Hydrophilic resin composition, and preparation method and application thereof

A technology of hydrophilic resin and composition, applied in the direction of epoxy resin glue, earthwork drilling, adhesive type, etc., can solve problems such as proppant agglomeration, achieve low air bubble content, high crushing strength, and prevent closure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

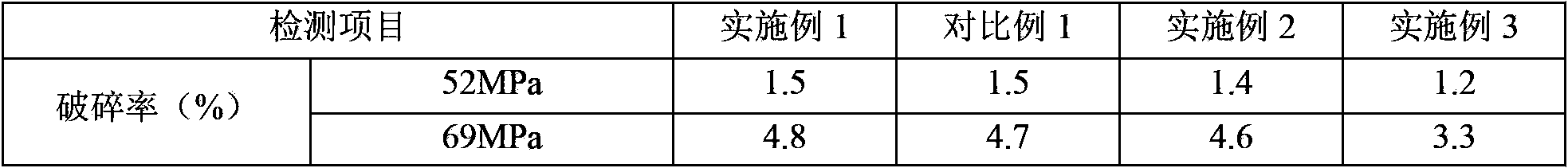

Examples

preparation example Construction

[0014] The invention provides a kind of preparation method of hydrophilic resin composition, the method comprises:

[0015] The epoxy resin is first contacted with at least one modifier, and the modifier is selected from acid anhydrides, and the conditions of the first contact make the hydroxyl group in the epoxy resin and the acid anhydride in the modifier group reactions; and

[0016] The mixture obtained from the first contacting is subjected to a second contacting with at least one basic material under conditions sufficient to cause the acid to form a salt.

[0017] According to the method of the present invention, the modifying agent is selected from acid anhydrides. When the modifier is contacted with the epoxy resin, the acid anhydride group reacts with the hydroxyl group contained in the molecular structure of the epoxy resin to form a carboxylic acid.

[0018] The acid anhydride is preferably selected from organic acid anhydrides, more preferably from aliphatic acid...

Embodiment 1

[0062] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-21, epoxy value 0.21mol / 100g, hydroxyl value 0.226mol / 100g) in 50g toluene, add 0.003 g hydroquinone, the pH value of the reaction solution was adjusted to 2. With stirring, the temperature was raised to 100°C, then 9.8g of maleic anhydride was added, and the reaction was stirred at this temperature for 2 hours; then the temperature was lowered to 40°C, 10.1g of triethylamine was added, and the reaction was continued for 0.5 hours to obtain The mixture evaporates the solvent with a rotary evaporator, thereby obtaining the hydrophilic resin composition of the present invention.

[0063] (2) Mix 100g of the hydrophilic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Qingtongxia Jinshengyuan Proppant Co., Ltd., with a particle size of 30-50 mesh) and stir for 2 minutes, then add 25g of tetrahydrophthalic anhydride and 3g of...

Embodiment 2

[0069] (1) Dissolve 100g of epoxy resin (commercially purchased from Langfang Nuoerxin Chemical Co., Ltd., brand E-51, epoxy value 0.51mol / 100g, hydroxyl value 0.046mol / 100g) in 50g of toluene, add 0.001 g hydroquinone, the pH value of the reaction solution was adjusted to 4. With stirring, the temperature was raised to 100°C, then 3.0g of maleic anhydride was added, and the reaction was stirred at this temperature for 3 hours; then the temperature was lowered to 50°C, 4.3g of tri-n-propylamine was added, and the reaction was continued for 0.5 hours, The obtained mixture was evaporated with a rotary evaporator to obtain the hydrophilic resin composition of the present invention.

[0070] (2) Mix 100g of the hydrophilic resin composition obtained in step (1) with 2000g of raw sand (commercially purchased from Qingtongxia Jinshengyuan Proppant Co., Ltd., with a particle size of 30-50 mesh) and stir for 2 minutes, then add 30g of diaminodiphenylmethane was stirred at 180°C for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| sphericity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com