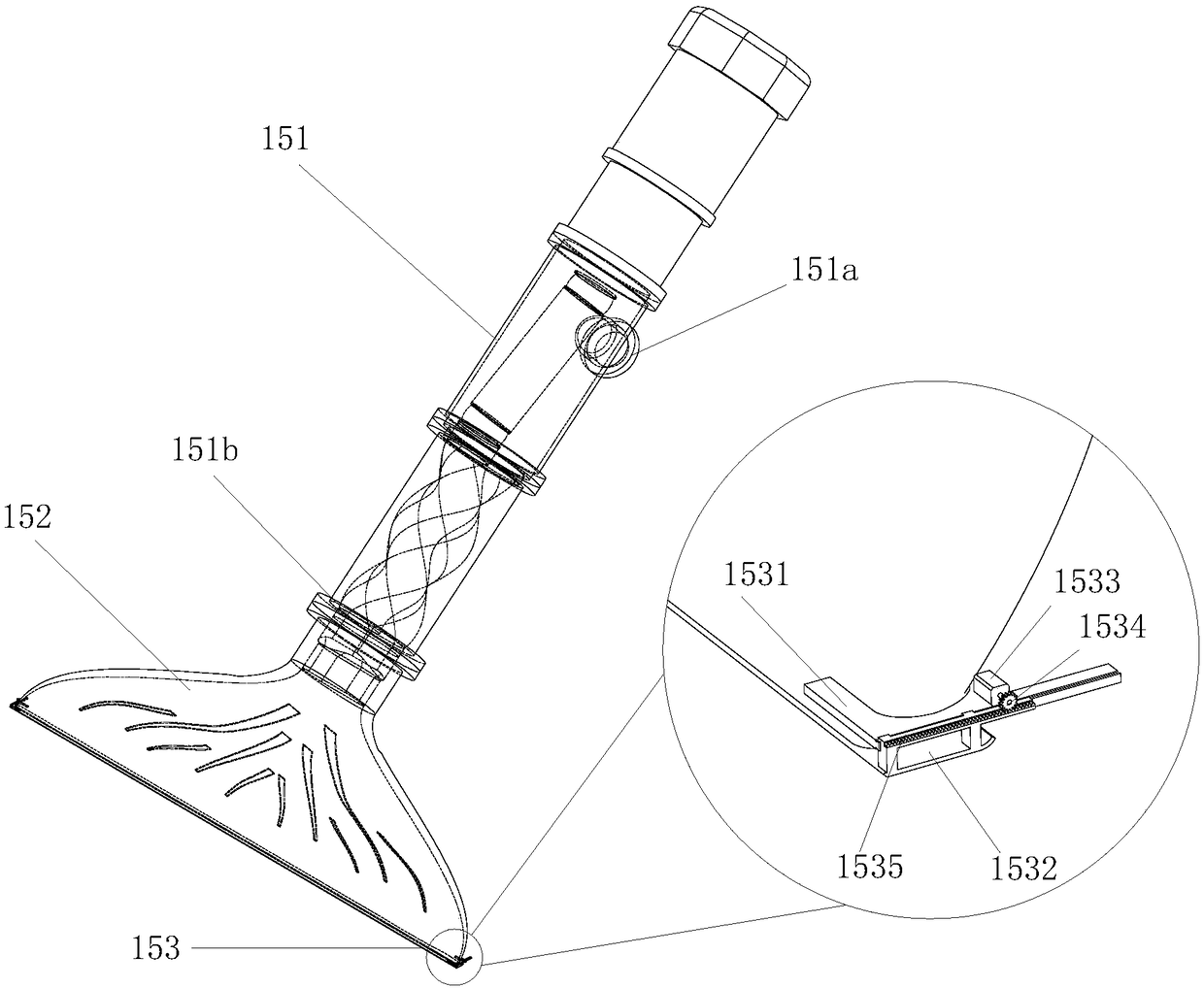

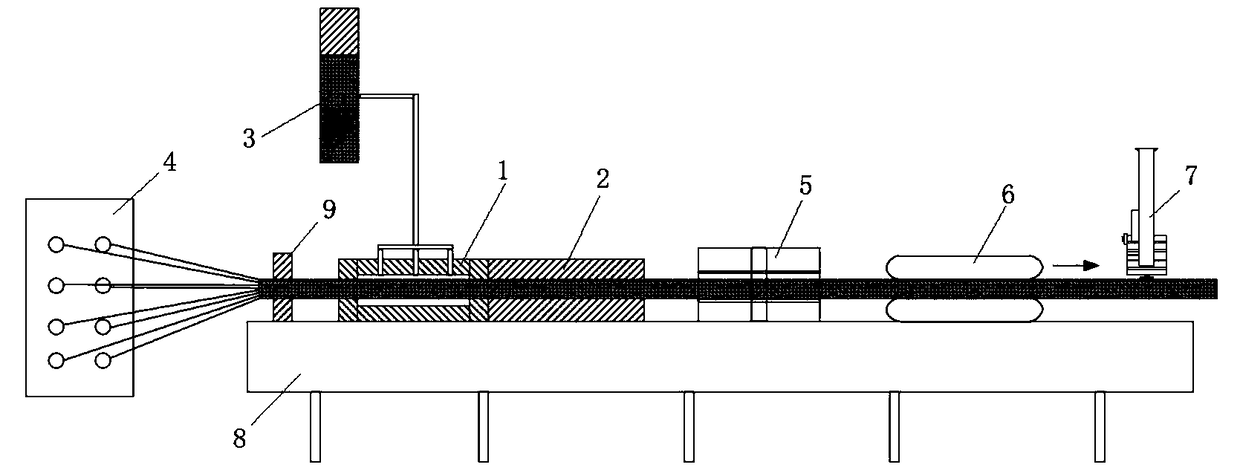

Preparation method and device of eccentric wear prevention pumping rod

InactiveCN101396874AExcellent performance of anti-eccentric wearPrevent slippageDrilling rodsDomestic articlesPre stressResin matrix

The invention relates to a method for preparing a composite material sucker rod which can prevent camber wear and a device thereof. Combining pultrusion and winding, fibre is immersed by resin matrix, and the composite material sucker rod is prepared by pultrusion, curing and shaping; the surface of the rod body is continuously wound with wearing fibre immersed by resin matrix glue after shaping; the rod body of the sucker rod, the surface of which is provided with a camber wear preventing layer of a spiral bar shape is obtained by curing; the rod body of the sucker rod is cut to be in fixed length, is connected with a metal joint by glue, and is treated in a joint curing furnace; the whole sucker rod is stretched by inherent stress. The surface of the rod body of the sucker rod is provided with the camber wear preventing layer of a spiral bar shape, thus having excellent camber wear preventing performance while ensuring a high intensity of the sucker body; the inverse cone structure of the metal joint and the pressure injection glue connection process ensure the joint part has the properties of high intensity and fatigue proof, the service life of which is consistent with the composite material rod body, and the reliability of the products is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

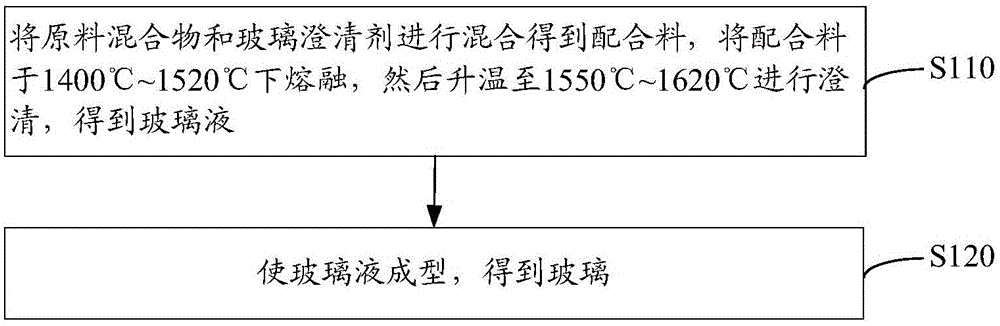

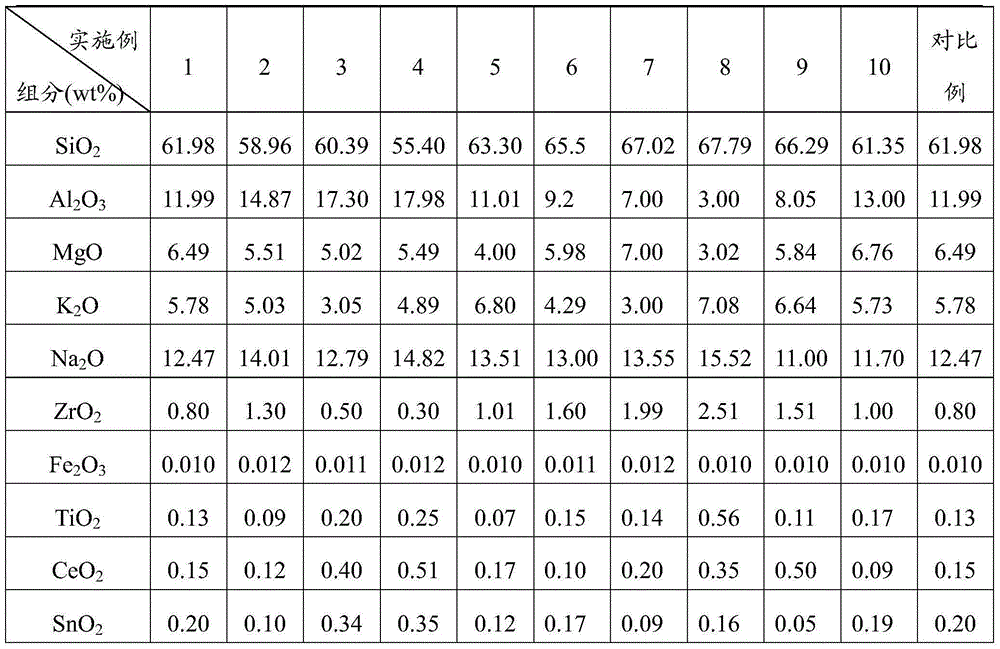

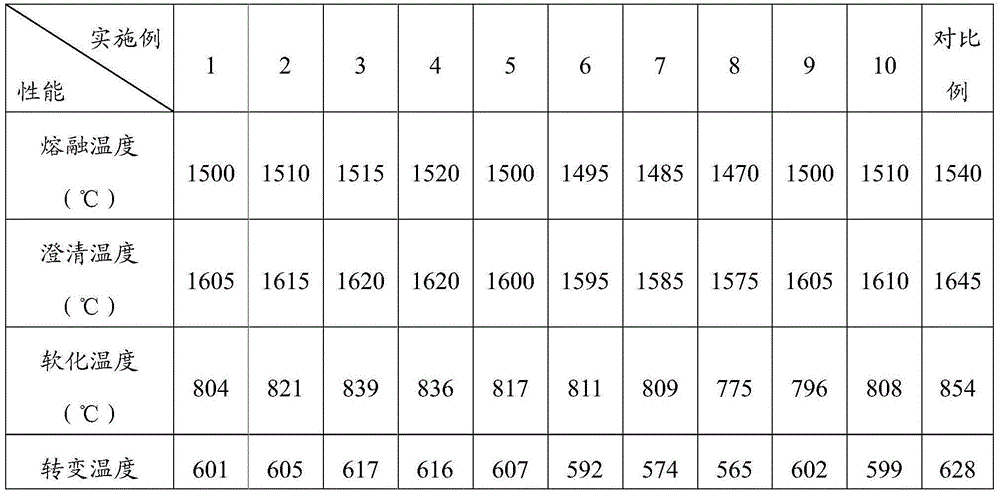

Glass clarifier and glass preparation method

ActiveCN105084756AReduce air bubble contentInhibition releaseGlass furnace apparatusGlass productionNitrateSodium sulfate

The invention relates to a glass clarifier and a glass preparation method. The glass clarifier contains nitrate, sodium sulfate, ceria and stannic oxide, wherein the mass ratio of nitrate to sodium sulfate to ceria to stannic oxide is (0.2-3.0): (1.0-3.0): (0.01-2.0): (0.01-1.5). Thus, the glass clarifier is non-toxic and harmless and is relatively good in clarification effect.

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD

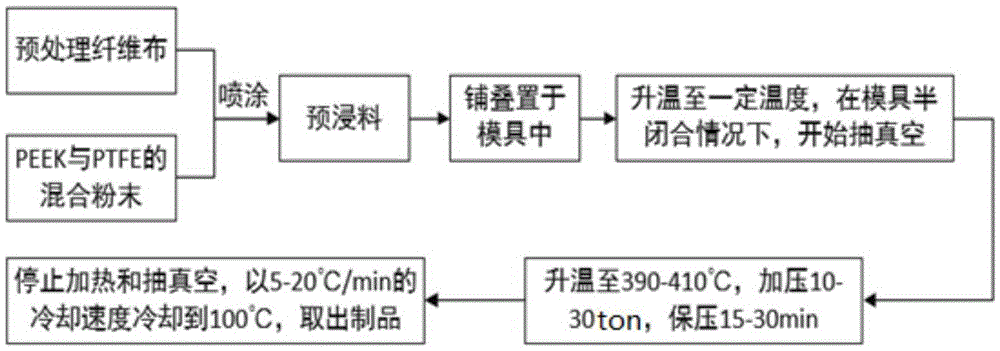

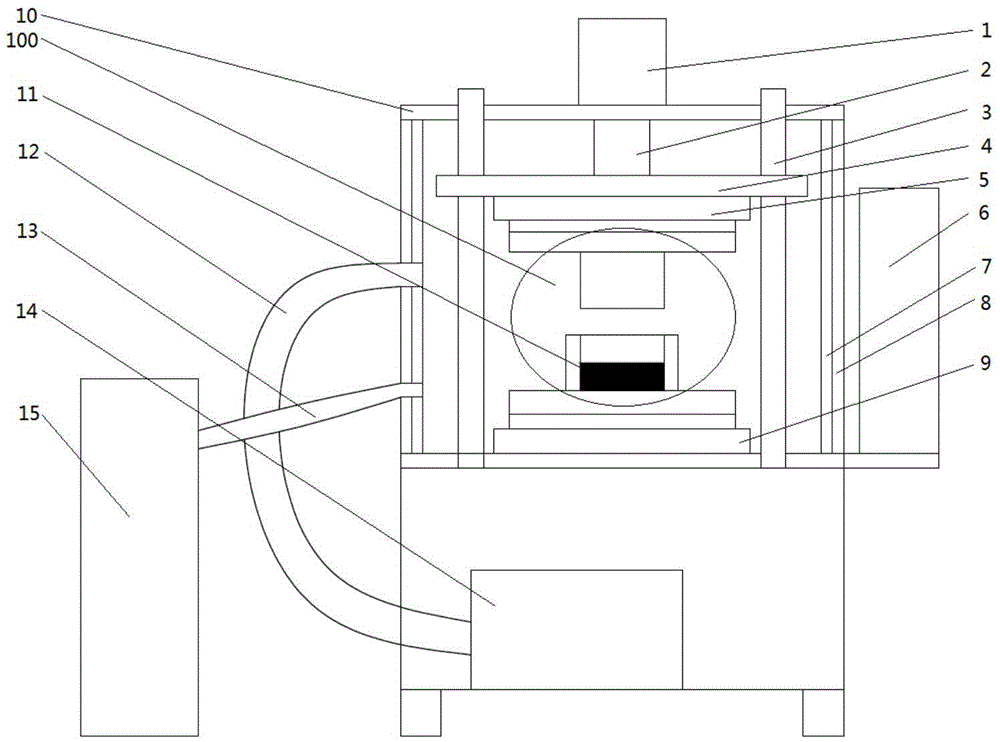

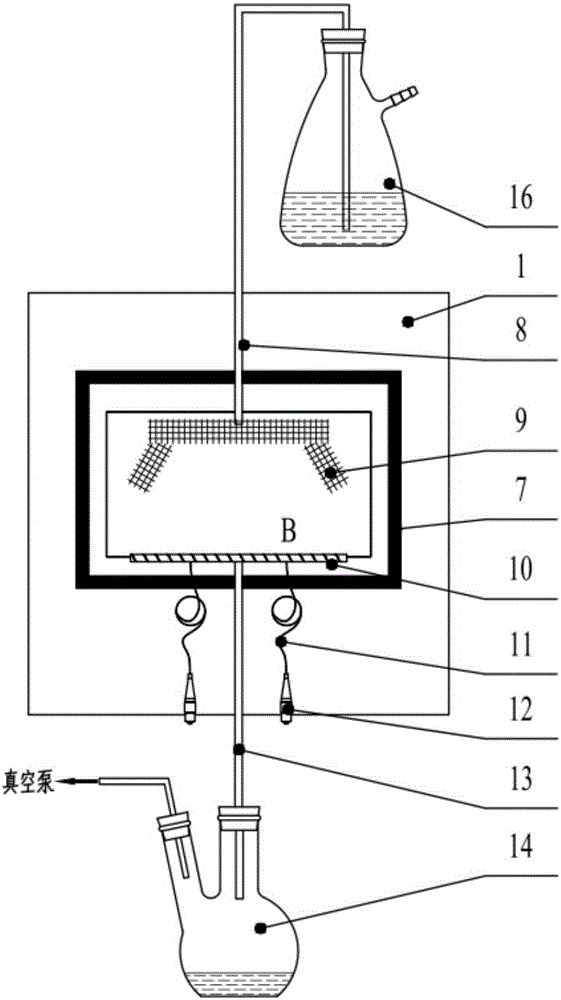

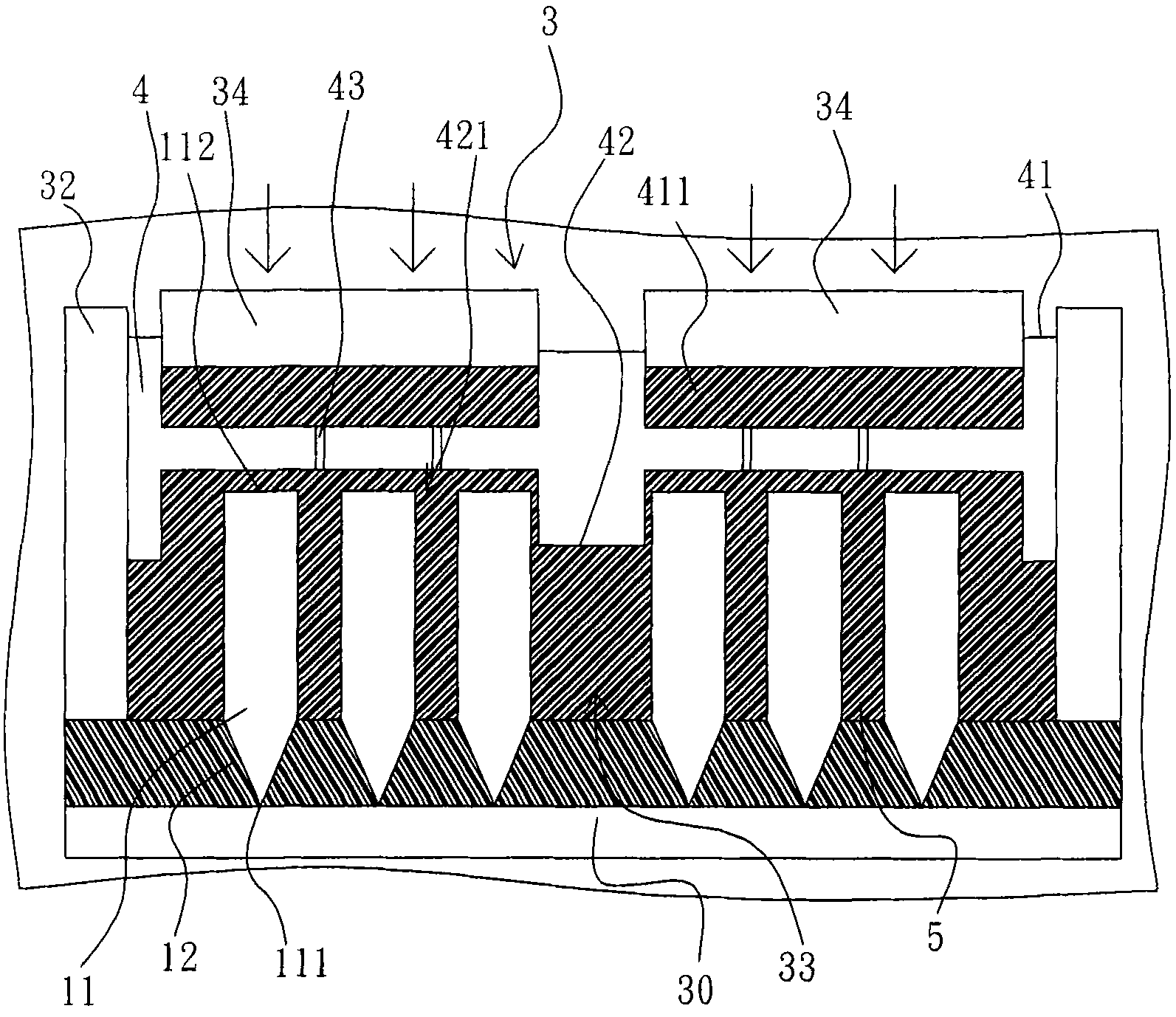

Hot press molding device for carbon fiber enhanced polyether-ether-ketone (PEEK) composite material and technological method thereof

The invention provides a hot press molding device for a carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. The hot press molding device comprises a hydraulic machine, a molding die and a vacuum system. According to the device, a heating unit is separated from the hydraulic machine, and a heating pipe is used for heating the die to achieve a high temperature hot pressing function; by carrying out hot press molding in a vacuum environment, the content of bubbles in resin can be greatly reduced, and the test piece surface smoothness and workpiece performances are improved; a cooling unit is arranged in the die, and cooling speed is regulated by regulating the flow and temperature of high pressure cold air, so as to control the crystallinity of matrix resin and realize flexible selection between high strength and high toughness. Correspondingly, the invention also provides a hot press molding method for the carbon fiber enhanced polyether-ether-ketone (PEEK) composite board. A carbon fiber enhanced polyether-ether-ketone (PEEK) composite board produced by adopting the device and the method disclosed by the invention through hot press molding is simple in production equipment and solves the problems that material internal porosity is large, resin impregnation fiber is insufficient, test piece performance is insufficient, molding cycle is long and the like during production of polyether-ether-ketone resin with high melting point and high viscosity.

Owner:HUAZHONG UNIV OF SCI & TECH

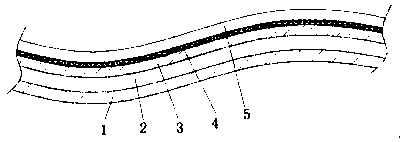

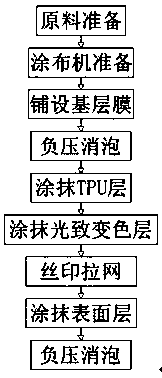

Anti-broken hot melt adhesive membrane used for automobile decoration and preparation method of anti-broken hot melt adhesive membrane

InactiveCN109135605AImprove the adhesion effectImprove surface wear resistanceFilm/foil adhesive primer layersHeat-activated film/foil adhesivesSurface layerWear resistant

The invention discloses an anti-broken hot melt adhesive membrane used for automobile decoration and a preparation method of the anti-broken hot melt adhesive membrane. The anti-broken hot melt adhesive membrane comprises a PVB base adhesive, a TPU adhesive layer is stuck to the outer wall on one side of the PVB base adhesive, a photochromic layer is stuck to the outer wall on the side, away fromthe PVB base adhesive, of the TPU adhesive layer, a nylon mesh cloth layer is stuck to the outer wall on the side, away from the TPU adhesive layer, of the photochromic layer, and a membrane surface layer is stuck to the outer wall on the side, away from the photochromic layer, of the nylon mesh cloth layer. The preparation method comprises the following steps of preparation of raw materials, wherein a PVB adhesive solution, an EVA adhesive solution and a TPU adhesive solution which are needed during production are mixed and stirred respectively, and then sampled and inspected respectively; preparation of coating machines, wherein the three coating machines are prepared, and adhesive storage cylinders and coating heads of the three coating machines are cleaned. By means of the anti-brokenhot melt adhesive membrane, improvement of the wear-resistant performance of the surface of the hot melt adhesive membrane is facilitated, by cooperatively arranging the nylon mesh cloth layer, improved of the adhesion effect of the surface layer of the membrane can be facilitated, the box stretching performance of the hot melt adhesive membrane is improved, and improvement of the elasticity of the hot melt adhesive membrane is facilitated.

Owner:安徽天念材料股份有限公司

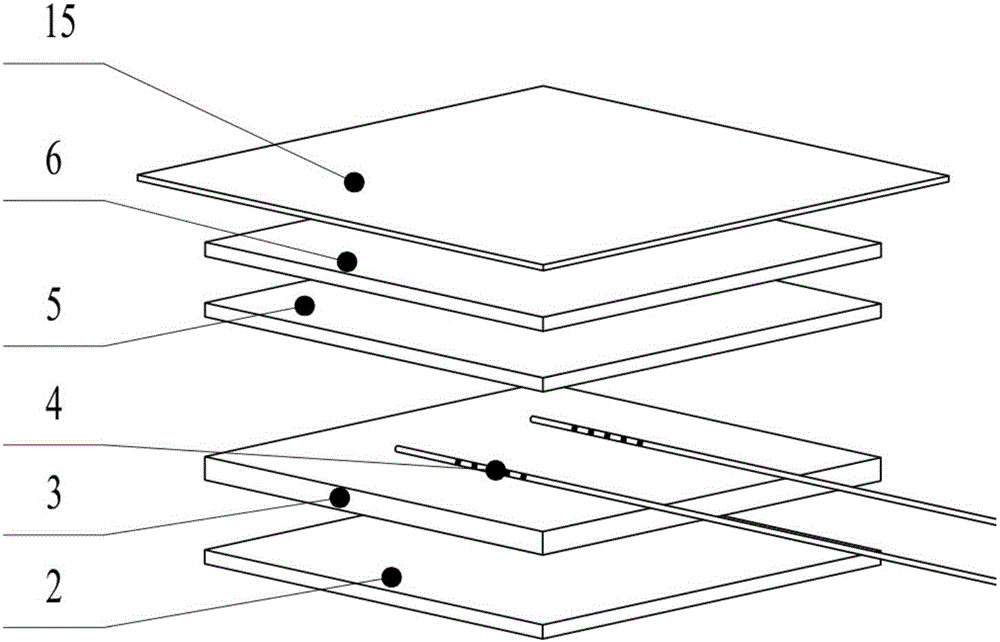

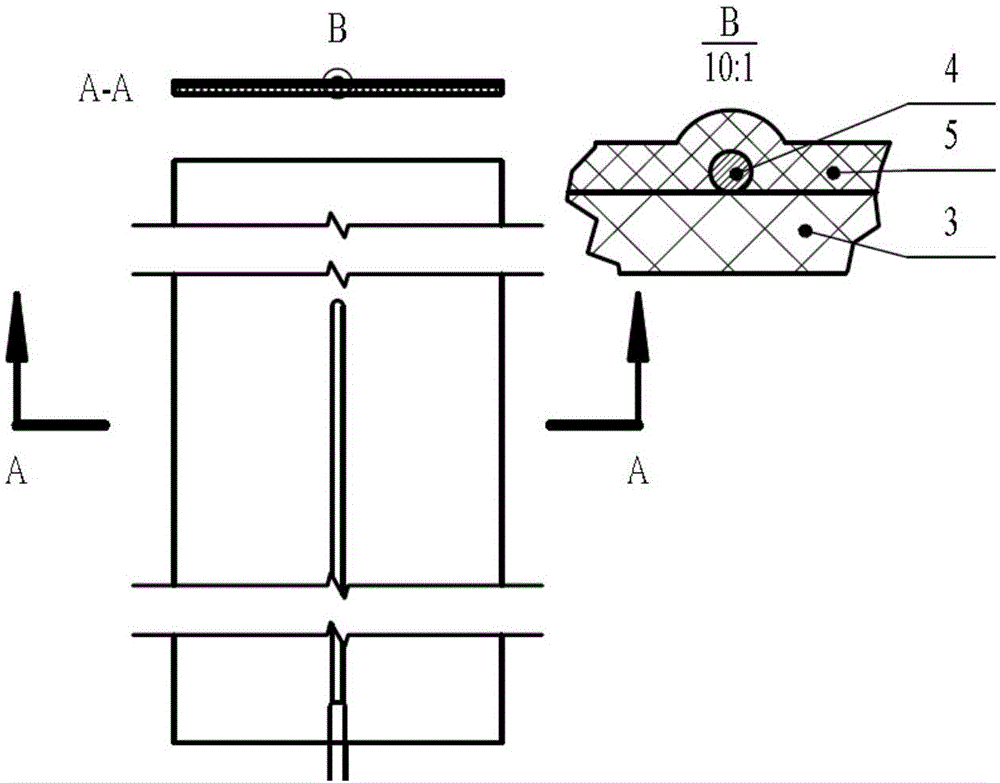

Manufacturing technology of glass fiber/epoxy resin composite material substrate type fiber bragg grating sensor

ActiveCN106633137AImprove performance and stabilityReduce internal stressMeasurement devicesOptical articlesFiberEpoxy

The invention discloses a manufacturing technology of a glass fiber / epoxy resin composite material substrate type fiber bragg grating sensor. The manufacturing technology comprises the steps that glass fiber / epoxy resin prepreg is procured to prepare a glass fiber / epoxy resin composite material substrate; a fiber bragg grating is fixed to the glass fiber / epoxy resin composite material substrate; the glass fiber / epoxy resin composite material substrate fixed with the fiber bragg grating is covered with a dry-state glass fiber cloth, vacuum aided filling of liquid epoxy resin is performed, and secondary curing molding is performed. The manufacturing technology adopts the secondary curing molding in the packaging process, the interlayer interface strength is remarkably improved, accordingly the testing precision and stability of the fiber bragg grating sensor are improved, batch production of the fiber bragg grating sensor can be achieved, and the manufacturing technology has wide market prospect and huge economic benefit.

Owner:SHANDONG UNIV

Thick-film and low-foam one-component polyurethane elastomer and preparation method thereof

InactiveCN103509169AImprove liquidityReduce air bubble contentPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyurethane elastomerPlasticizer

The invention relates to a thick-film and low-foam one-component polyurethane elastomer and a preparation method thereof. The elastomer is prepared from a one-component polyurethane resin, filler, a neutral chemical defoaming agent and other assistants. The preparation method comprises the following steps: firstly mixing the raw materials such as polyether, the filler, a solvent, a plasticizer and the like in a reaction kettle; adding diisocyanate and the solvent to the reaction kettle to evenly mix and stir, and heating to 80-85 DEG C to react for 2 hours; finally adding a catalyst to react for 30 minutes; cooling to 60 DEG C, and adding the neutral chemical defoaming agent; discharging after stirring for 30 minutes. The bubble content of the one-component polyurethane elastomer to which the neutral chemical defoaming agent is added is reduced by 30-80% in comparison with that of the elastomer to which the neutral chemical defoaming agent is not added; the film can be coated 5mm-1cm one time; the storage stability is 3-6 months.

Owner:SHANGHAI BOSEAN WORLD NEW MATERIAL TECH CO LTD

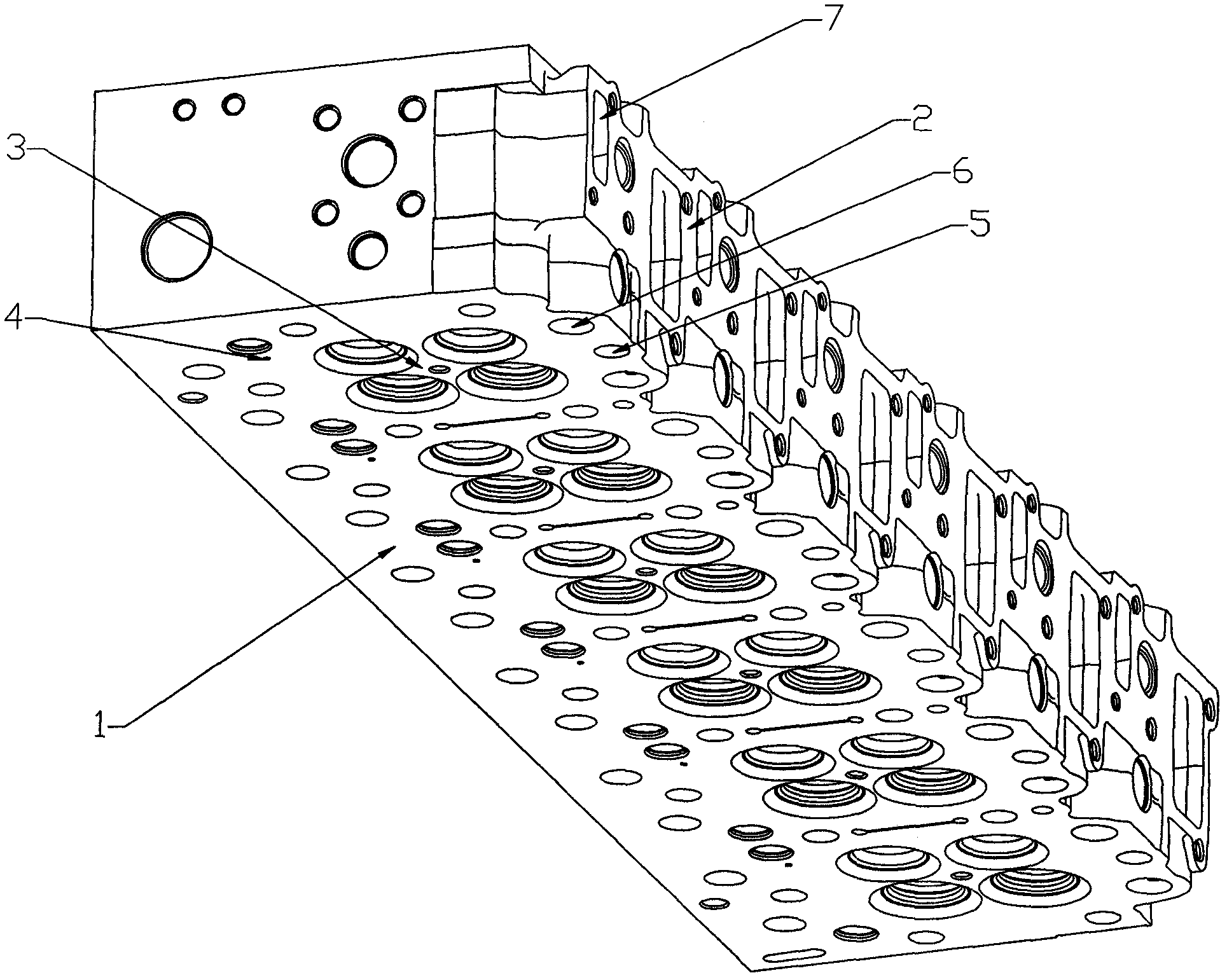

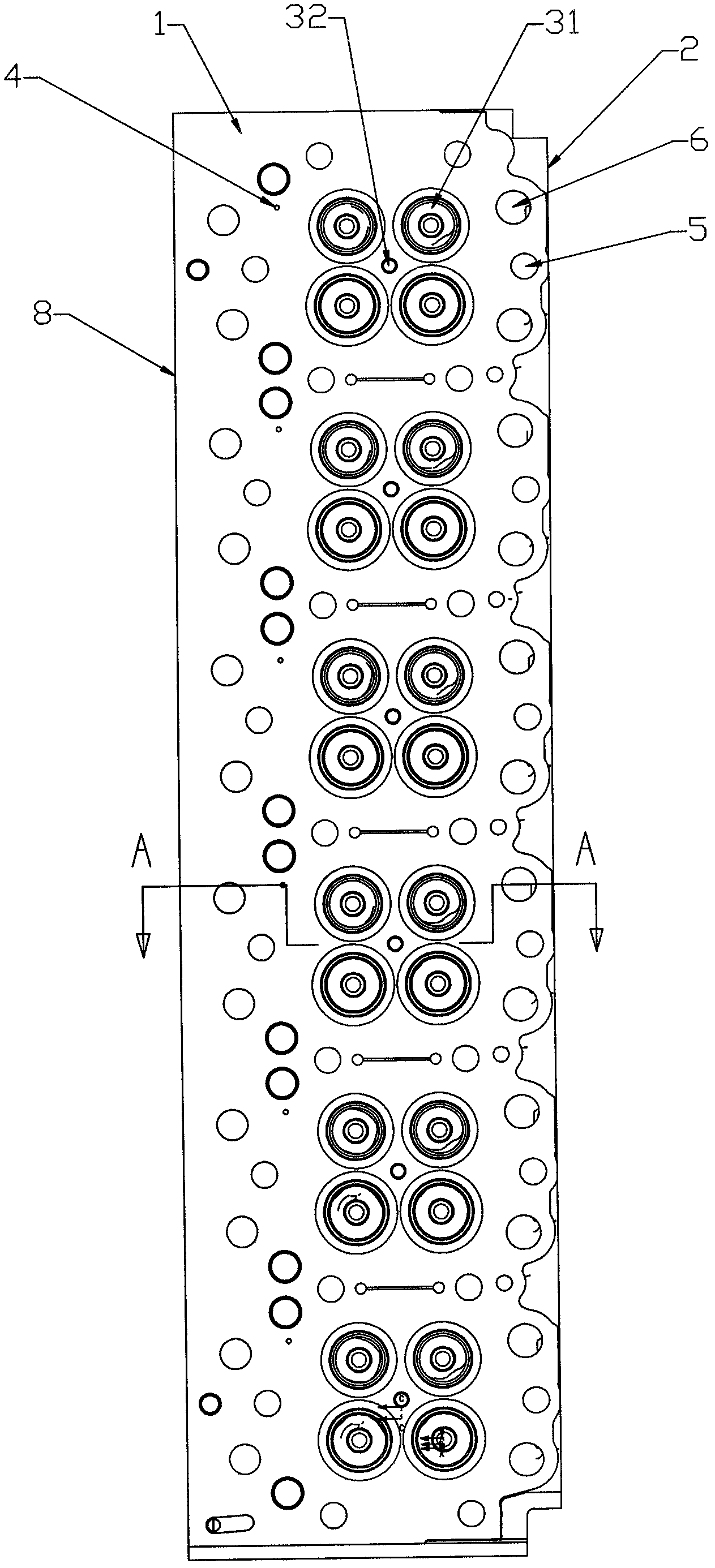

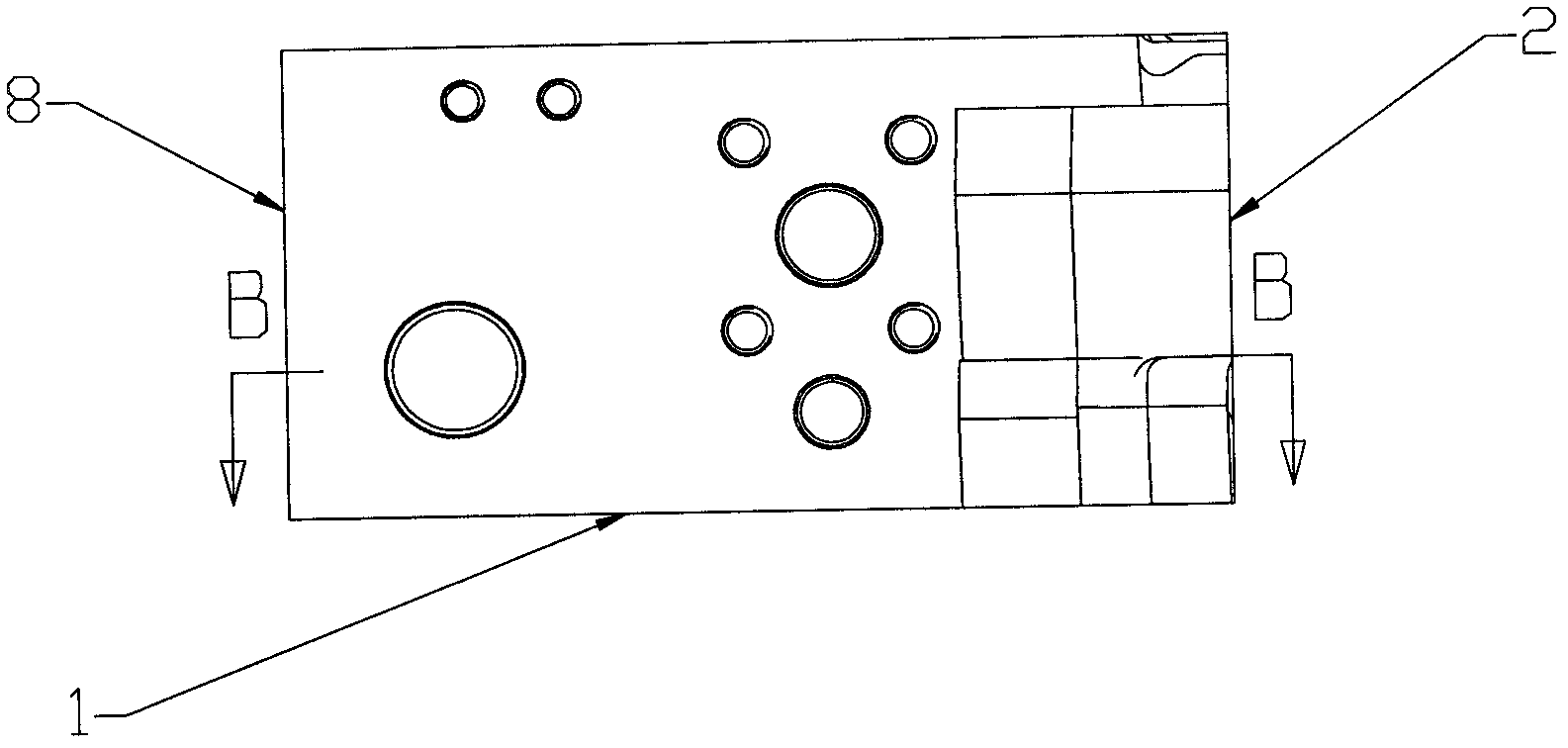

Integral cylinder cover of water-cooled four-valve diesel engine and corresponding diesel engine water cooling method

InactiveCN102758701ANo short circuitImprove cooling effectLiquid coolingCylinder headsCooling effectWater cooling

The invention discloses an integral cylinder cover of a water-cooled four-valve diesel engine and a corresponding diesel engine water cooling method based on the cylinder cover. According to the cylinder cover, a partition plate for partitioning a water cooling cavity into an upper cavity and a lower cavity is arranged in the water cooling cavity, wherein a water feeding passage for communicating the upper cavity and the lower cavity is formed on one side of the partition plate; a bottom plate is provided with an exhaust duct side exhaust hole corresponding to the water feeding passage; and a water inlet hole and an intake duct side exhaust hole which are communicated with the lower cavity are formed on the other side of the bottom plate. The diesel engine water cooling method comprises the following steps of: circulating water cooling outside a diesel engine cylinder from one side to the other side through a circulating water pump; and flowing the cooling water into the lower cavity from the water inlet hole on the bottom plate of the cylinder cover, then flowing to the upper cavity through the water feeding passage from the lower cavity and flowing out from the water outlet. By arranging the partition plate in the cylinder cover, forced cooling water passes through a nose bridge region so as to guarantee a cooling effect of the noise bridge region and the bottom plate of the cylinder cover; and bubbles produced on the outer wall of the cylinder can be quickly washed away and vapor can be discharged, so that cooling water of high water temperature does not easily occur in the diesel engine.

Owner:GUANGXI YUCHAI MASCH CO LTD

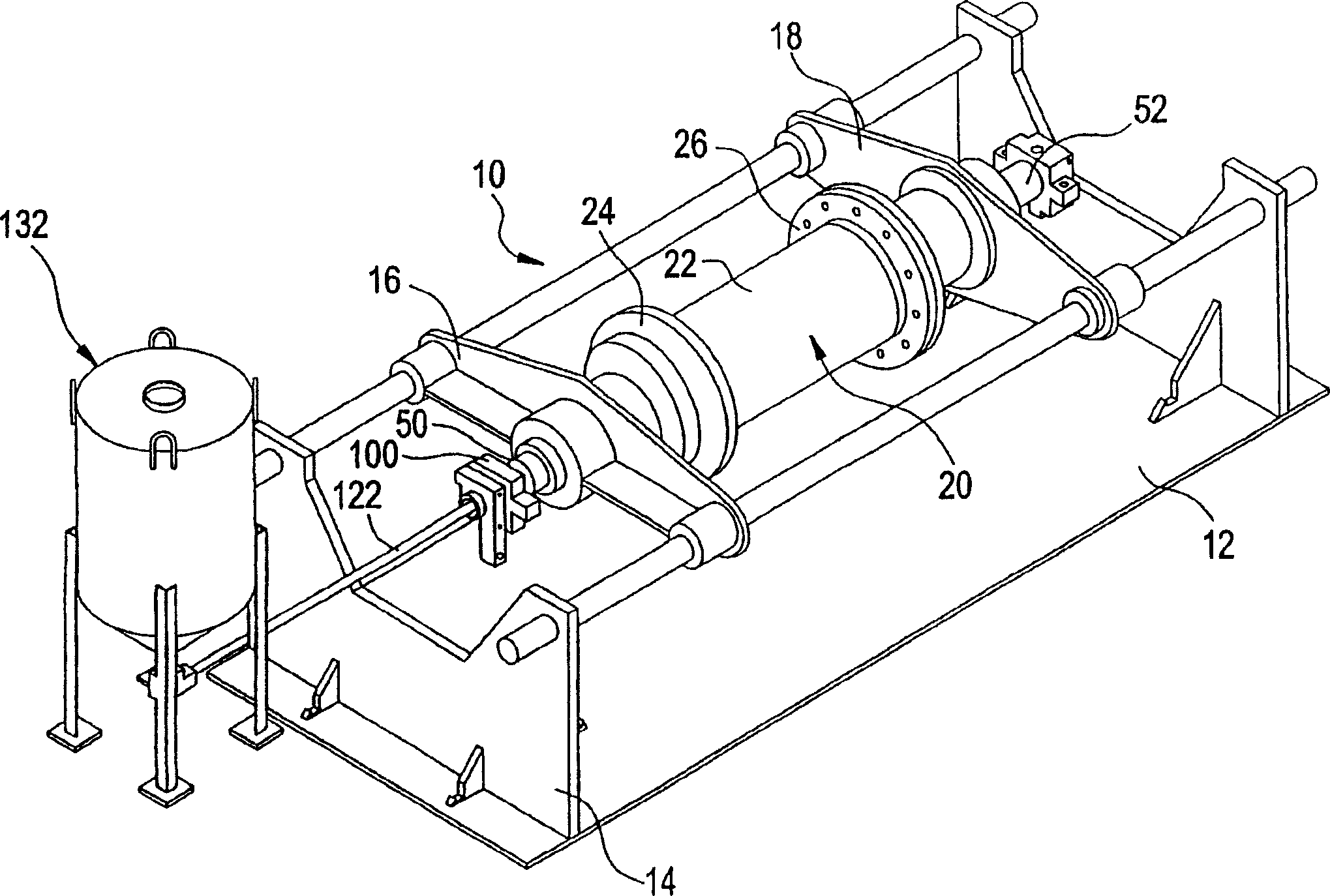

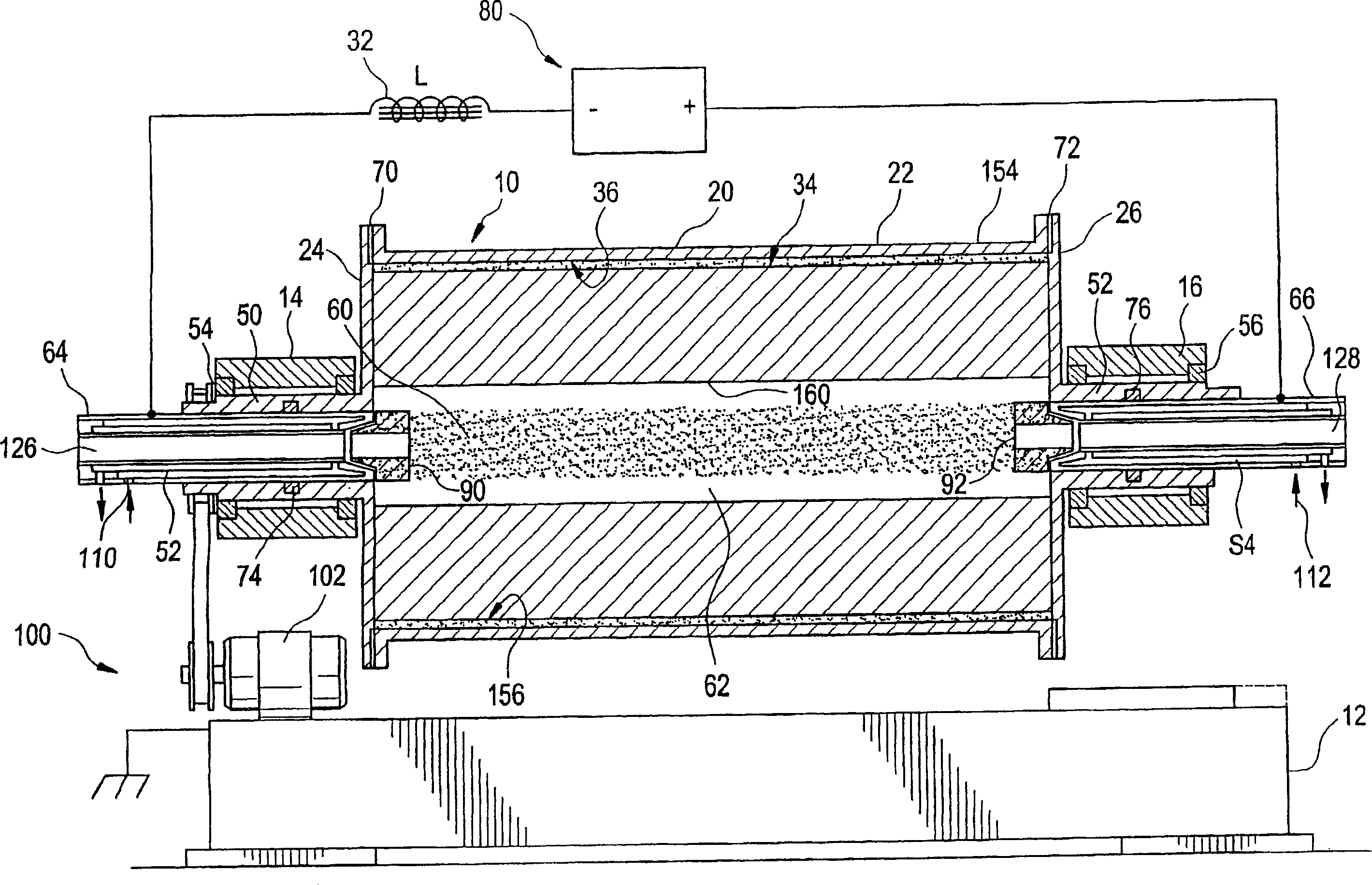

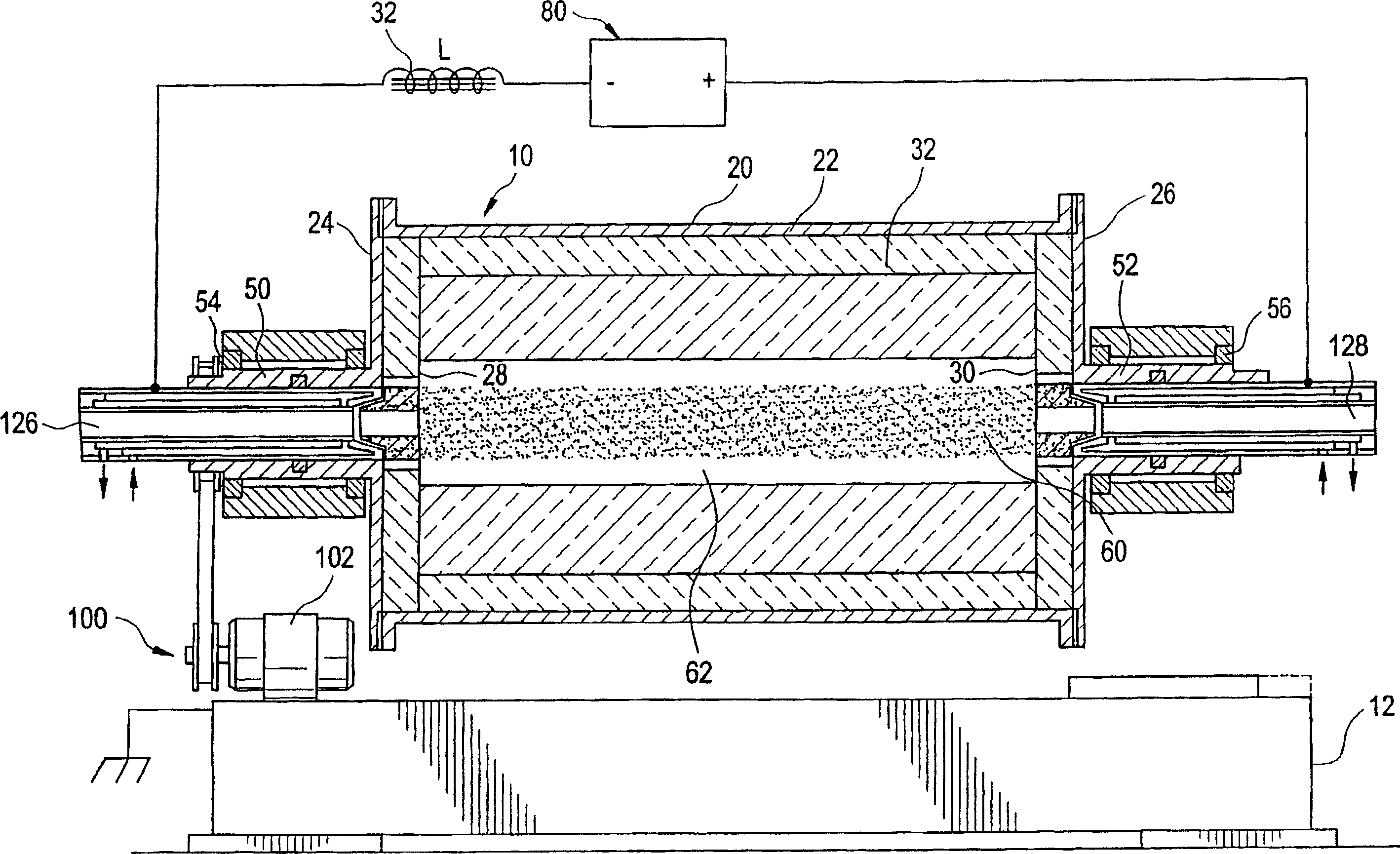

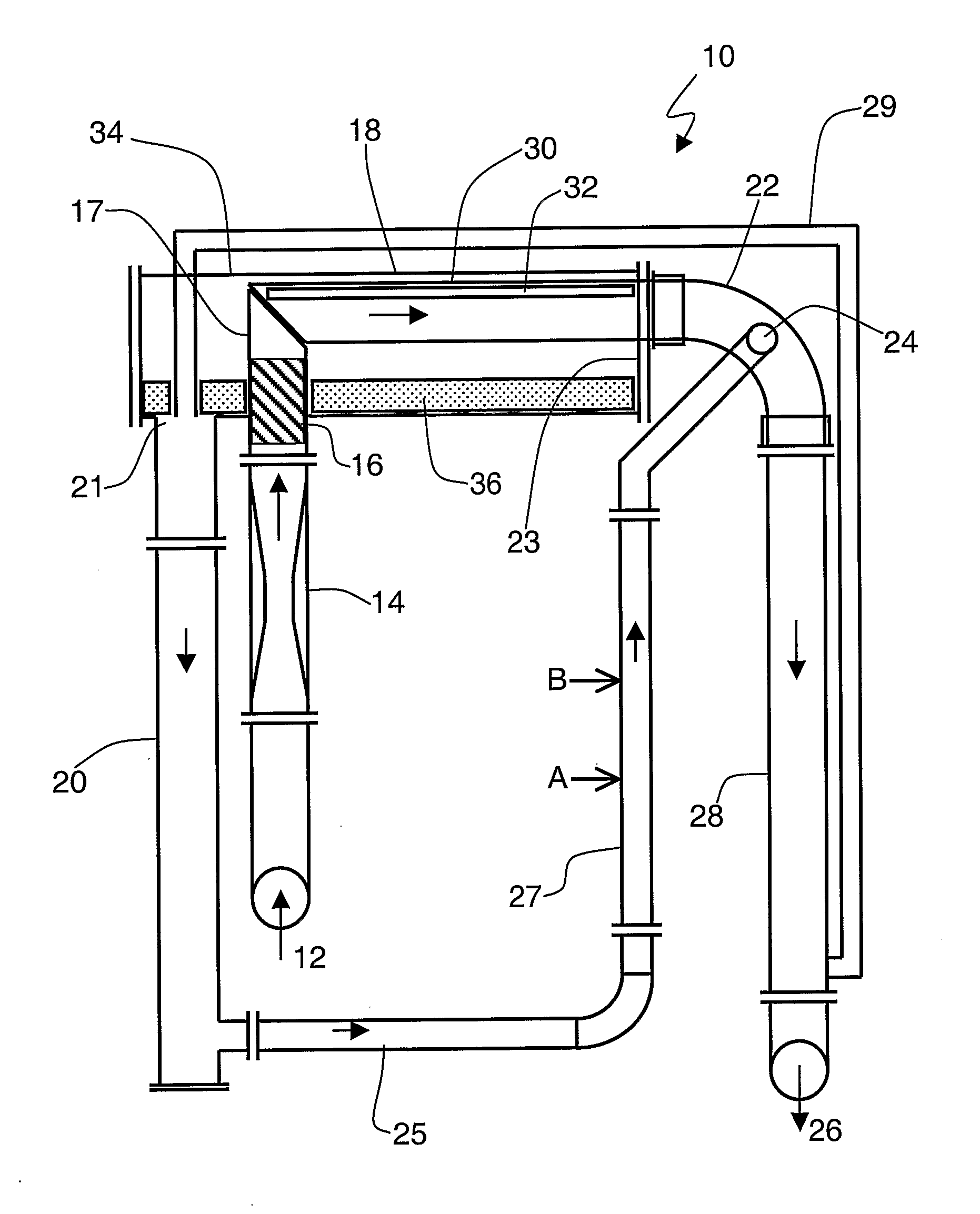

Fabrication of heavy walled silica tubing

A method for producing a silica glass body having a low bubble content includes melting silica sand in a chamber (62) of a rotating furnace housing (20) to form molten silica. Helium-containing gas is fed into the chamber, both during introduction of the sand and during the heating step. The helium diffuses more readily from the molten silica than other gases, resulting in lower bubble content. The furnace is heated by establishing a gas plasma arc (60) between spaced electrodes (64, 66) within the chamber.

Owner:GENERAL ELECTRIC CO

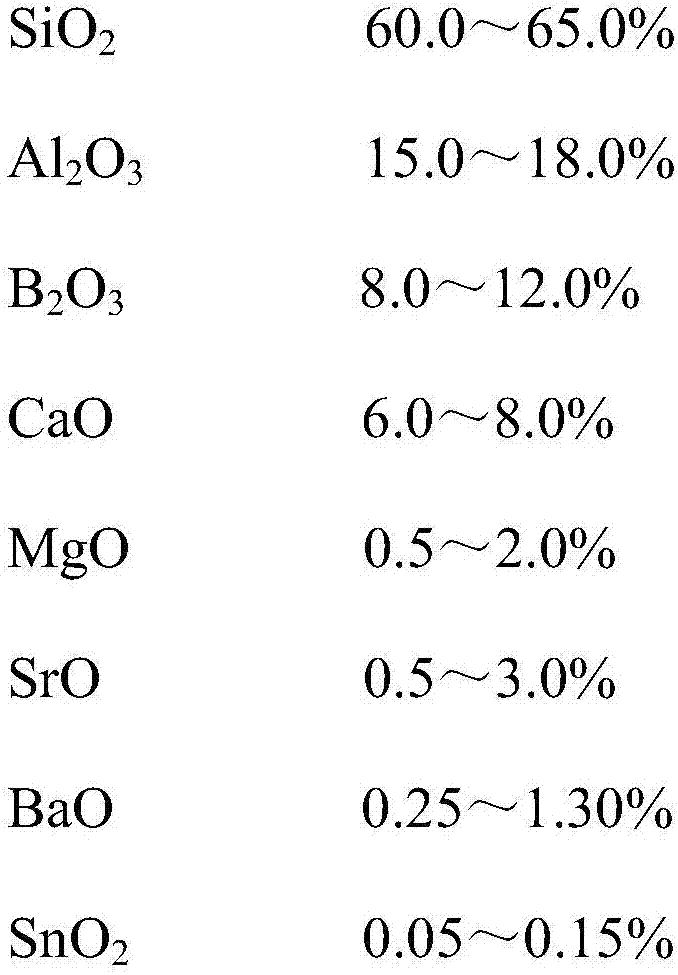

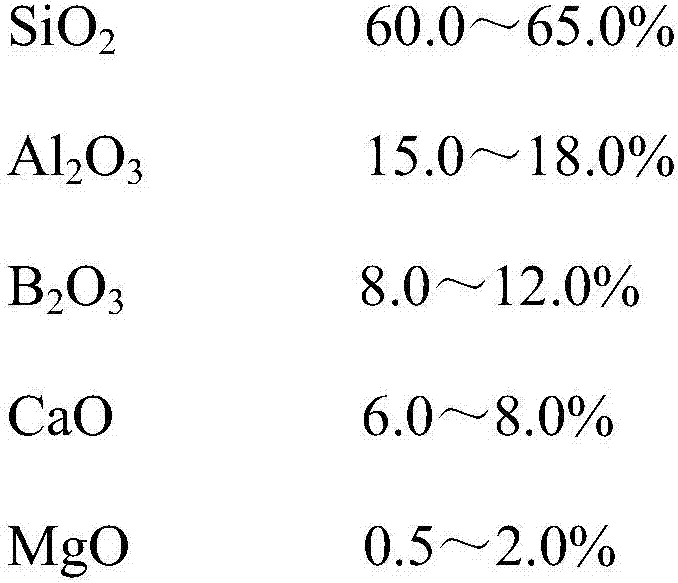

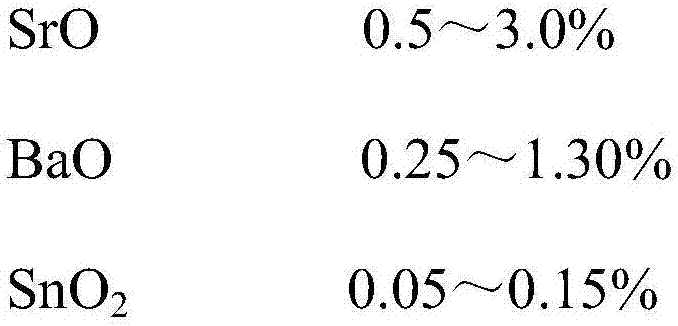

Liquid crystal substrate glass and preparation method thereof

The invention provides liquid crystal substrate glass and a preparation method thereof. The liquid crystal substrate glass consists of the following oxides in percentages by mass: 60.0-65.0% of SiO2, 15.0-18.0% of Al2O3, 8.0-12.0% of B2O3, 6.0-8.0% of CaO, 0.5-2.0% of MgO, 0.5-3.0% of SrO, 0.25-1.30% of BaO, 0.05-0.15% of SnO2 and inevitable impurities. The preparation method comprises the following steps: uniformly mixing the raw materials; melting and clarifying the raw materials and then drawing the raw materials by overflowing to form the liquid crystal substrate glass. The environmentally friendly oxide SnO2 is used as a clarifying agent, alkali metal oxide is not added, and the purpose of eliminating air bubbles on the premise of not polluting the environment is achieved.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

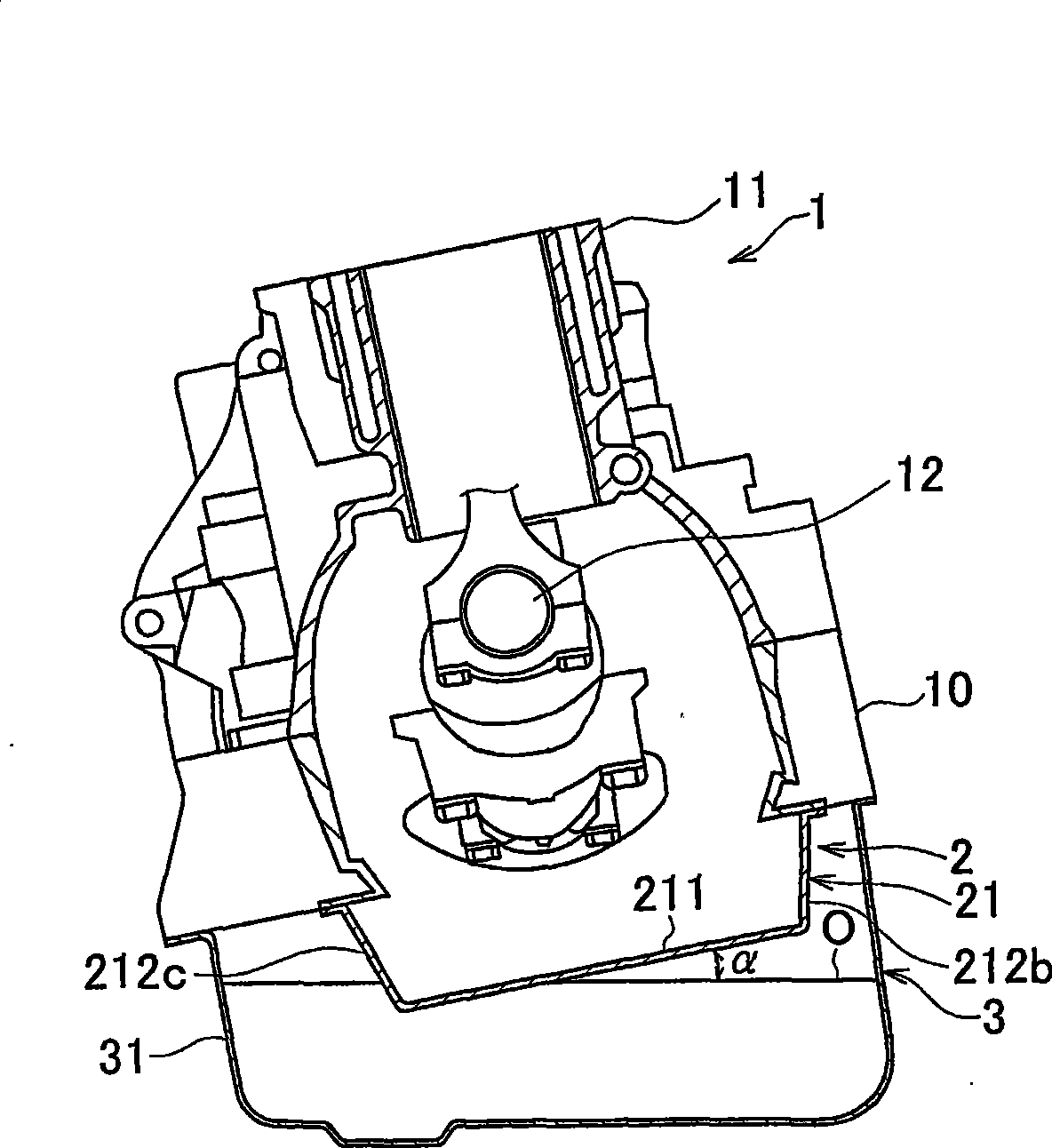

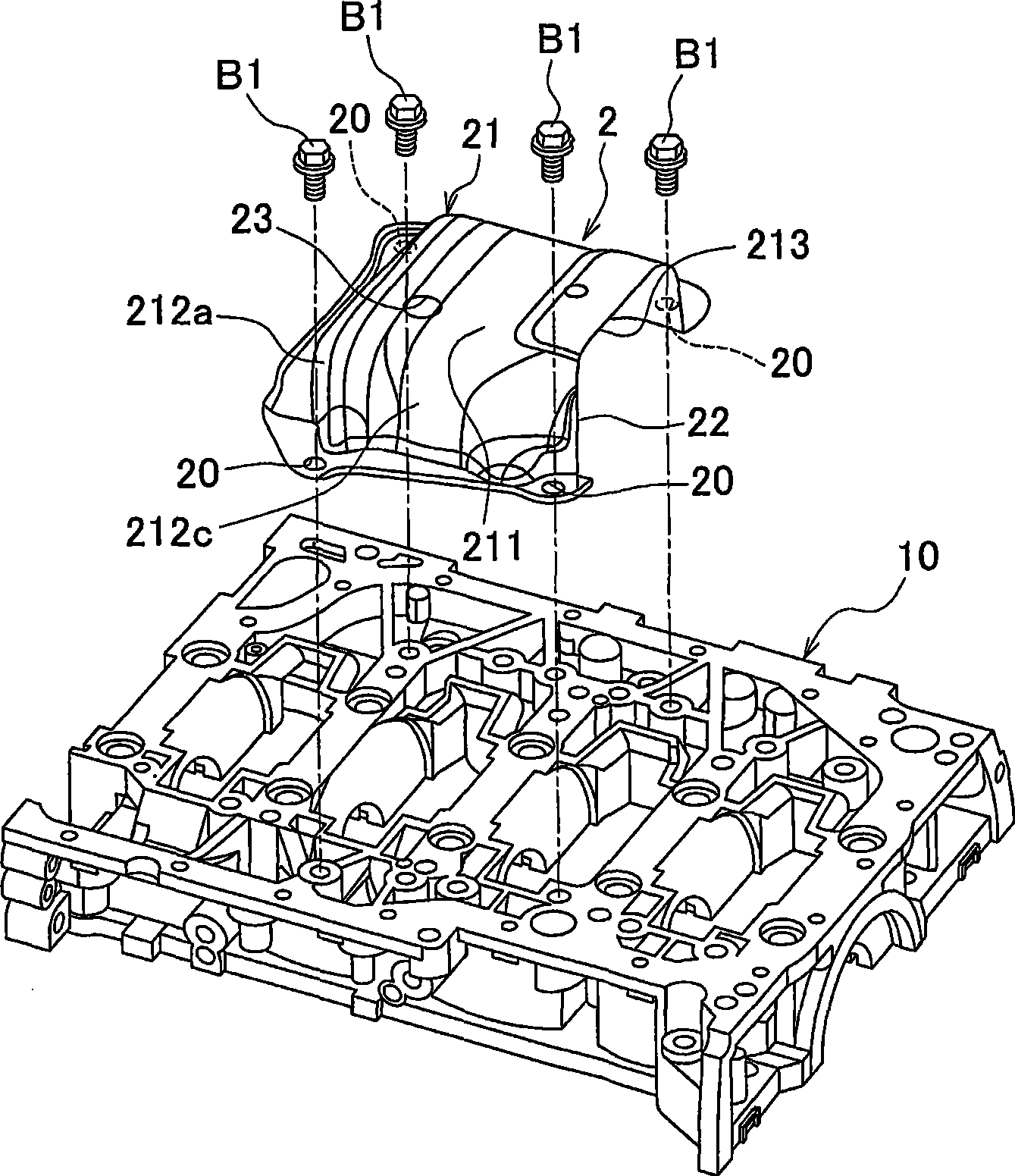

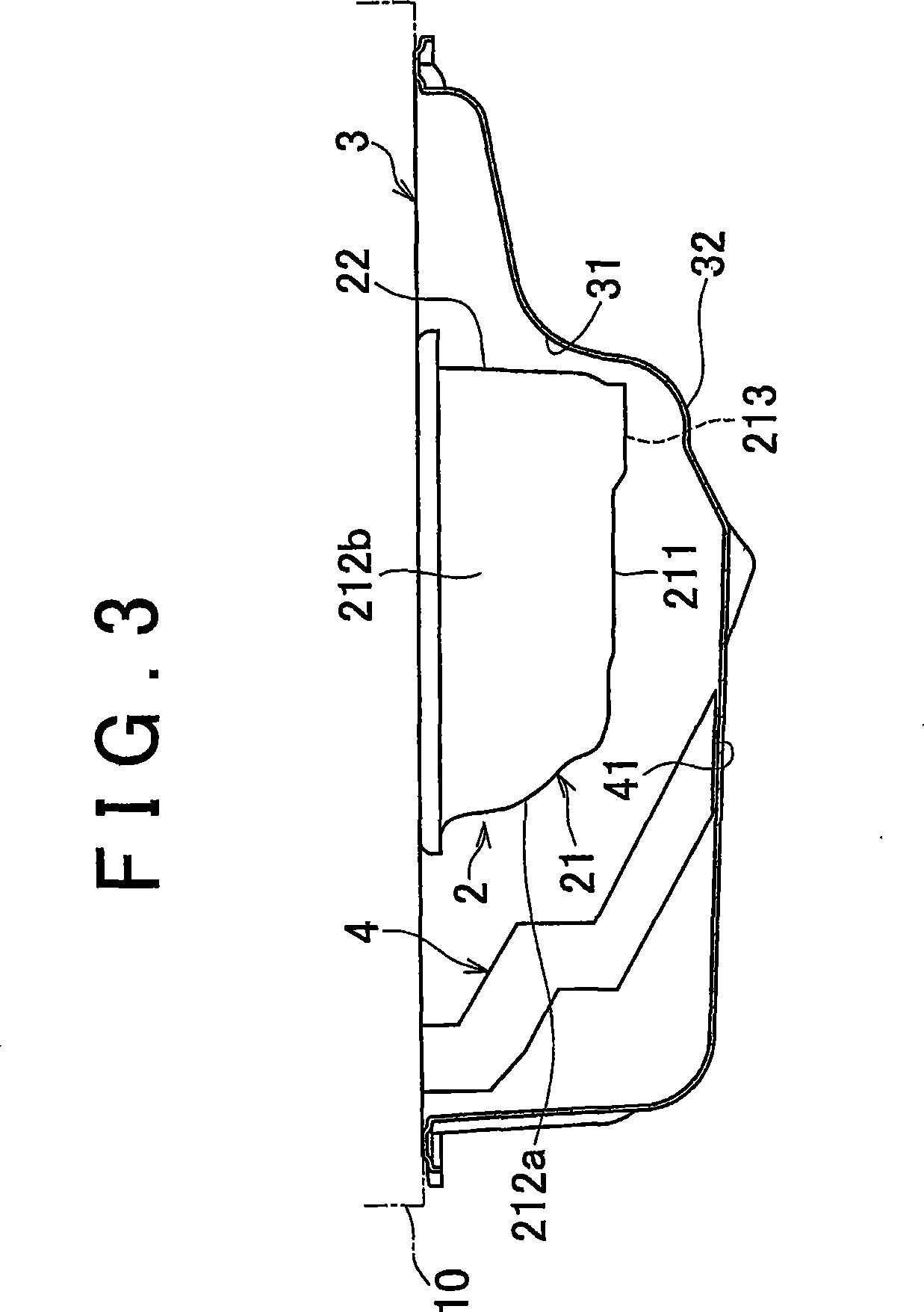

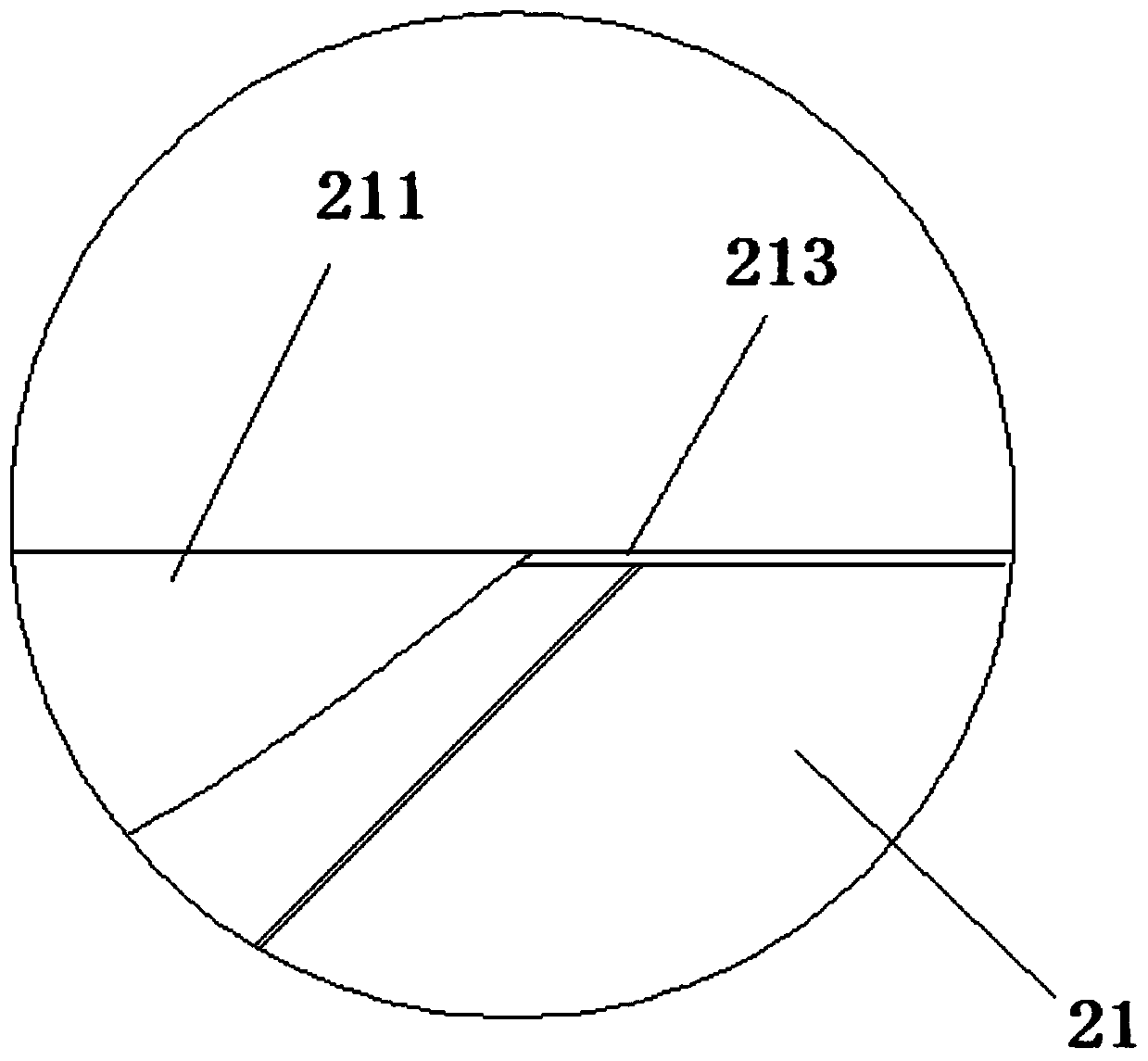

Oil pan structure for internal combustion engine

InactiveCN101389832AEliminate Bubble ProblemsReduce air bubble contentOilsumpsMachines/enginesExternal combustion engineInternal combustion engine

An oil pan structure for an internal combustion engine includes an oil pan (3) and a baffle plate (2) provided inside the oil pan (3) having a storage section (21) for collecting oil that is returned after circulating through the engine to lubricate and cool the engine. The storage section has a generally flat bottom (211) with a generally rectangular shape as viewed in a plan view, and front, left, and right side walls (212a, 212b, and 212c) that extend upward from the bottom (211), The storage section also has an oil drain port (22) through which the oil in the storage section (21) is drained into the oil pan (3) , The opening of oil drain port is near and faces a wall (31) of the oil pan.

Owner:TOYOTA JIDOSHA KK

Propolis-safflower oil soft capsule and preparation method thereof

InactiveCN103815395AWonderful and unique biological functionObvious Physiological and Pharmacological EffectsAnthropod material medical ingredientsMetabolism disorderPropolisOrganic solvent

The invention discloses a propolis-safflower oil soft capsule and a preparation method thereof. Contents of 1,000 soft capsules comprise 150-195 g of propolis, 290-390 g of safflower oil and 2-6 g of beewax, and a rubber sheet comprises the components of gelatin, glycerinum and drinking water in a proportion of 1:0.4:1 by weight. The preparation method comprises the following steps: blending, preparing the rubber sheet, and preparing soft capsules. According to the invention, propolis and safflower oil are matched for use for the first time, so that the healthcare functions that the human immunity is enhanced by the propolis and the blood lipids are regulated by the safflower oil are developed more effectively; the pure natural squeezed safflower oil is adopted, and a stable oil coated propolis powder homogeneous structure is formed by utilizing the stable structure of a beewax biological frame, so that digestive absorption of human small intestine lipids is facilitated. The treatment process for rubber sheet bubbles in the traditional soft capsule preparation technology is optimized, and the content of the rubber sheet bubbles is obviously reduced. Natural propolis, squeezed safflower oil and beewax are used as raw materials in all contents, and organic solvents and emulsifiers are not added.

Owner:伊犁百信草原蜂业有限责任公司

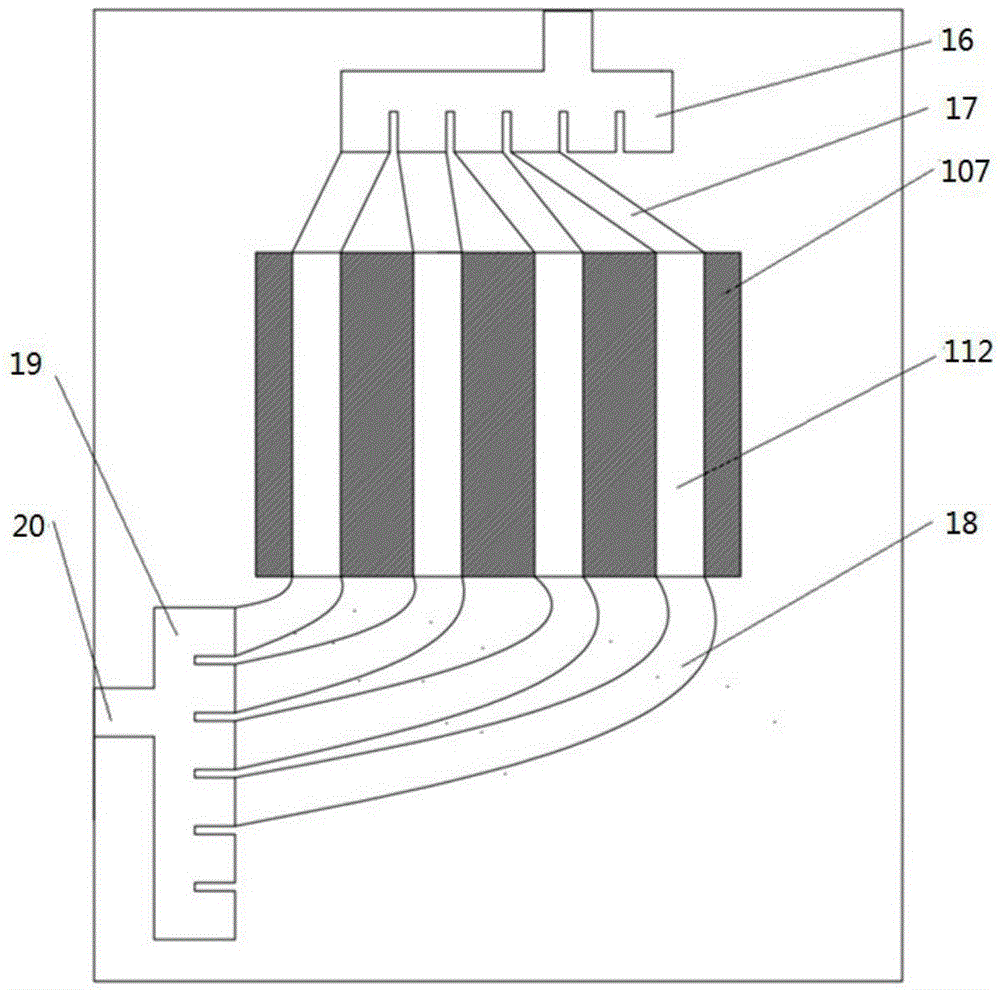

Copper-clad plate production equipment and copper-clad plate processing method

ActiveCN109435422ASolve problems such as low production yieldGuaranteed continuous productionLamination ancillary operationsLaminationEngineeringCopper

The invention relates to the field of copper-clad plate production, and particularly discloses copper-clad plate production equipment and a copper-clad plate processing method. The equipment comprisesa first coating device, a first roller, a second coating device, a first rolling device, a second roller and a second rolling device which are arranged front the front part to the rear part in sequence, wherein baking devices are arranged on the front side of the first rolling device, between the first rolling device and the second device, and on the rear side of the second rolling device; the structure of the first coating device is the same with that of the second coating device; the structure of the first roller is the same with that of the second roller. Through the copper-clad plate production equipment and the copper-clad plate processing method, the problem, in the prior art, of low copper-clad plate production yield caused by defects like air bubble inclusion and nonuniform prepreg components during reinforcing material glue dipping and glue solution curing processes can be solved.

Owner:安徽鸿海新材料股份有限公司

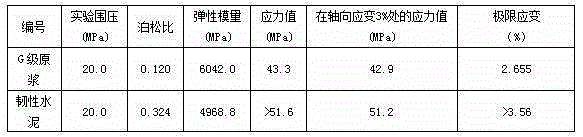

Tough oil well cement

InactiveCN106278003AStrong ability to change laterallyLow elastic modulusSolid waste managementFiberPlastic yielding

The invention discloses tough oil well cement. The cement is characterized by being prepared from components in parts by weight as follows: 100 parts of cement, 1-15 parts of active filler, 1-5 parts of a toughening material, 0.01-0.05 parts of staple fibers, 1-5 parts of an additive, 0.1-0.2 parts of a water educing agent, 1-5 parts of a fluid loss agent, 1-2 parts of an antifoaming agent and 1-5 parts of a retarder. An oil well cement sheath is high in lateral deformation capacity, low in elasticity modulus, high in plastic yielding point and good in elasticity; the oil well cement ring has very high ultimate strain value, can absorb larger impact energy and greatly improves the deformation performance of set cement compared with raw slurry, so that the requirement for cement performance in the oil and gas well development process is met, and cementing quality and follow-up development are guaranteed.

Owner:JIAHUA SPECIAL CEMENT

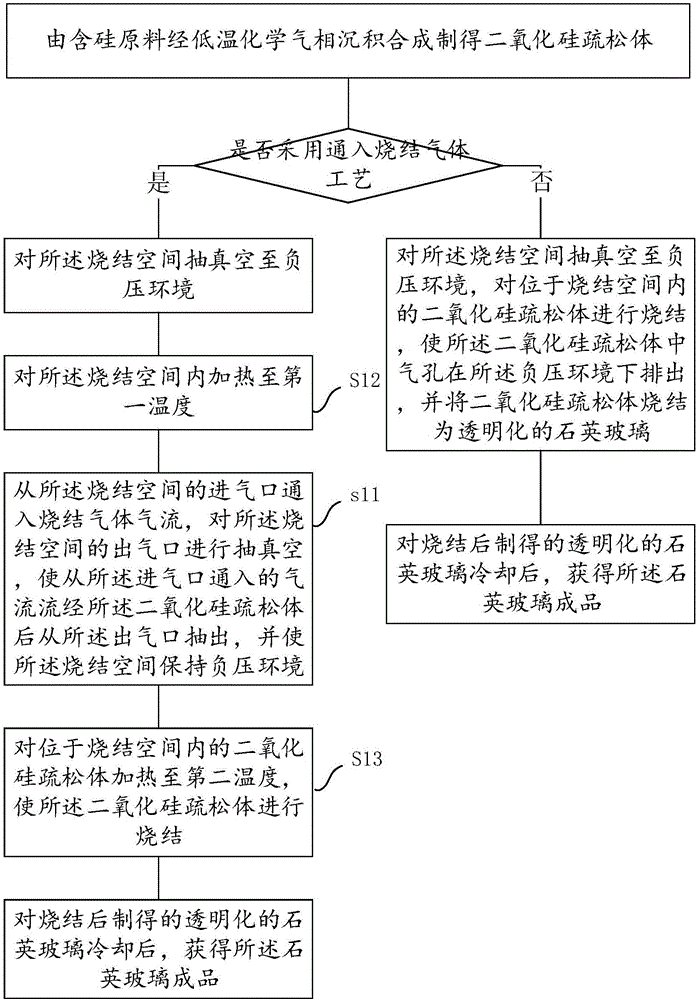

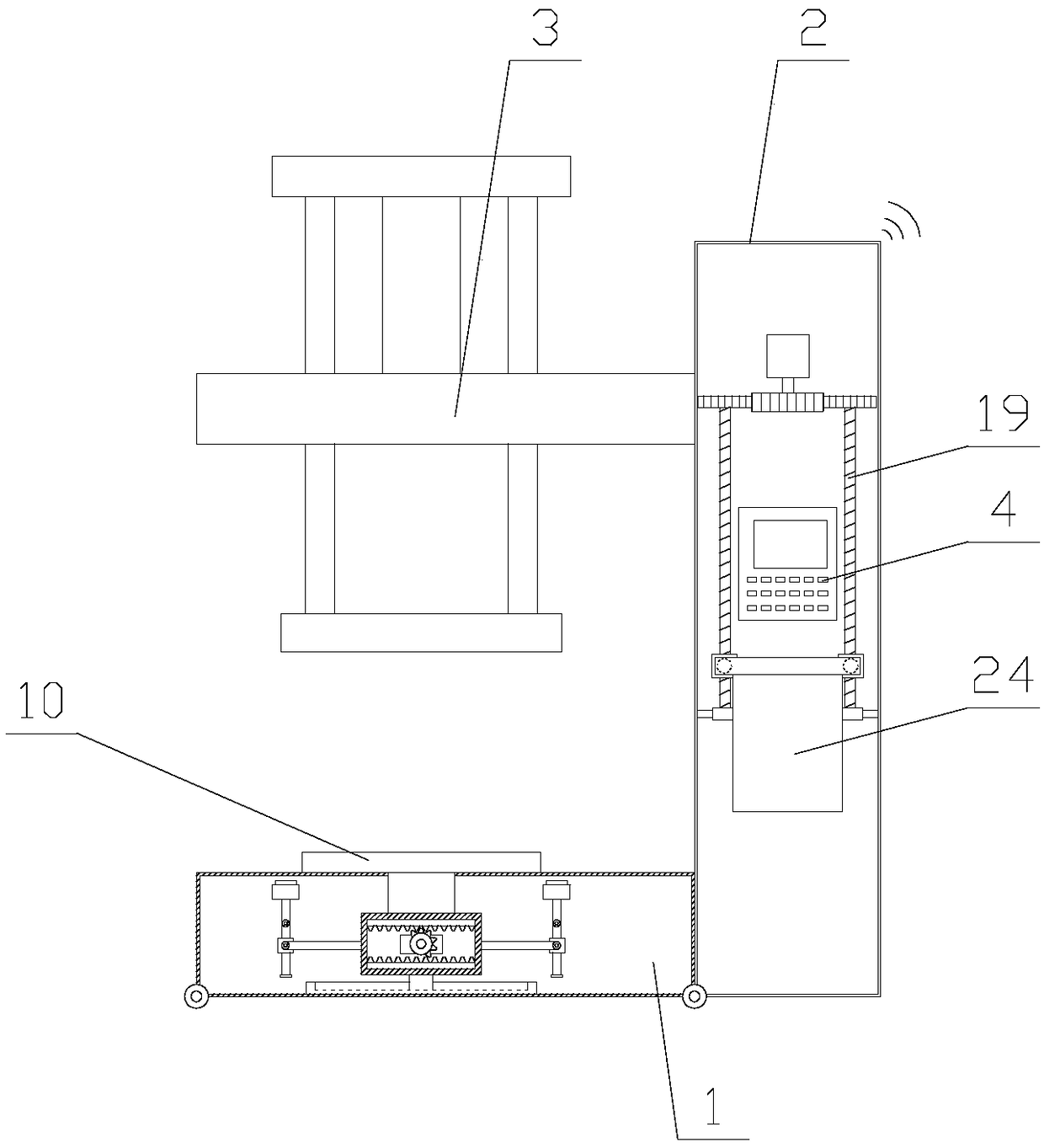

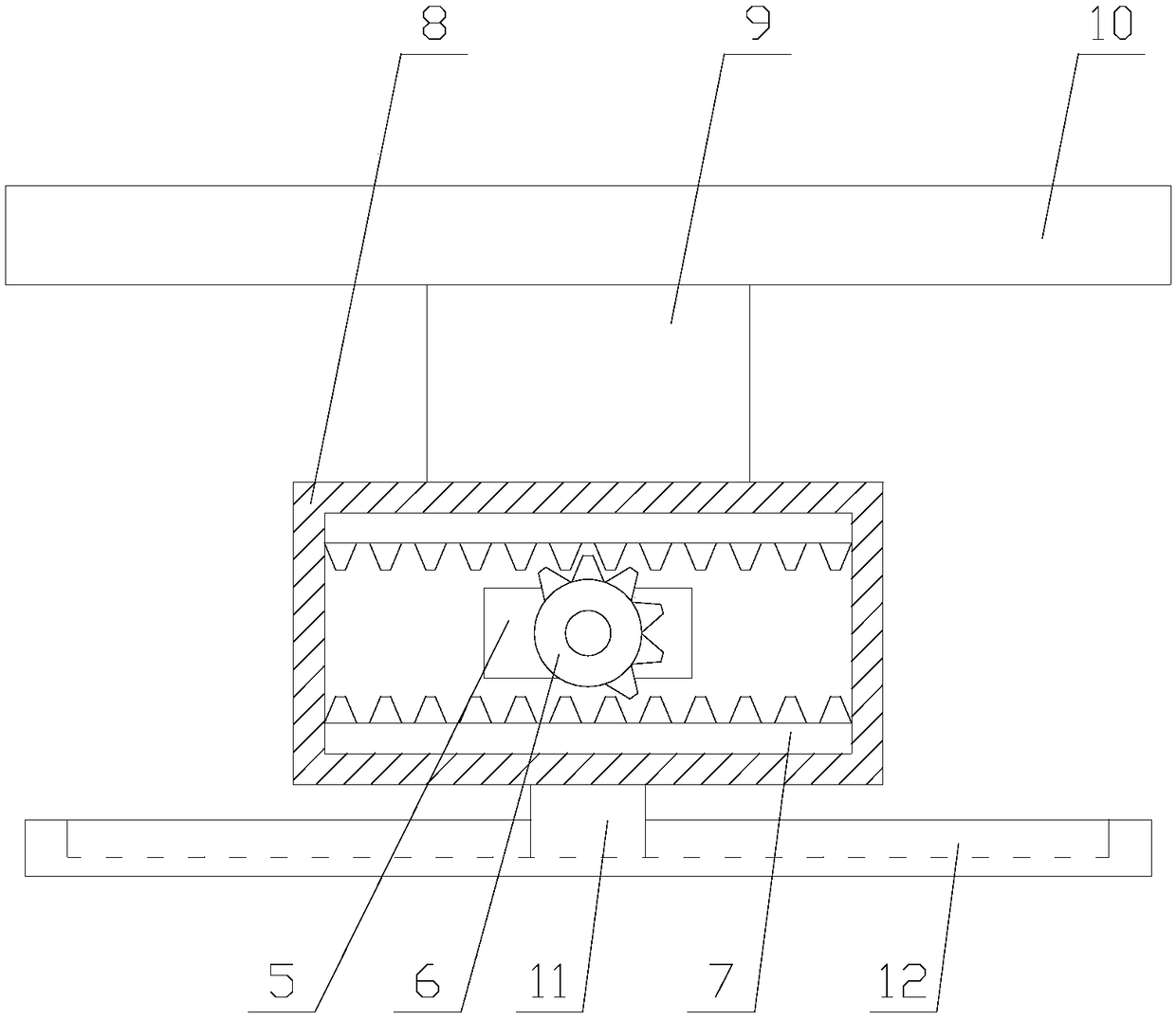

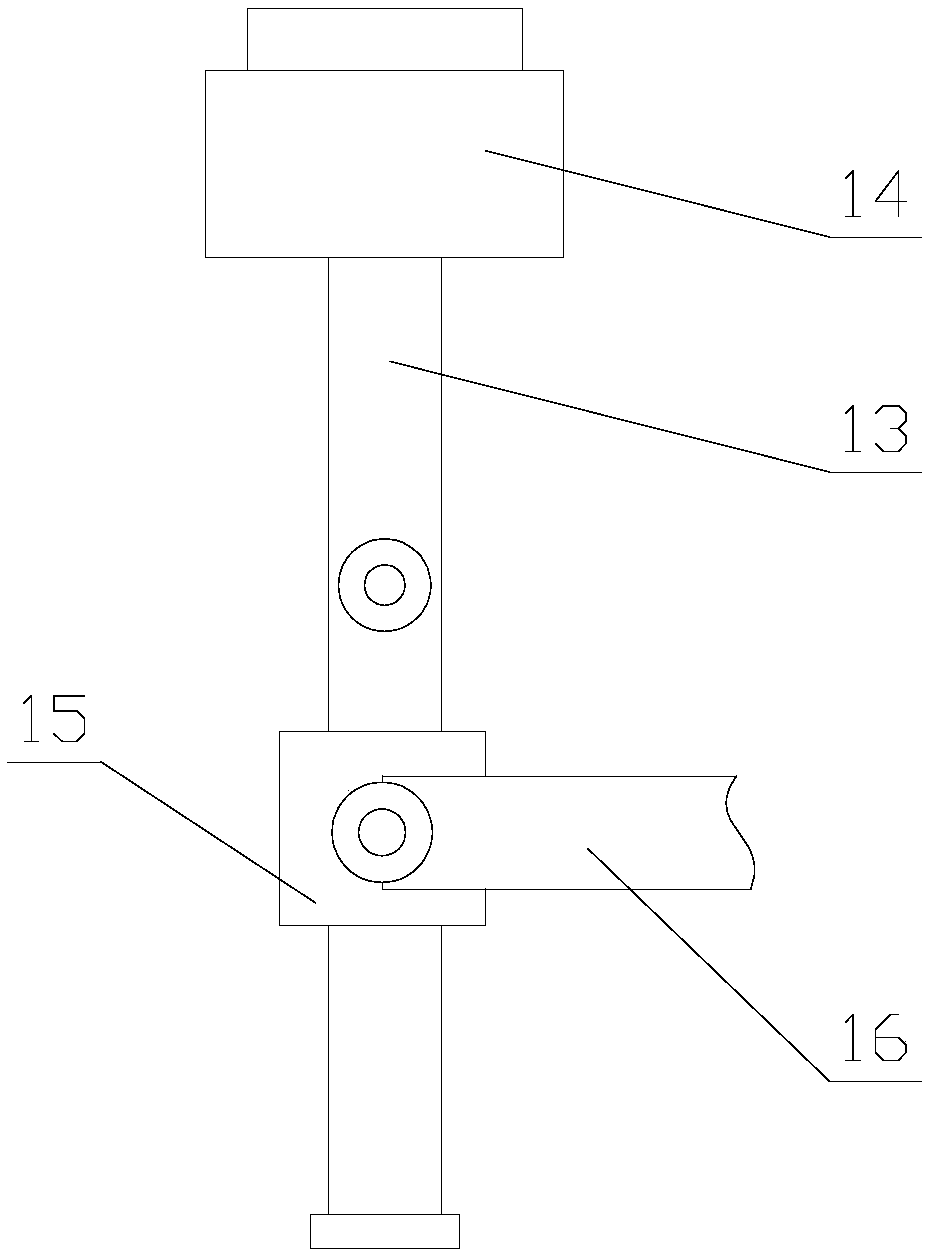

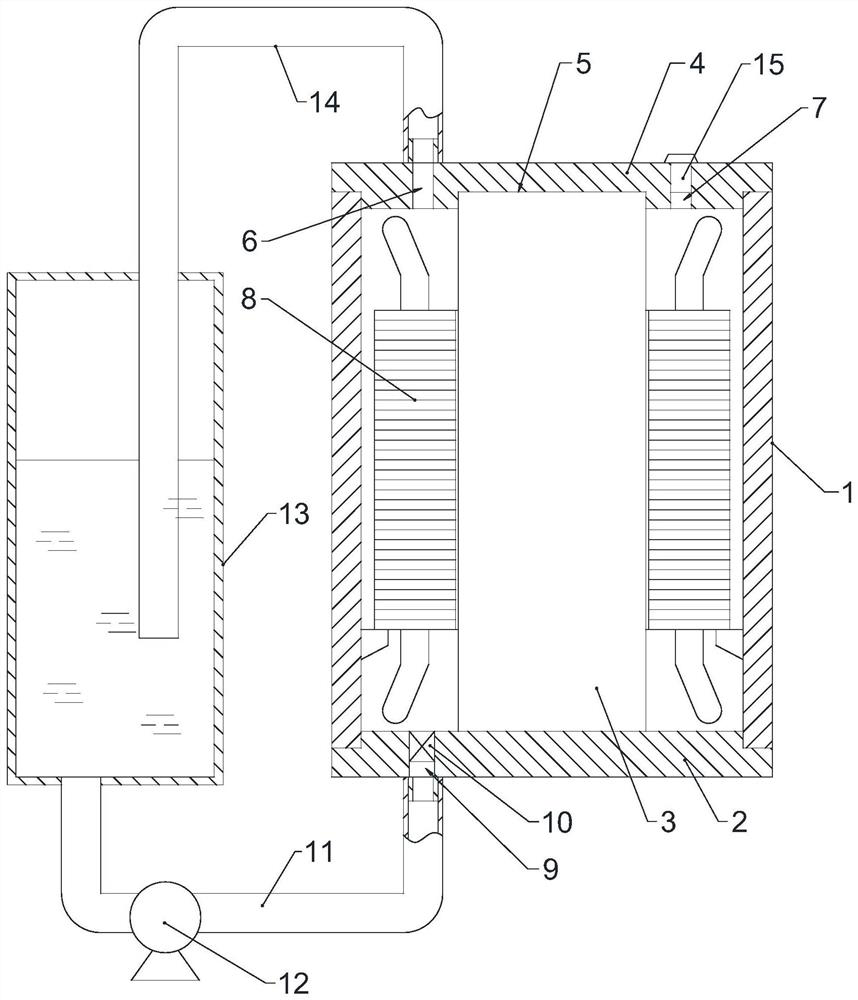

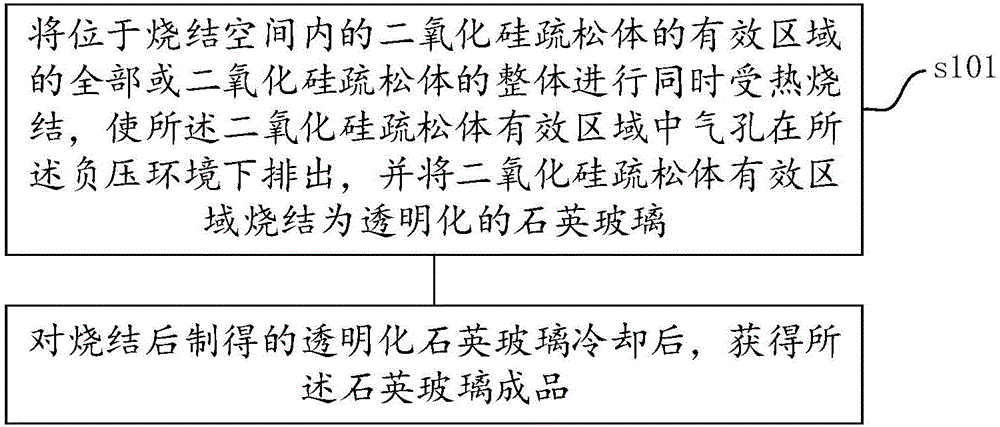

Sintering device and system for preparing quartz glass

ActiveCN106116122AImprove sintering efficiencyImprove product qualityGlass shaping apparatusWhole bodySynthesis methods

The invention relates to a sintering device and system for preparing quartz glass, relating to the field of preparing quartz glass and mainly aiming at avoiding or reducing the generation of bubbles in preparation of the quartz glass by adopting indirect synthesis method technology, and improving the sintering efficiency of the quartz glass and lowering the cost. The sintering device for preparing quartz glass comprises a furnace body, wherein a vacuumizing channel communicated with a sintering space is also arranged on the furnace body, and used for vacuumizing the sintering space to a negative pressure environment so as to sinter silica loose body in the sintering space, pores in the silica loose body are discharged under the negative pressure environment, and the silica loose body is sintered to transparent quartz glass. According to the sintering device and system for preparing quartz glass, the sintering device for preparing the quartz glass can conduct sintering under the negative pressure environment, and the content of bubbles in the obtained finised quartz glass after sintering can be decreased, so that the quality of the quartz glass product is improved, the whole body is heated and sintered simultaneously, the sintering efficiency of the silica loose body is increased and the cost is lowered.

Owner:CHINA BUILDING MATERIALS ACAD

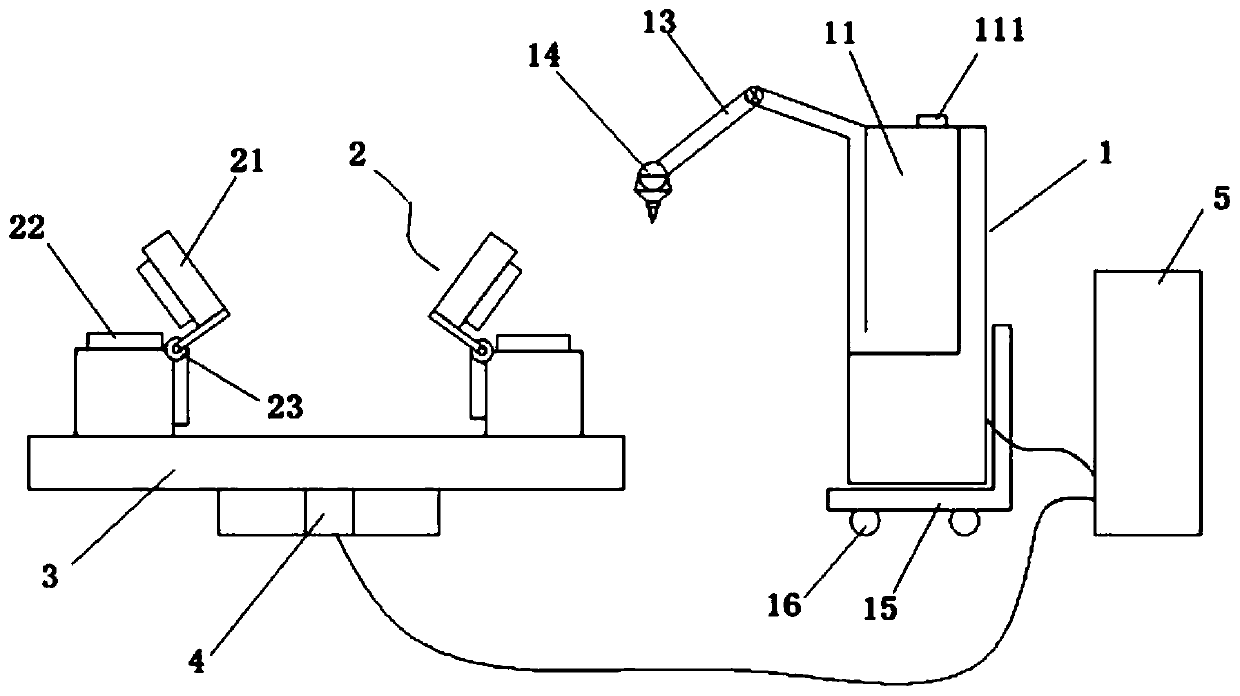

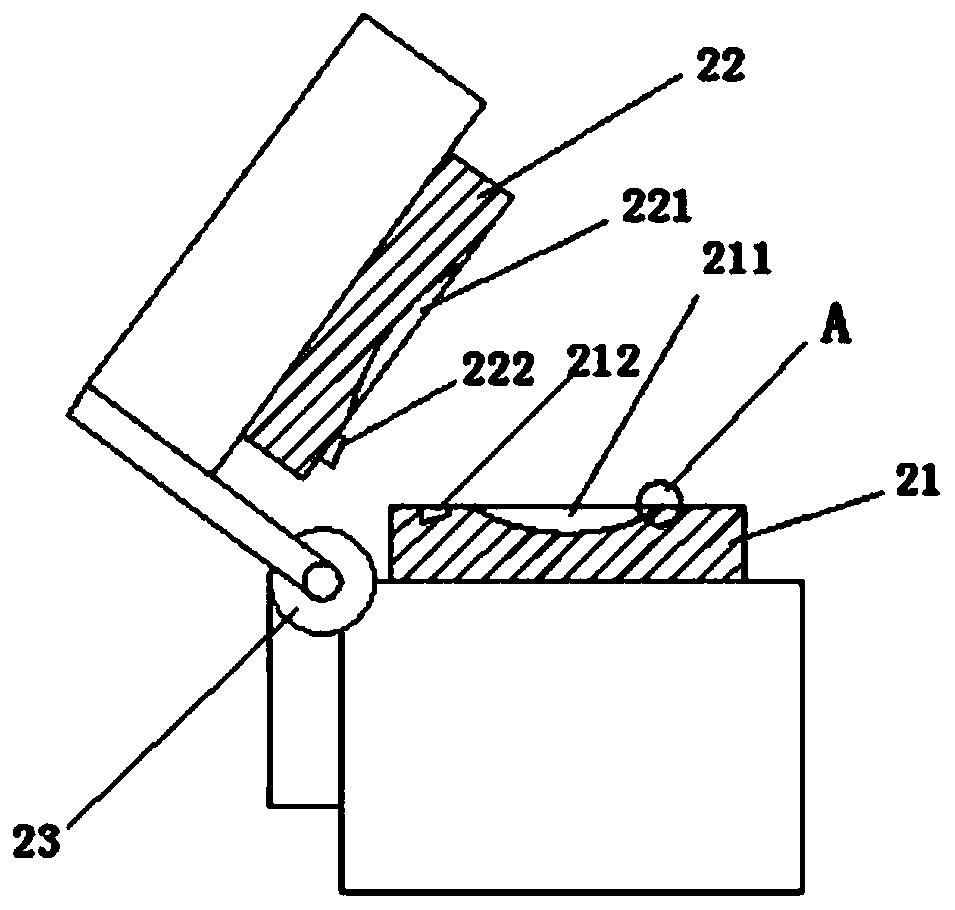

Hydraulic casting equipment with defoaming function

The invention relates to hydraulic casting equipment with a defoaming function. The hydraulic casting equipment comprises a base, a supporting column, a hydraulic device and a control screen, and further comprises a defoaming mechanism and a protection mechanism, wherein the defoaming mechanism comprises a shaking assembly and an auxiliary assembly, the shaking assembly comprises a first motor, ahalf gear, a rack, a moving frame, a connecting block and a supporting plate, the auxiliary assembly comprises two swing units, the protection mechanism comprises a second motor, a first gear, a lifting plate, a baffle and two control assemblies. According to the hydraulic casting equipment with the defoaming function, through the defoaming mechanism, the supporting plate can drive a casting moldto shake, an ultrasonic wave emitter can be aligned with the casting mold to swing and emit ultrasonic waves for defoaming, so that the content of bubbles in the formed casting is reduced, the production quality of the casting is improved, a control screen can be protected through the protection mechanism, and the practicability and the reliability of the hydraulic casting equipment are greatly improved.

Owner:SHENZHEN LEILING GUANGTONG TECH DEV CO LTD

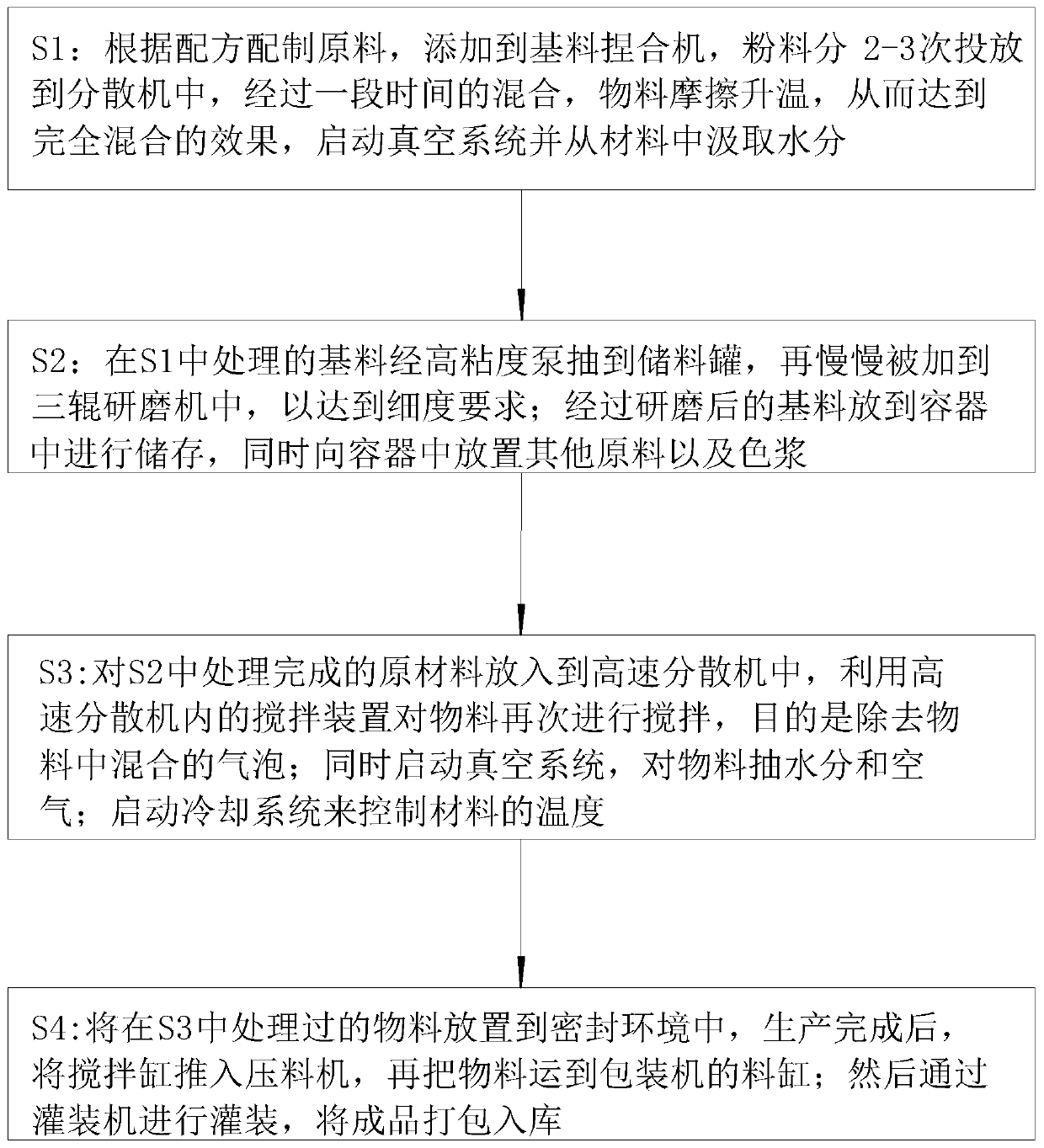

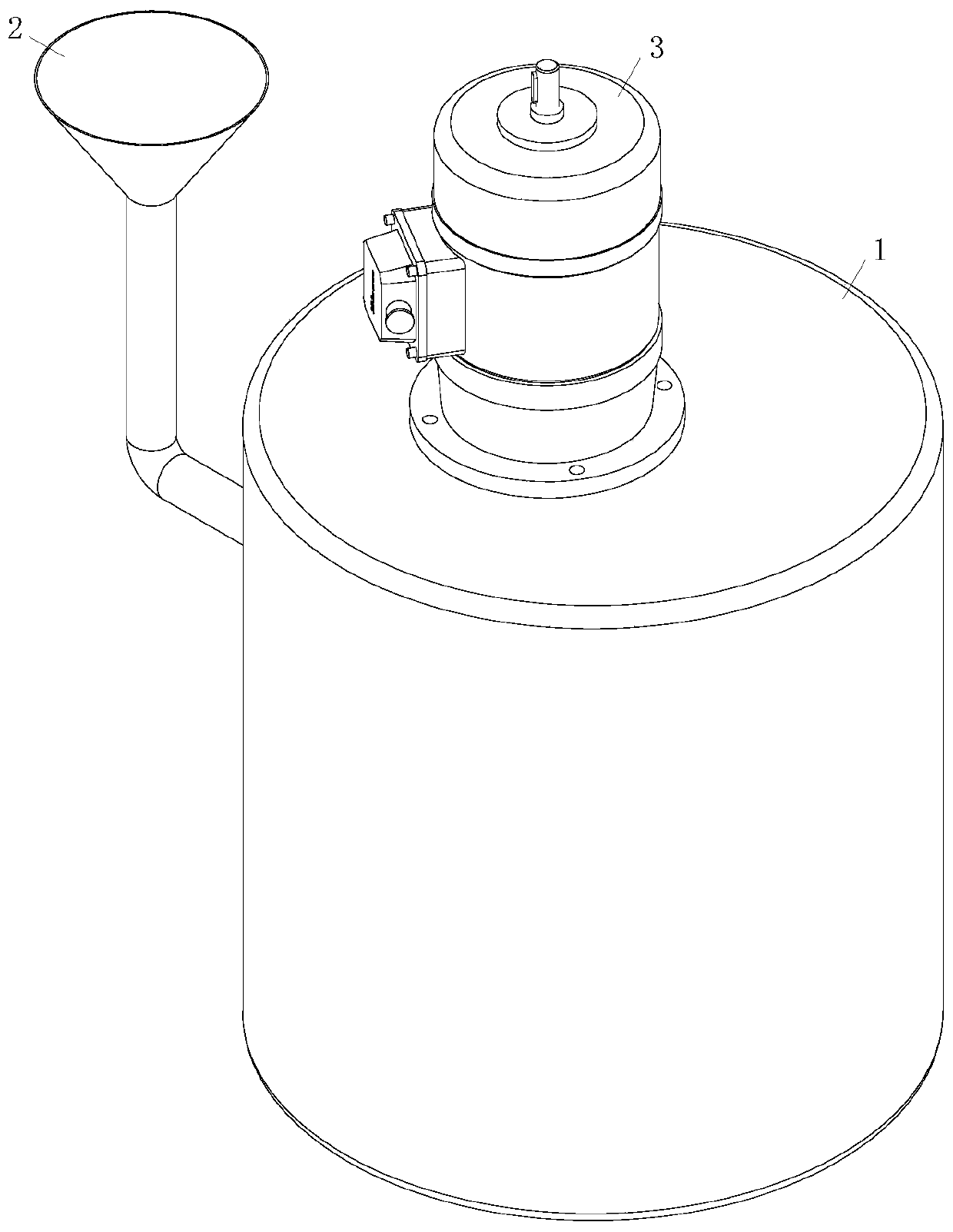

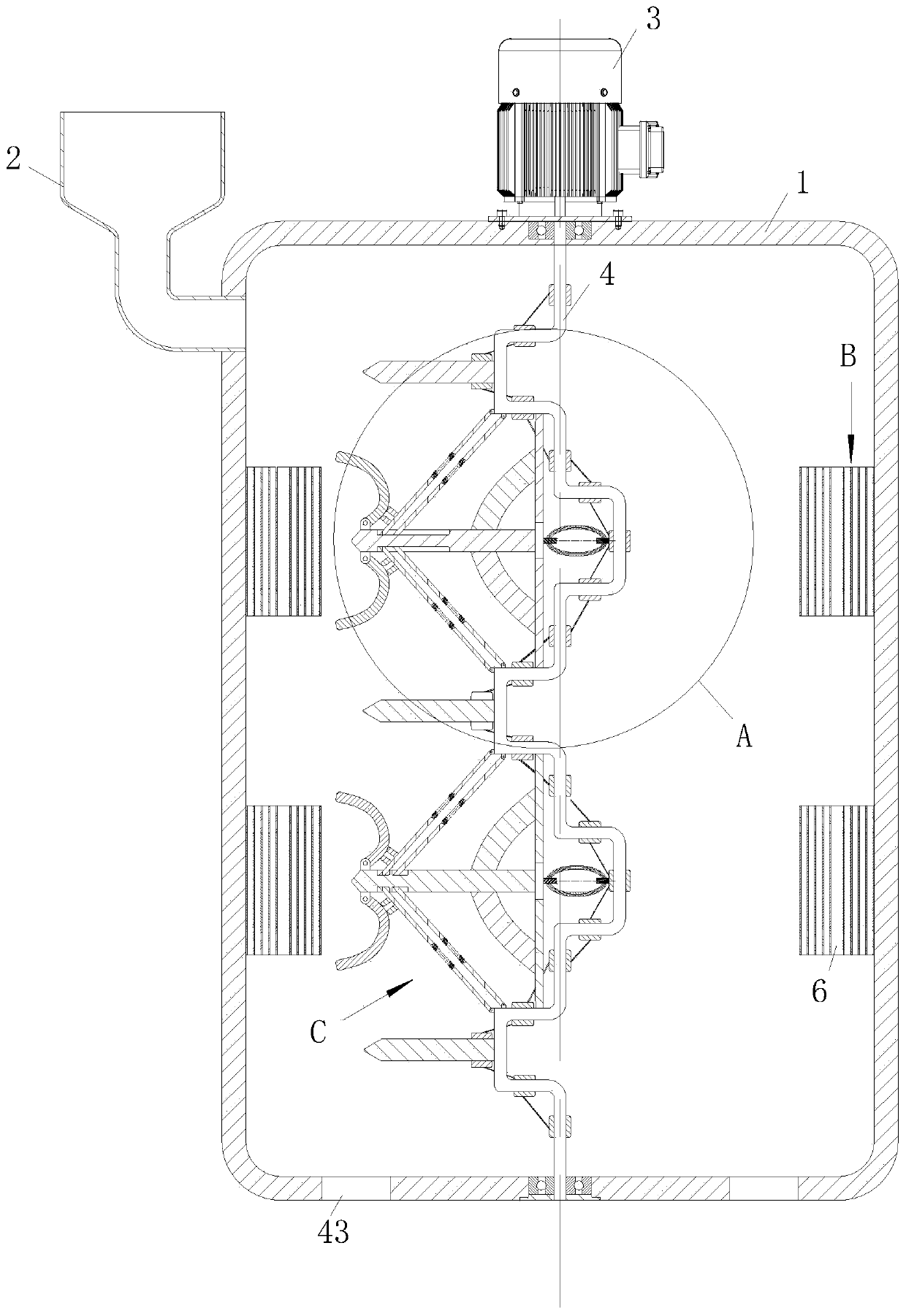

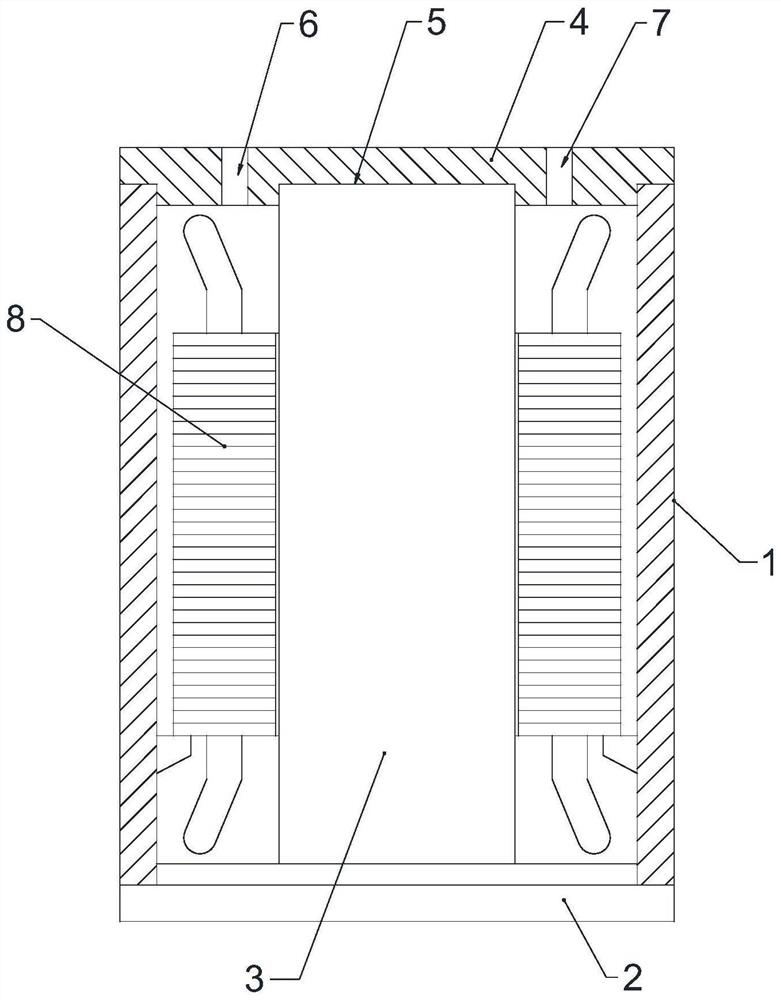

Sealant production method

PendingCN110368825AStir fully and evenlyReduce air bubble contentRotary stirring mixersMixing methodsEngineeringMethods of production

The invention belongs to the technical field of sealant production, and particularly relates to a sealant production method. By the cooperation work of a motor, arcuate connecting shafts, scraping knives and scraping blocks, when materials are in a stirring process, the difference of a speed of a stirring center and a speed of a stirring outside is reduced, so that stirring of the materials is relatively sufficient and uniform, a bubble content in the materials is reduced, and at the same time, linkage of the scraping blocks can clean the arcuate connecting shafts and the scraping knives, so that a rotating speed is further strengthened, and the stirring effect is improved. By the joint work of the arcuate connecting shafts, blades, arc-shaped push rods and coil plates, the coil plates arestraightened to contact with the materials to stir the materials, and at the same time the coil plates can also clean the blades. The propulsive force generated by resetting of the coil plates can clean the arcuate connecting shafts and the scraping knives, and can also change a speed of the stirring center, so that a content of bubbles produced during the stirring process of the materials is reduced.

Owner:陈宁

Stator glue pouring tool and stator glue pouring method based on same

PendingCN113258735AHigh Design Power DensityReduce volumeManufacturing stator/rotor bodiesCooling/ventillation arrangementElectric machineButt joint

The invention relates to a stator glue pouring tool and a stator glue pouring method based on the same. The stator glue pouring tool comprises a lower sealing plate in sealed butt joint with one end of a motor shell, a mold column vertically connected to the lower sealing plate and inserted into the center of the motor shell, and an upper sealing plate in sealed butt joint with the other end of the motor shell, wherein a groove matched with the mold column is formed in the upper sealing plate, the mold column is inserted into the groove in the upper sealing plate, and an upper glue pouring hole and an exhaust hole are additionally formed in the upper sealing plate. The stator glue pouring tool can perform integral glue pouring on the motor stator and the motor shell, so that the space between the stator and the motor shell is filled with the pouring sealant, the heat conduction efficiency between the stator and the motor shell is improved, and the temperature of a winding is reduced.

Owner:苏州精力电气有限公司

Hydrophilic resin composition, and preparation method and application thereof

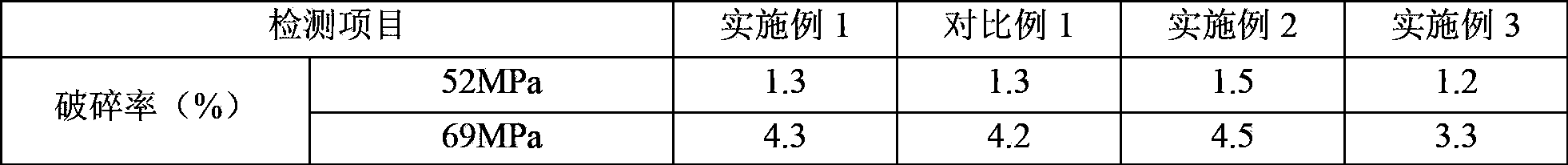

InactiveCN103848958AReduce air bubble contentGood dispersionFluid removalEpoxy resin adhesivesWater basedFracturing fluid

The invention provides a hydrophilic resin composition and a preparation method thereof. The method comprises the following steps: allowing an epoxy resin to have first contact with a modifier selected from acid anhydride to make the hydroxy group in the epoxy resin react with the acid anhydride group in the modifier; and allowing a mixture obtained through the first contact to have second contact with an alkaline substance in order to make an acid form a salt. The invention also provides an application of the hydrophilic resin composition in the preparation of fracturing propping agents. The fracturing propping agent obtained by coating raw sand with the hydrophilic resin composition has good dispersibility, and do not agglomerate basically; the content of bubbles in a water-based fracturing fluid carrying out the fracturing propping agent is low; and the fracturing propping agent has a high crushing limit, and can effectively prop cracks in order to prevent the closure of the cracks.

Owner:ELION RESOURCE GROUP

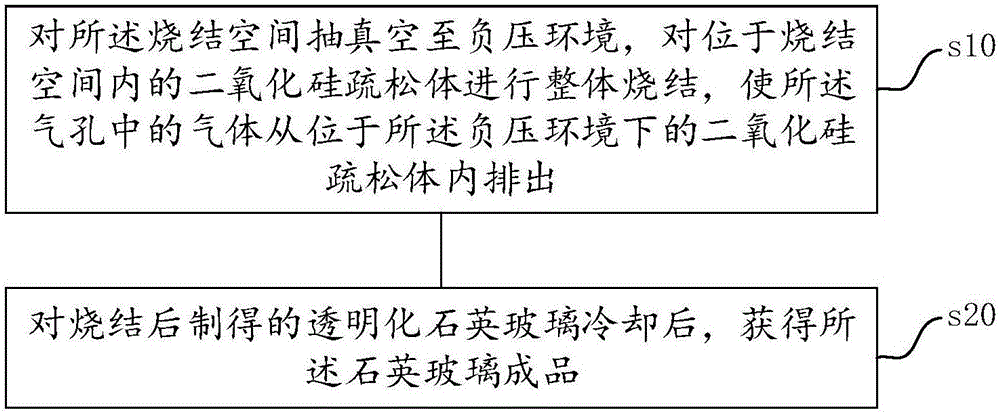

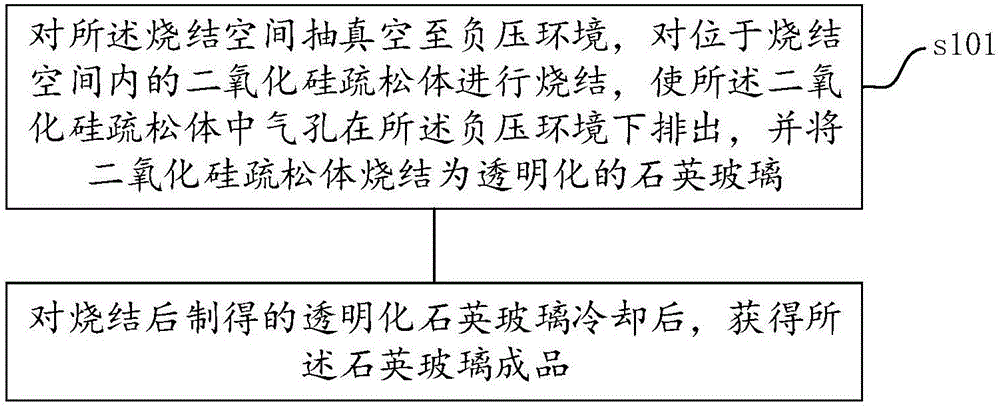

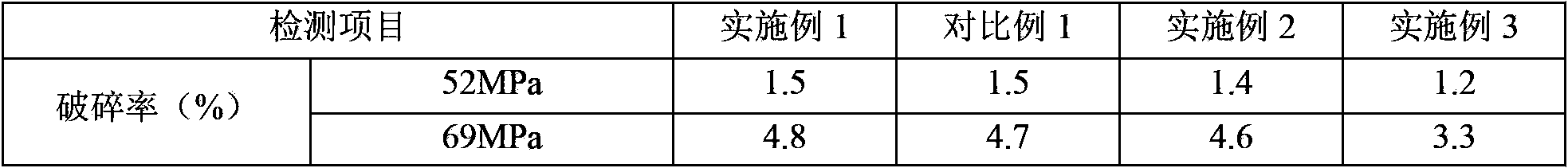

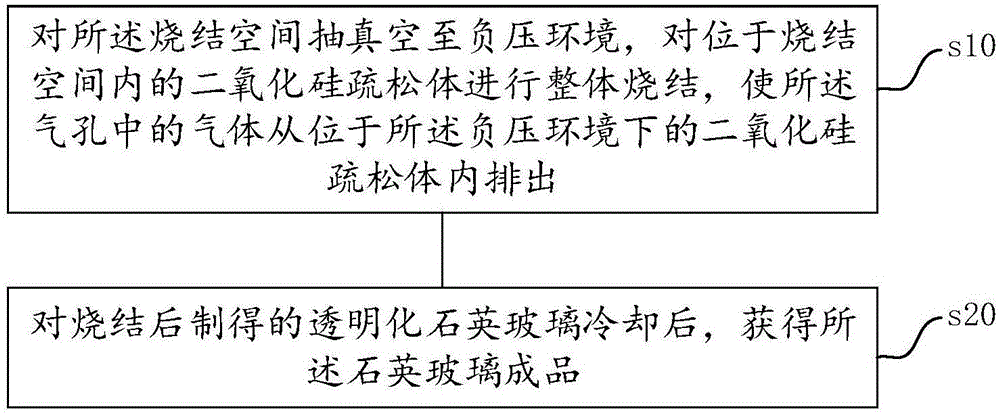

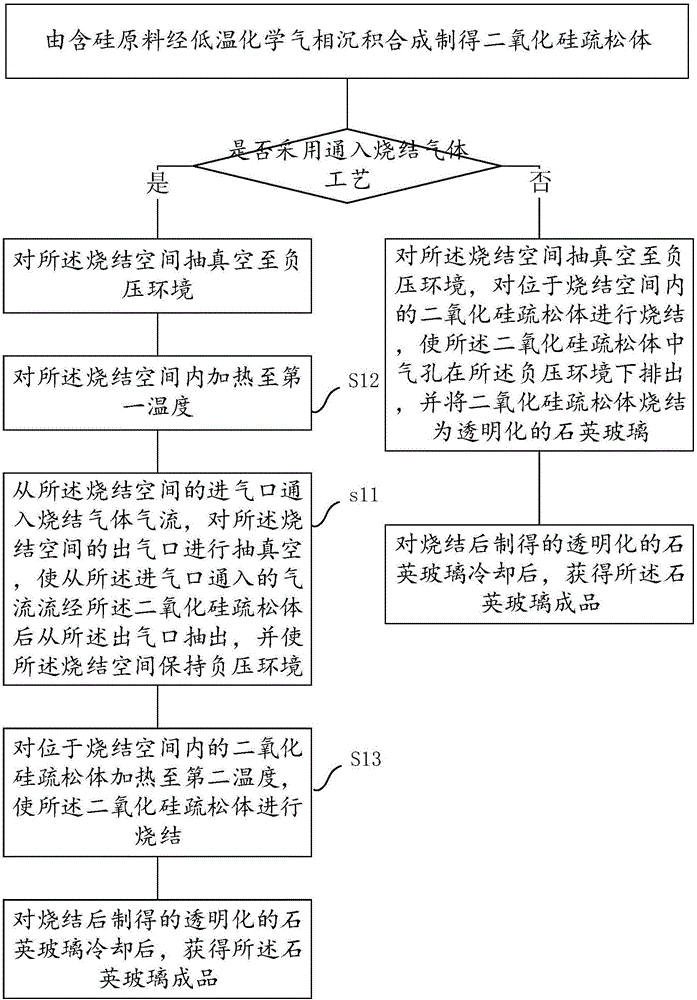

Sintering method for preparing silica glass and silica glass

InactiveCN106396350AImprove sintering efficiencyImprove product qualityGlass shaping apparatusSynthesis methodsSilica gel

The invention relates to a sintering method for preparing silica glass and the silica glass, relates to the field of silica glass preparation and mainly aims to avoid or reduce the generation of bubbles during silica glass preparation through an indirect synthesis method, increase the sintering efficiency of the silica glass and reduce the cost. The method is used for sintering a silica loose body in sintering space. The method comprises the following steps: vacuumizing the sintering space into a negative pressure environment, sintering the silica loose body in the sintering space, discharging air holes in the silica loose body under the negative pressure environment, and sintering the silica loose body into transparent silica glass; cooling the transparent silica glass, thus obtaining a silica glass finished product. In the silica glass finished product obtained after sintering, the content of the bubbles in the silica glass finished product can be reduced, so that the product quality of the silica glass is increased; through integral and simultaneous heating and sintering, the sintering efficiency of the silica loose body is increased, and the cost is reduced.

Owner:CHINA BUILDING MATERIALS ACAD

Preparation method of toughened glass

ActiveCN106396366AReduce air bubble contentGlass furnace apparatusGlass tempering apparatusChemistryMagnesium nitrate

The invention discloses a preparation method of toughened glass. The preparation method comprises the following steps: (1) mixing 87 to 97 parts of raw materials with 3 to 6 parts of a glass clarifier to obtain a mixture, heating the mixture to the temperature of 1755 to 1765 DEG C to be molten, later lowering to the temperature of 1520 to 1530 DEG C to be clarified for 20 to 25min, then heating to the temperature of 1620 to 1630 DEG C, and lowering the temperature to 1520 to 1530 DEG C to obtain a glass melt, and (2) forming the glass melt; the glass clarifier comprises 3 to 4 parts of nitrate, 0.4 to 0.6 part of tin oxide, 0.3 to 0.5 part of calcium carbonate and 0.1 to 0.2 part of magnesium carbonate, wherein the nitrate comprises the following components in percentage by weight: 5 to 8% of sodium nitrate, 5 to 8% of potassium nitrate, 5 to 8% of magnesium nitrate, 5 to 8% of aluminum nitrate and 68 to 80% of ammonium nitrate. By adopting the preparation method of the toughened glass disclosed by the invention, the content of bubbles in the glass can be effectively reduced.

Owner:浙江九龙山实业股份有限公司

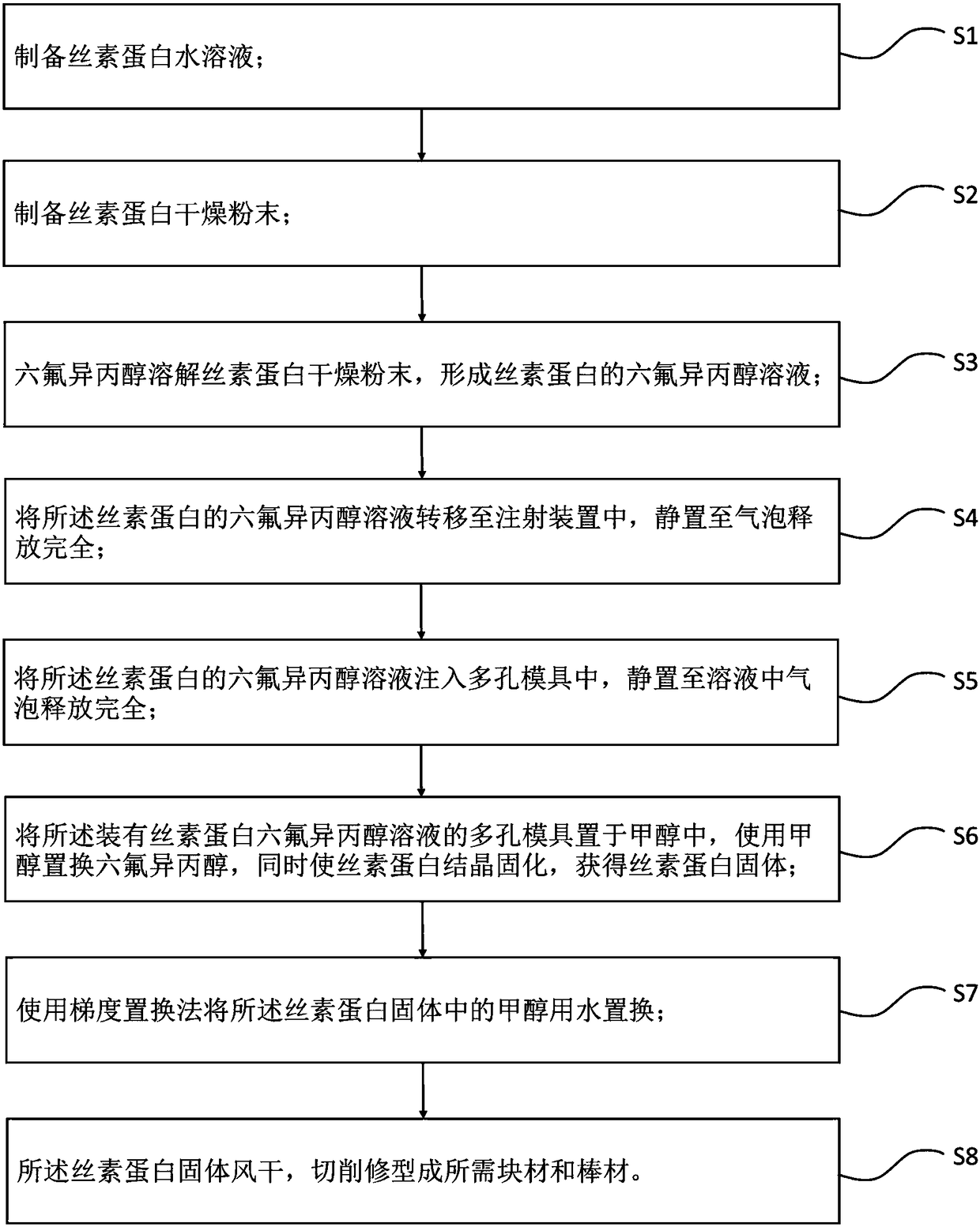

Silk fibroin block material and preparation method thereof

The invention provides a silk fibroin block material and a preparation method thereof. The preparation method comprises: preparing a silk fibroin aqueous solution; preparing silk fibroin dry powder; dissolving the silk fibroin dry powder in hexafluoroisopropanol to form a silk fibroin fluoroisopropanol solution; transferring the silk fibroin hexafluoroisopropanol solution into an injection device,and standing until gas bubbles are completely released; injecting the silk fibroin hexafluoroisopropanol solution into a porous mold, and standing until the gas bubbles in the solution are completelyreleased; replacing the hexafluoroisopropanol with methanol while carrying out crystallization curing to obtain a silk fibroin solid; replacing the methanol in the silk fibroin solid with water by using a gradient displacement method; and carrying out air drying on the silk fibroin solid, and carrying out cutting shaping to obtain the required block material. According to the present invention, the prepared silk fibroin block material has characteristics of large volume, low gas bubble content, uniform component, controllable molecular weight and controllable mechanical property, and can be widely used in biological implant devices, degradable tableware, toys and other fields.

Owner:江西丝科生物科技有限公司

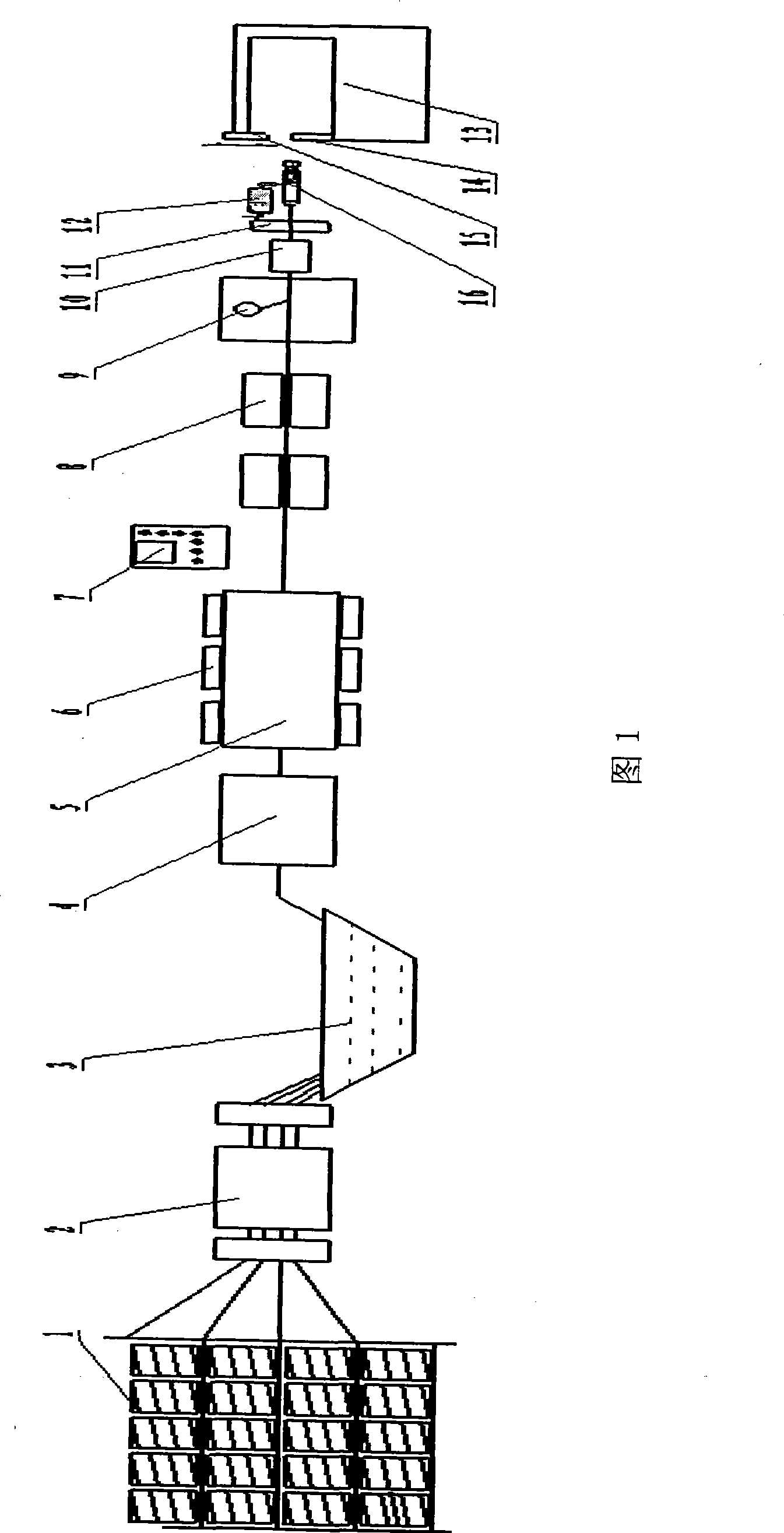

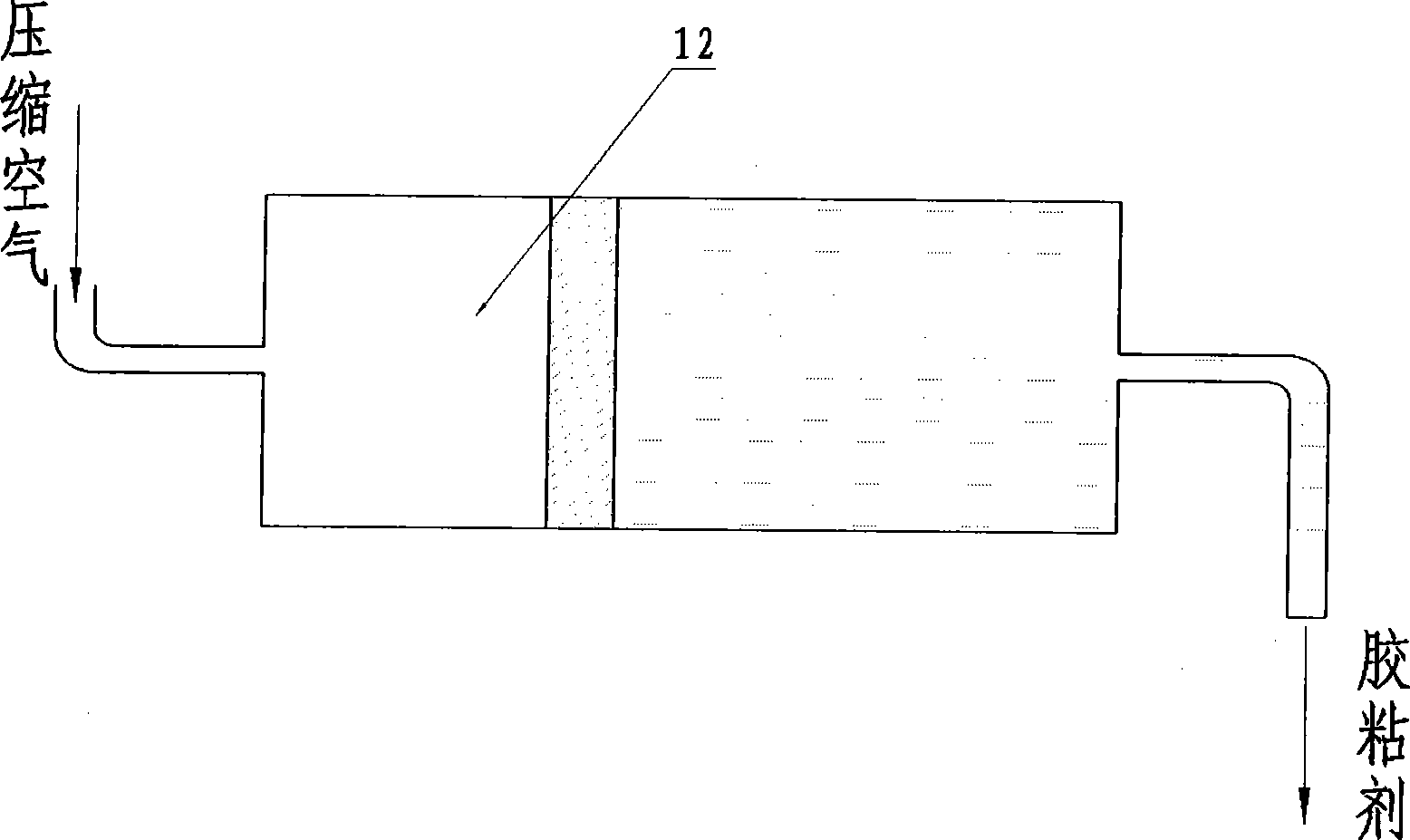

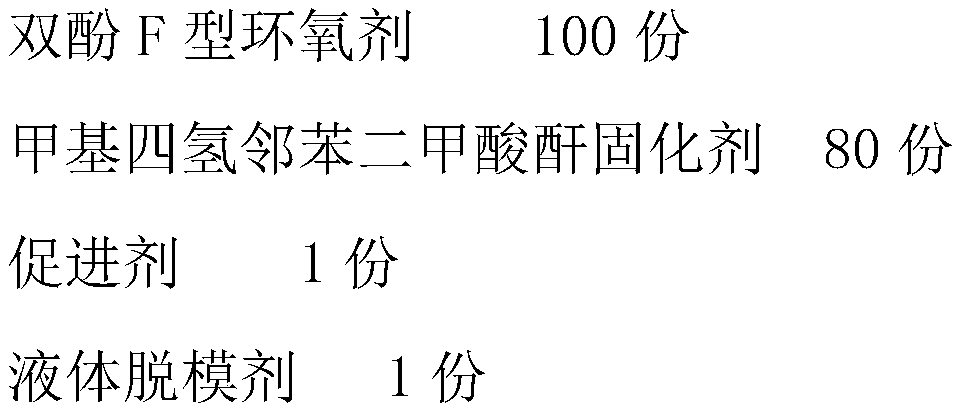

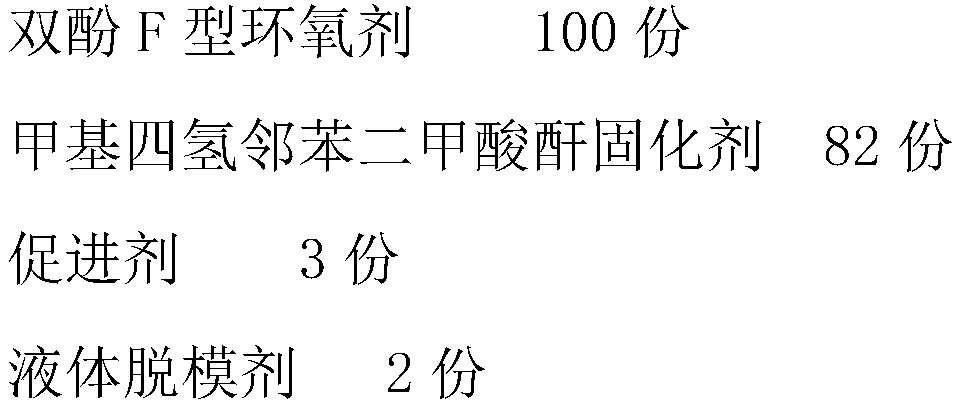

Glass fiber reinforced epoxy resin base profile for electric power system, production method and device

A glass fiber reinforced epoxy resin base profile for an electric power system is prepared from glass fiber and epoxy resin glue through injection-pultrusion, wherein the profile has a T-shape, an L-shape, an H-shape or a U-shape structure, and is characterized in that by setting the T-shape, L-shape, H-shape or U-shape profile, the weight of the insulating core rod made of the profile is effectively reduced, meanwhile the use of a hollow material is avoided, namely the internal insulation problem of the insulating core rod is avoided, and the insulation performance of the insulating core rodis improved, and the structural stability of the profile is effectively improved by arranging one or more preset curvature circular arc structures on the outer surface of the profile. The glass fiberand the epoxy resin are injected into one body by the injection-pultrusion process, so that the glass fiber can be fully impregnated, and the produced profile has less bubbles, excellent electrical and mechanical properties and stability are realized.

Owner:STATE GRID CORP OF CHINA +2

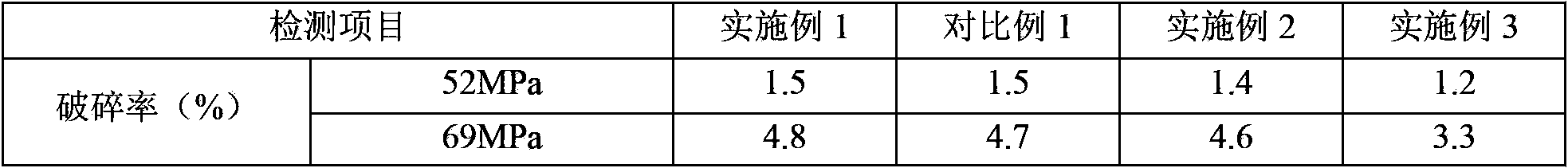

Fracturing propping agent and its preparation method

InactiveCN103849369AGood dispersionReunion won't happenFluid removalDrilling compositionWater basedPolymer science

The invention provides a fracturing propping agent preparation method, and a fracturing propping agent prepared through the method. The fracturing propping agent preparation method is characterized in that the fracturing propping agent is obtained by curing a mixture containing aggregate particle particles and a laminating adhesive; and the laminating adhesive is a hydrophilic resin composition, and a preparation method of the hydrophilic resin composition comprises the following steps: allowing an epoxy resin to have first contact with a modifier selected from acid anhydride to make the hydroxy group in the epoxy resin react with the acid anhydride group in the modifier; and allowing a mixture obtained through the first contact to have second contact with an alkaline substance under acid-to-salt conditions. The fracturing propping agent can be well dispersed in a water-based fracturing fluid, the content of bubbles in the water-based fracturing fluid carrying the fracturing propping agent is low, and the fracturing propping agent also has a high crushing limit.

Owner:ELION RESOURCE GROUP

Fracturing propping agent and preparation method thereof

The invention provides a preparation method of a fracturing propping agent, and the fracturing propping agent prepared by the preparation method. The preparation method of the fracturing propping agent comprises curing of a mixture containing aggregate particles and a laminating adhesive, and the laminating adhesive is a hydrophilic resin composition. A preparation method of the hydrophilic resin composition is as follows: performing first contact of epoxy resin and at least one modifier; and under the conditions being enough to enable an acid to from a salt, performing second contact of a mixture obtained by the first contact and at least one alkaline substance; wherein under the first contact condition, part of epoxy groups in the epoxy resin react with groups capable of providing protons in the modifier. The fracturing propping agent has high crushing resistant strength, has good dispersion in a water base fracturing fluid, and basically does not agglutinate; and the water base fracturing fluid carrying the fracturing propping agent is low in bubble content.

Owner:ELION RESOURCE GROUP

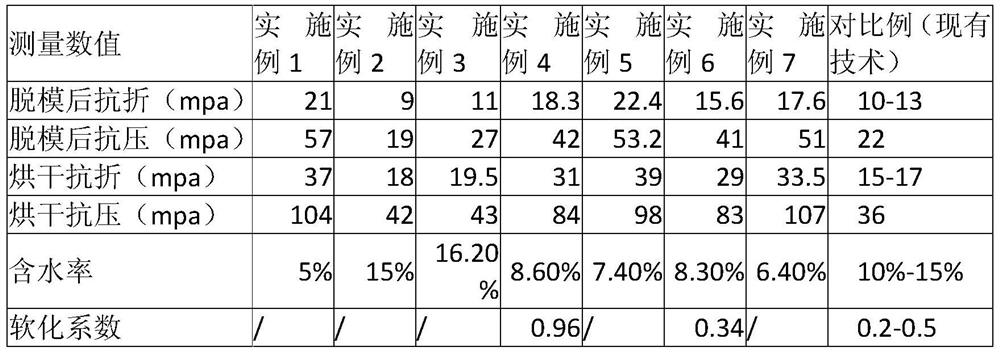

Wood magnesium board and preparation method thereof

PendingCN113956019AHigh strengthReduce manufacturing costFeeding arrangmentsInorganic saltsPulp and paper industry

The invention relates to the technical field of materials, and particularly discloses a wood magnesium board and a preparation method thereof. The wood magnesium board is prepared from the following raw materials in percentage by weight: 20-40% of magnesium oxide, 10-20% of a magnesium sulfate solution, 20-30% of wood flour, 0.2-0.3% of metal oxide, 3-4% of non-metal oxide, 1-2% of inorganic salt, 0.5-1% of acid, 0.1-0.5% of a waterproof agent and 1-2% of a modifier. The invention also discloses a preparation method of the wood magnesium board. The preparation method comprises the following steps: accurately metering raw materials; and conducting mixing, stirring, dispersing, metering and paving under a dry process, conducting pre-pressing, carrying out secondary hot press molding, conducting demolding, cutting and sanding in a short time, drying frame pieces, finally finely cutting and sanding a finished product, and packaging and delivering a finished product. The production cost is effectively reduced, the production period is shortened, and the plate is high in strength, good in toughness, environment-friendly and non-toxic.

Owner:ANHUI HANHUA BUILDING MATERIALS TECH

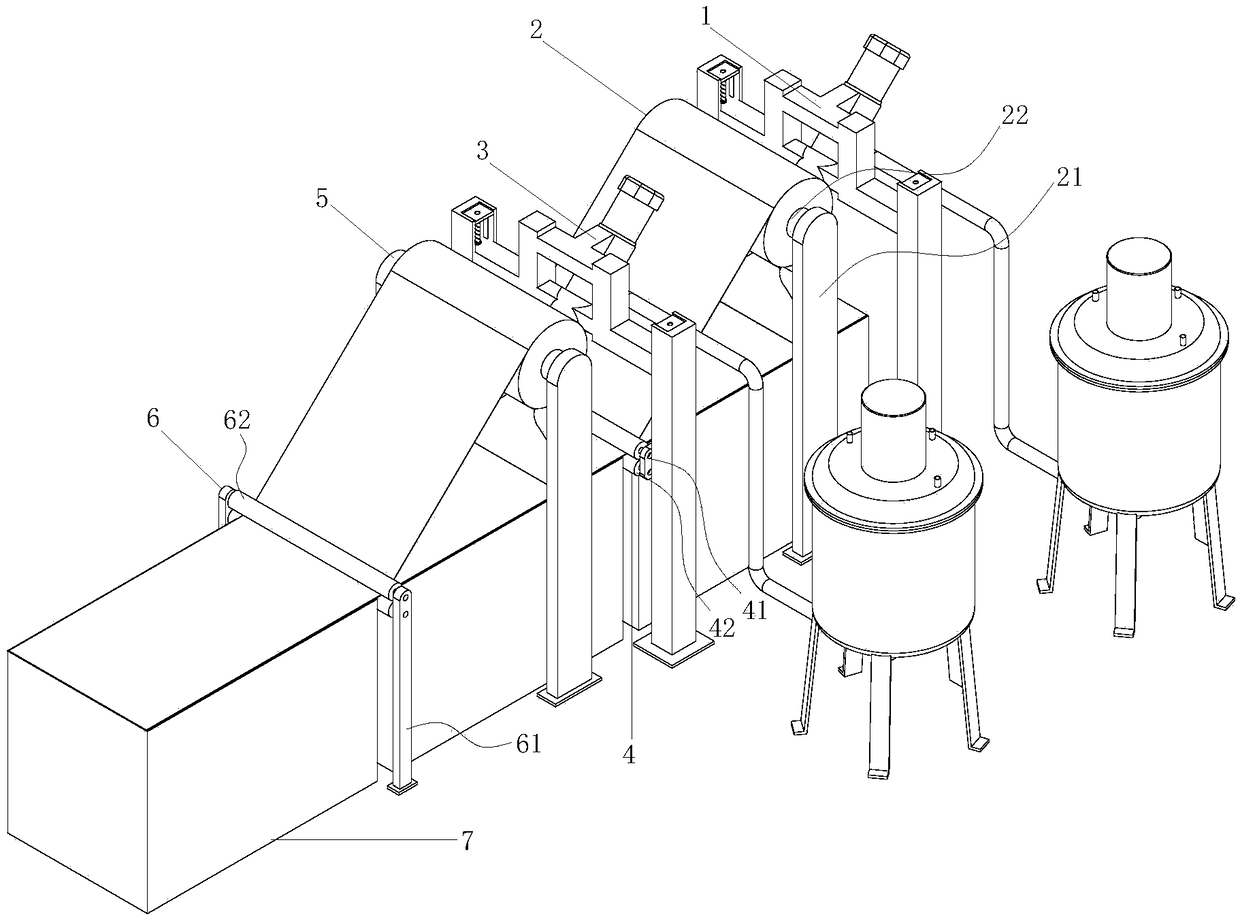

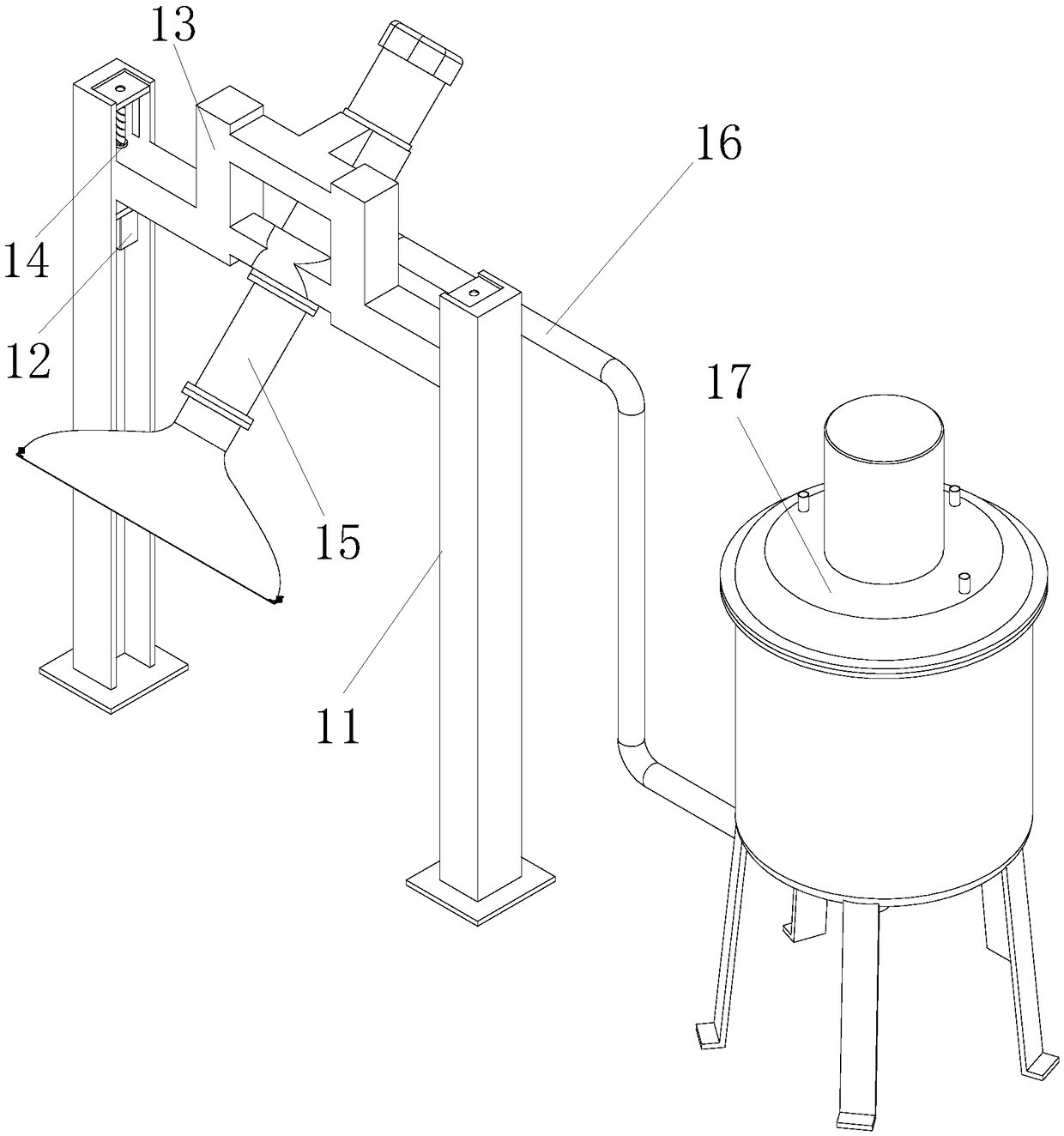

Flow Separator And Flow Separator Method

InactiveUS20080156744A1Reduce flow rateImprove accuracyWater/sewage treatment by centrifugal separationDispersed particle separationProduct gasEngineering

Disclosed is a flow separator, typically for use in separating liquid from gas in a flowing mixture of liquid and gas, e.g. water, oil and gas in a hydrocarbon well production fluid pipeline, the separator having a swirl generator disposed at the inlet to a cylindrical separation chamber and the separation chamber having an elongate liquid extraction slot formed along its wall, such that in operation the swirling flow centrifugally pushes the liquid towards the wall of the separation chamber to exit the separation chamber through the extraction slot into a collection chamber which may allow the return of the extracted liquid back into the main flow using a U-shaped tube.

Owner:SCHLUMBERGER TECH CORP

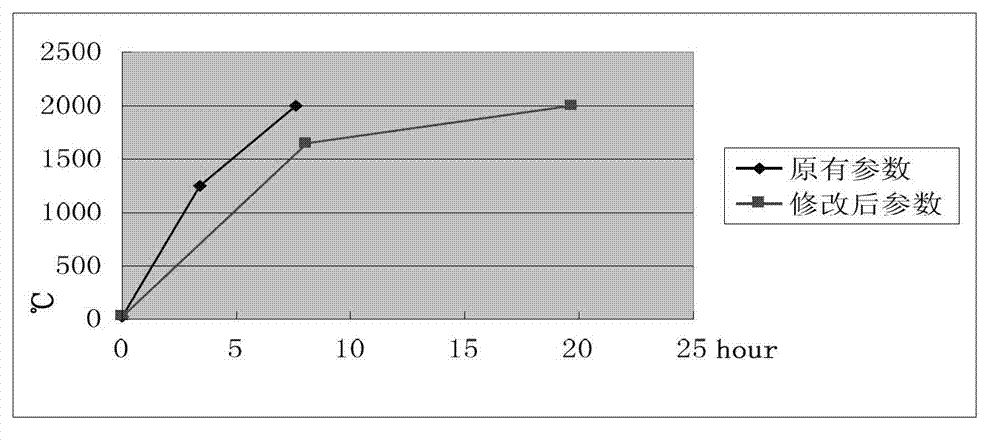

Method for heating and melting precast shaped filler in sapphire crystal growth

InactiveCN103243388AMeet density requirementsReduce air bubble contentAfter-treatment apparatusPolycrystalline material growthCrucibleLarge size

The invention discloses a method for heating and melting a precast shaped filler in sapphire crystal growth, which comprises the following steps: starting a heating system to heat from 25 DEG C to 1650 DEG C, wherein the heating gradient is 200 DEG C / h; and after the temperature reaches 1650 DEG C, changing the temperature increase gradient to 30 DEG C / h, and further heating to 2000 DEG C until a block material is completely molten. The precast shaped filler disclosed by the invention causes less bubble defects in comparison with a crystal block treated by a flame method; the packed density of the precast shaped filler can be up to 2.6-2.8 g / cm<3>; and more materials can be filled under the condition of not changing the size of a crucible, thereby meeting the requirements for the density of the raw material in large-size sapphire crystal growth in China at present.

Owner:苏州海铂晶体有限公司

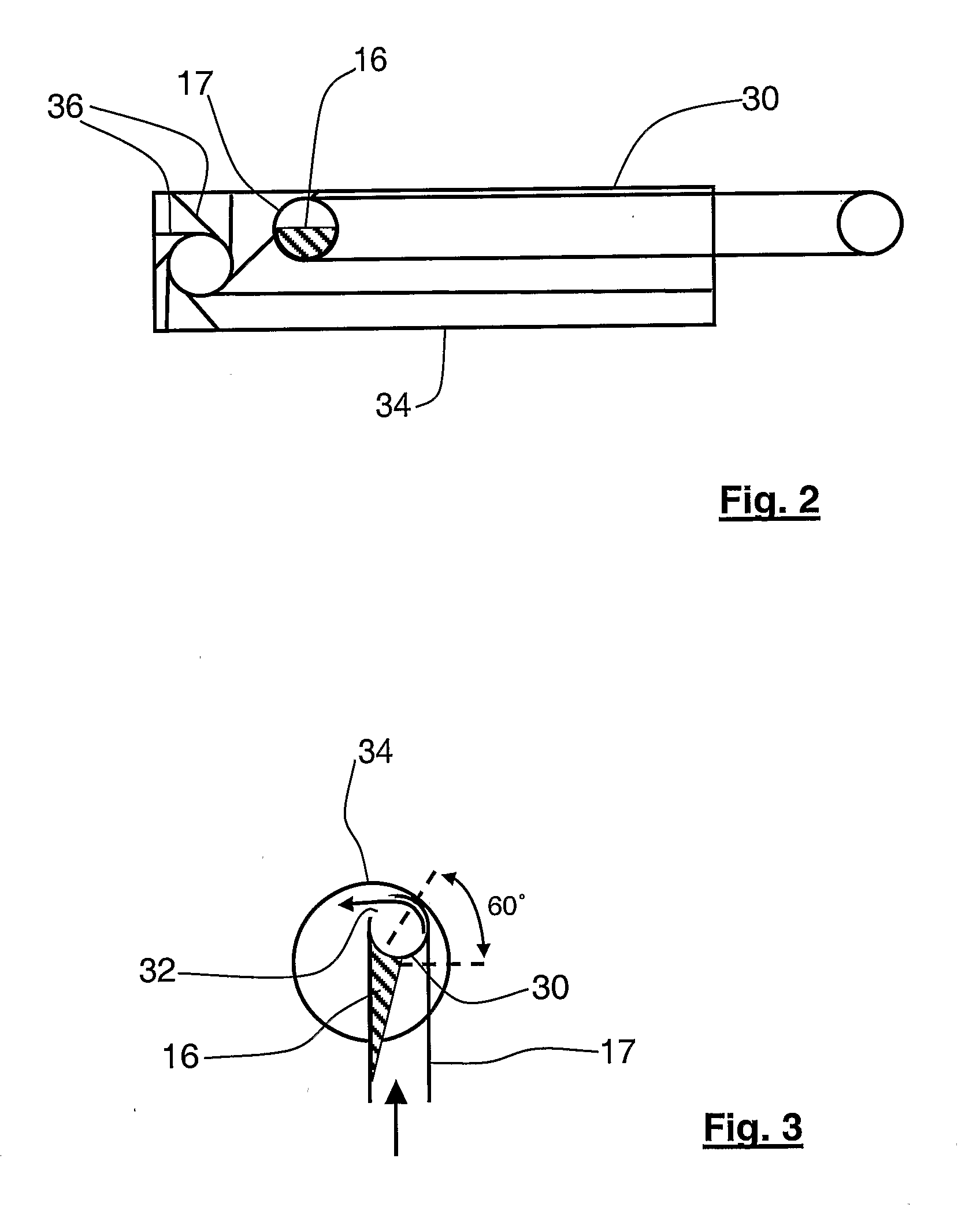

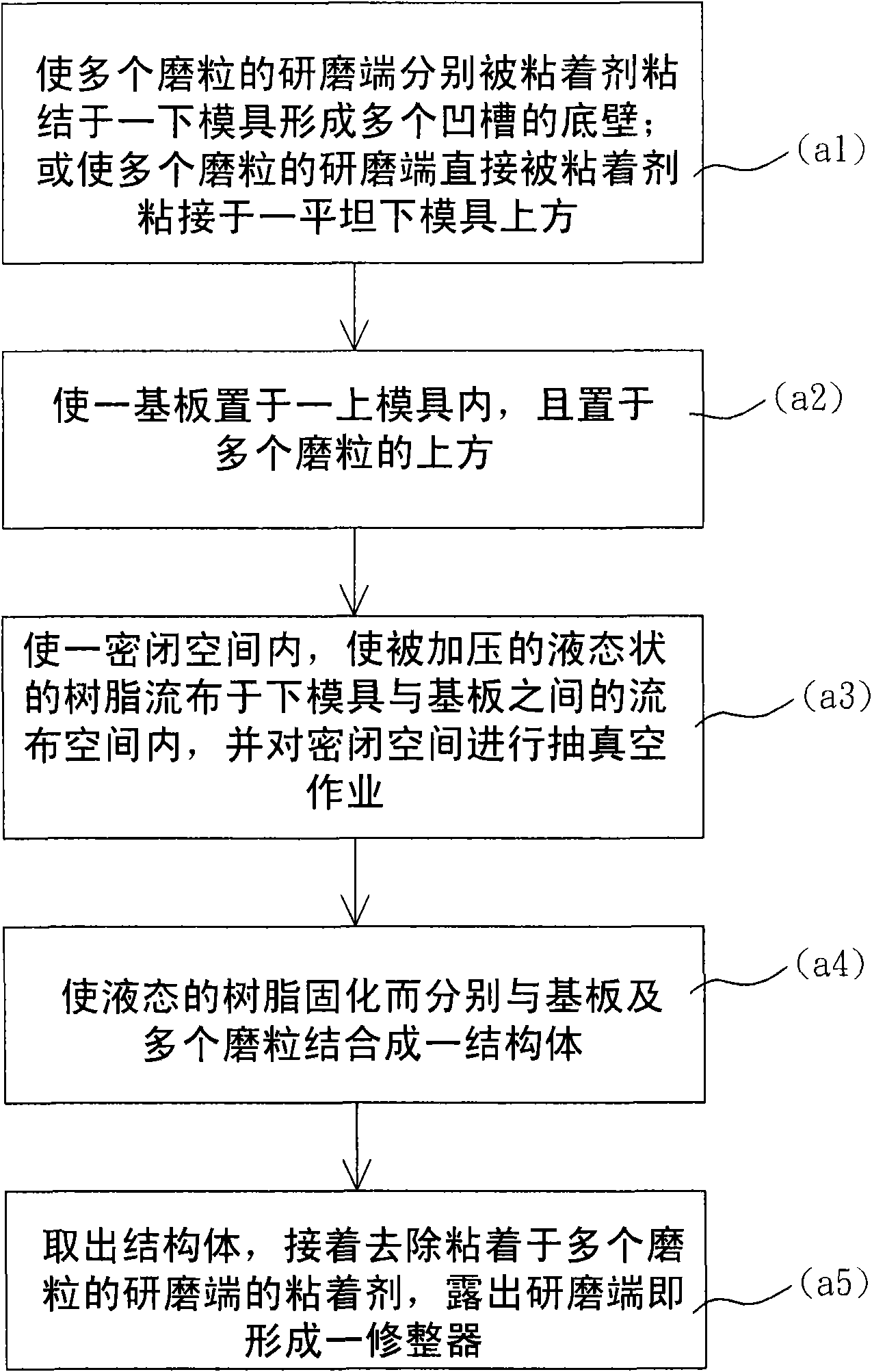

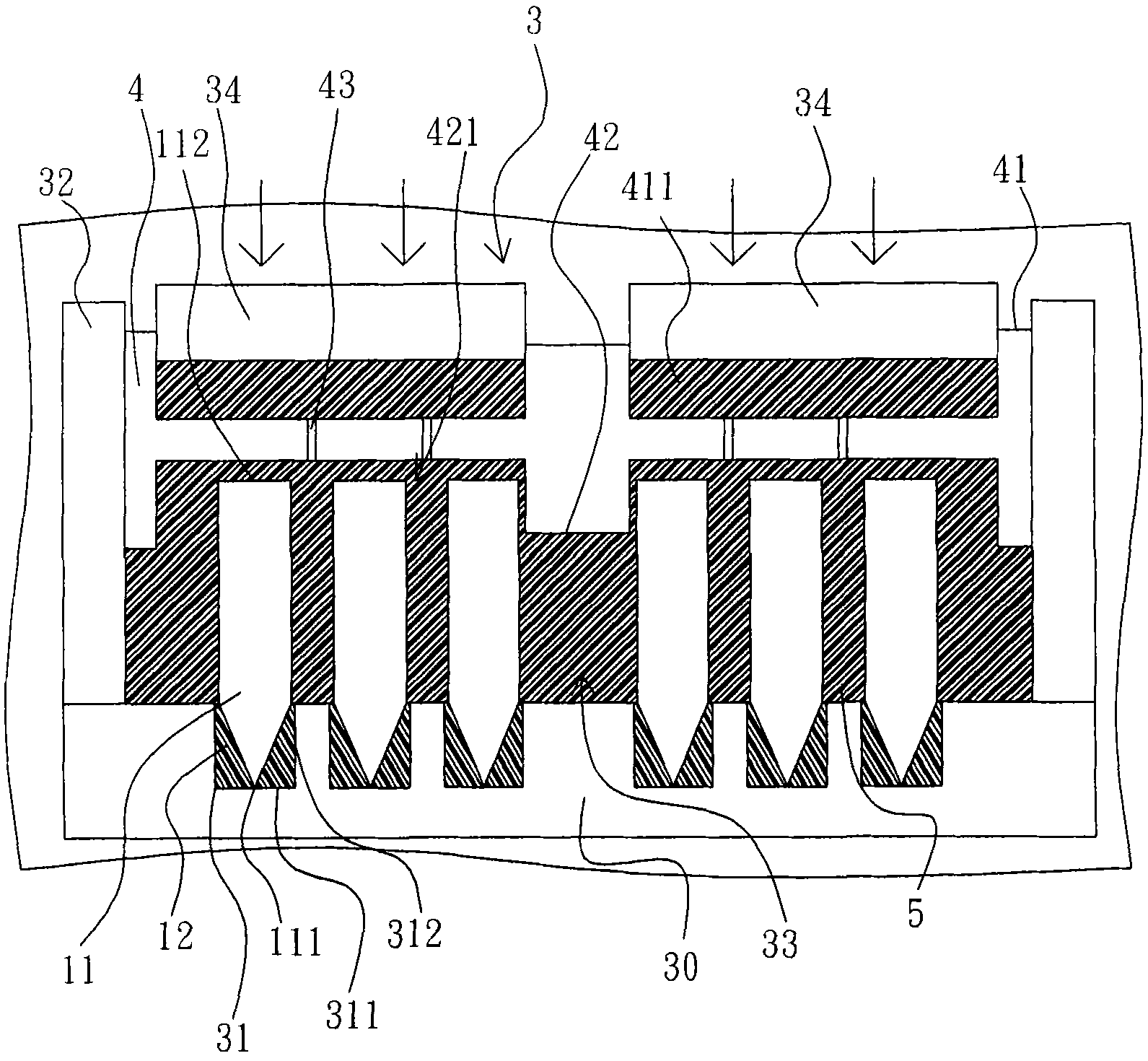

Method for preparing trimmer

InactiveCN102092007AReduce air bubble contentIncrease holding powerSemiconductor/solid-state device manufacturingAbrasive surface conditioning devicesPolymer chemistryLiquid resin

The invention discloses a method for preparing a trimmer, which comprises: fixing the grinding ends of a plurality of abrasive particles on a lower die by adhesive, pouring liquid resin, allowing the liquid resin to solidify to fixedly combine with the plurality of abrasive particles and removing the adhesive adhered on the grinding ends. During the liquid resin pouring operation, the plurality of abrasive particles do not shift and have the same protruding height, and the grinding end face of the trimmer is flatter; and the resin combined with the plurality of abrasive particles, before solidification, is subjected to pressurization and vacuumizing to reduce the air bubble content of the resin and increase the holding force of the resin for the plurality of abrasive particles, so that the plurality of abrasive particles do not strip when trimming a grinding pad.

Owner:林舜天 +1

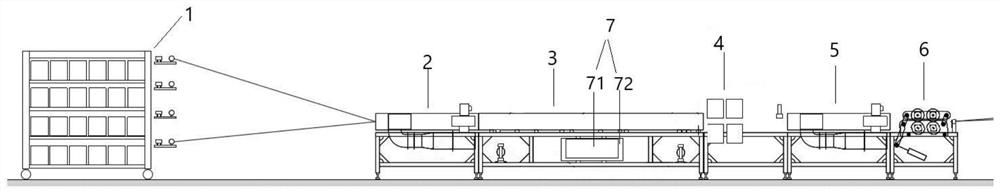

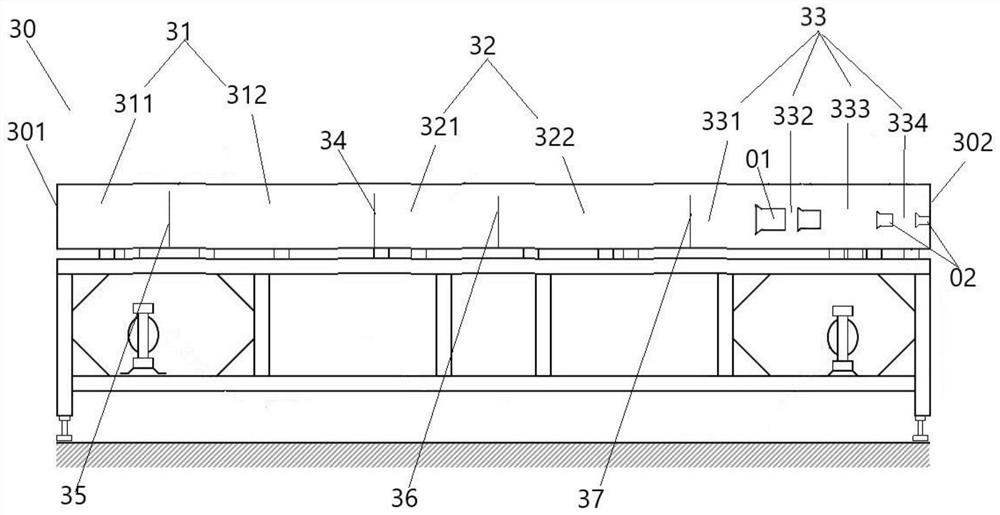

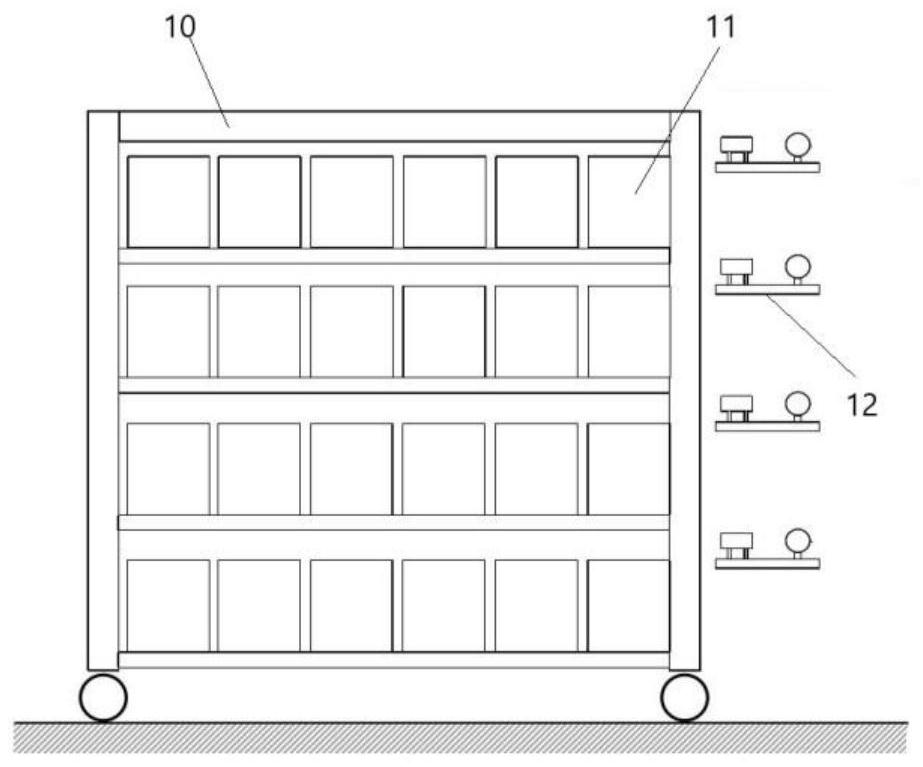

Pultrusion material production system and method and glass fiber reinforced plastic pultrusion strip

The invention discloses a pultrusion material production system and method and a glass fiber reinforced plastic pultrusion strip. The pultrusion material production system comprises a yarn supply system, an impregnation system, a curing system and a traction mechanism; the impregnation system comprises a first impregnation area, a second impregnation area and a pultrusion area, and a draining plate is arranged between the first impregnation area and the second impregnation area; the first impregnation area is used for primary resin impregnation of fibers, the draining plate is used for scraping part of primary resin impregnated in the fibers, and the second impregnation area is used for secondary resin infiltration of the fibers; and the fibers penetrate through the pultrusion area to be extruded into a fiber-resin material in a preset shape. According to the pultrusion material production system, bubbles generated during secondary resin impregnation of the fibers are few, the contentof bubbles in glass fiber reinforced plastics obtained through pultrusion is reduced, and the strength of the glass fiber reinforced plastics is high.

Owner:ZHENSHI GRP HUAZHI RES INST (ZHEJIANG) CO LTD

Automobile inner door armrest assembly mold system

The invention discloses an automobile inner door armrest assembly mold system which comprises an injection machine, at least two foaming molds, a turnplate and a turnplate motor. The turnplate motor is connected to the turnplate to drive the turnplate to rotate autologously. The foaming molds are uniformly distributed at the edge of the upper side face of the turnplate; and the injection machine is arranged on one side of the turnplate. The automobile inner door armrest assembly mold system disclosed by the invention is simple in structure and easy to implement, and can achieve continuous injection processing, reduce the bubble content in a finished product, enhance the processing efficiency and reduce the rejection rate of the products.

Owner:SHANGHAI DAOLANGZHOU AUTOMOTIVE TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com