Tough oil well cement

An oil well cement and toughness technology, which is applied in the field of tough cement, can solve the problems of the difference in elasticity and deformation between the cement sheath and the casing, loss of interlayer isolation and protective casing, high impact force and internal pressure of the cement sheath, etc., to achieve The effect of ensuring volume stability, improving compactness and fluidity, and stably increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

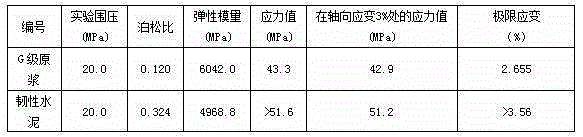

Image

Examples

Embodiment 1

[0033] A tough oil well cement, consisting of the following components in parts by weight:

[0034] 100 parts of cement;

[0035] Active filler 1 part;

[0036] 1 part of toughening material;

[0037] Short fiber 0.01 part;

[0038] 1 part of admixture;

[0039] 0.1 parts of water reducing agent;

[0040] 1 part fluid loss reducer;

[0041] 1 part of defoamer;

[0042] 1 part retarder.

[0043] In the present invention, the cement is grade G oil well cement.

[0044] In the present invention, the active filler is fly ash, wherein the fly ash is Class I fly ash or Class II fly ash, and the fly ash has the particle characteristics of glass microspheres and potential chemical activity, which is helpful for reducing cement slurry Reduced water consumption, increased fluidity, improved compactness and later strength have excellent effects.

[0045] In the present invention, the toughening material is redispersible latex powder. The redispersible latex powder is flexible r...

Embodiment 2

[0050] A tough oil well cement, consisting of the following components in parts by weight:

[0051] 100 parts of cement;

[0052] 15 parts active filler;

[0053] 5 parts of toughening material;

[0054] Short fiber 0.05 part;

[0055] 5 parts of admixture;

[0056] 0.2 parts of water reducing agent;

[0057] 5 parts of fluid loss reducer;

[0058] 2 parts of defoamer;

[0059] 5 parts of retarder.

[0060] In the present invention, the cement is grade G oil well cement.

[0061] In the present invention, the active filler is fly ash, wherein the fly ash is Class I fly ash or Class II fly ash, and the fly ash has the particle characteristics of glass microspheres and potential chemical activity, which is helpful for reducing cement slurry Reduced water consumption, increased fluidity, improved compactness and later strength have excellent effects.

[0062] In the present invention, the toughening material is modified asphalt, and the modified asphalt is cationic emulsif...

Embodiment 3

[0067] A tough oil well cement, consisting of the following components in parts by weight:

[0068] 100 parts of cement;

[0069] 8 parts active filler;

[0070] 3 parts of toughening material;

[0071] Short fiber 0.03 part;

[0072] 3 parts of admixture;

[0073] 0.1 parts of water reducing agent;

[0074] 3 parts of fluid loss reducer;

[0075] 1 part of defoamer;

[0076] 3 parts retarder.

[0077] In the present invention, the cement is grade G oil well cement.

[0078] In the present invention, the active filler is fly ash, wherein the fly ash is Class I fly ash or Class II fly ash, and the fly ash has the particle characteristics of glass microspheres and potential chemical activity, which is helpful for reducing cement slurry Reduced water consumption, increased fluidity, improved compactness and later strength have excellent effects.

[0079] In the present invention, the toughening material is elastic particles, and the elastic particles are superfine natura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com