Wood magnesium board and preparation method thereof

A wood magnesium and wood powder technology, applied in the field of materials, can solve the problems of board influence, long production cycle, increased production cost, etc., and achieve the effects of improving overall strength, reducing production cost, and weak surface strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

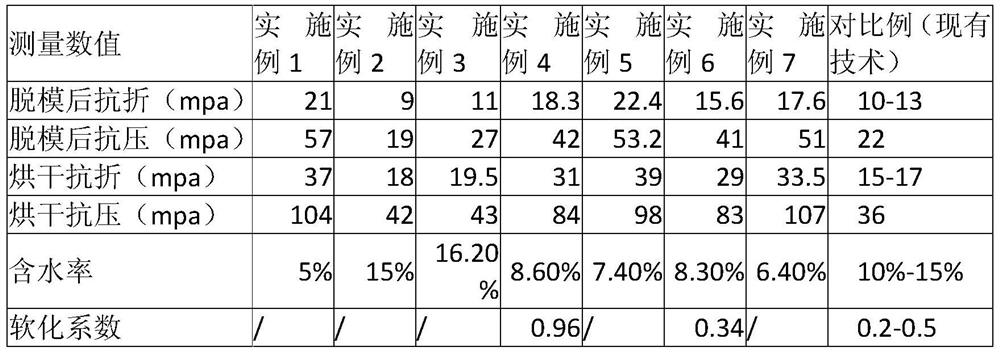

Examples

Embodiment 1

[0041] A kind of preparation method of wood magnesium board, comprises the following steps:

[0042] Step 1. Precise measurement of raw materials; weigh 40kg of magnesium oxide, 40kg of 29.5-degree magnesium sulfate solution, 30kg of wood powder, 200g of aluminum oxide, 3kg of magnesium silicate, 300g of oxalic acid, 500g of waterproofing agent, and 2kg of modifier, and pass through the tank The negative pressure air delivery metering system can weigh the raw materials, which can control the measurement accuracy error to one thousandth, and can be weighed through the negative pressure air delivery metering system of the tank warehouse, and the error control is more accurate;

[0043] Step 2, dry mixing and stirring; using a column type high-speed mixer with a blade speed of 1000 revolutions per minute, the above raw materials are mixed evenly at high speed under the dry process;

[0044] Step 3, dispersing; using a column type low-speed mixer, the blade speed is 10 revolutions...

Embodiment 2

[0052] A kind of preparation method of wood magnesium board, comprises the following steps:

[0053] Step 1. Accurate measurement of raw materials; weigh 40kg of magnesium oxide, 40kg of magnesium sulfate solution at 29.5 degrees, 30kg of wood powder, 200g of aluminum oxide, 3kg of magnesium silicate, 300g of oxalic acid, 500g of water repellent, and 2kg of common market modifiers. The negative pressure air delivery metering system of the tank warehouse can weigh raw materials, which can control the measurement accuracy error within one thousandth, and can be weighed by the negative pressure air delivery metering system of the tank warehouse, and the error control is more accurate;

[0054] Step 2, dry mixing and stirring; using a column-type high-speed mixer with a blade speed of 1100 revolutions per minute, the above-mentioned raw materials are mixed evenly at high speed under the dry process;

[0055] Step 3, dispersing; using a column-type low-speed mixer, the blade speed ...

Embodiment 3

[0063] A kind of preparation method of wood magnesium board, comprises the following steps:

[0064] Step 1. Accurate measurement of raw materials; weigh 40kg of magnesium oxide, 40kg of magnesium sulfate solution at 29.5 degrees, 30kg of wood powder, 200g of aluminum oxide, 3kg of magnesium silicate, 300g of oxalic acid, 500g of water repellent, and 2kg of common market modifiers. The negative pressure air delivery metering system of the tank warehouse can weigh raw materials, which can control the measurement accuracy error within one thousandth, and can be weighed by the negative pressure air delivery metering system of the tank warehouse, and the error control is more accurate;

[0065] Step 2, dry mixing and stirring; using a column type high-speed mixer with a blade speed of 1000 revolutions per minute, the above raw materials are mixed evenly at high speed under the dry process;

[0066] Step 3, dispersing; using a column-type low-speed mixer, the blade speed is 15 revo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com