Oil pan structure for internal combustion engine

A technology for oil pans and internal combustion engines, which is applied in oil pans, engine lubrication, mechanical equipment, etc., and can solve problems such as oil foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

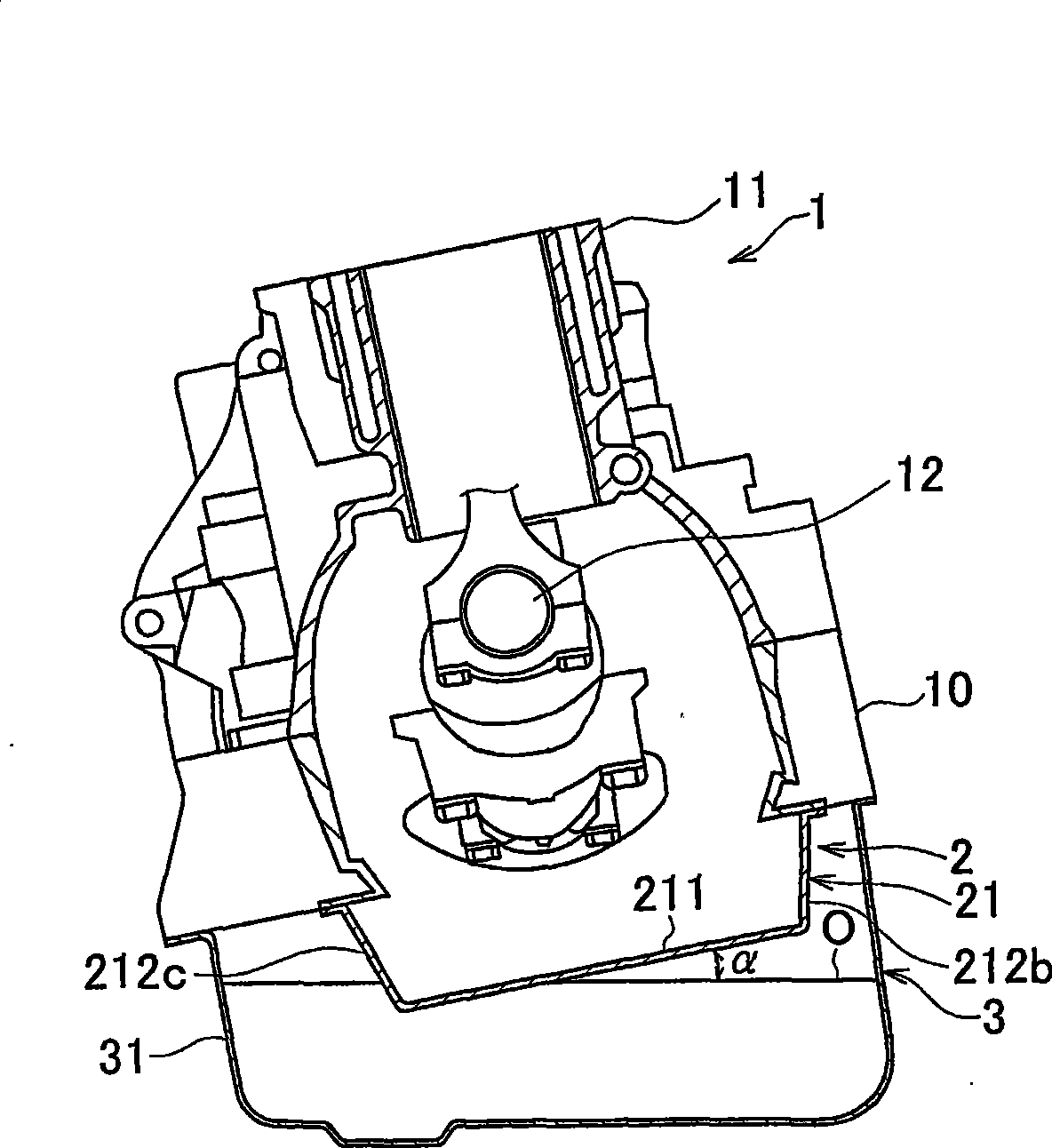

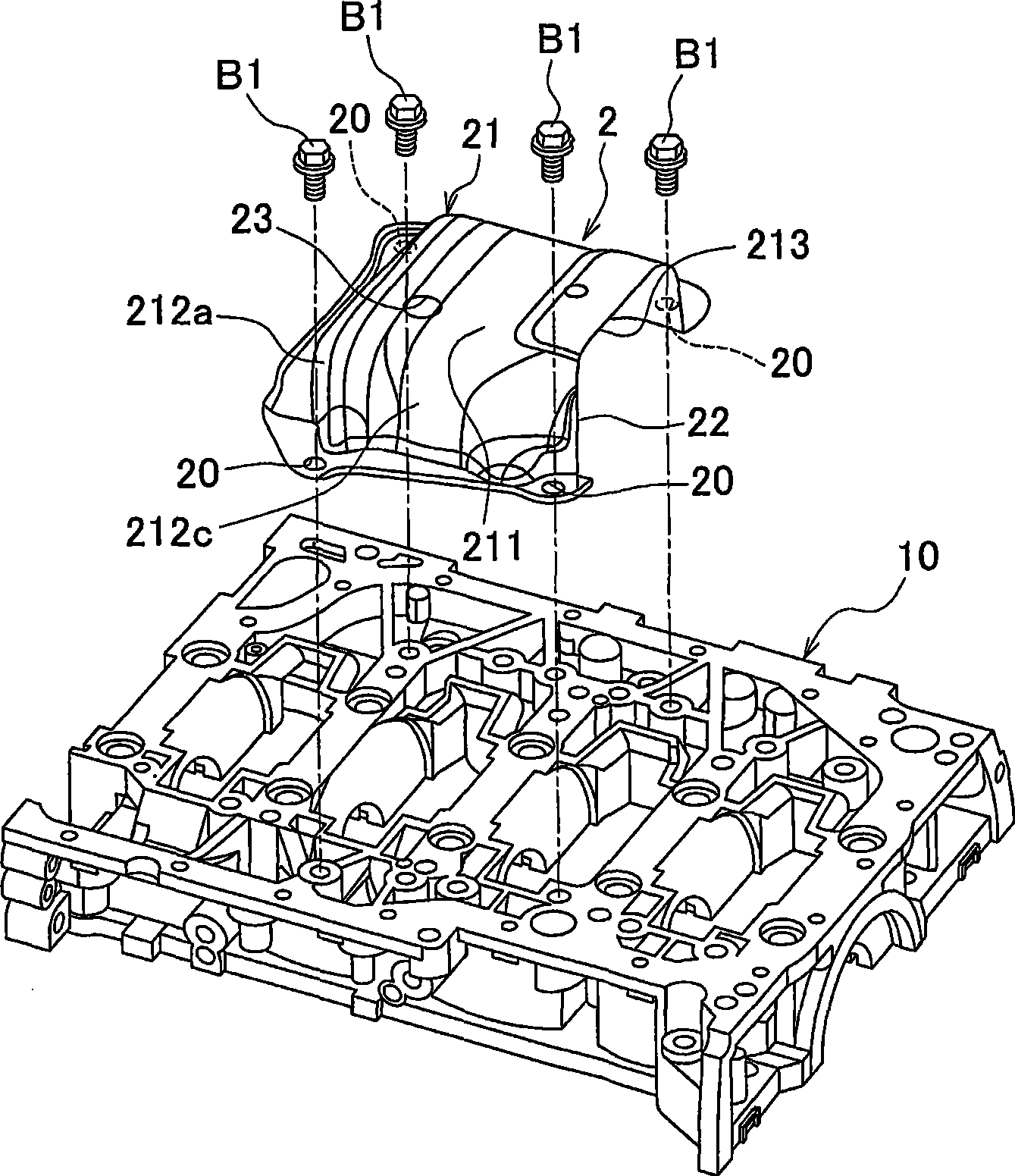

[0015] FIG. 1 shows an example in which an oil pan structure according to an embodiment of the present invention is applied to an inline four-cylinder engine. A trapezoidal trapezoidal frame 10 is attached to the lower surface of the cylinder block 11 of the engine 1 . A crankshaft 12 is rotatably supported between the trapezoidal frame 10 and the cylinder block 11 . In this case, one end of the crankshaft 12 is located on the front side of the engine 1 , and the other end of the crankshaft 12 is located on the rear side of the engine 1 . In other words, the axial direction of the crankshaft 12 coincides with the longitudinal direction of the engine 1 .

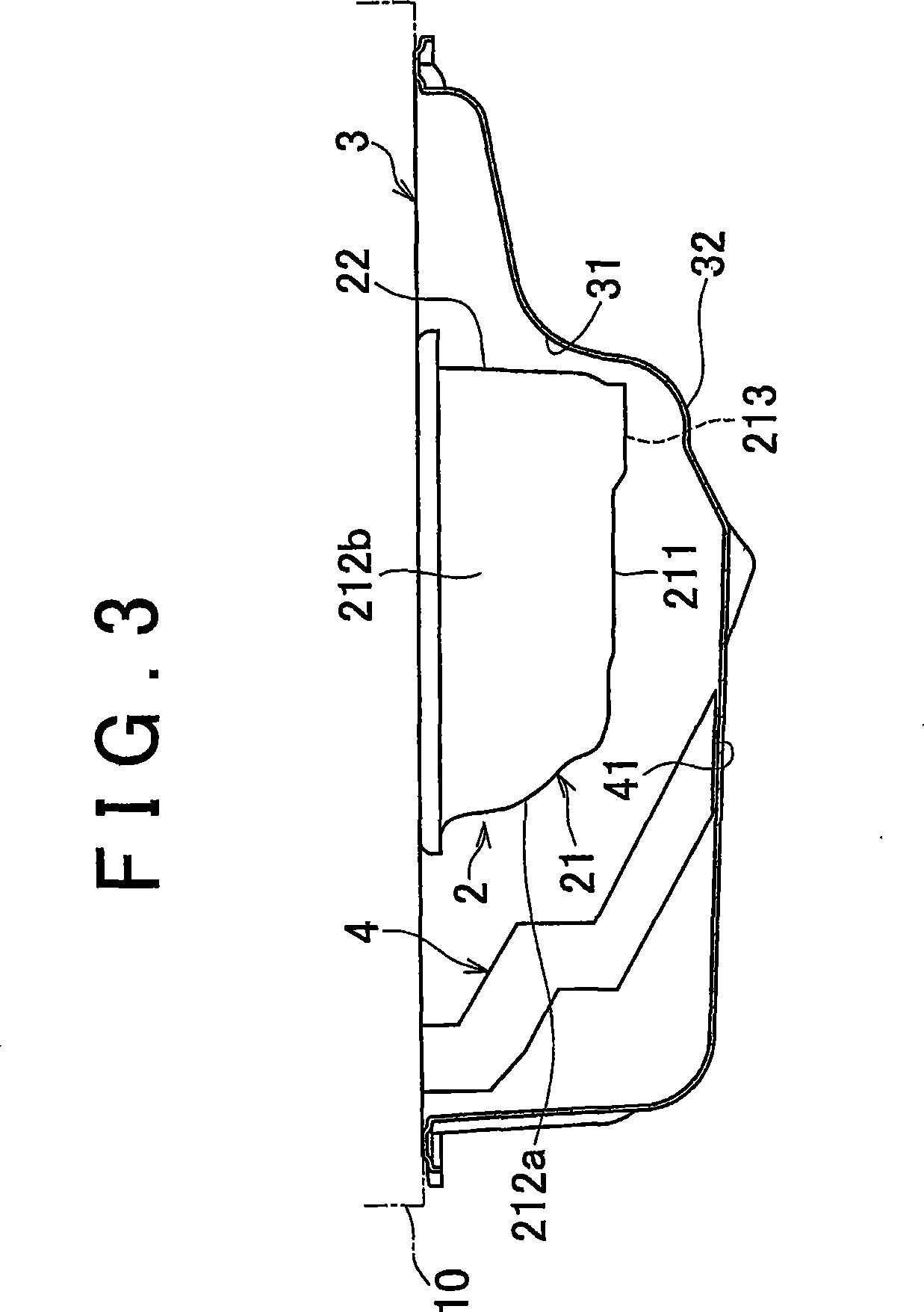

[0016] As shown in FIG. 2 , the baffle plate 2 having a generally rectangular shape in plan view is fixed close to the middle of the lower surface of the trapezoidal frame 10 by bolts B1 passing through bolt holes 20 at four corners. The periphery of the oil pan 3 is connected to the outer periphery of the lower surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com