Fabrication of heavy walled silica tubing

A technology of quartz and quartz glass, applied in the field of thick-walled SiO2 manufacturing, can solve problems such as increasing processing time, and achieve the effect of reducing the content of bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The improvement in quality of quartz glass resulting from reduced bubble formation is obtained by increasing the rate at which bubbles escape from the molten glass during glass formation. A considerable reduction in bubble formation can be obtained by selecting a suitable gas or gas mixture for feeding the quartz sand into the process furnace and / or as process gas for the melting process.

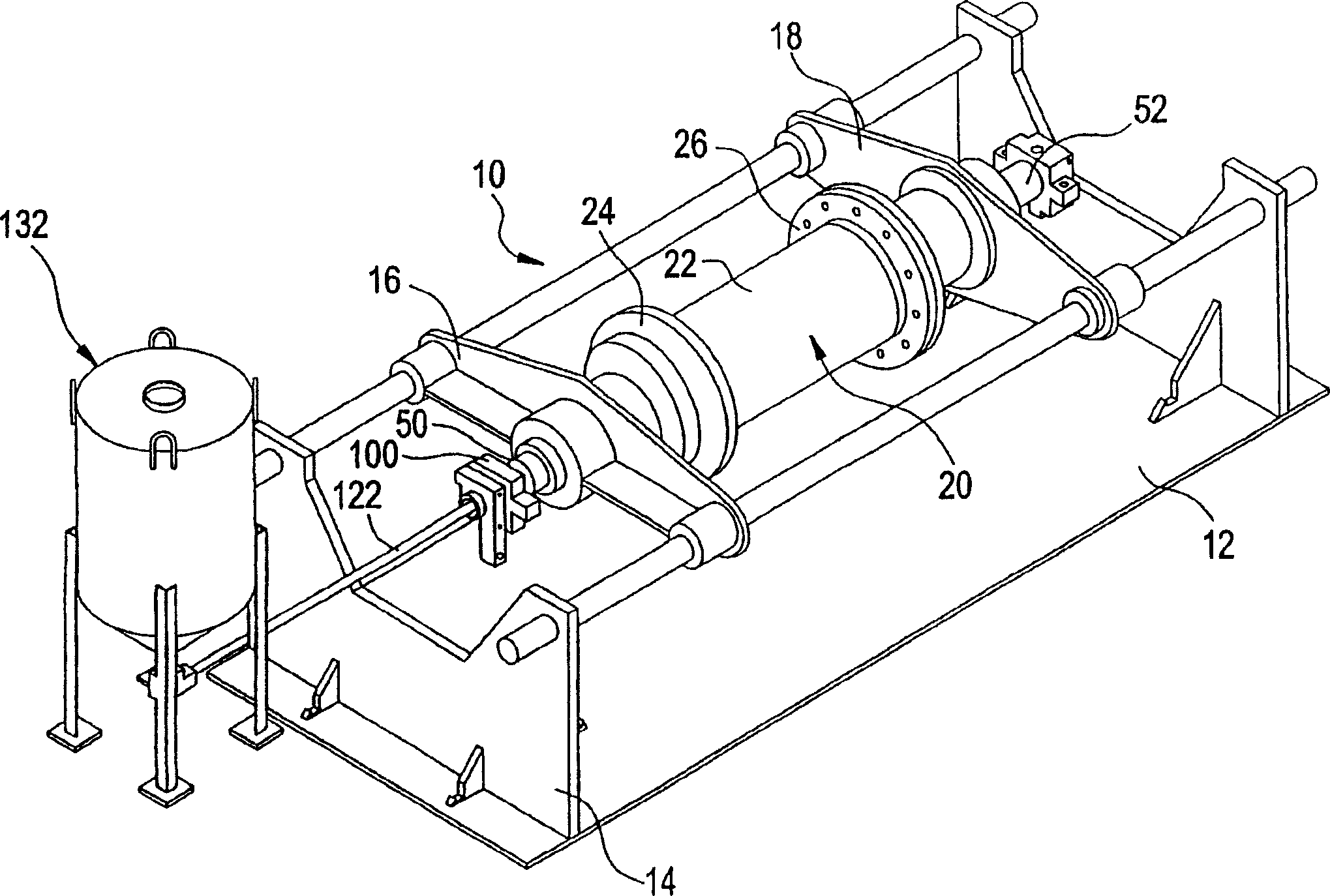

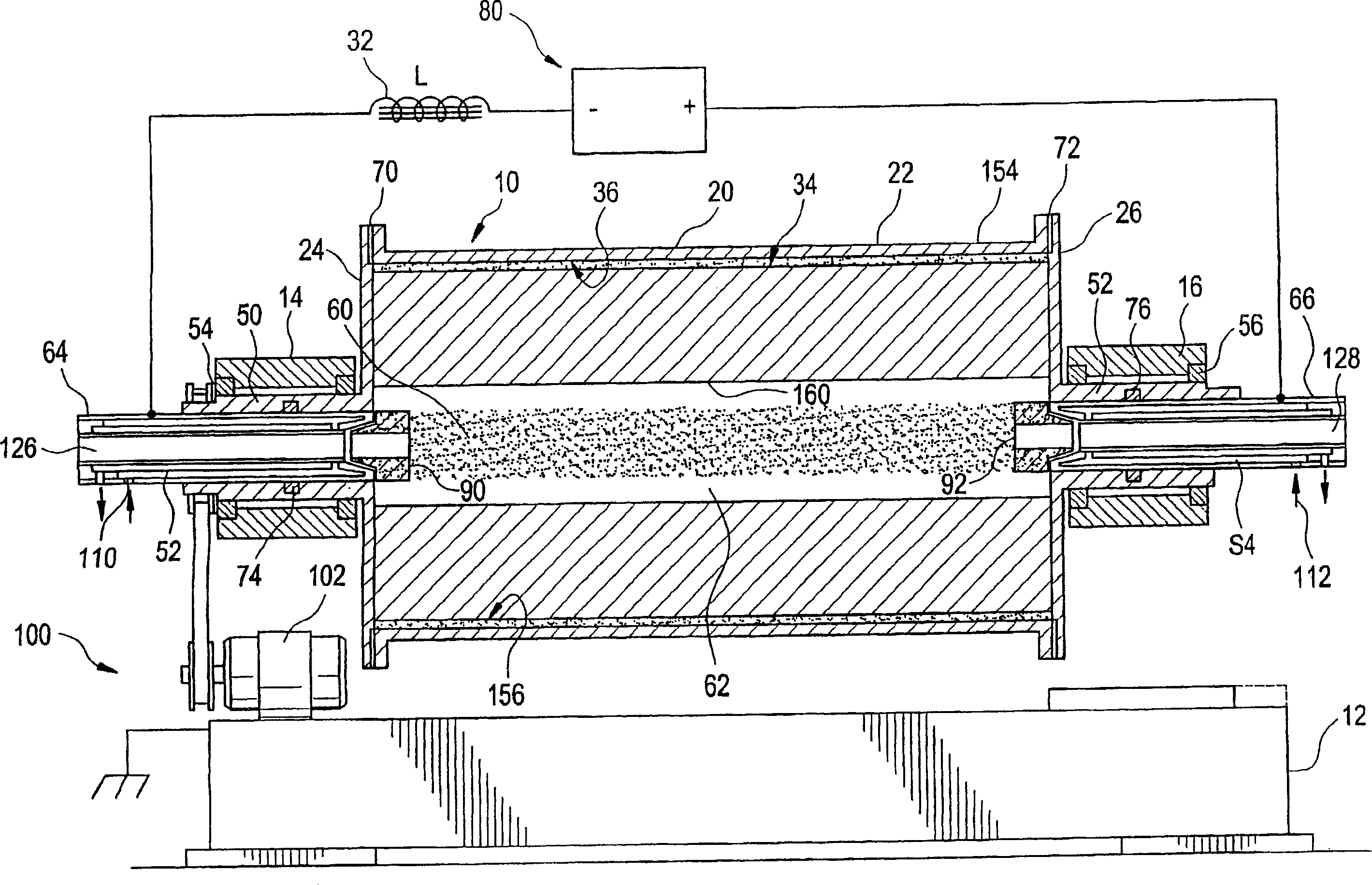

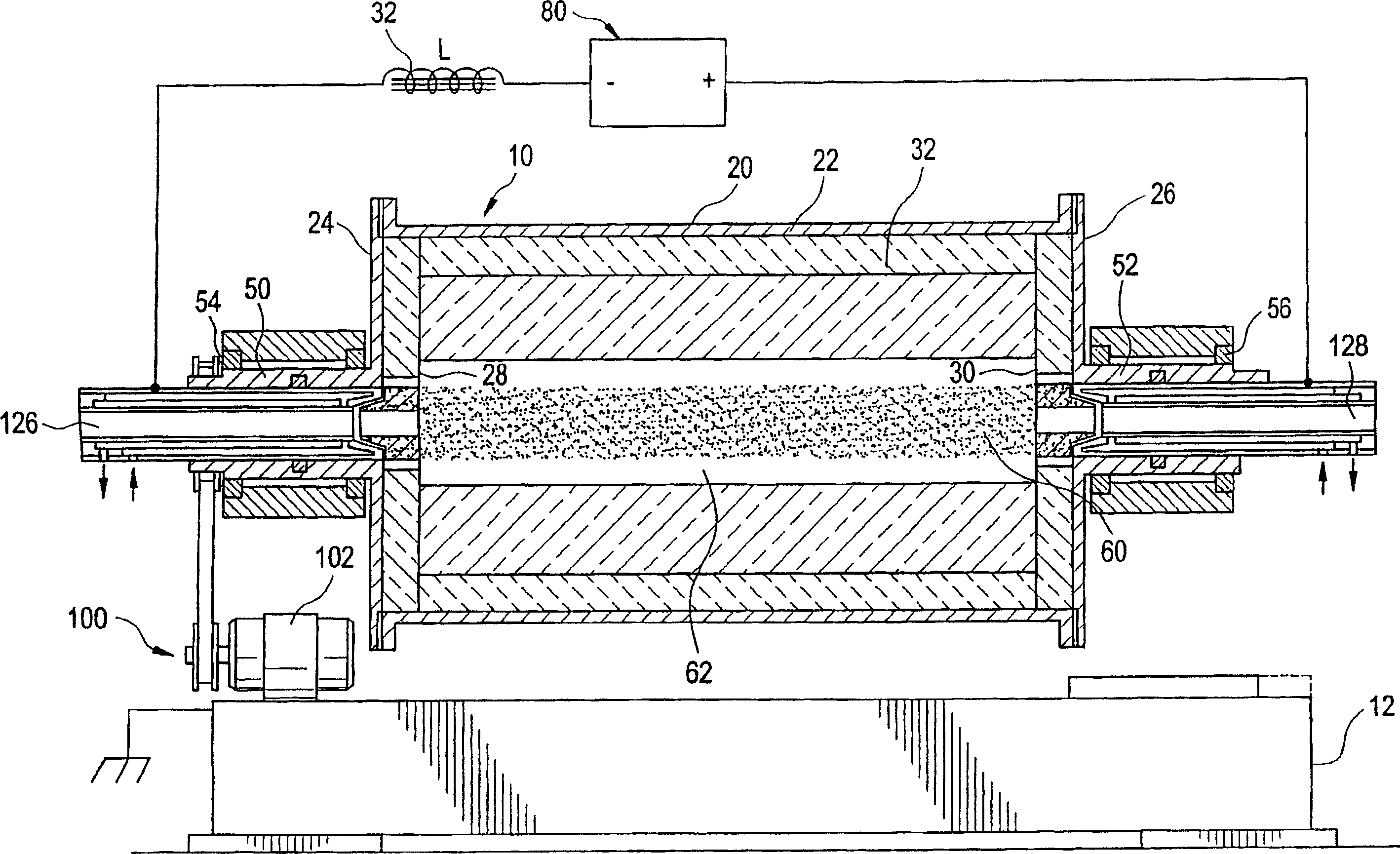

[0025] figure 1 An exemplary rotary furnace 10 is shown for performing the melting process, although it should be understood that the specific configuration of the furnace may be varied. While the furnace is shown using plasma arc heating, it should be understood that resistive heating or other heating systems may alternatively be used with the furnace.

[0026] As used herein, the term "particles" generally refers to all small, crushed, granular, precipitates, deposits, slugs or other finely divided quartz particles used as a raw material in the formation of quartz glass . The te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com