Patents

Literature

34results about How to "Improve the adhesion effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

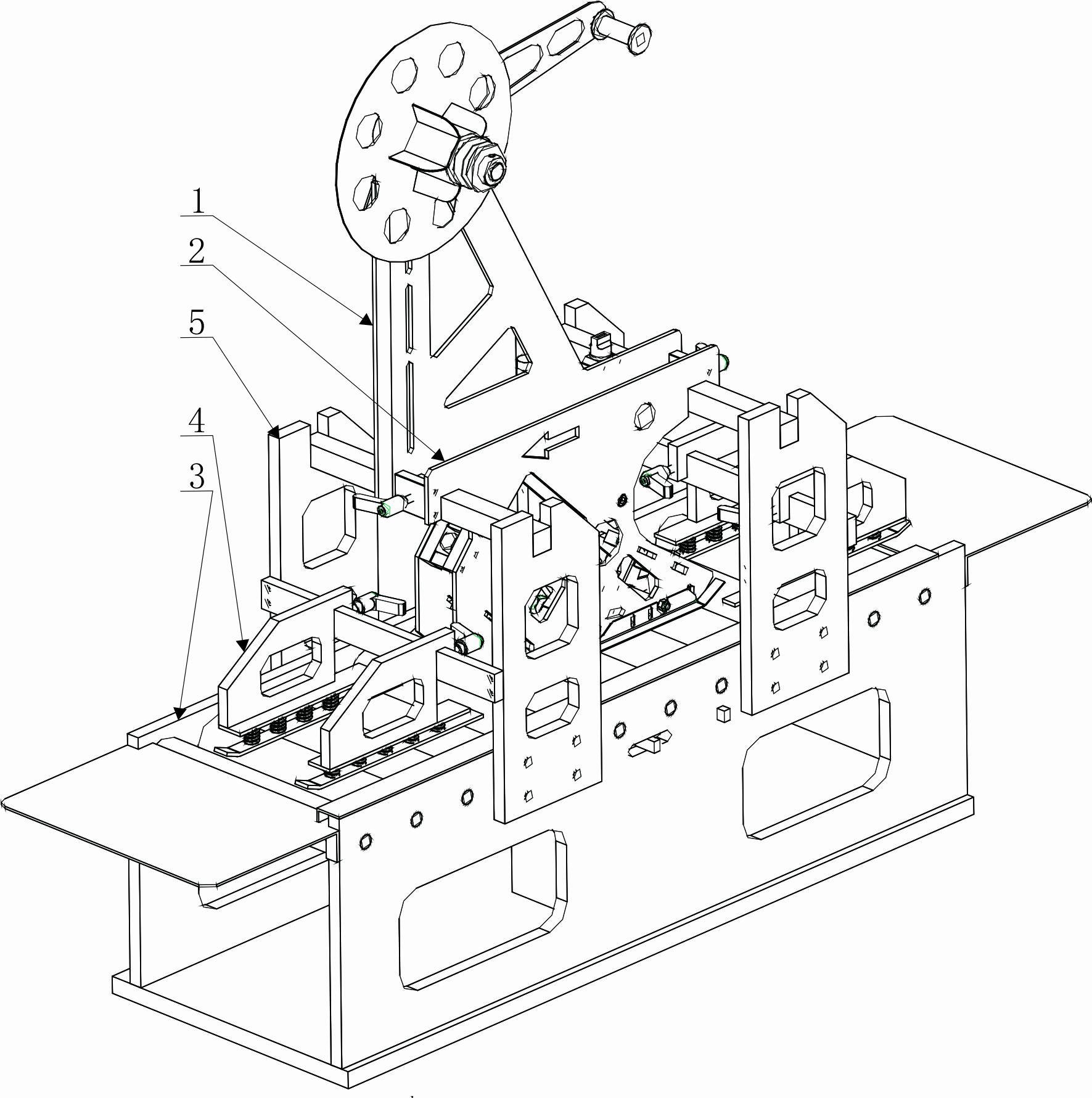

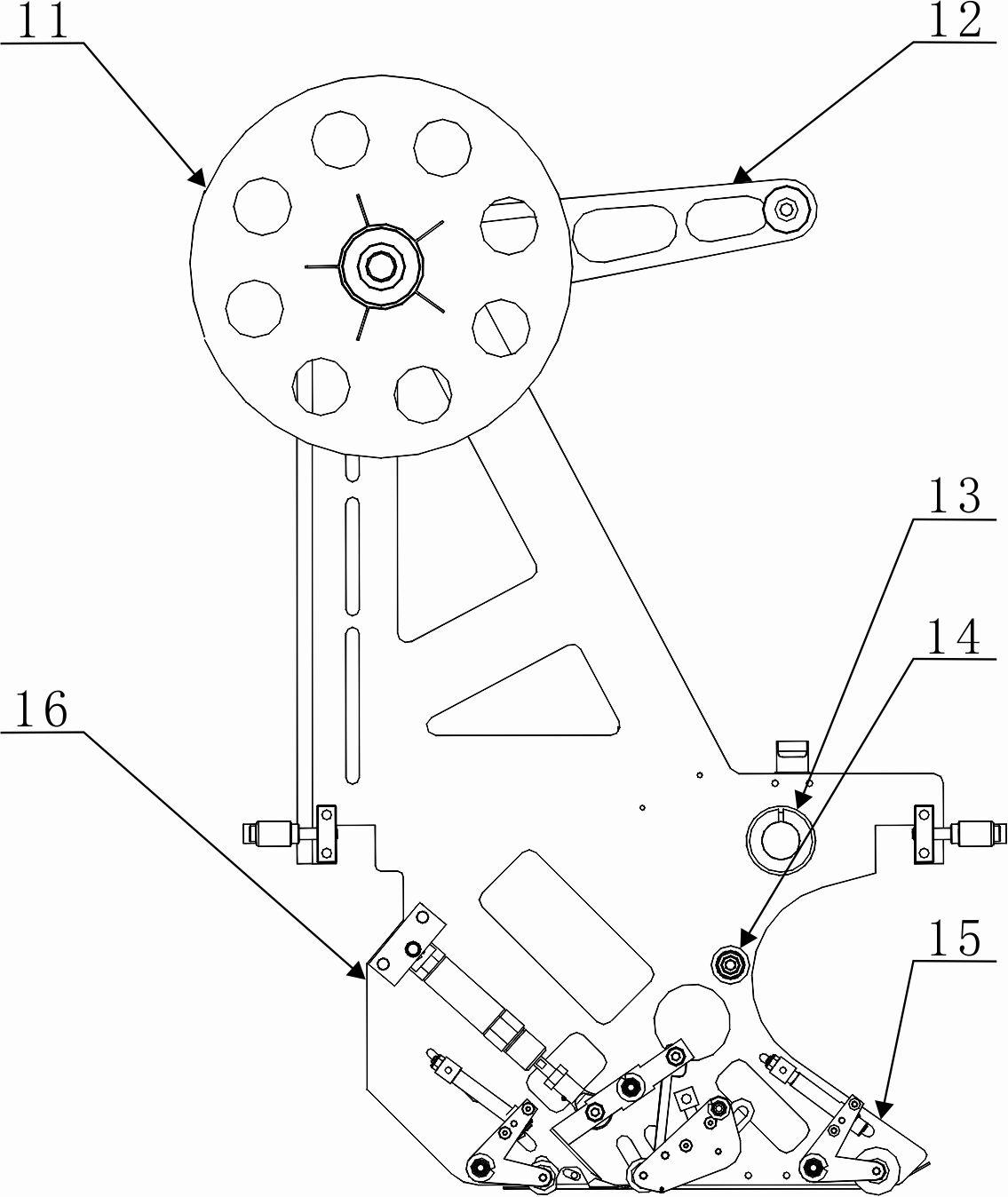

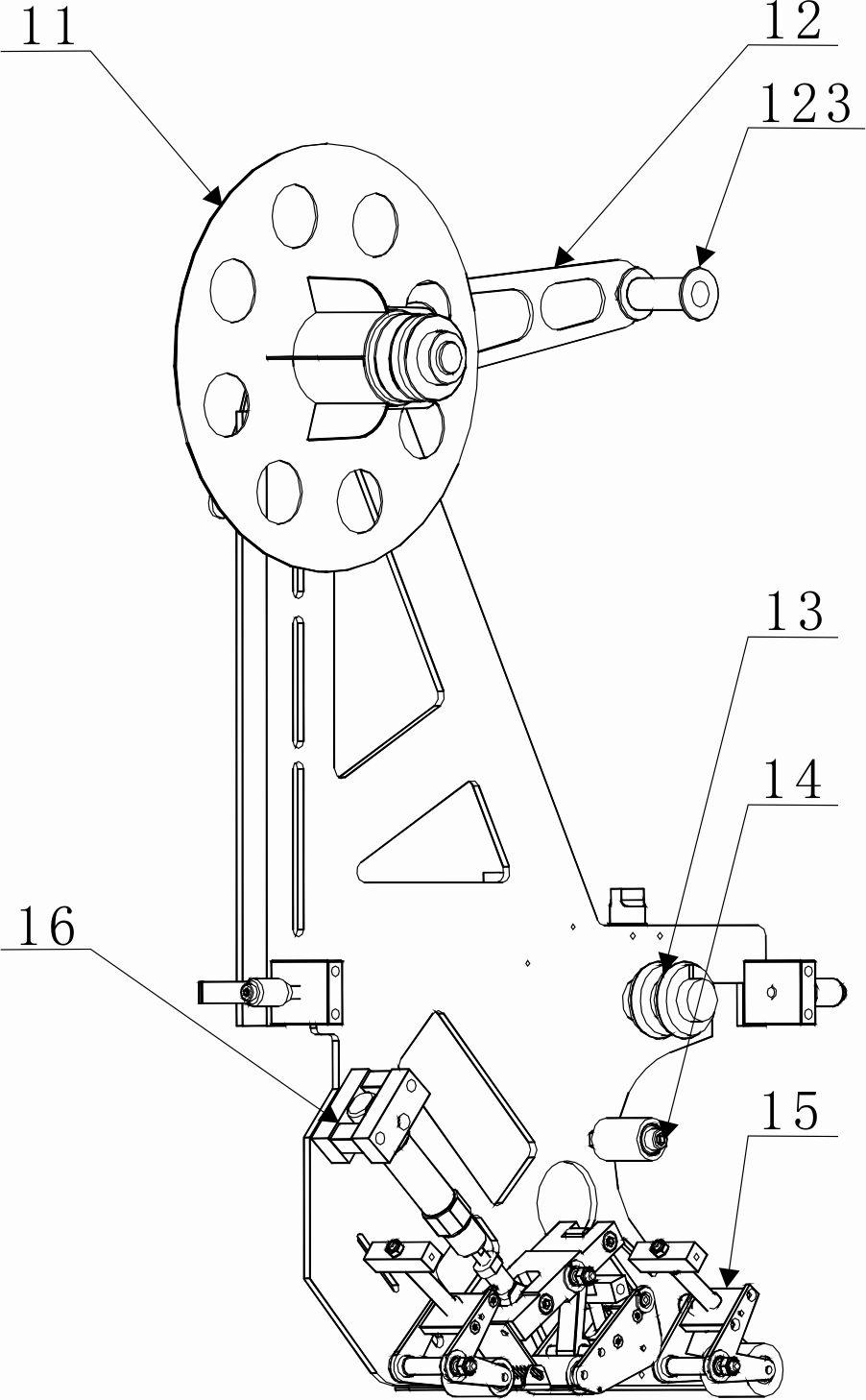

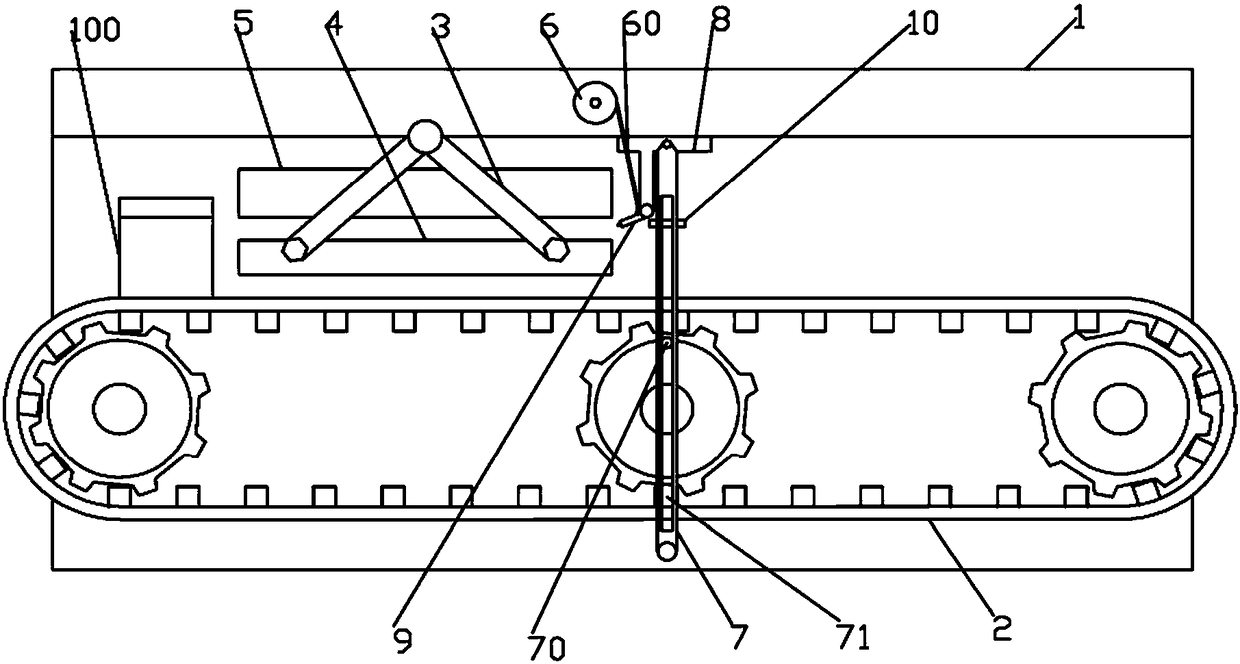

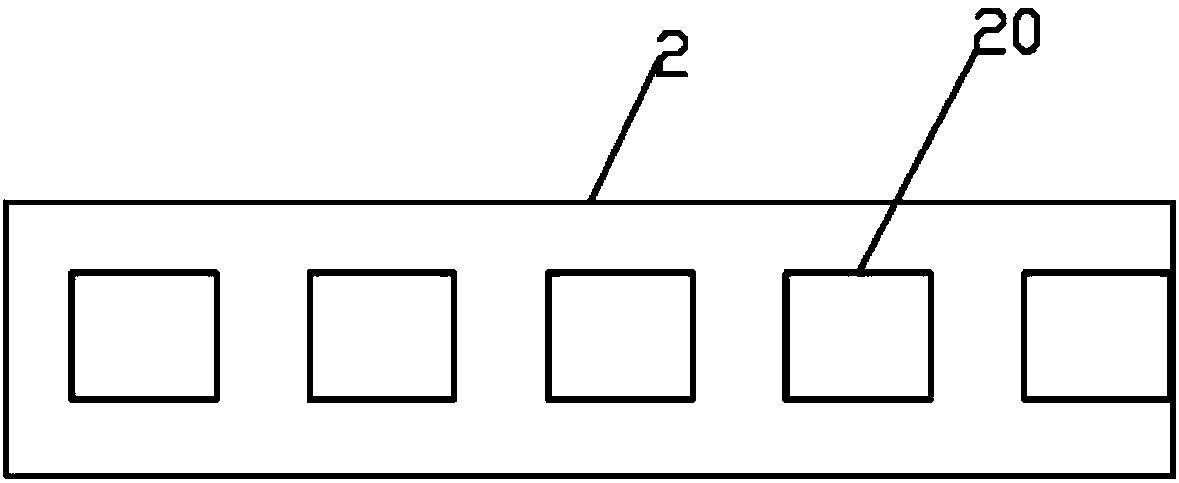

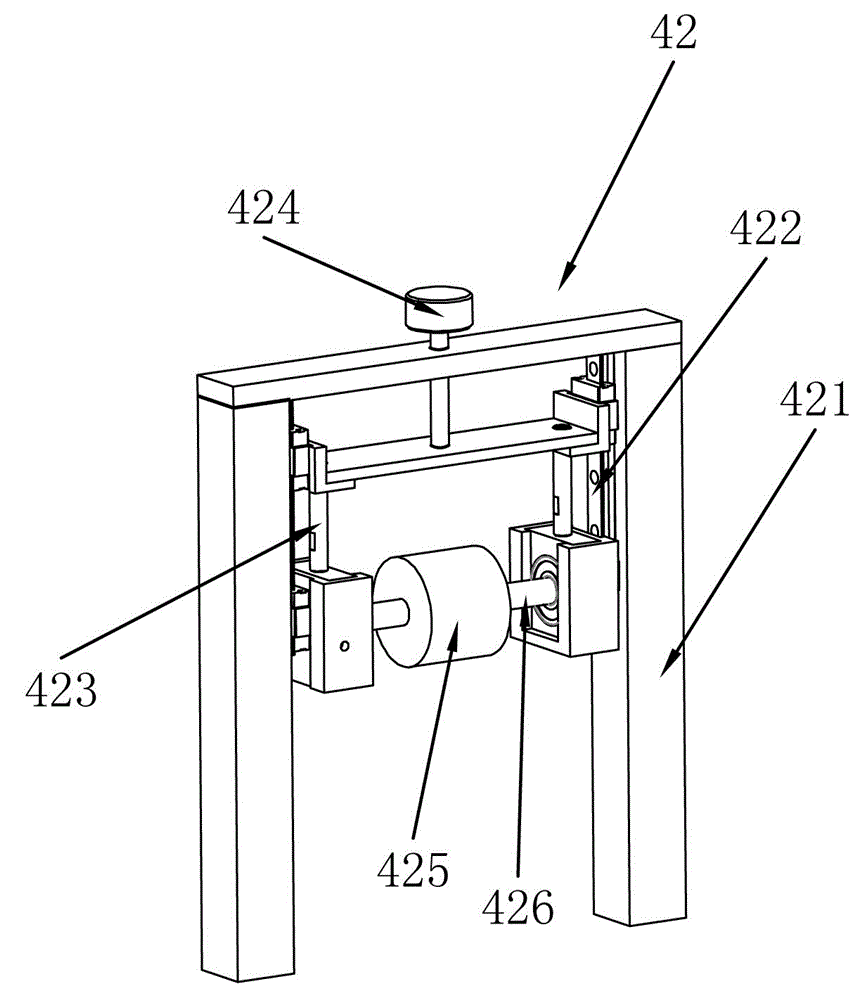

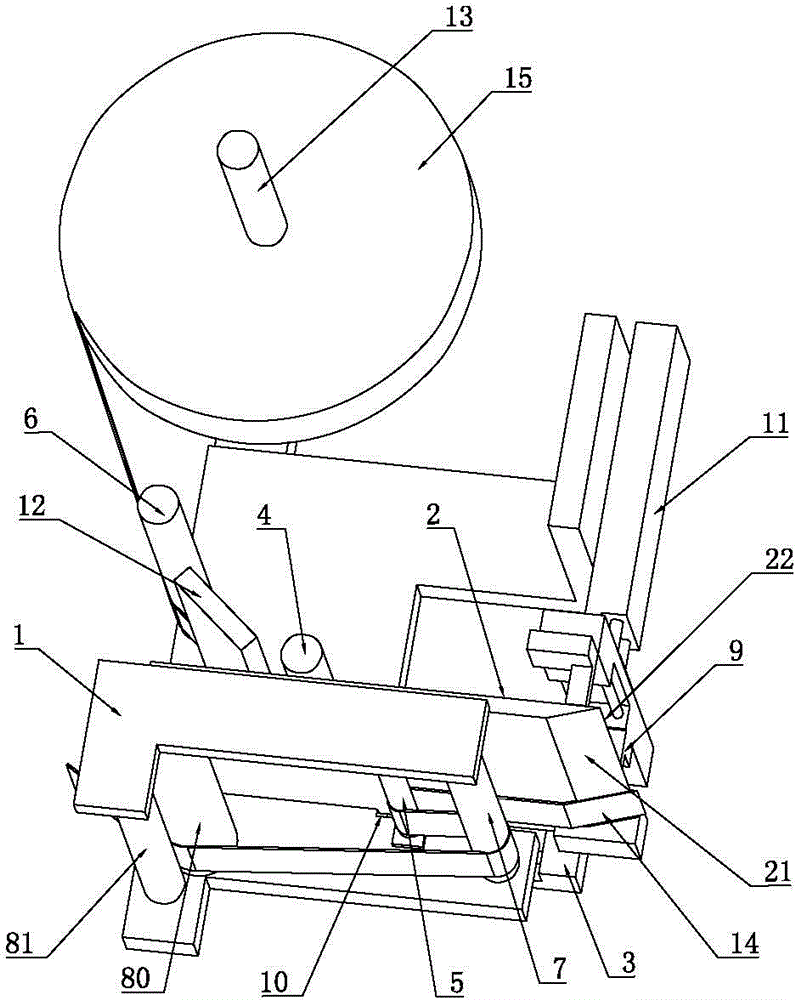

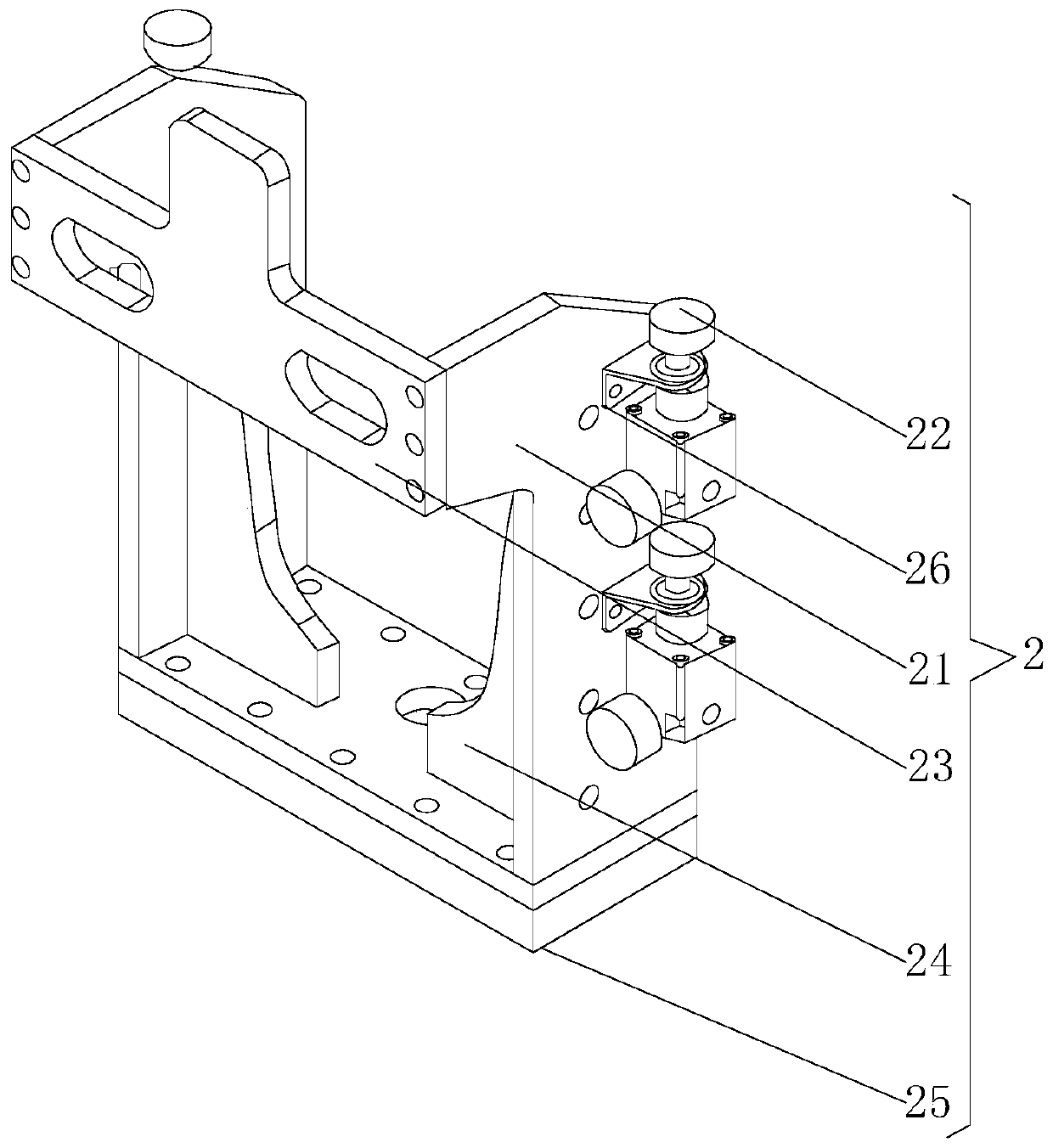

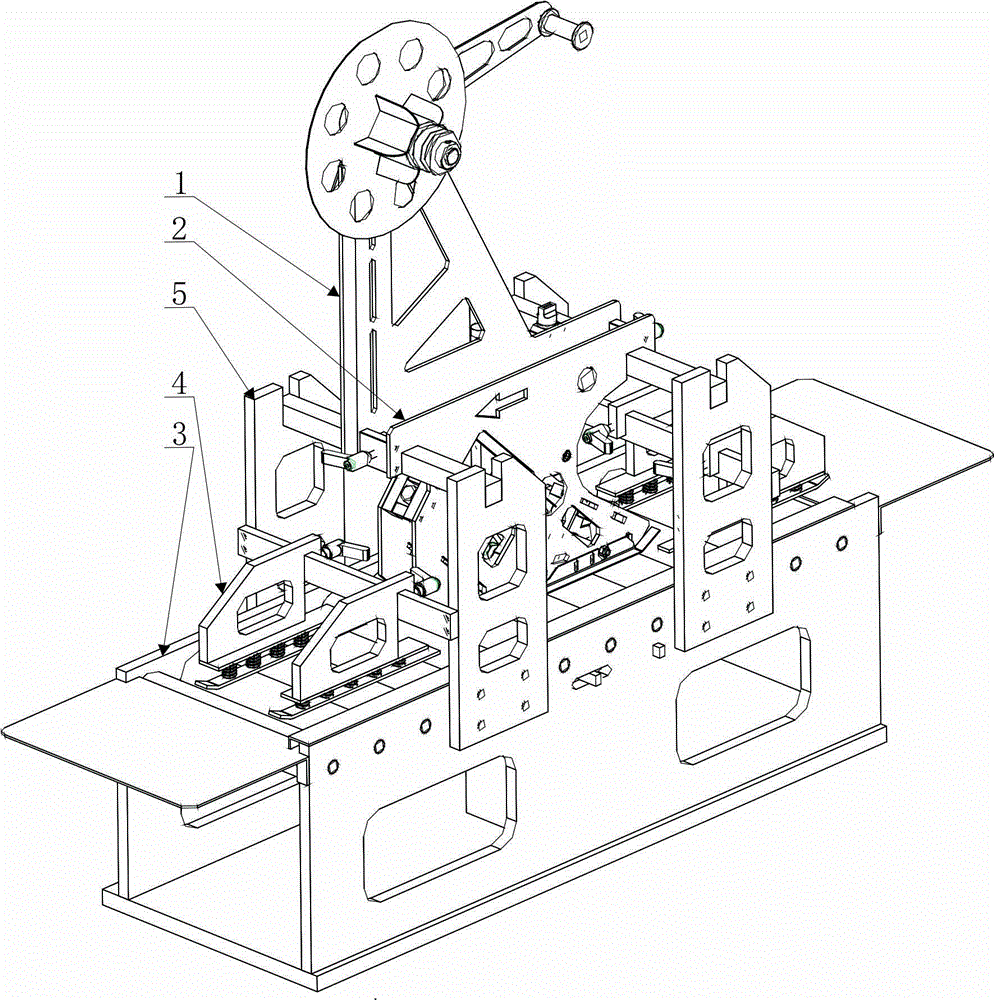

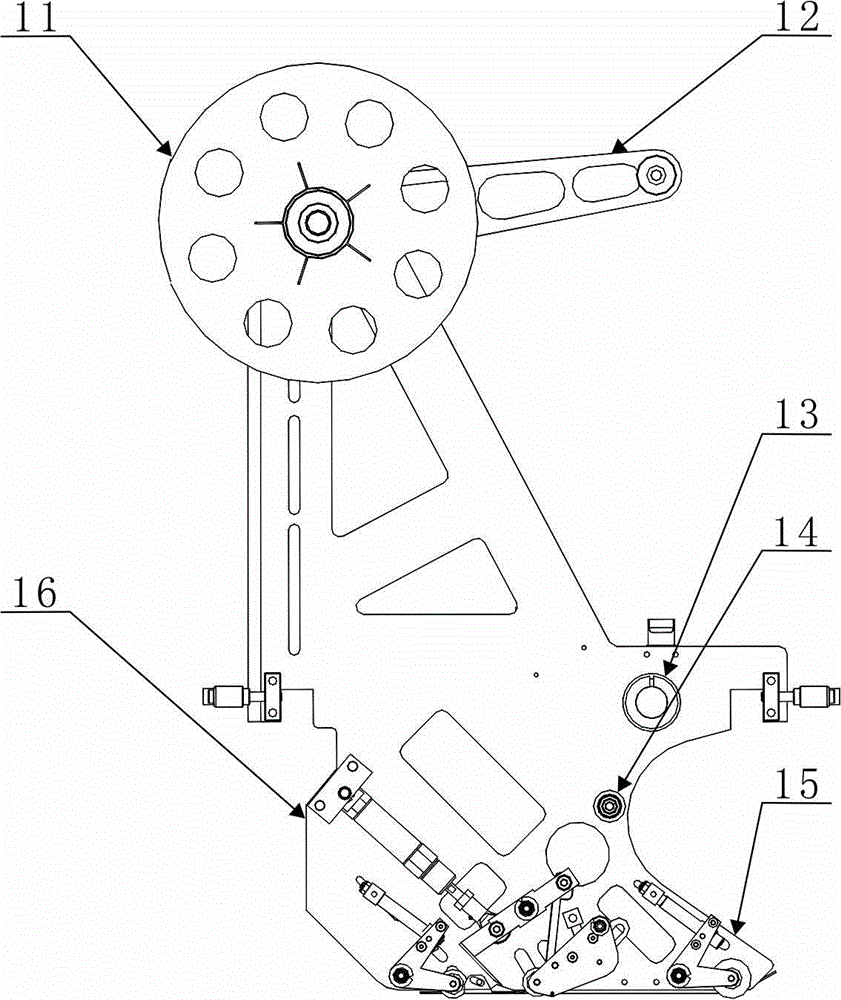

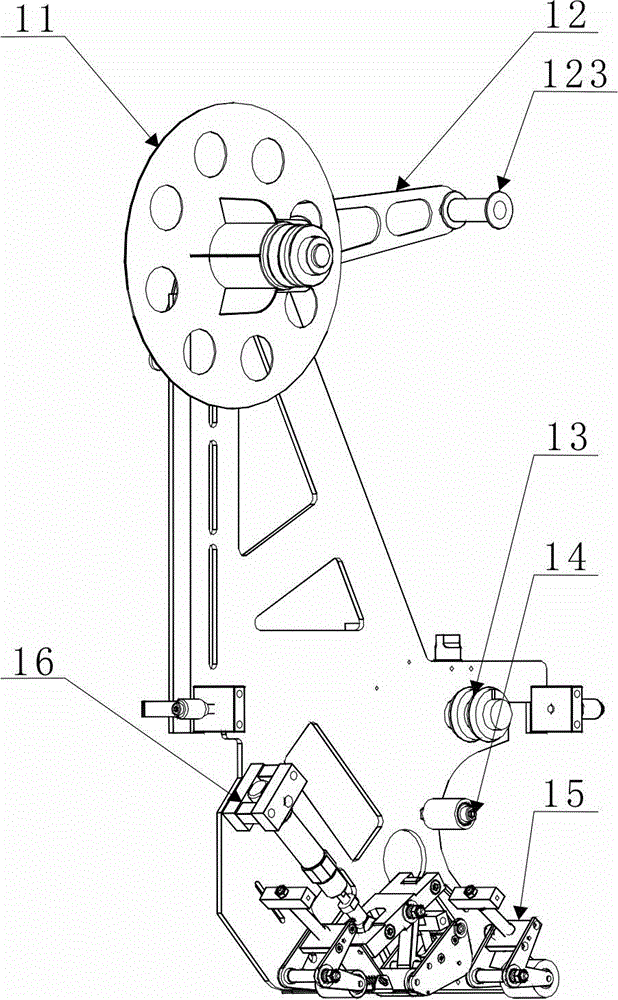

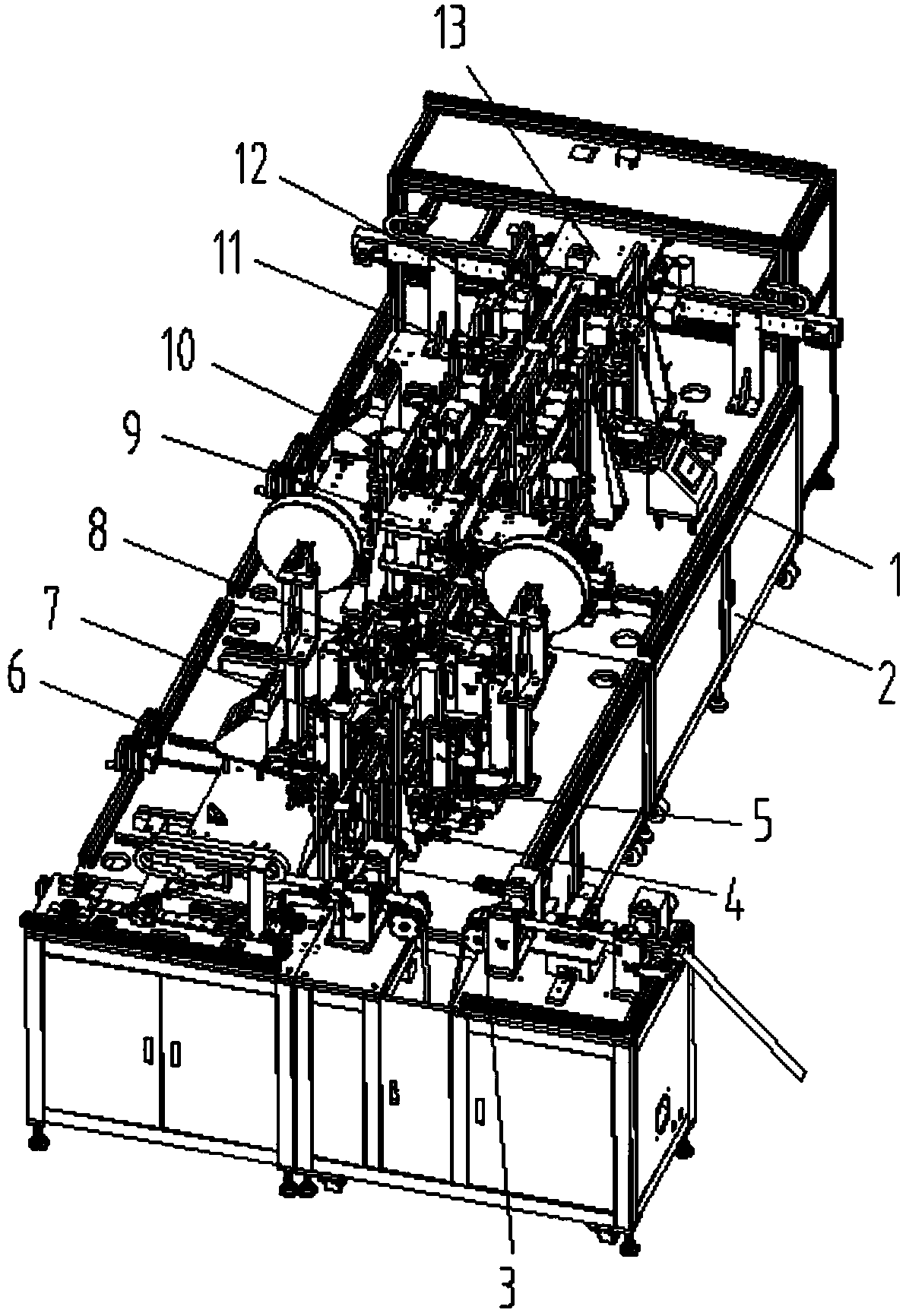

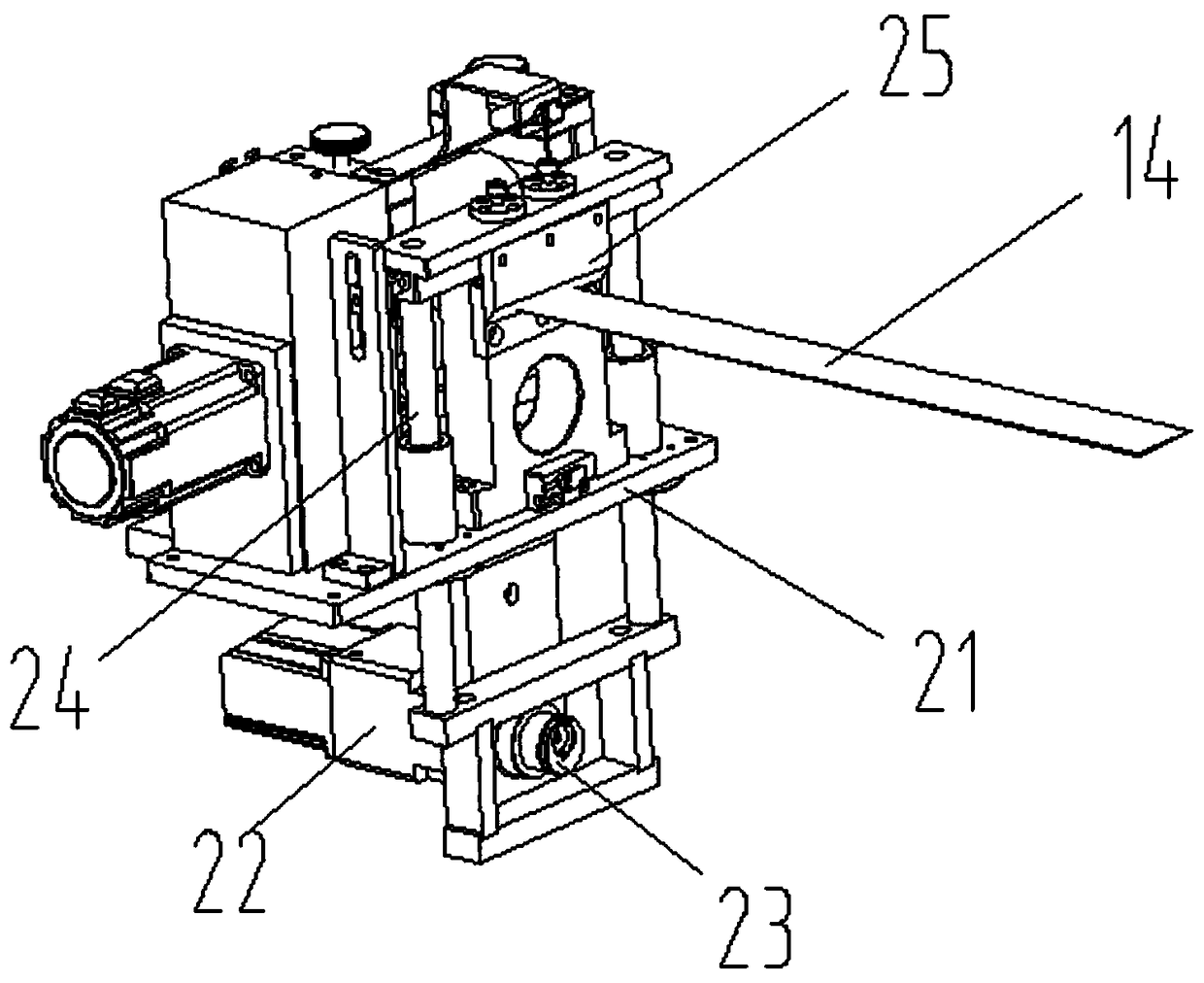

Novel tape adhering machine

ActiveCN102674069AImprove glue application efficiencySimple structureArticle deliveryKnuckleEngineering

The invention discloses a novel tape adhering machine which comprises at least one tape adhering head and a base, wherein the tape adhering head comprises a main mounting plate a and an assorted mounting plate which is matched with the main mounting plate a; a tape fixing wheel and a cutting mechanism are arranged on the main mounting plate a; the tape fixing wheel is arranged at the top of the main mounting plate a for fixing a tape; the cutting mechanism is arranged at the lower part of the main mounting plate a; the cutting mechanism is provided with a cylinder to drive a prepressing module and a cutter to complete the tape adhering and cutting tasks; and the base is used for fixing the tape adhering head and conveying materials which are required to be adhered. The novel tape adhering machine utilizes the lever principle to complete the tape adhering and cutting tasks through a driving link which consists of the cylinder and a knuckle bearing, so the adhering efficiency is greatly increased, in addition, the structure of the tape adhering head is also correspondingly simplified, and the cost is lowered; and moreover, the novel tape adhering machine meets different specification requirements on the materials which are needed to be adhered, and the adhering effect is improved.

Owner:POLYGON AUTOMATION TECH CHENGDU

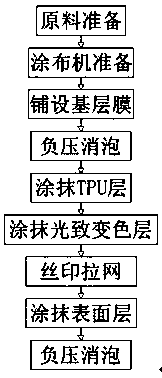

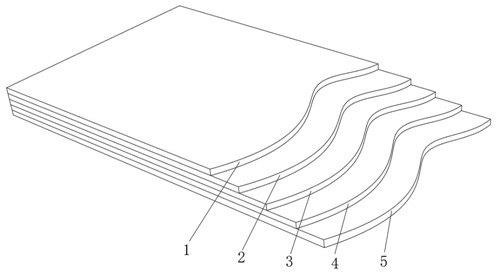

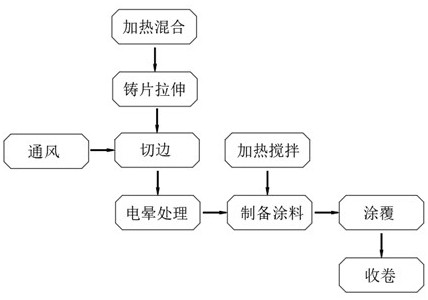

Anti-broken hot melt adhesive membrane used for automobile decoration and preparation method of anti-broken hot melt adhesive membrane

InactiveCN109135605AImprove the adhesion effectImprove surface wear resistanceFilm/foil adhesive primer layersHeat-activated film/foil adhesivesSurface layerWear resistant

The invention discloses an anti-broken hot melt adhesive membrane used for automobile decoration and a preparation method of the anti-broken hot melt adhesive membrane. The anti-broken hot melt adhesive membrane comprises a PVB base adhesive, a TPU adhesive layer is stuck to the outer wall on one side of the PVB base adhesive, a photochromic layer is stuck to the outer wall on the side, away fromthe PVB base adhesive, of the TPU adhesive layer, a nylon mesh cloth layer is stuck to the outer wall on the side, away from the TPU adhesive layer, of the photochromic layer, and a membrane surface layer is stuck to the outer wall on the side, away from the photochromic layer, of the nylon mesh cloth layer. The preparation method comprises the following steps of preparation of raw materials, wherein a PVB adhesive solution, an EVA adhesive solution and a TPU adhesive solution which are needed during production are mixed and stirred respectively, and then sampled and inspected respectively; preparation of coating machines, wherein the three coating machines are prepared, and adhesive storage cylinders and coating heads of the three coating machines are cleaned. By means of the anti-brokenhot melt adhesive membrane, improvement of the wear-resistant performance of the surface of the hot melt adhesive membrane is facilitated, by cooperatively arranging the nylon mesh cloth layer, improved of the adhesion effect of the surface layer of the membrane can be facilitated, the box stretching performance of the hot melt adhesive membrane is improved, and improvement of the elasticity of the hot melt adhesive membrane is facilitated.

Owner:安徽天念材料股份有限公司

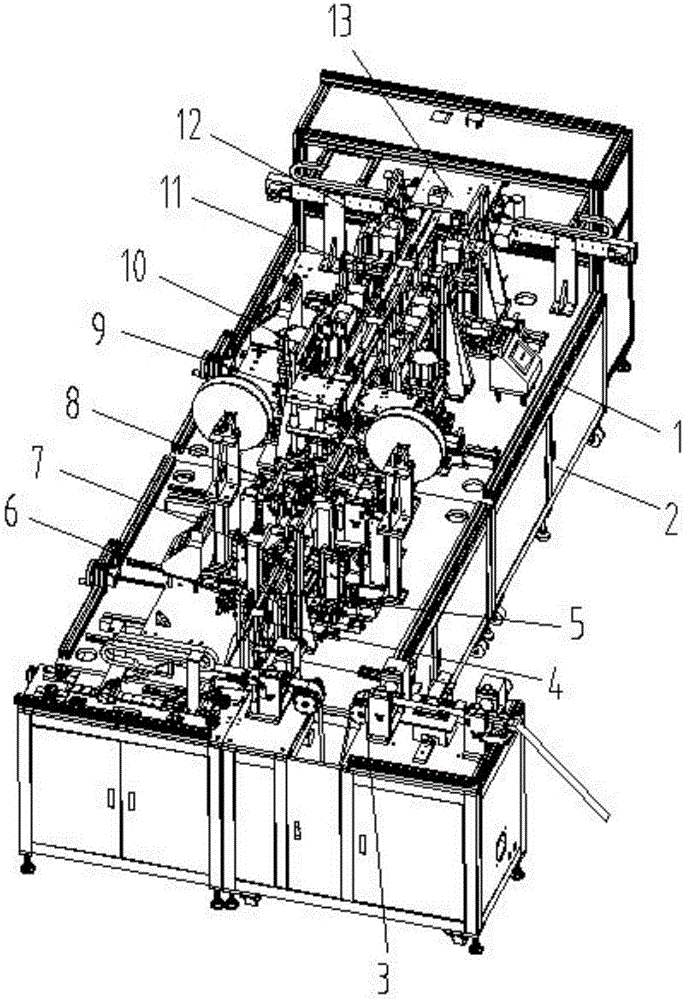

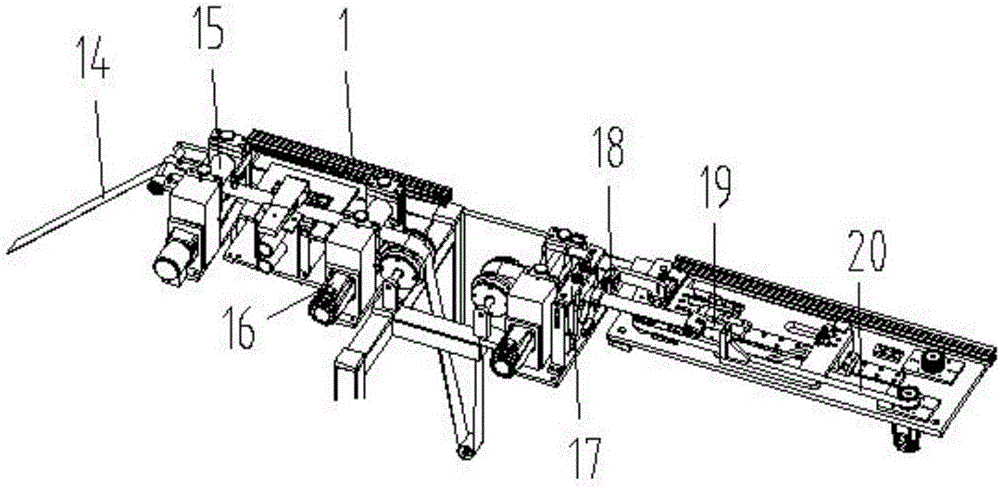

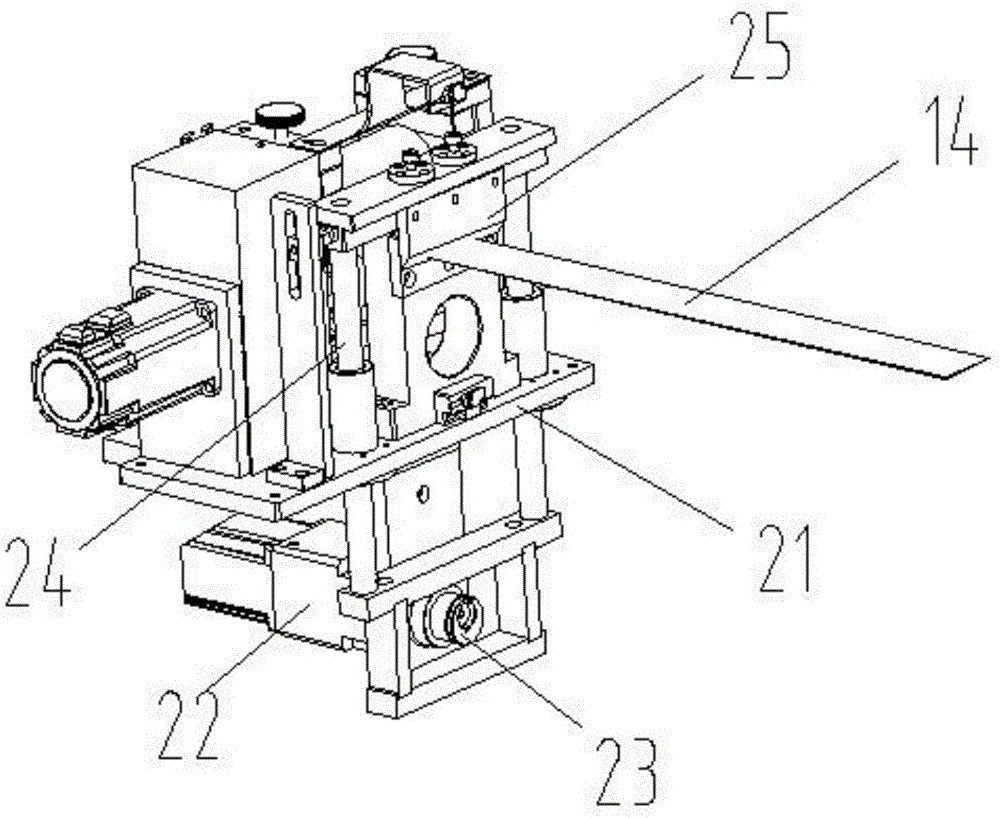

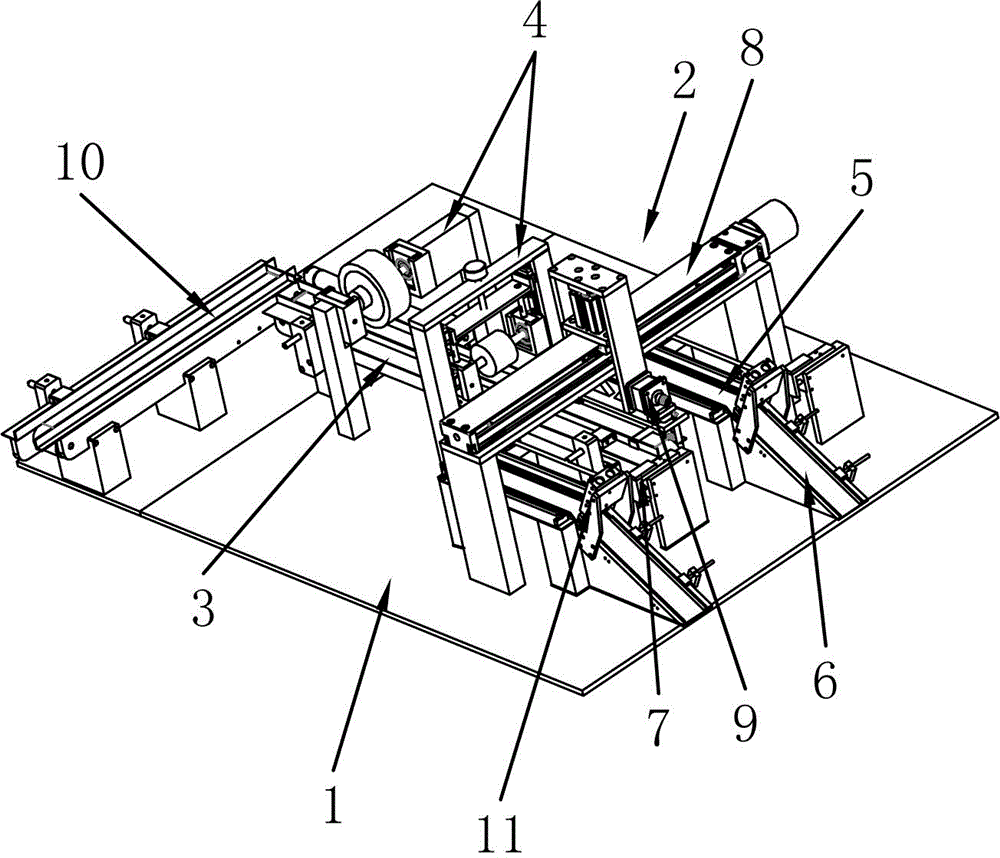

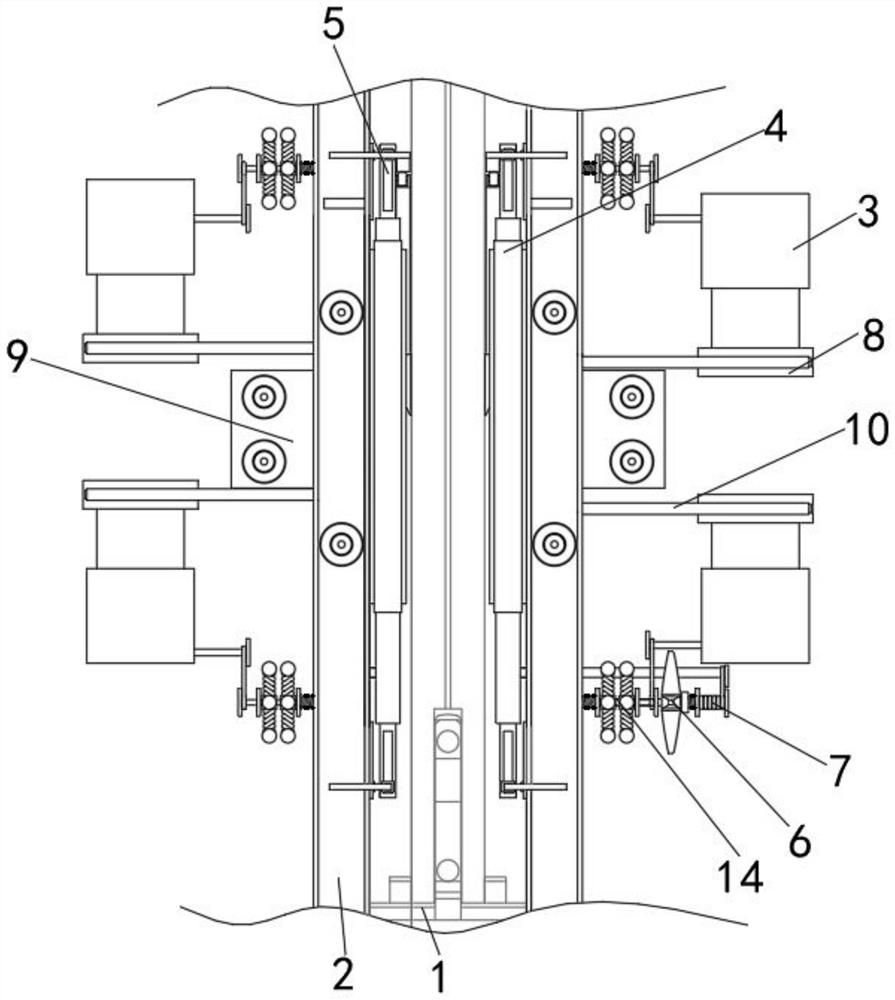

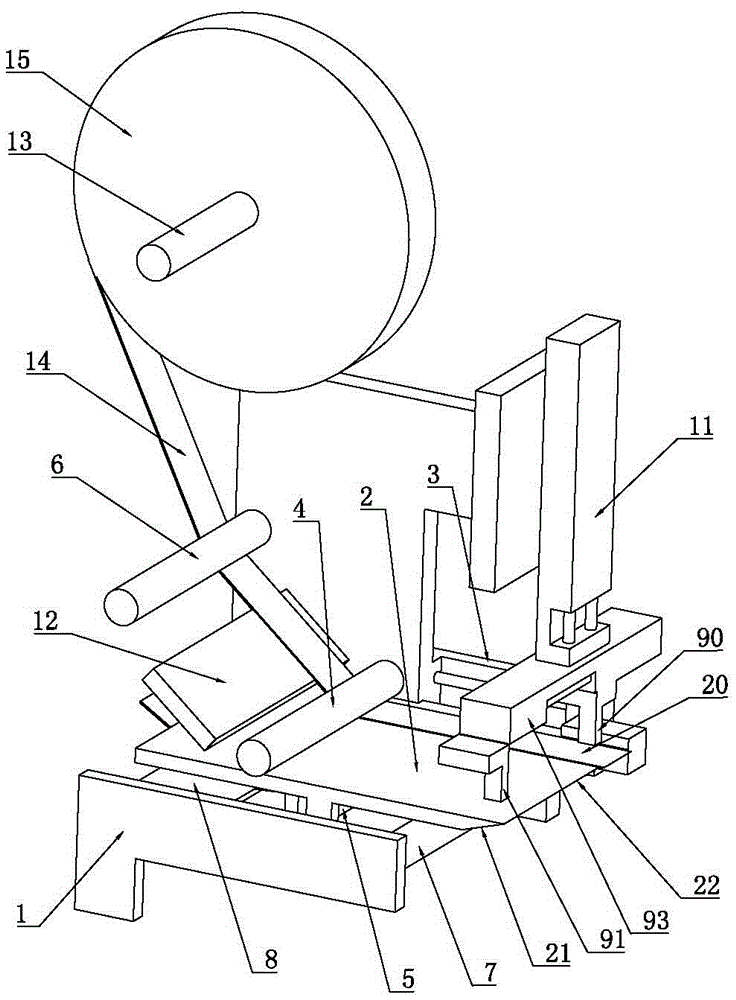

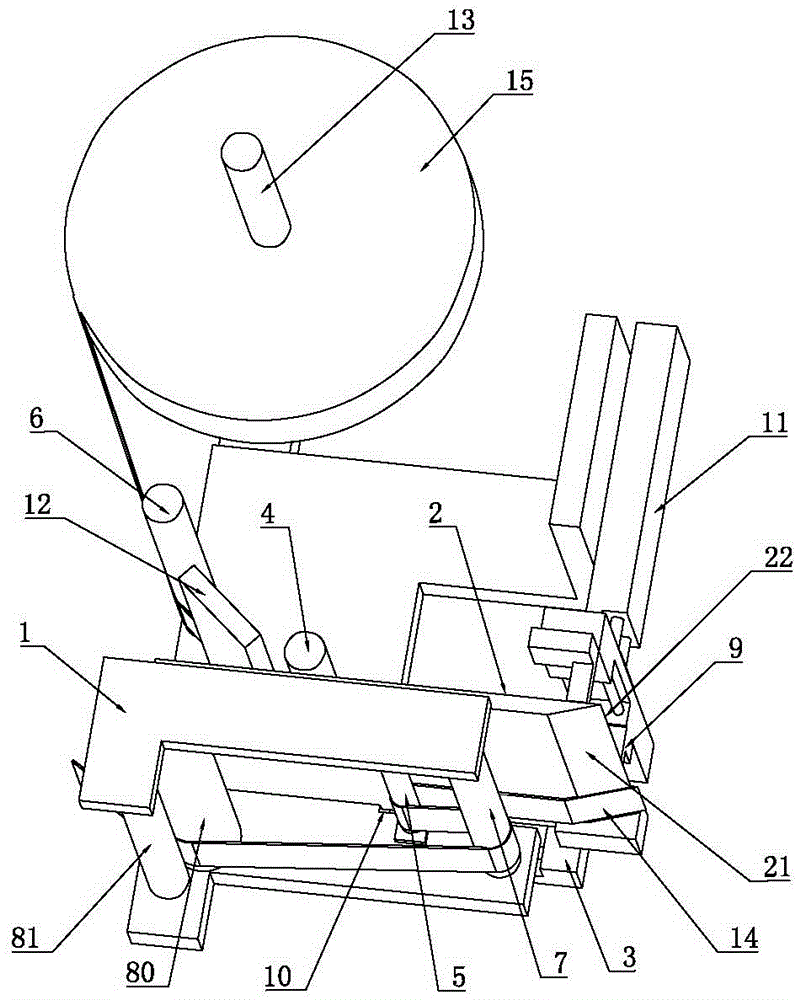

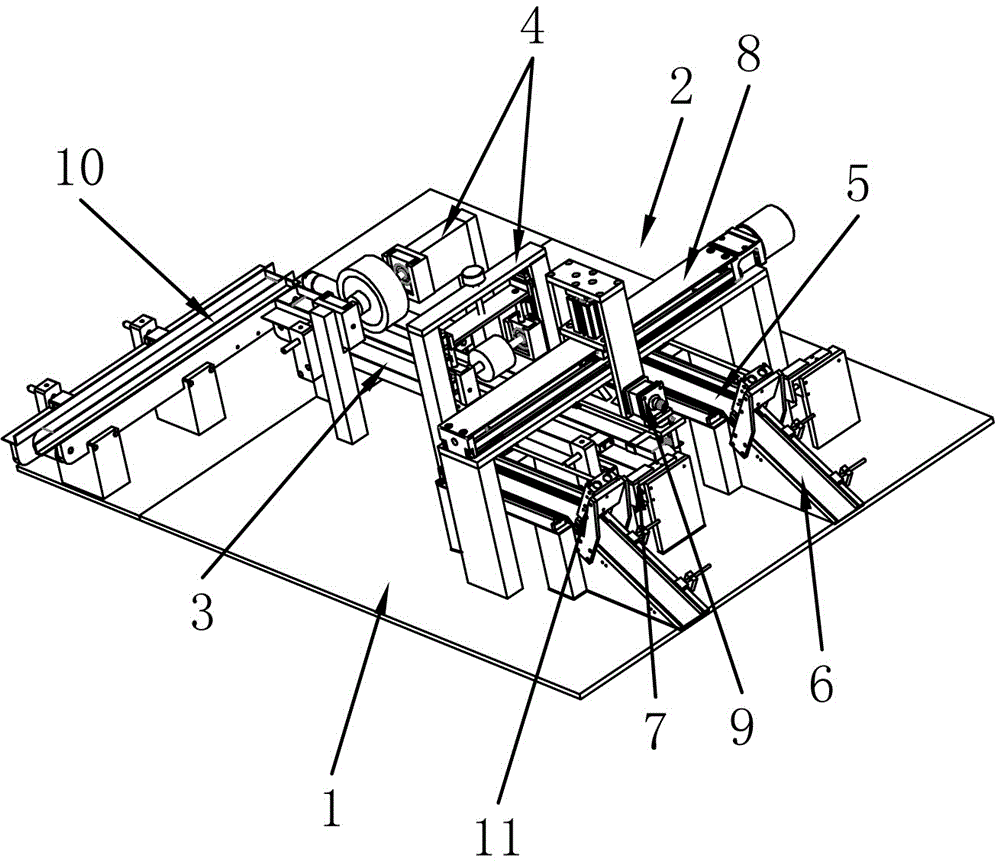

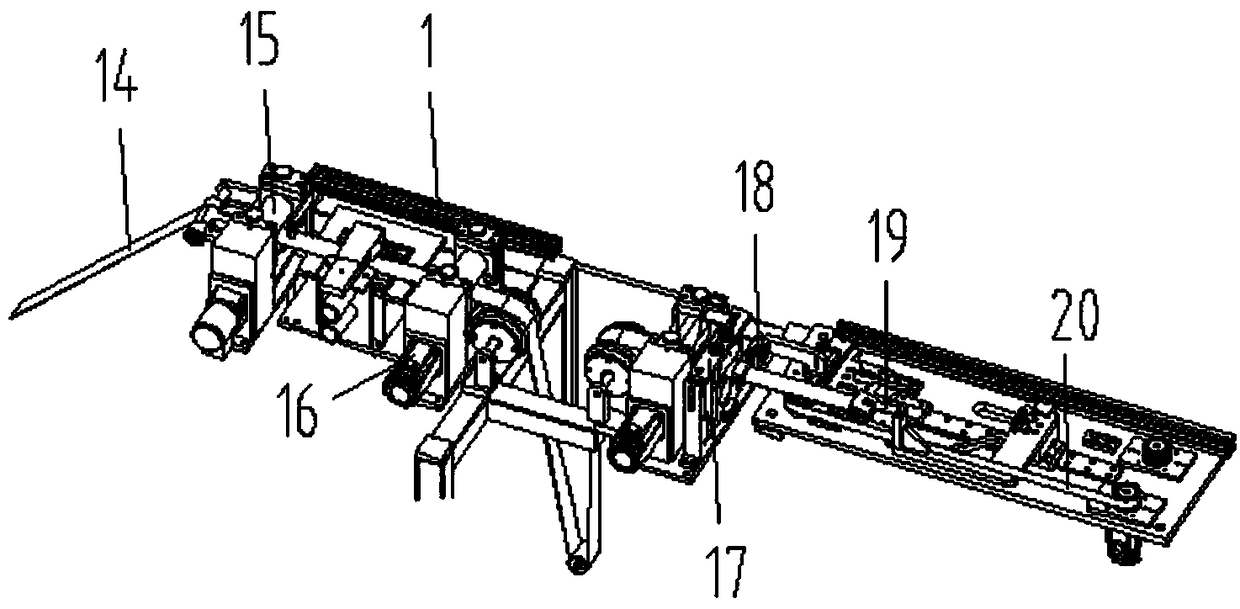

Fully-automated flexible flat cable pipe processing machine

ActiveCN106782888AImprove processing efficiencyImprove yield rateApparatus for feeding conductors/cablesDistribution controlVisual inspection

The invention relates to a fully-automated flexible flat cable pipe processing machine. The fully-automated flexible flat cable pipe processing machine comprises a frame and a power distribution control cabinet, wherein the frame is provided with a conveying chute and a feeding device which are matched with each other; the feeding device comprises a feeding forward-backward movement device, and the feeding forward-backward movement device is provided with a feeding left-right movement device; a feeding lifting device is arranged on the feeding left-right movement device, uniformly provided with a feeding clamp matched with products, and provided with a feeding guide rod matched with the conveying chute; the frame is sequentially provided with an edge spacing detecting device, a wire stripping device, an adhesive applying device, a heat pressing device, a trimming device, a visual inspection device and a circuit detecting device, which are matched with the products on the conveying chute. The fully-automated flexible flat cable pipe processing machine achieves fixed-distance product feeding through matching between the feeding device and the conveying chute and further achieves continuous and integrated flexible flat cable processing, thereby greatly improving the processing efficiency and the yield rate.

Owner:大千纺织(安徽)有限公司

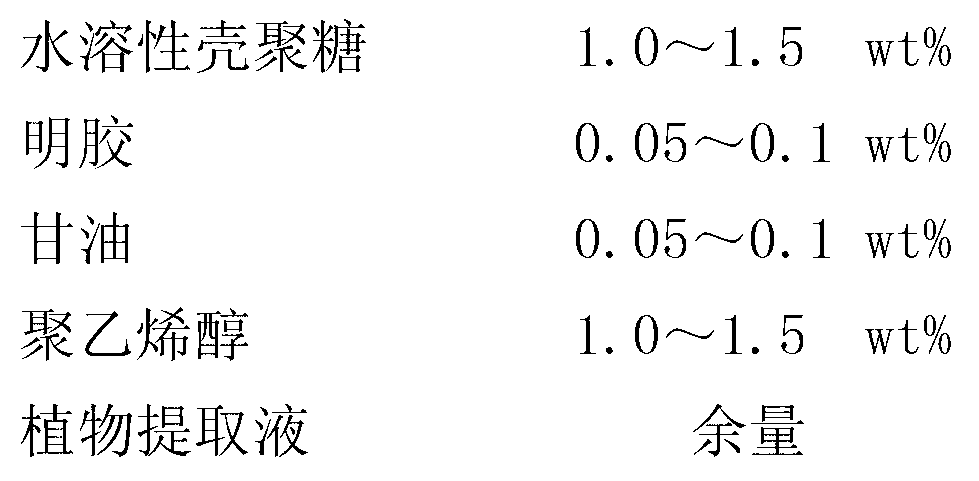

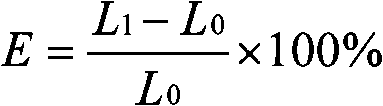

Degradable non-poisonous seed-coating agent and preparation method thereof

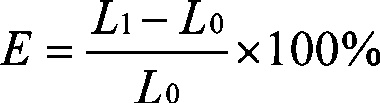

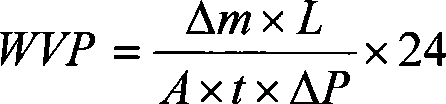

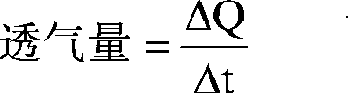

InactiveCN101416650AHigh adhesionSeed coat capacity is goodBiocideAnimal repellantsChemistryApparent viscosity

A degradable nontoxic seed coating agent comprises basic materials of water-soluble chitosan of 1.0-1.5wt%, gelatine of 0.05-0.1wt%, glycerol of 0.05-0.1wt%, PVA of 1.0-1.5wt% and plant extract of remainder, with the tensile strength of 18.7MPa, elongation of 10.1%, vapor transmission rate of 12.69g.mm / mm2.hr.mmHg, air permeability of (CO2)0.358*10-10ml.cm / cm2s.cmHg, air permeability of (O2)0.215*10-10ml.cm / cm2s.cmHg, hygroscopic rate of 47% and apparent viscosity of 290cp; uses water-soluble chitosan, PVA and plant extract to form seed coating film to not only meet performance requirement of conventional seed coating agents, but remarkably improve performance of film.

Owner:DALIAN POLYTECHNIC UNIVERSITY

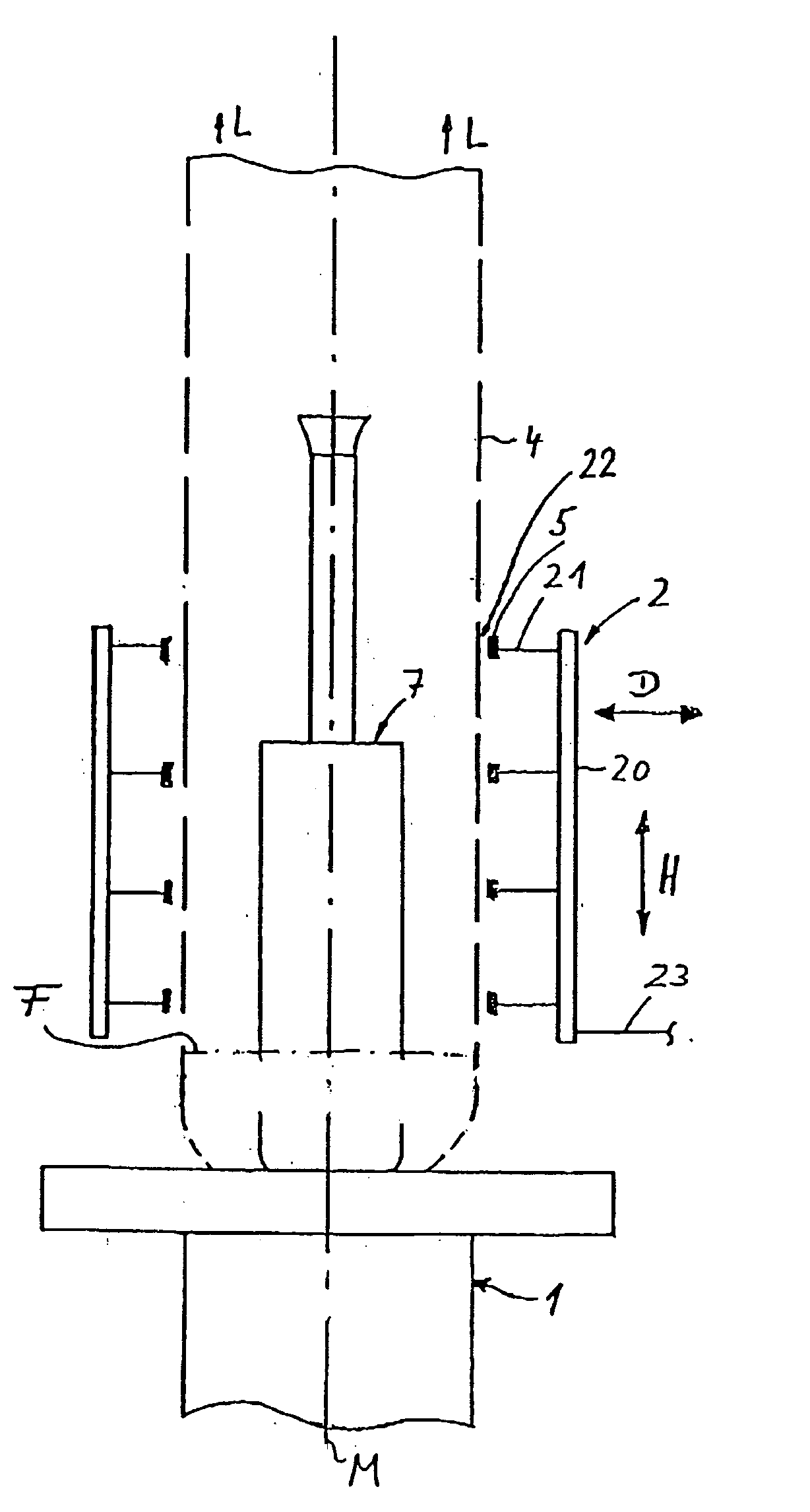

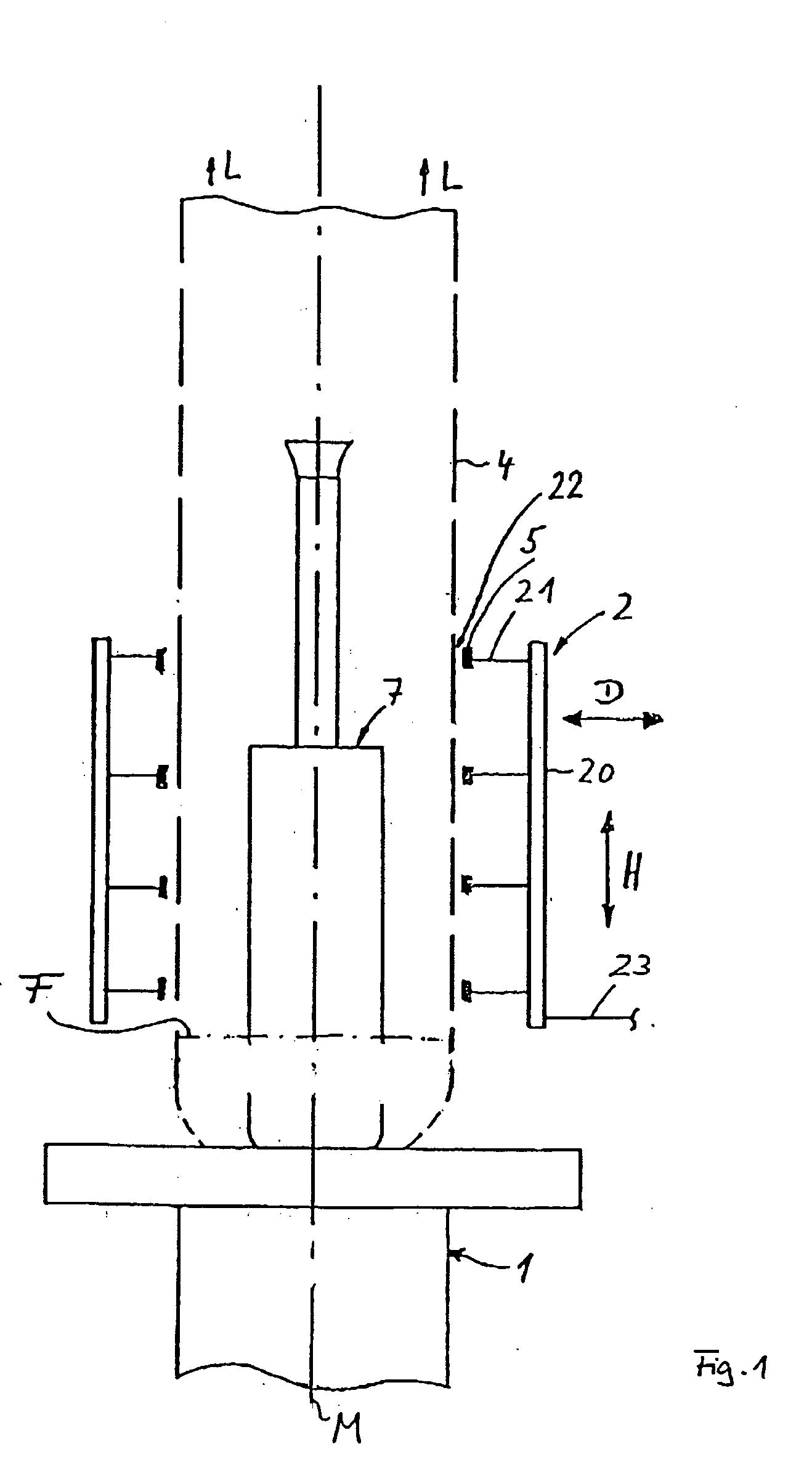

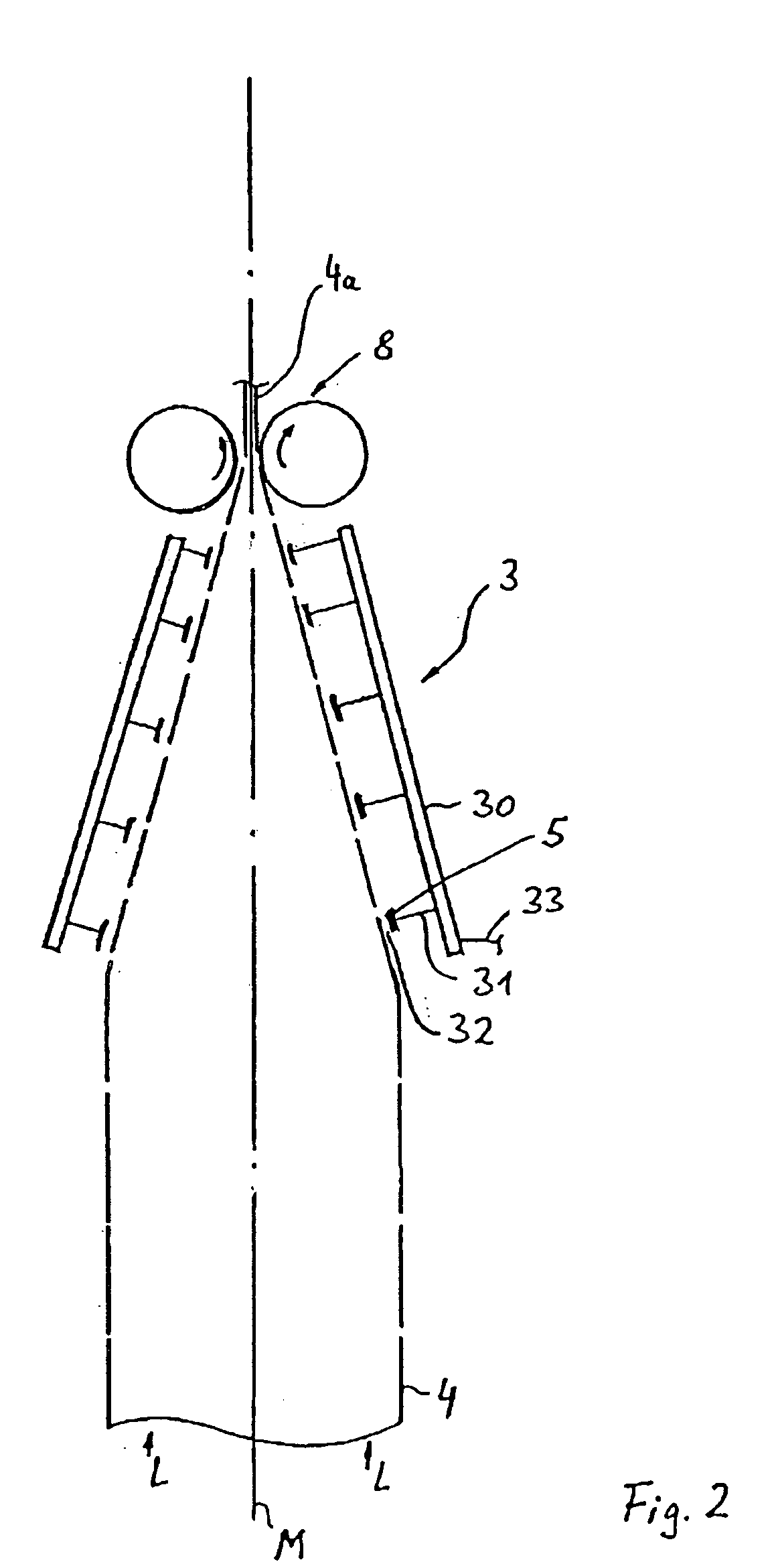

Method and device for producing a film made of a thermoplastic material

InactiveUS20050029713A1Improve product qualityAvoid contactConfectionerySweetmeatsEngineeringThermoplastic materials

A method and a device for producing a film made of a thermoplastic material, wherein a plastic melt is blown up into a film bubble and is shaped into a desired film by a calibrating arrangement, and a downstream arranged flattening device. For providing as contactless as possible a guidance, calibration and flattening, film guidance elements are used with a laminar uniform air cushion between the film guidance element and the surface of the film bubble, without contact between the surface of the film bubble and the film guidance element.

Owner:REIFENHAUSER GMBH & CO MASCHFAB

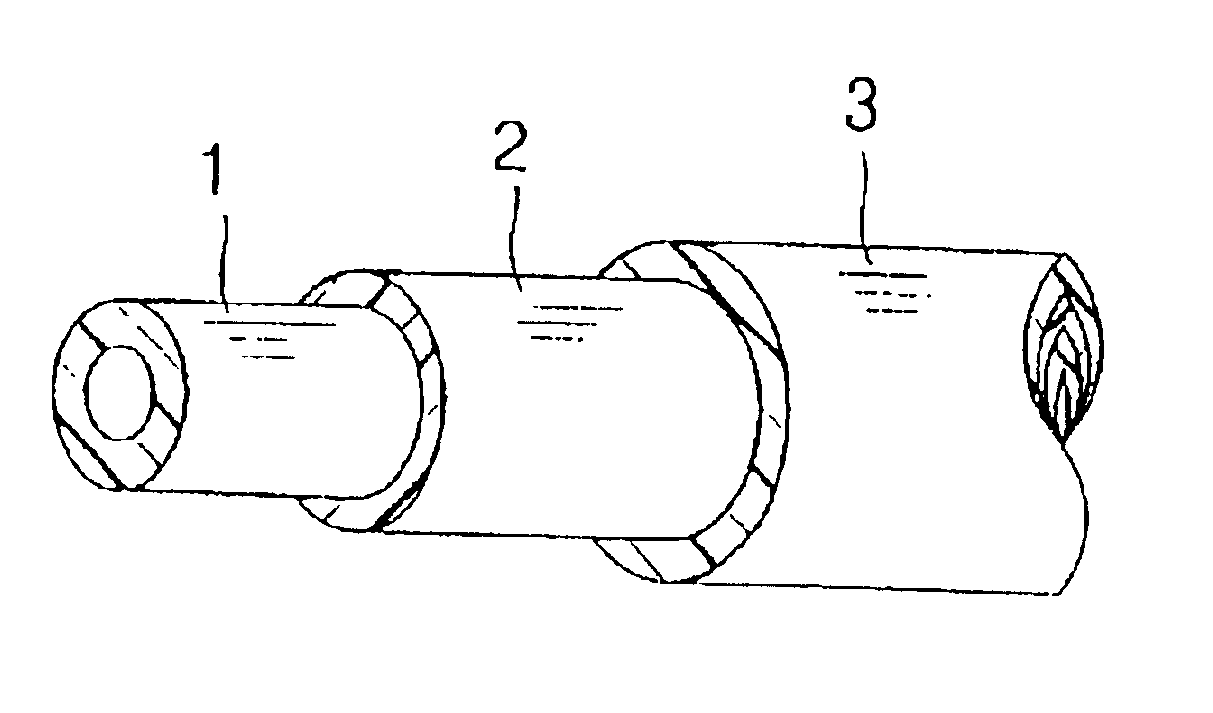

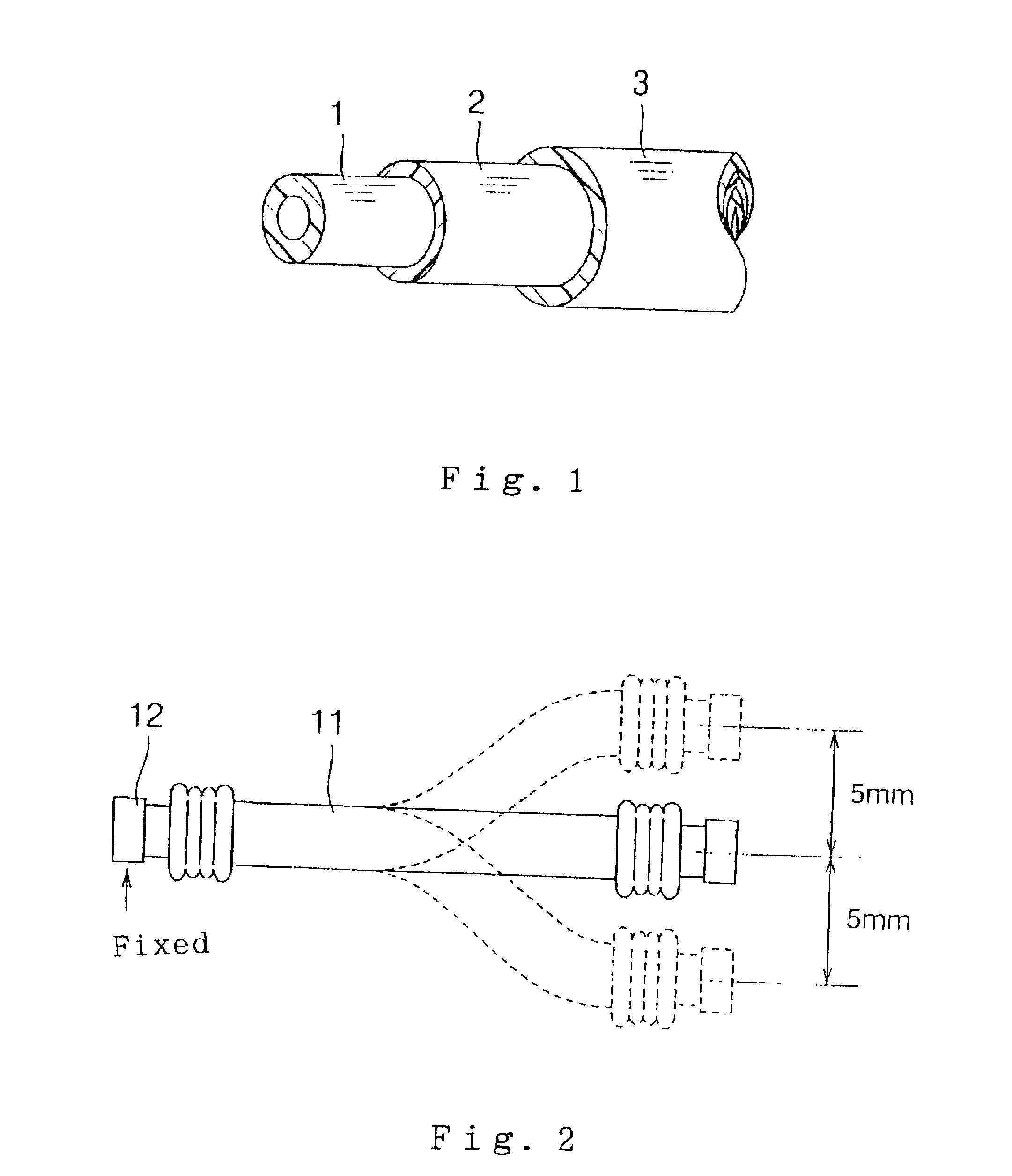

Hose

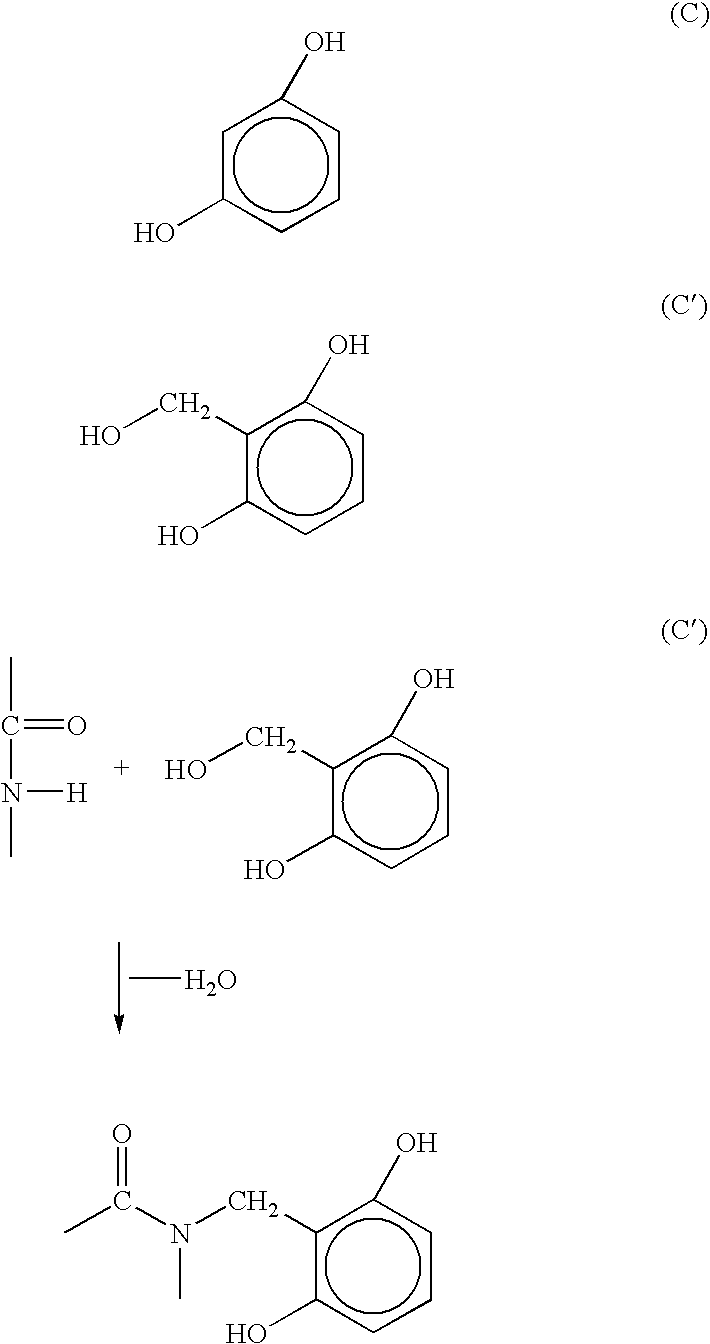

InactiveUS6838141B2Excellent gas barrier performanceLight weightVehicle componentsThin material handlingPolymer scienceMetal foil

A hose of a laminated structure which comprises a rubber layer composed of a rubber composition, and a laminate including a metal foil and a resin, the rubber composition including:(A) a rubber including at least one of an ethylene-propylene-diene terpolymer and an ethylene-propylene copolymer;(B) a peroxide vulcanizing agent;(C) a resorcinol compound; and(D) a melamine resin.The hose is light in weight, less costly, and has excellent gas barrier properties.

Owner:SUMITOMO RIKO CO LTD

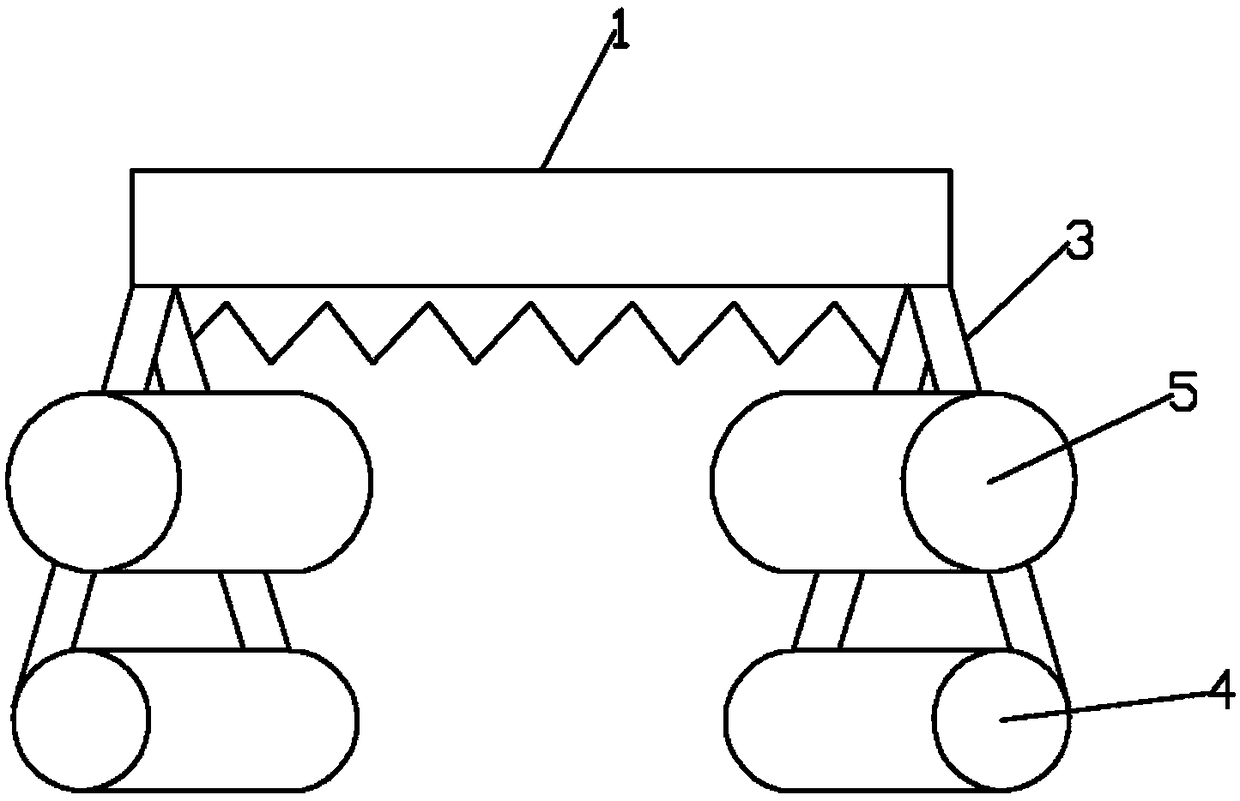

Food packaging equipment

InactiveCN108482756AAvoid elevationAvoid it happening againWrapper twisting/gatheringArticle deliveryCartonFood packaging

The invention relates to the technical filed of packaging, in particular to food packaging equipment which comprises a rack, a conveying mechanism, a leveling mechanism and an adhesive sealing mechanism. The conveying mechanism comprises a motor, a conveying belt and at least two gears. The leveling mechanism comprises two extruding sections symmetrically arranged above the conveying belt. Each extruding section comprises a fixing support, an extruding roller used for extruding the side faces of a carton, and a leveling roller used for closing a cover of the carton. The adhesive sealing mechanism comprises anadhesive tape roll, an oscillating rod, a sliding block and a pull blade used for pulling the adhesive tape on the adhesive tape roll to the center line of the top covered by the leveling rollers, of the carton. The rack is fixedly connected to a cutting knife used for cutting the adhesive tape. According to the technical scheme, a gap between the two opposite carton covers of thetop of the carton is prevented effectively.

Owner:重庆勋勋商贸有限责任公司

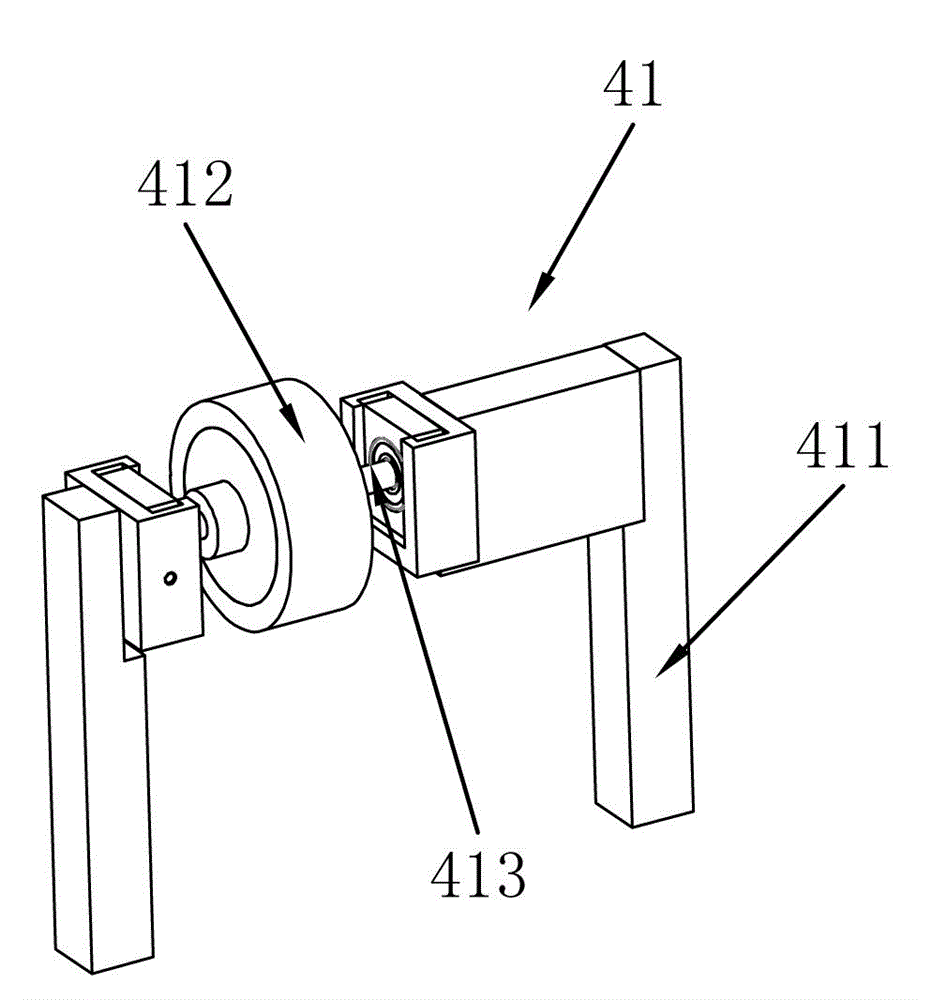

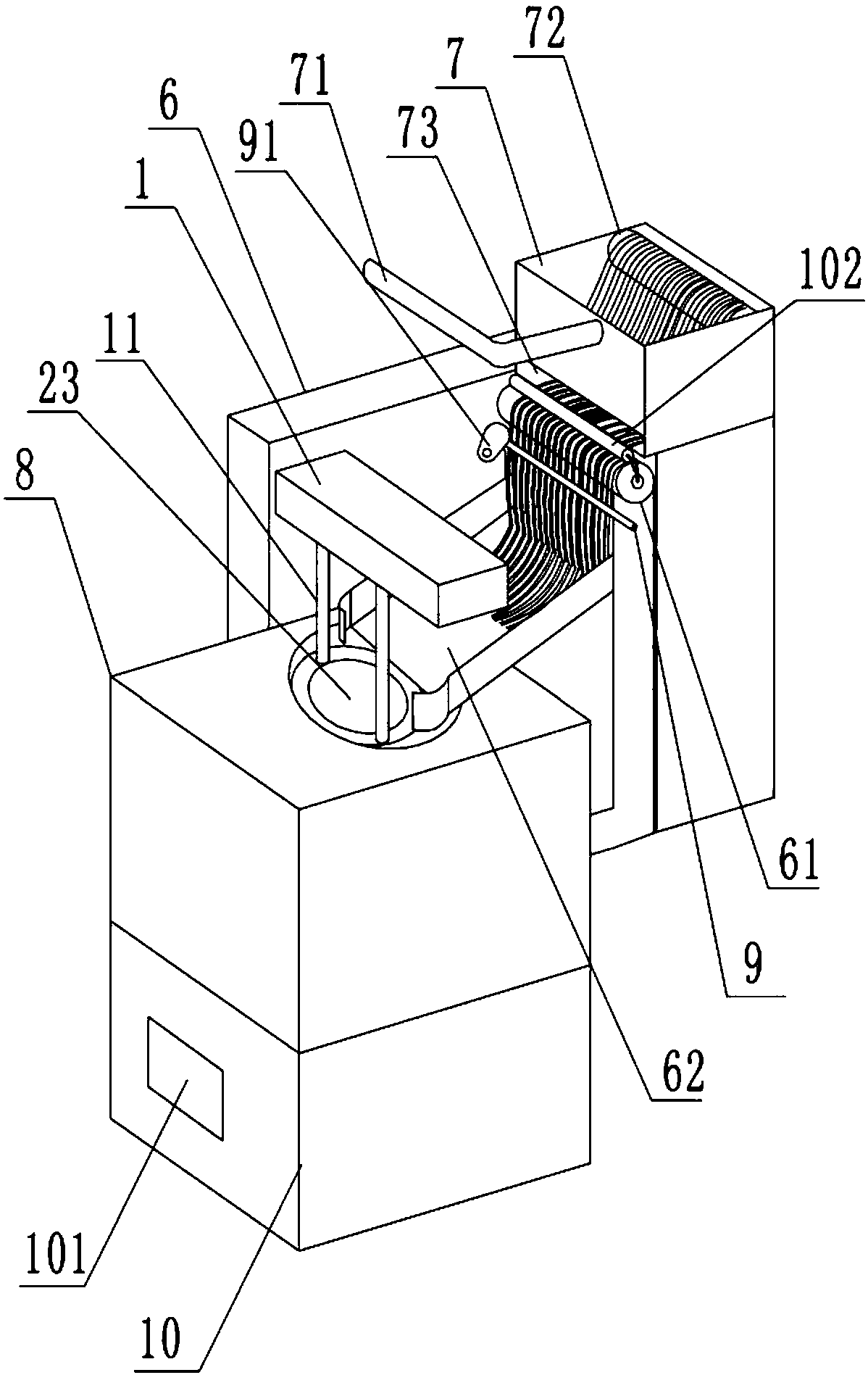

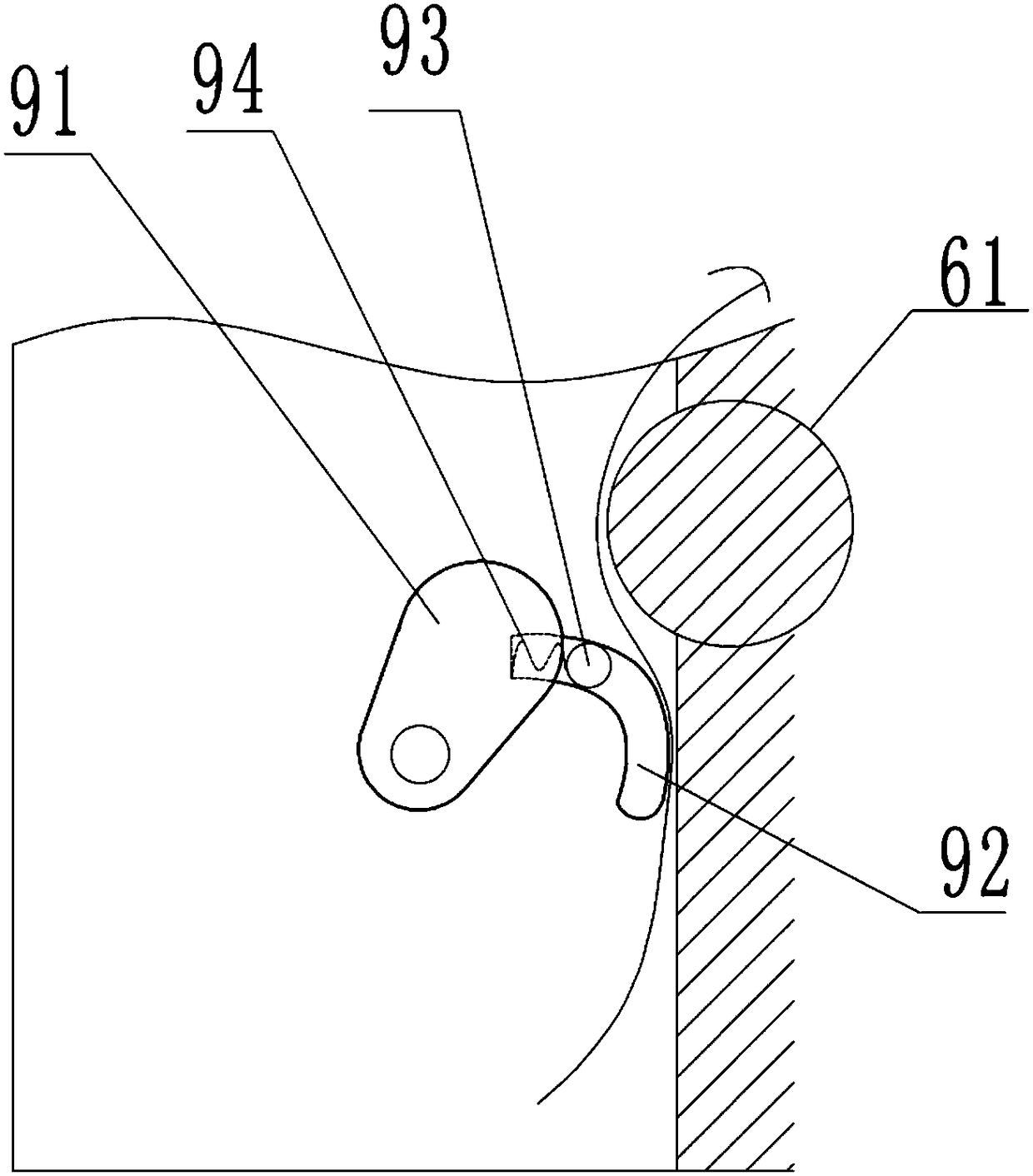

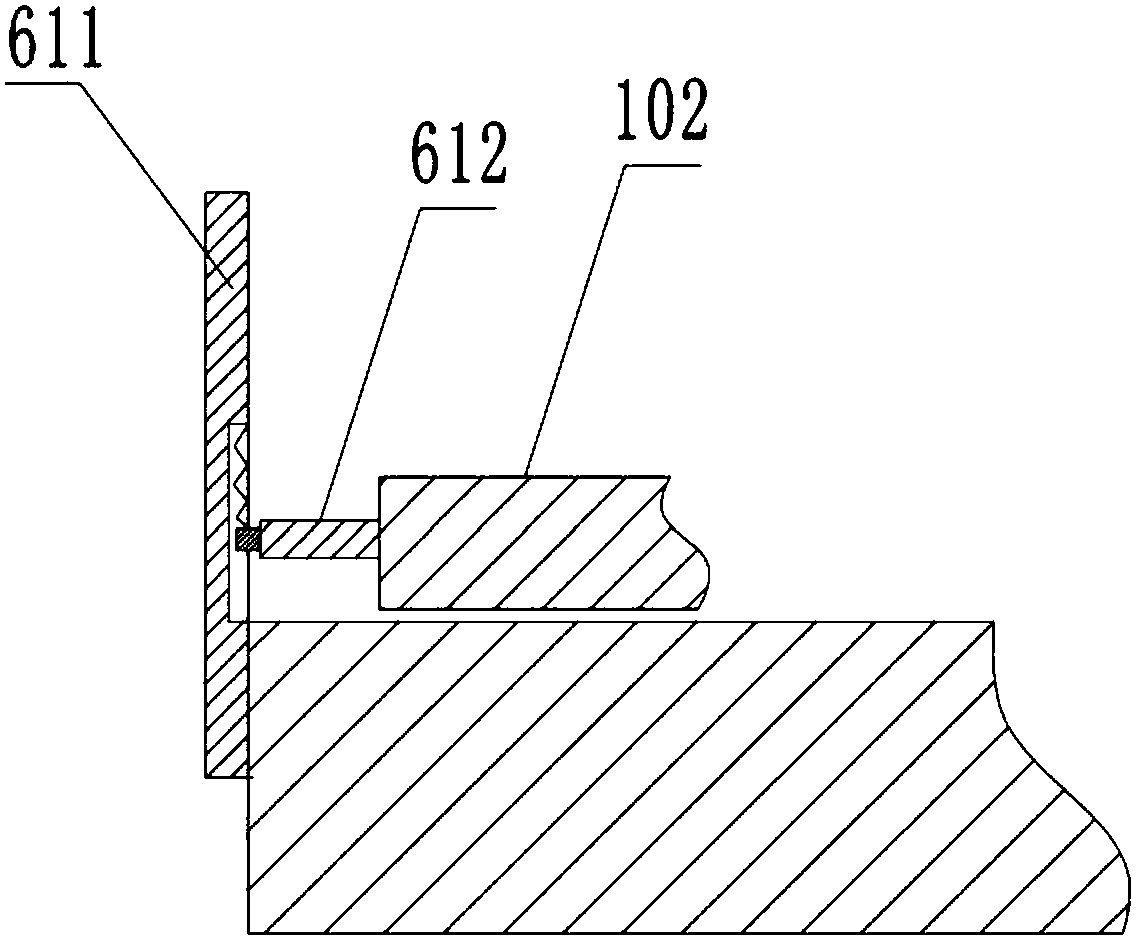

Film-laminating and splitting machine

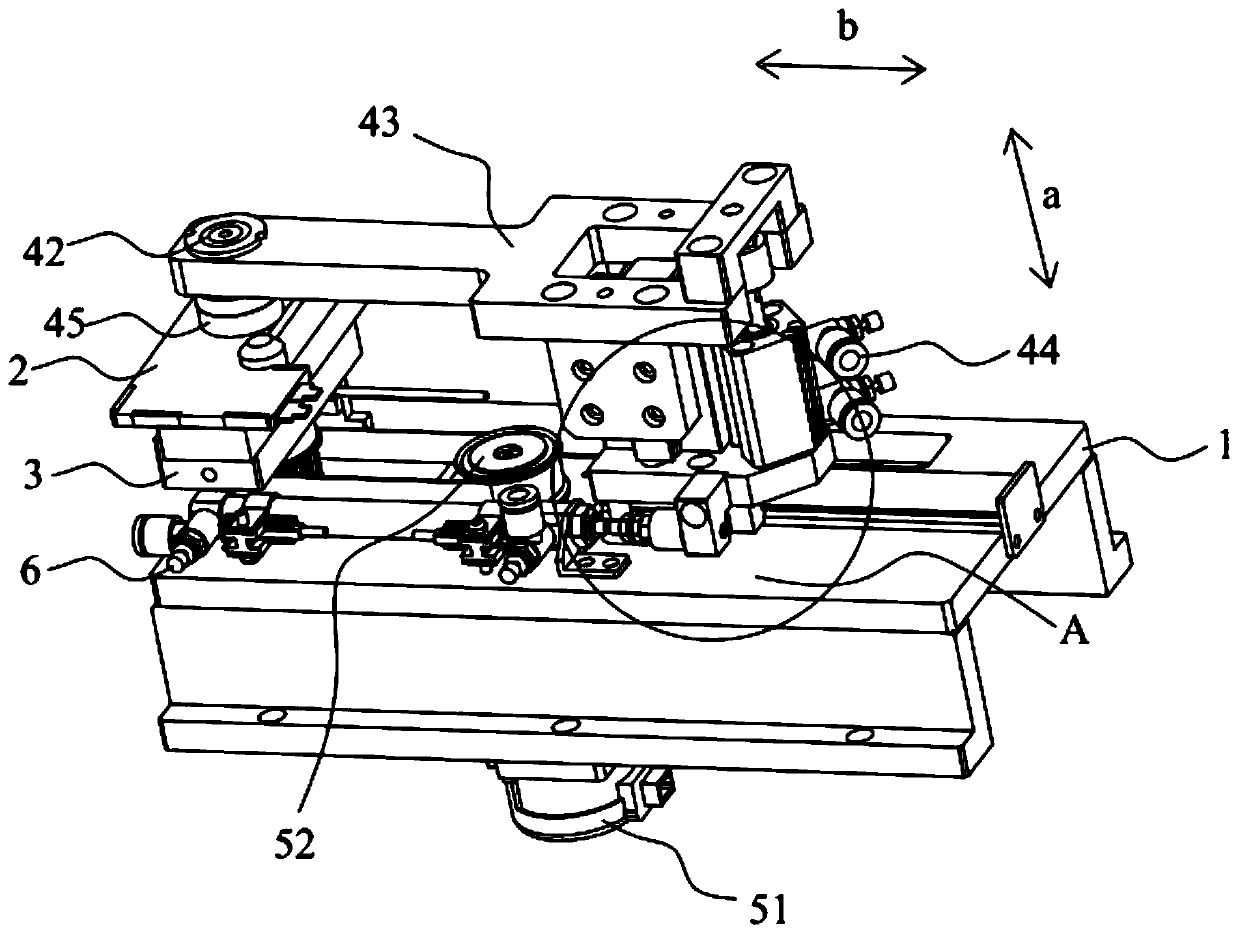

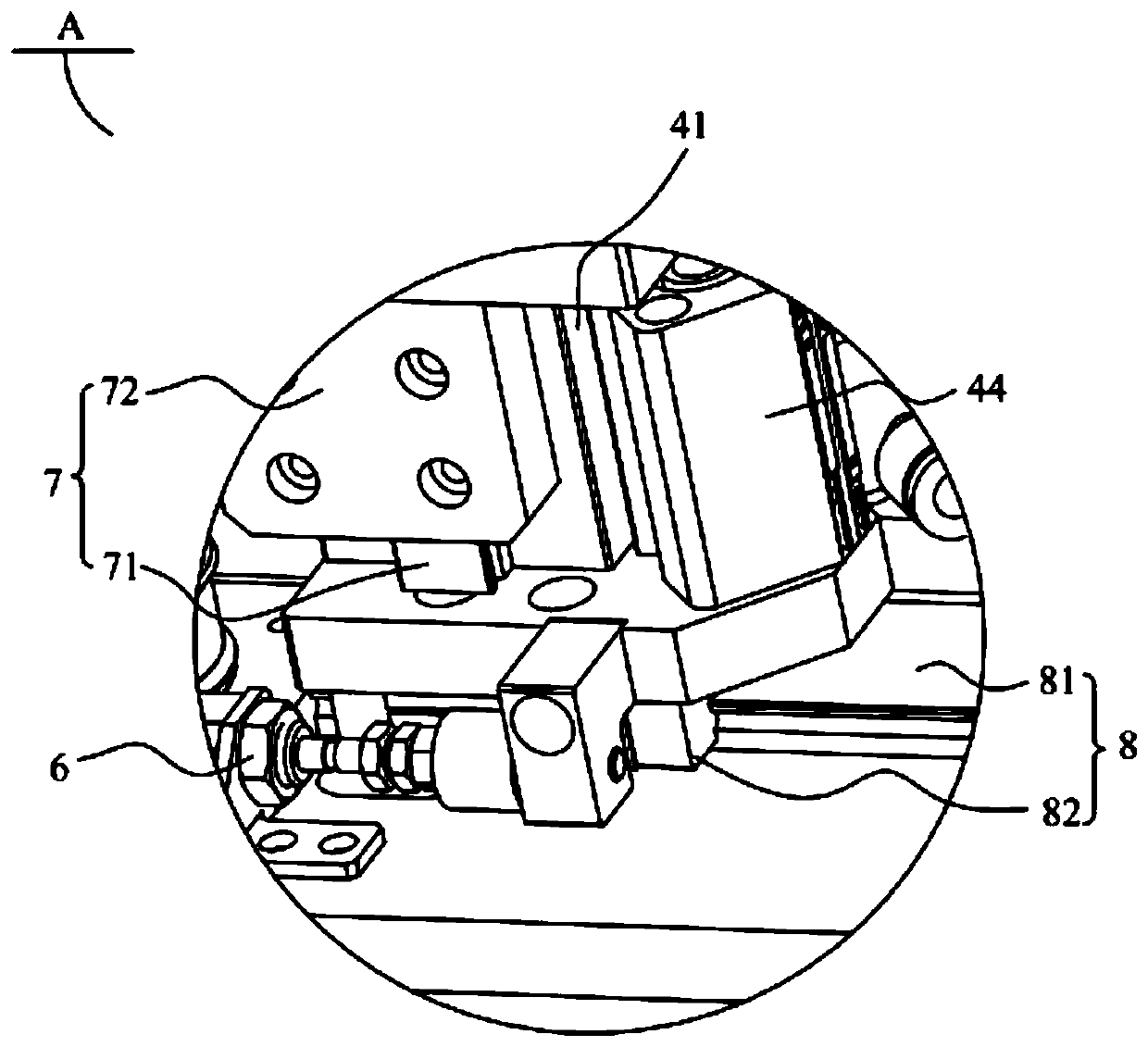

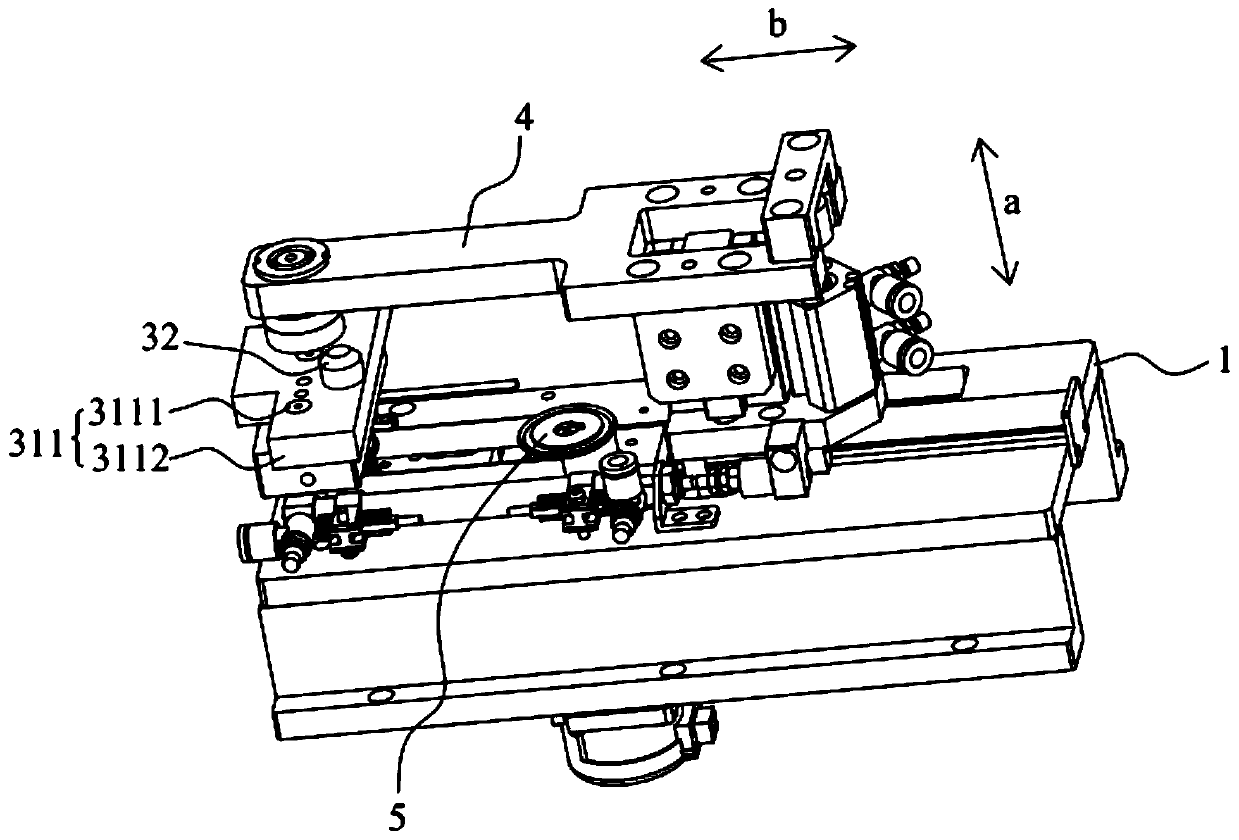

ActiveCN104308889AAvoid it happening againHigh glue cutting efficiencyPackagingMetal working apparatusMechanical engineeringCoating

The invention relates to the field of LED (Light Emitting Diode) light emitting element processing equipment, in particular to a film-laminating and splitting machine. The film-laminating and splitting machine comprises a frame and a splitting mechanism, wherein the splitting mechanism is arranged on the frame, is used for laminating a film to a material and splitting the material, and comprises a material conveying guide rail which is used for conveying the material; an adhesive coating component for film lamination is arranged between the start end and the tail end of the material conveying guide rail; conveying sliding rails are arranged on two sides of the tail end of the material conveying guide rail respectively; a transporting component which is used for transporting the material to the conveying sliding rails is further arranged above the conveying sliding rails; an overturning piece which is used for overturning the material is arranged on the side, opposite to the material conveying guide rail, of the transporting component; a finished product sliding rail is further arranged at the tail end of each conveying sliding rail; a splitter component which is used for splitting the material is further arranged at the tail end of each conveying sliding rail. The whole process is automatically completed; an adhesive tape on an adhesive coating wheel needs to be replaced by a new adhesive tape only when being completely consumed, and finished products are stacked in a material falling box; the whole film-laminating and splitting process is automatically completed, the film-laminating and splitting efficiency is high, the adhesive coating effect is good, and the production efficiency is greatly improved.

Owner:深圳市泓普光电科技有限公司

Automatic adhesive pasting device

An automatic adhesive pasting device structurally comprises a suction nozzle and a taking platform, wherein the suction nozzle and the taking platform are arranged on a rack, a first tensioning roller is arranged above the taking platform, a second tensioning roller is arranged below the taking platform, adhesive tape is pre-tightened to the taking platform through the first tensioning roller and the second tensioning roller, the taking platform is provided with a taking position, the suction nozzle sucks foam at the taking position under the action of external driving force and is in a static state at the moment, and then the taking platform moves in the direction far from the suction nozzle under the action of the external driving force to make the adhesive tape aligned with the suction nozzle in a suspended state; meanwhile, the second tensioning roller drives the adhesive tape on the back of the taking platform to move along with the taking platform so that the adhesive tape in the suspended state can move towards the back of the taking platform and be stripped off from the foam to be taken. According to the automatic adhesive pasting device, in the taking process, the situation that the foam drives the adhesive tape to move can be effectively prevented, and the adhesive tape is made to keep constant tension all the time; as a result, the production efficiency can be improved, and a good adhesive pasting effect is ensured.

Owner:东莞华誉精密技术有限公司

Spinning system and use method thereof

ActiveCN108193326AImprove the adhesion effectCleanup implementationFibre cleaning/opening machinesSevering fibresCavity wallSpin system

The invention relates to the technical field of spinning, in particular to a spinning system. The system comprises a rack, a cleaning part, a conveying part and a cutting part; the cleaning part, theconveying part and the cutting part are all connected with the rack; the cleaning part comprises a cleaning box, a blowpipe and a fiber roller wound with bast fiber, and the fiber roller is rotationally connected to the cavity wall of the cleaning box; an opening allowing the bast fiber to pass is formed in the side, away from the fiber roller, of the cleaning box, and the blowpipe is located above the opening; the rack is provided with a transition roller allowing the bast fiber to pass, and a conveying channel is arranged below the transition roller; the conveying part is located below the transition roller, and the conveying part is used for conveying the bast fiber. Accordingly, impurities in the bast fiber can be removed, and the bast fiber can be likely to be mixed with and adhere toother fiber.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

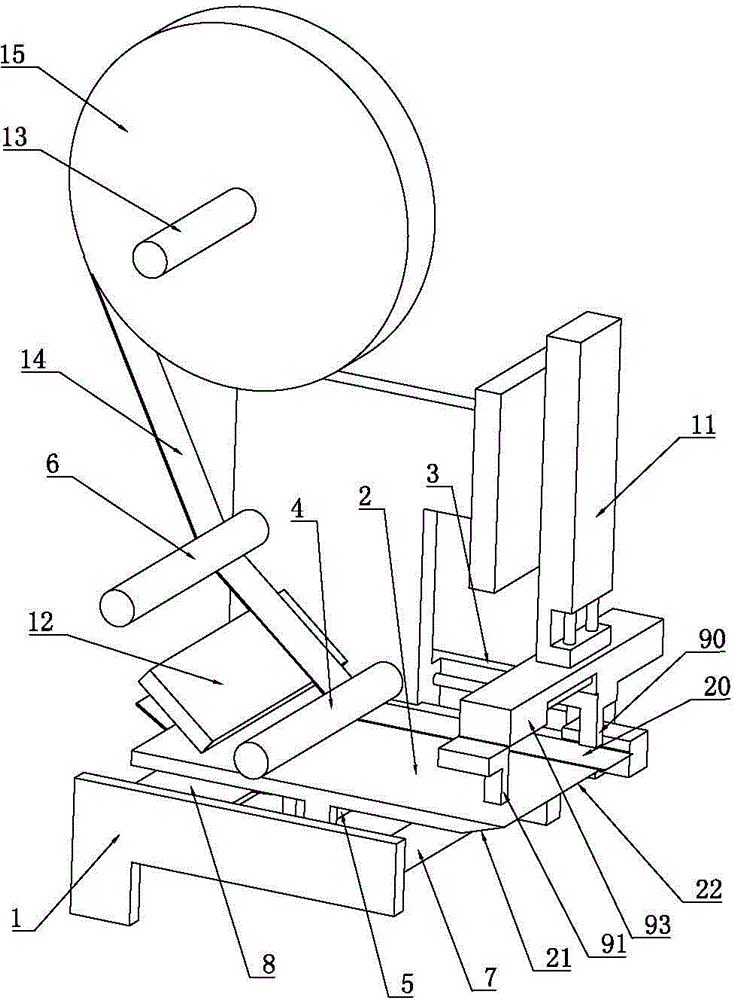

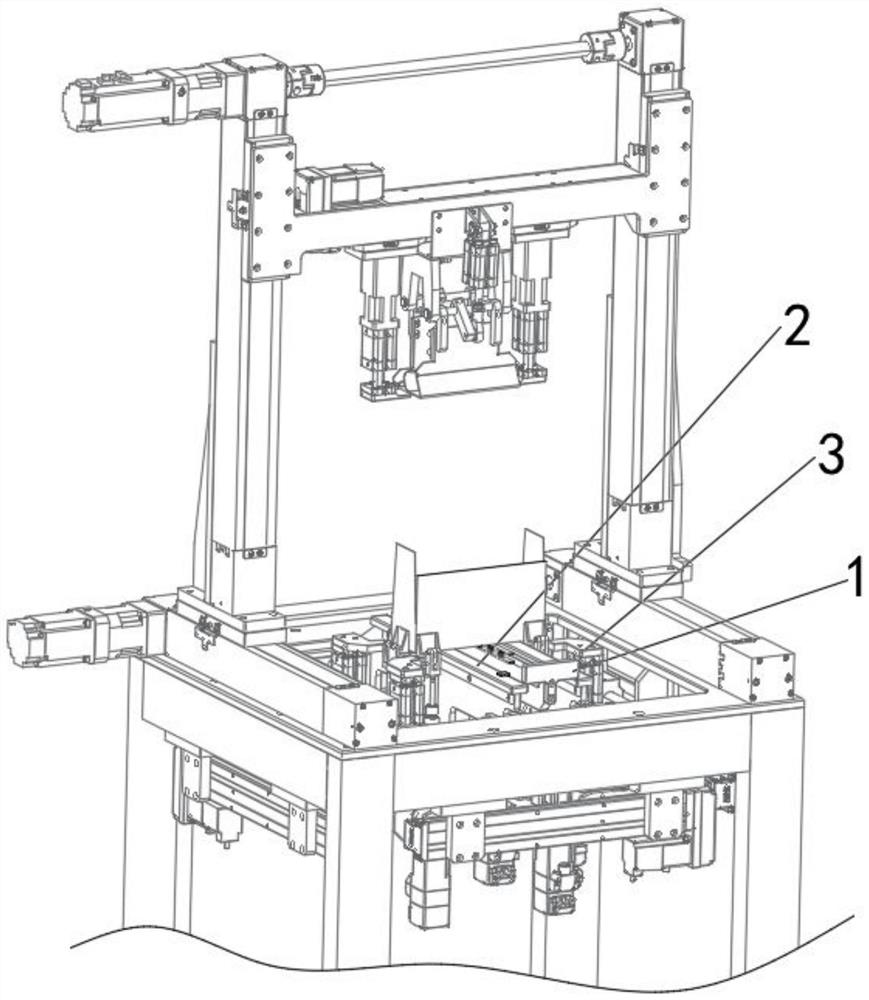

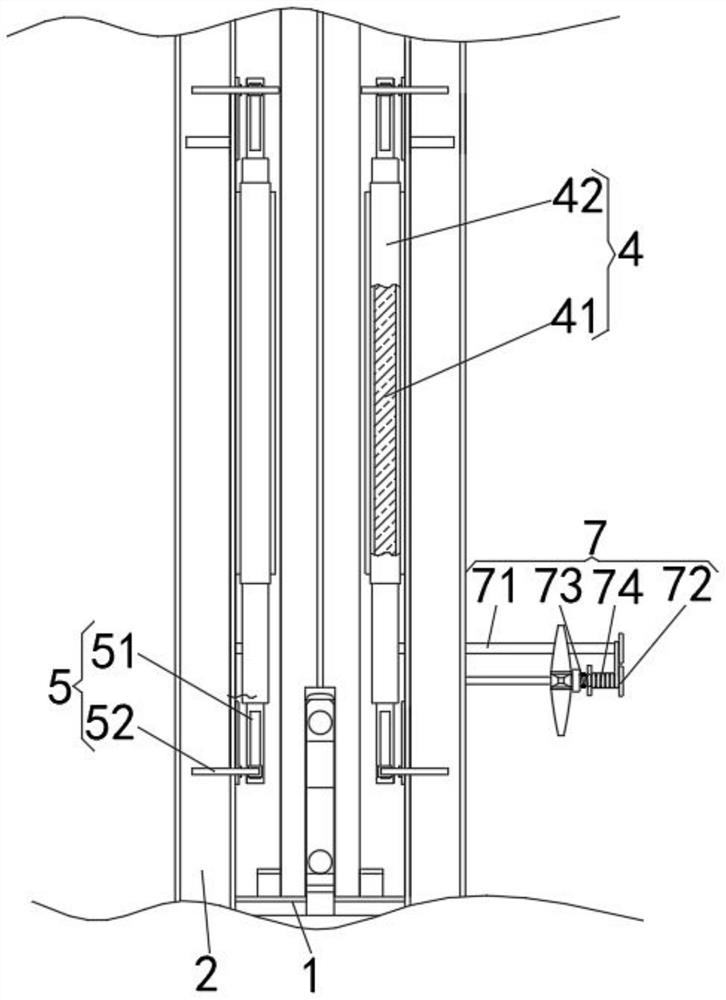

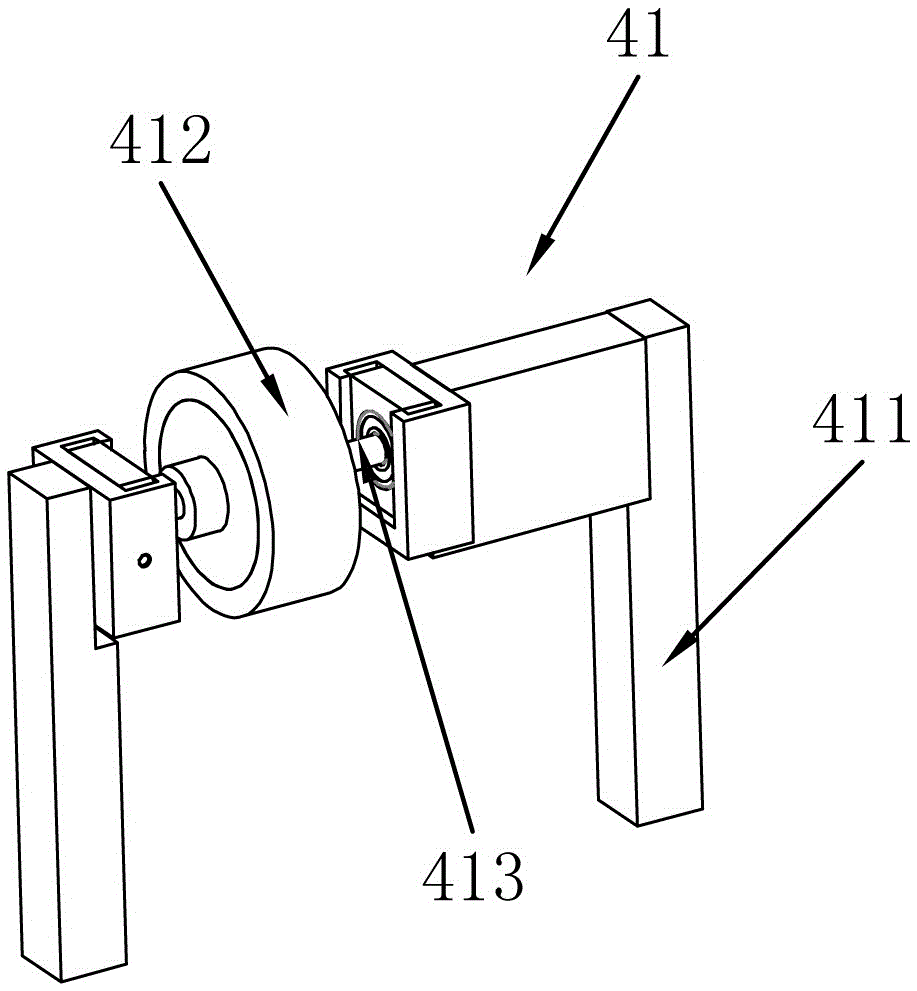

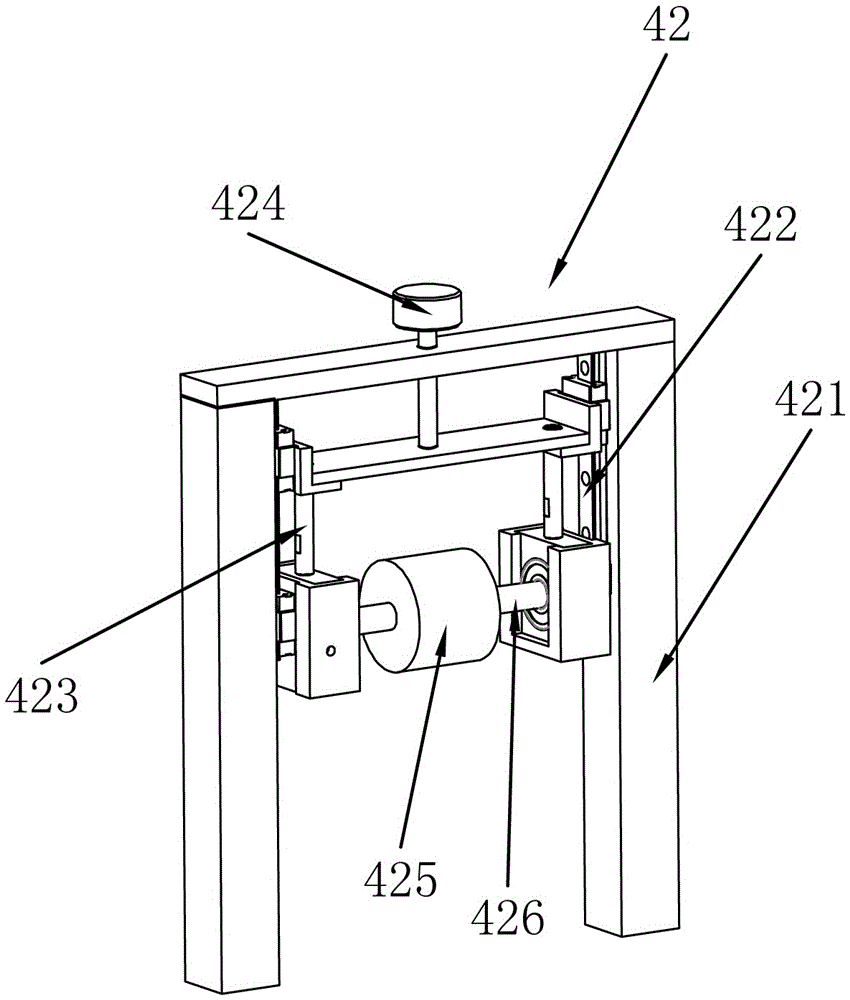

Rotating device for multi-surface adhesive bonding of battery cell

PendingCN110350235AReduce the likelihood of changeShorten positioning timePrimary cell manufactureAssembling battery machinesState of artMechanical engineering

The invention discloses a rotating device for the multi-surface adhesive bonding of a battery cell and belongs to the technical field of battery processing. The invention aims to solve problems such as long work hours, low stability, and poor adhesive bonding effect caused by requirements of a battery cell multi-surface adhesive bonding device in the prior art for frequent switching of battery cell work positions and re-positioning. The rotating device comprises a supporting seat, a fixing mechanism and a rotation driving mechanism; the supporting seat is used for supporting the battery cell;the fixing mechanism comprises a pressing block capable of freely rotating around a rotating shaft; the pressing block is arranged to one side of the supporting seat and is used for tightly pressing the battery cell on the supporting seat; and the rotation driving mechanism is configured to be capable of driving the supporting seat and the battery cell to rotate. The rotating device has the advantages of good stability, short adhesive bonding time and good adhesive bonding effect. With the rotating device adopted, the multi-surface adhesive bonding of the battery cell in the same working position can be realized.

Owner:BOZHON PRECISION IND TECH CO LTD

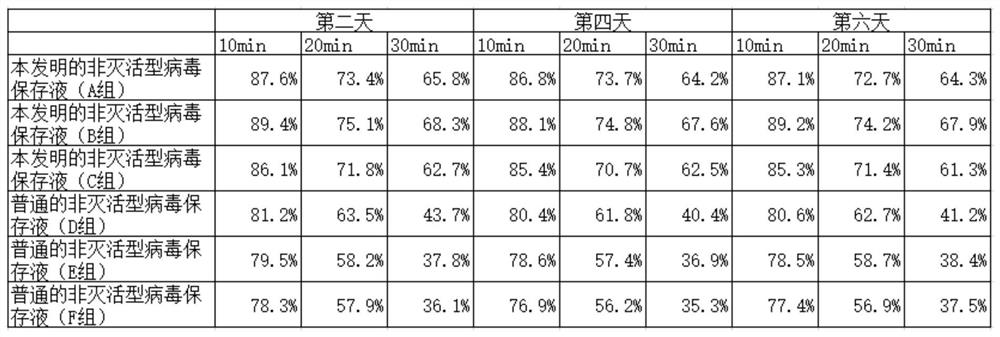

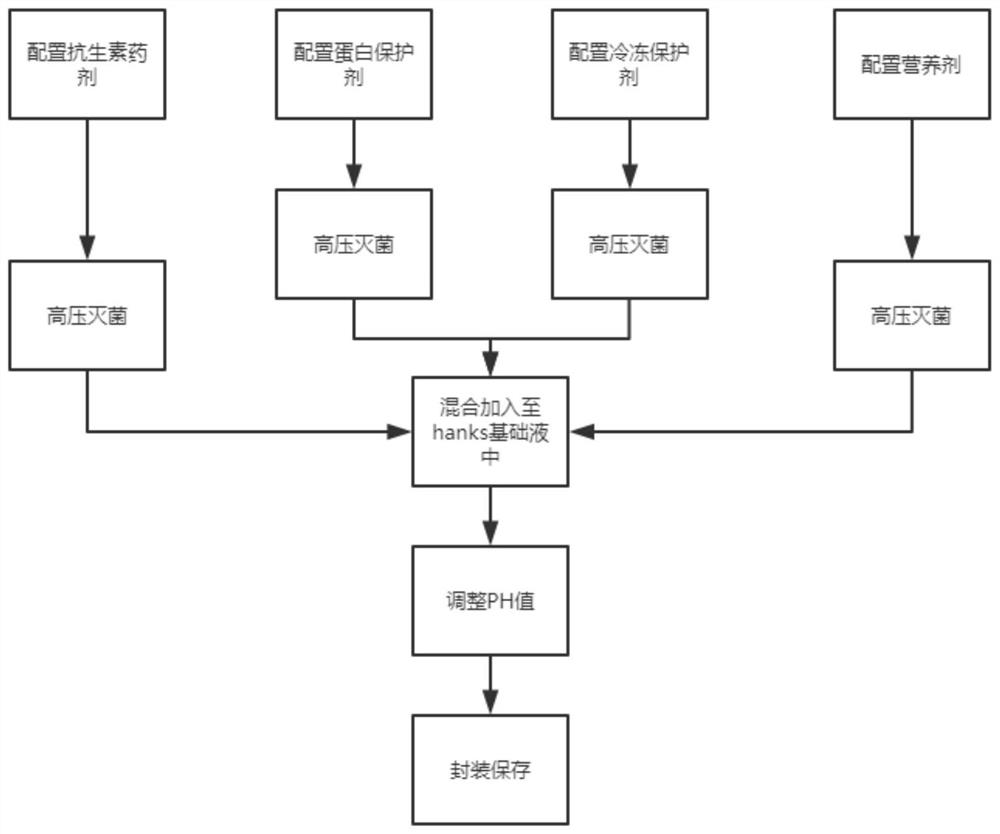

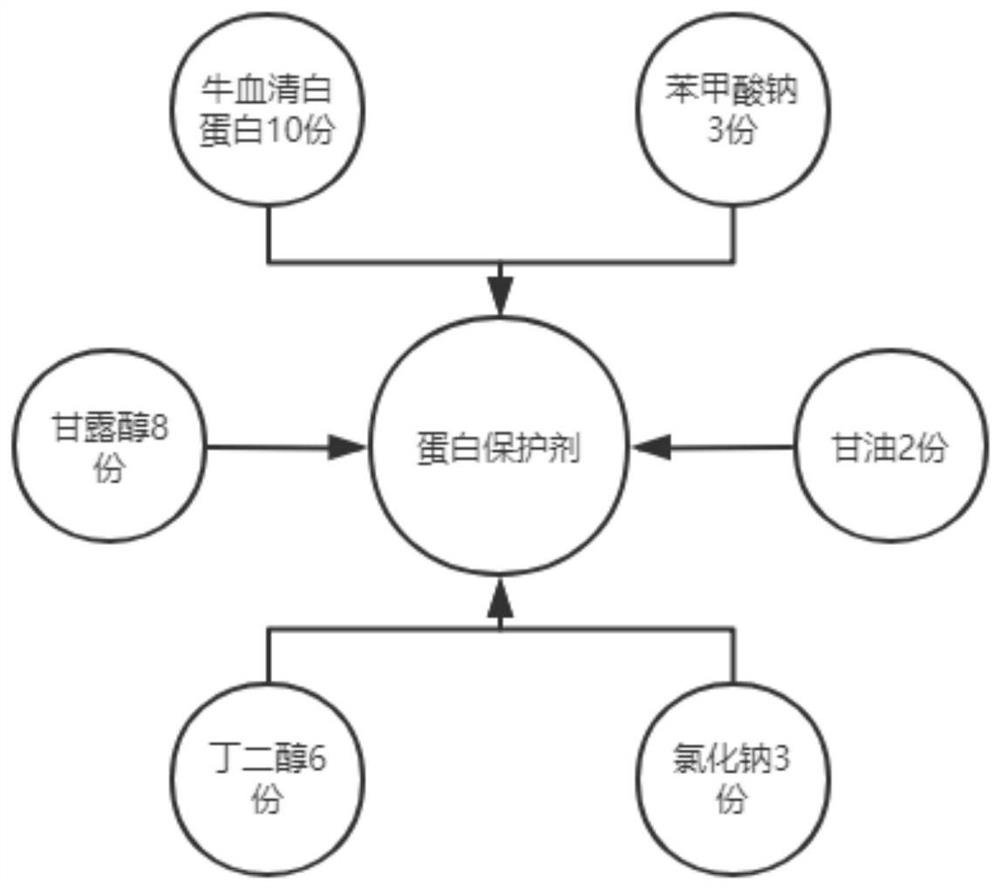

A high-safety non-inactivated virus preservation solution and its preparation method

ActiveCN113046412BEnhanced inhibitory effectImprove the adhesion effectMicrobiological testing/measurementNutritionPolythylene glycol

The invention provides a high-safety non-inactivated virus preservation solution and a preparation method thereof. The preservation solution includes hanks base solution, antibiotic medicament, protein protectant, cryoprotectant and nutrient, and the protein protectant includes bovine Serum albumin, mannitol, glycerin, butylene glycol, sodium chloride and sodium benzoate, described cryoprotectant comprises sodium alginate, polyethylene glycol, glucose, and described nutrient comprises asparagine, glutamine, threonine, aspartic acid, valine, leucine, isoleucine, said antibiotic agent includes gentamicin, amclocillin sodium and amikacin. Inhibit the influence of bacteria and fungi on viruses by antibiotics, protect the protein shell of viruses by protein protectants, stabilize the protection solution at low temperatures by cryoprotectants, and enable viruses to survive in the protection solution by nutrients .

Owner:MIRACLEAN TECH

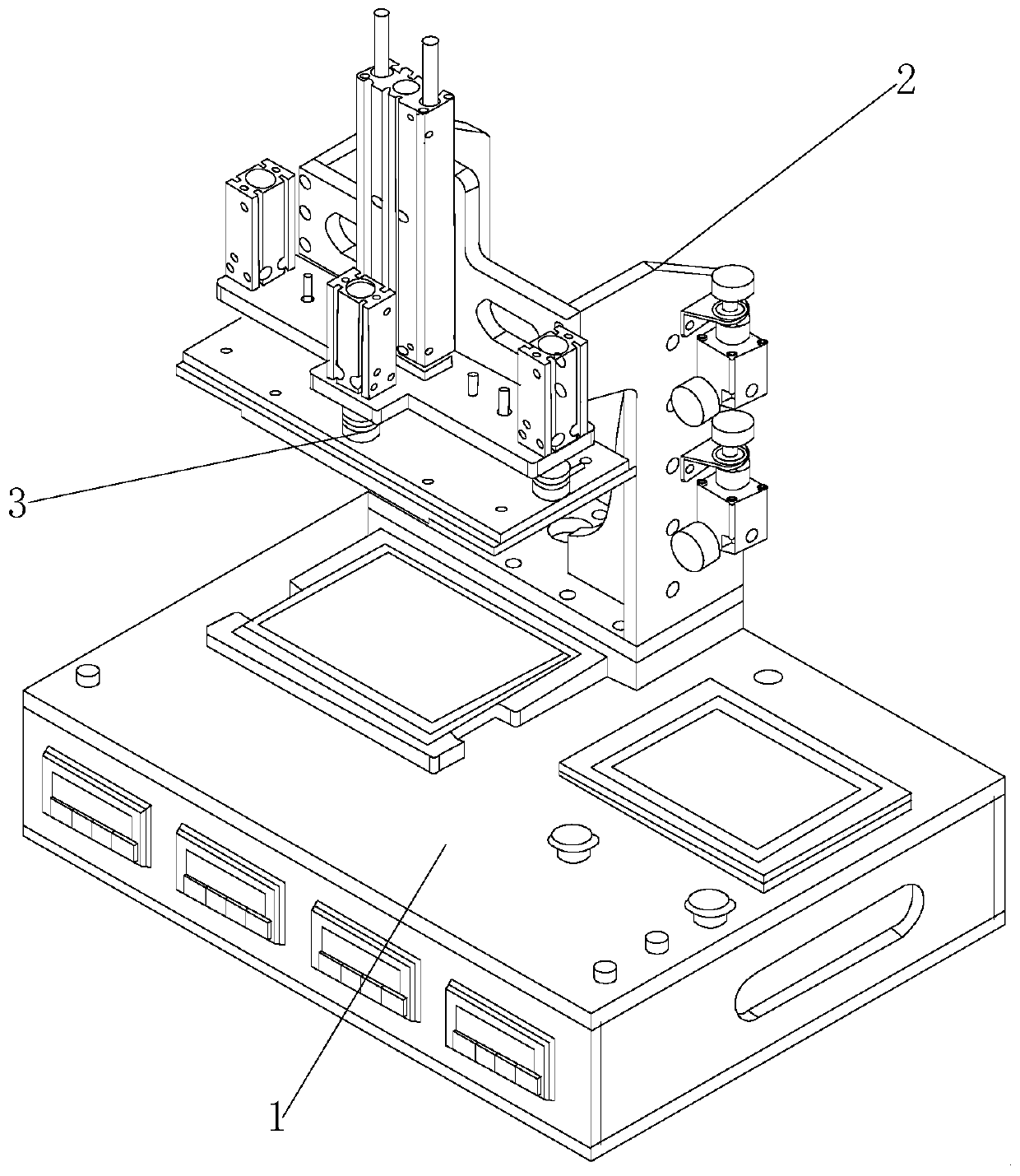

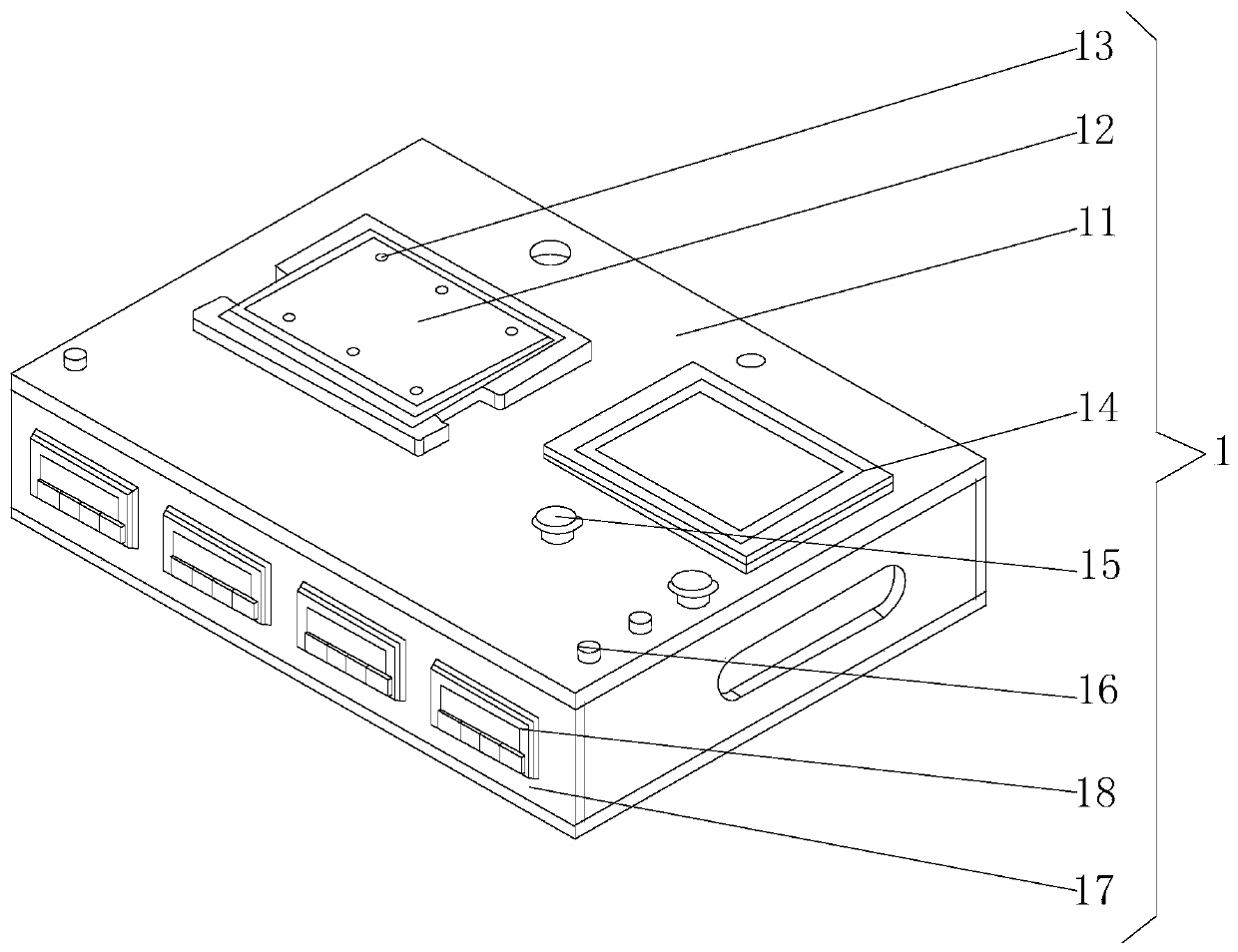

Plastic frame film attaching detection tool

PendingCN111061074ASolve the problem of poor adhesive effectSolve the problem of uneven artificial forceApparatus for force/torque/work measurementNon-linear opticsPlate pressureStructural engineering

The invention discloses a plastic frame film attaching detection tool, which comprises a bearing mechanism, a supporting mechanism and a pressing head mechanism, wherein the upper left corner of the top of the bearing mechanism is fixedly connected with the bottom of the supporting mechanism, and the top of the supporting mechanism is fixedly connected with one side of the pressing head mechanism;the bearing mechanism comprises a tool panel, a bearing plate, a positioning column, an all-in-one machine, an alarm, a starting button, a tool side plate, a pressure display dial plate and a tool side plate. According to the plastic frame film attaching detection tool, a first cylinder, a second cylinder and a pressure sensor are arranged, the second air cylinder can drive the pressing head mechanism to move downwards, after the pressing head mechanism reaches the position, the first air cylinder begins to press downwards to act on the pressure sensor, the pressure sensor drives the pressingplate to press and attach a film and a plastic frame through guiding of a guide column and a guide sleeve, the arranged guide column and the guide sleeve can guide and limit the fixing plate, and theproblem that the film attaching effect is poor due to uneven manual film attaching force is effectively solved.

Owner:NANJING WOLIAN TECH

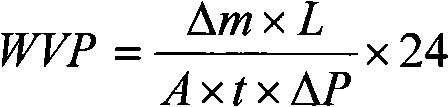

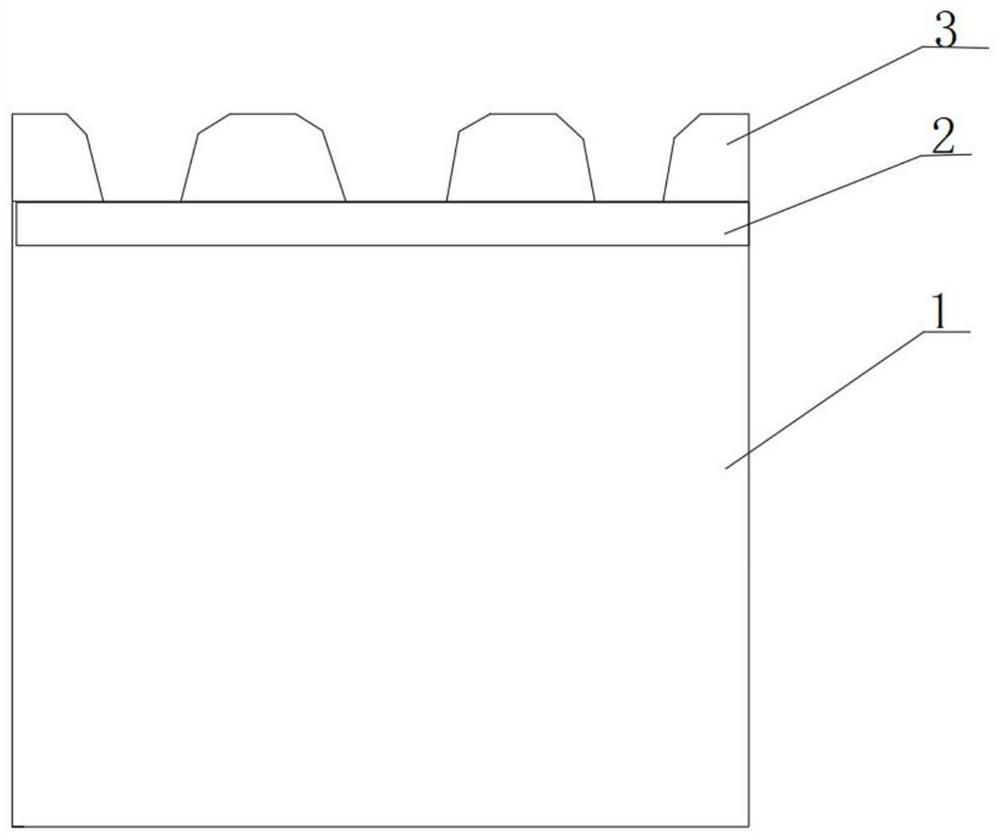

High-silicon heat storage honeycomb ceramic filler with high acid resistance and compactness

The invention discloses a high-acid-resistance compact high-silicon heat-storage honeycomb ceramic filler which is prepared by the following steps: by taking quartz, feldspar, pyrophyllite, china clay, ball clay and kaolin as main raw materials, adjusting the adding proportions of the quartz, the feldspar, the pyrophyllite, the china clay, the ball clay and the kaolin through calculation, and uniformly mixing the quartz, the feldspar, the pyrophyllite, the china clay, the ball clay and the kaolin, thereby obtaining the high-acid-resistance compact high-silicon heat-storage honeycomb ceramic filler. The high-silicon heat-storage honeycomb ceramic filler is prepared by performing ball milling on the raw materials to obtain a mixture, ensuring that the content of silicon dioxide in the mixture is greater than or equal to 65wt%, adding an adhesive, a lubricating agent and a proper amount of water into the mixture, performing ball milling, fully mixing, kneading, pugging, forming, drying and sintering to obtain the high-silicon heat-storage honeycomb ceramic filler. The acid corrosion resistance of the high-silicon heat-storage honeycomb ceramic filler is enhanced by more than 98%; the sintering temperature is increased to 150-200 DEG C, and the volume density is increased to 2.3-2.6 g / cm < 3 >, so that the compactness of the heat storage filler is improved, the honeycomb wall material is difficult to corrode and cannot be pulverized and collapsed, and the service life is prolonged to more than two years.

Owner:JIANGXI BOCENT TEC CO LTD

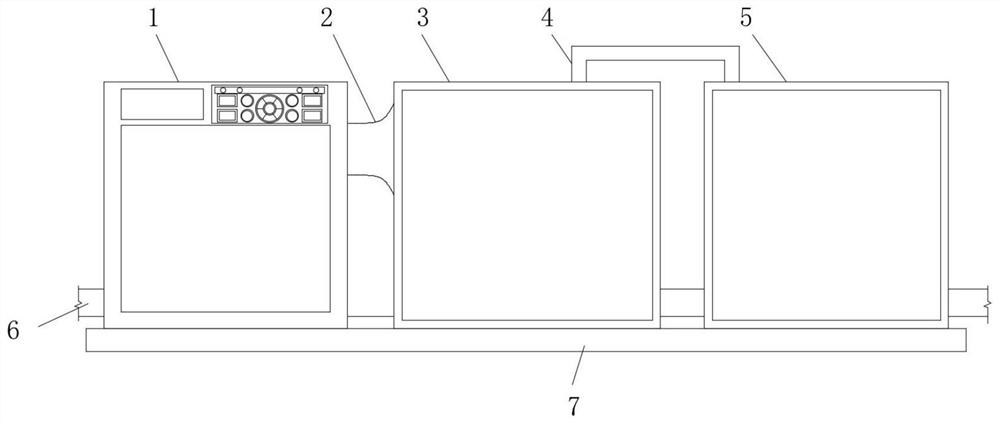

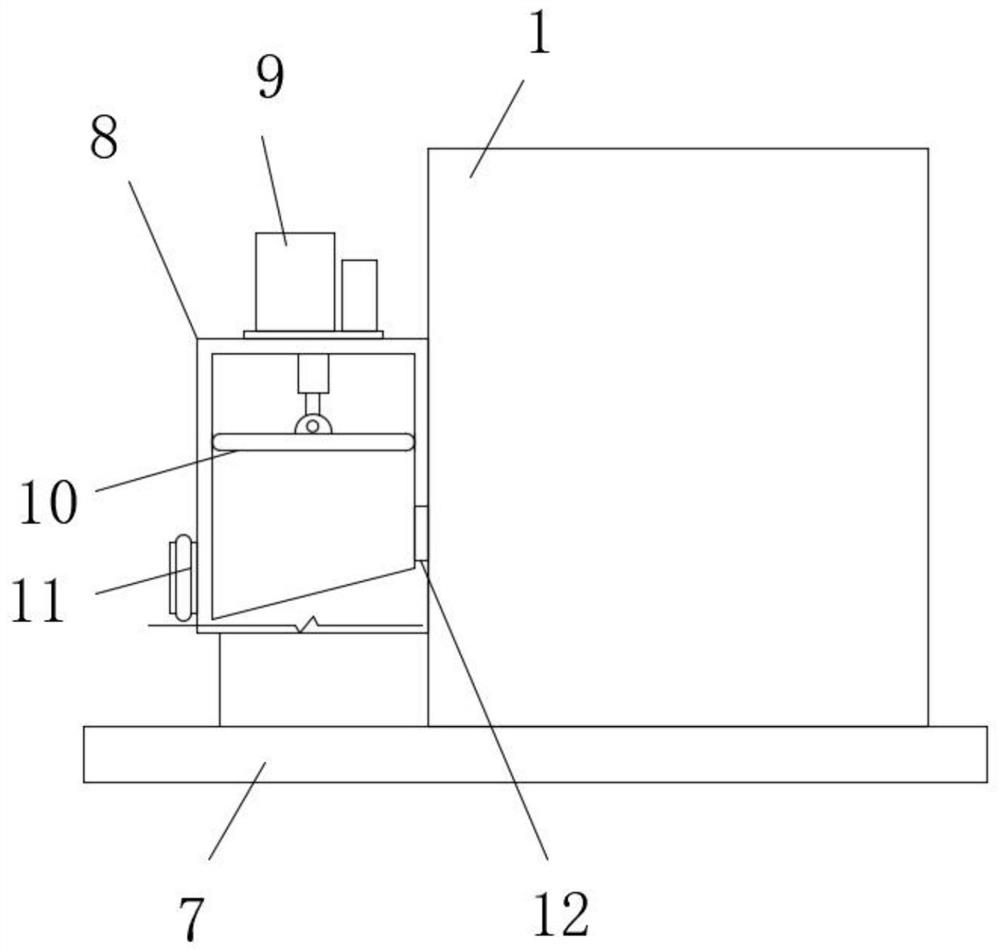

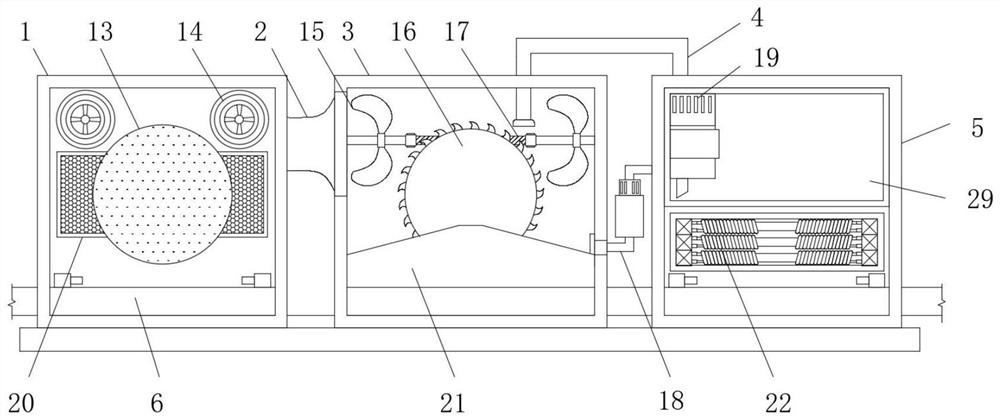

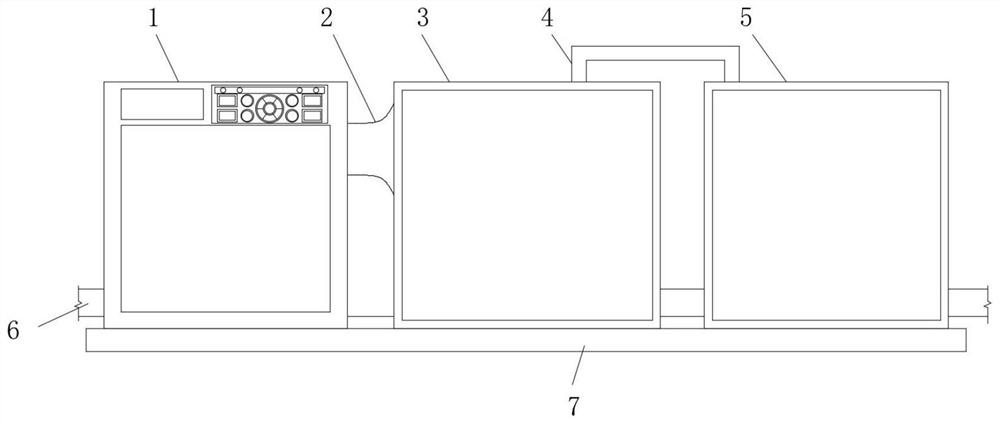

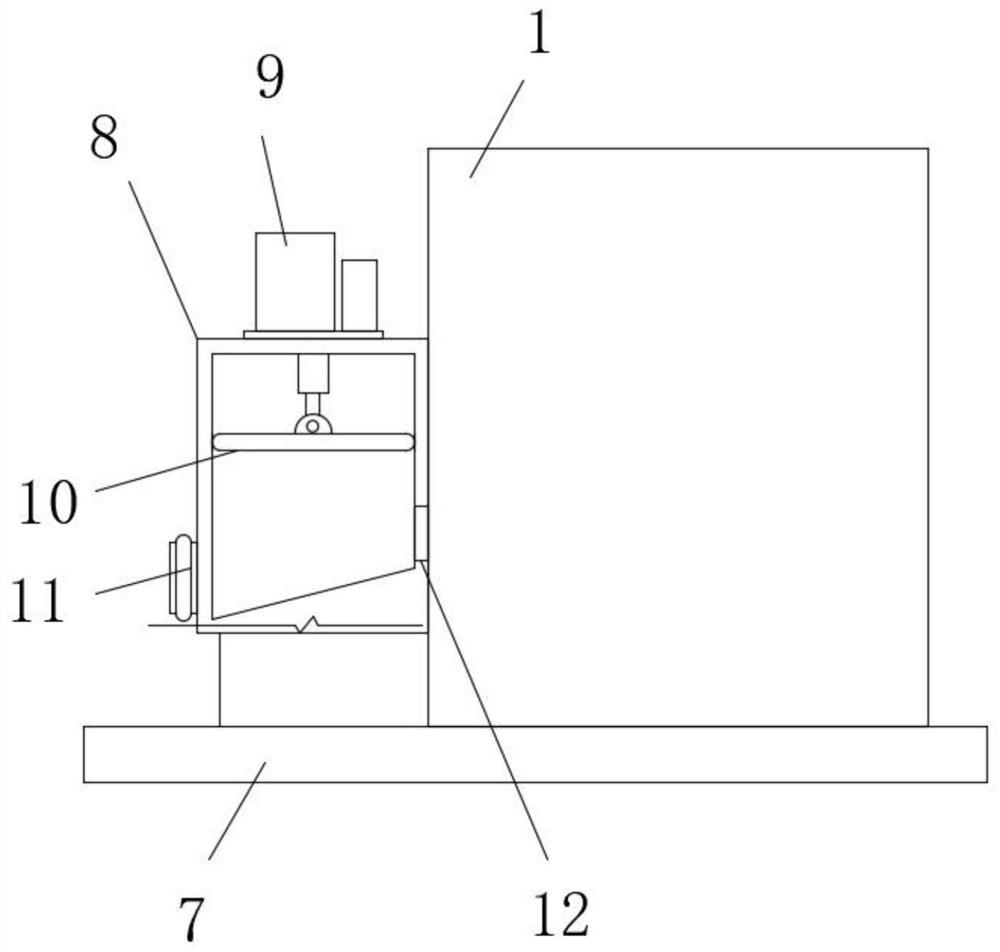

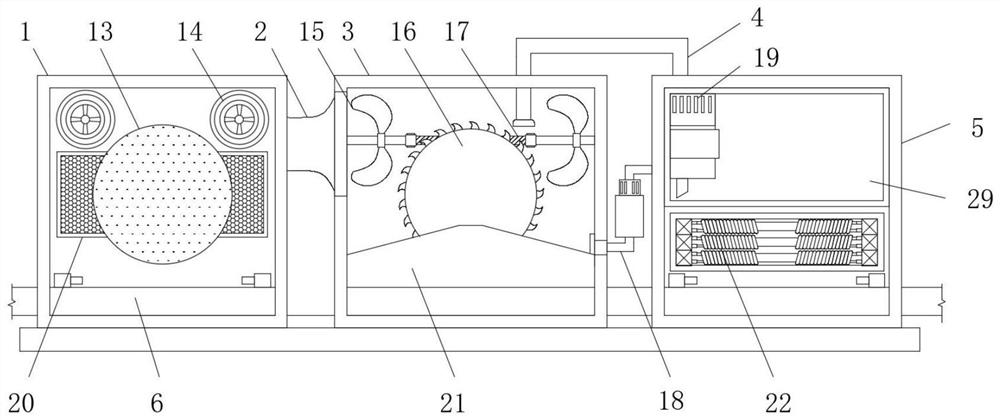

An assembly line for the production of wooden boxes

ActiveCN113021097BImprove the adhesion effectImprove adsorption capacityCircular sawsBark-zones/chip/dust/waste removalTransmission beltPolishing

The invention discloses an assembly line for producing wooden boxes, relates to the technical field of wooden box production, and includes a wood board grinder, a wood board cutter, an air dryer, a base, a grinding roller, a dust catch assembly, a transmission worm, and a positioning assembly. The top of the above-mentioned base is fixedly installed with a board grinder, a wood cutter and an air dryer respectively from left to right, and the inside of the wood grinder, wood cutter and air dryer are all horizontally equipped with transmission chain plates; There is a linked dust capture component installed in the machine. When the wooden box is produced, the grinding roller can be driven to rotate when the wooden board is firstly polished. At the same time, the outer first side belt shaft can pass through the transmission belt. Drive the dust capture assembly with the second side belt shaft to rotate. The dust capture inner column in the dust capture assembly can effectively and quickly absorb the debris in the grinding process to ensure the cleanliness of the device. Snap components improve adhesion.

Owner:绍兴竺玉包装有限公司

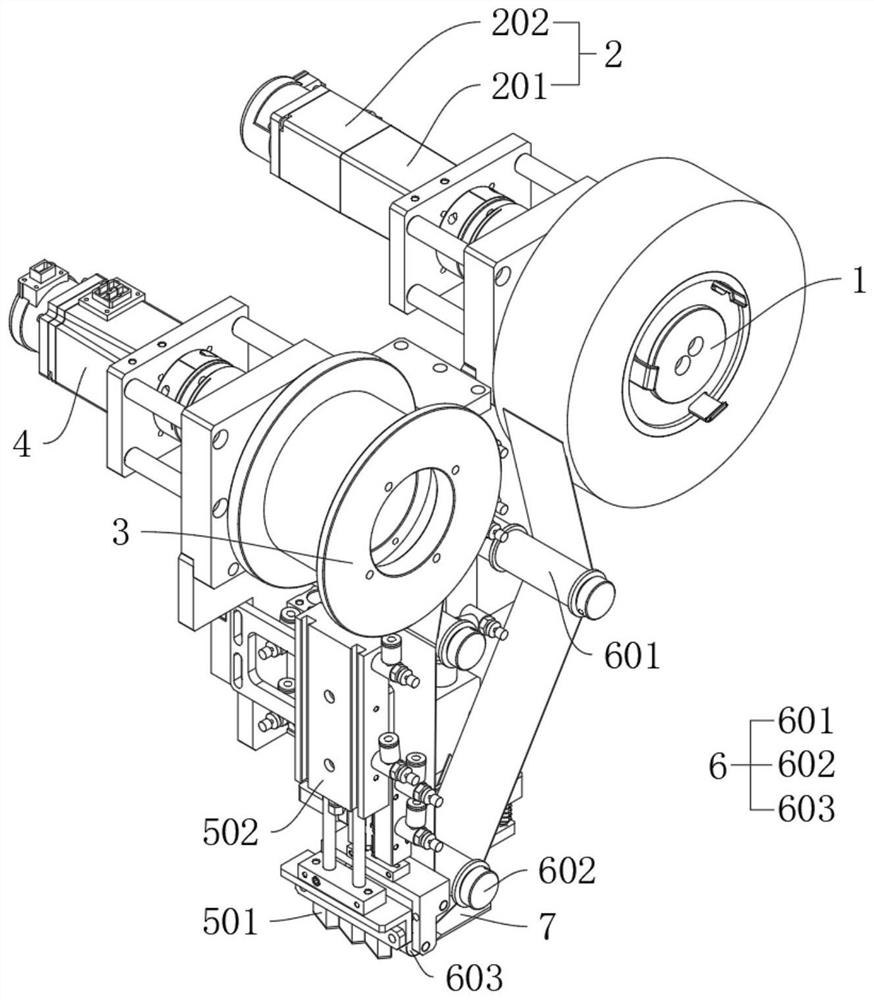

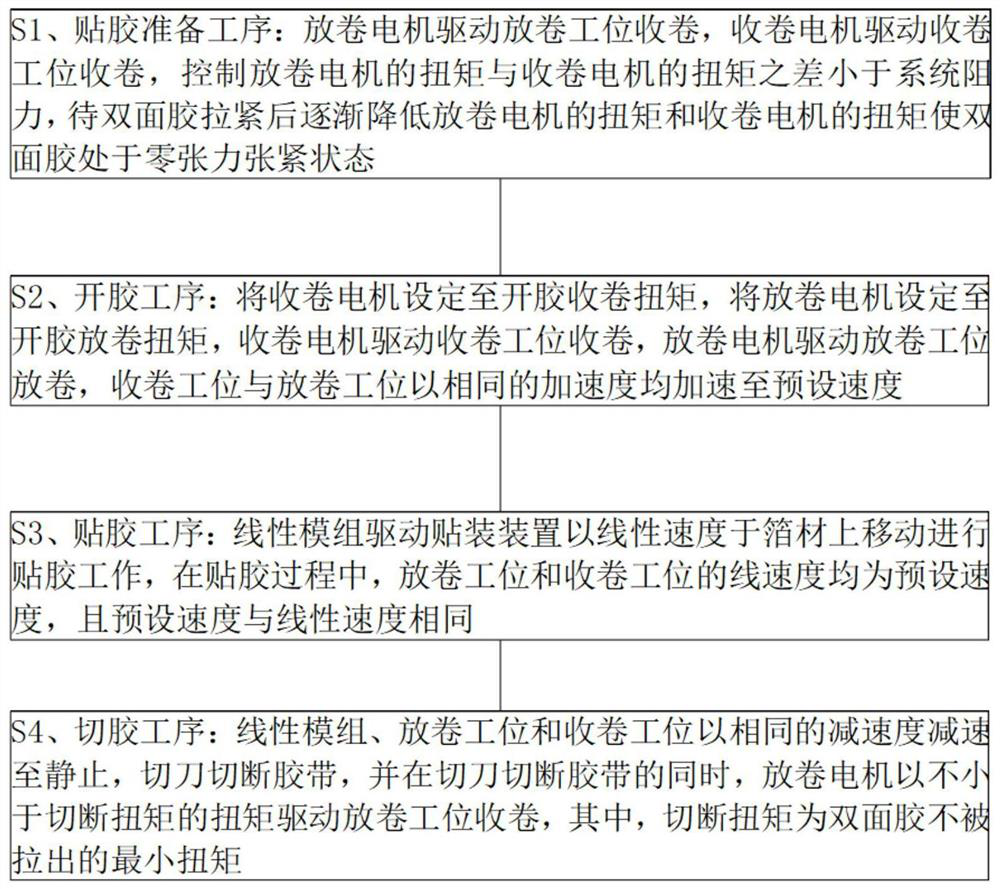

Adhesive pasting device, adhesive pasting mechanism and adhesive pasting method for double faced adhesive tape zero-tension adhesive pasting

PendingCN111703953AAvoid wrinklesPrevent appearanceFilament handlingArticle deliveryPolymer scienceAdhesive belt

The invention discloses an adhesive pasting device, an adhesive pasting mechanism and an adhesive pasting method for double faced adhesive tape zero-tension adhesive pasting, and belongs to foil adhesive pasting equipment. The adhesive pasting device comprises an unreeling station, a reeling station, a reeling motor and an adhesive pasting assembly. The unreeling station releases double faced adhesive tape, and after the double faced adhesive tape is pasted to foil through the adhesive pasting assembly, the reeling motor drives the reeling station to conduct reeling work on left isolation paper of the double faced adhesive tape. An unreeling drive assembly is further included and drives the unreeling station to conduct unreeling work. In the adhesive pasting process, unreeling work and reeling work are synchronously conducted. The reeling and unreeling servo arrangement is further optimized, multiple work conditions are finely divided, near-zero-tension double faced adhesive tape pasting is achieved, after adhesive pasting, the adhesive tape does not rebound or wrinkle, and the appearance of the foil and the adhesive tape is improved; and then the average stress of the whole widthof the foil is improved, and the tape breakage probability is reduced.

Owner:JIANGSU KATOP AUTOMATION CO LTD

Novel tape adhering machine

ActiveCN102674069BSimple structureImprove glue application efficiencyArticle deliveryEngineeringMechanical engineering

The invention discloses a novel tape adhering machine which comprises at least one tape adhering head and a base, wherein the tape adhering head comprises a main mounting plate a and an assorted mounting plate which is matched with the main mounting plate a; a tape fixing wheel and a cutting mechanism are arranged on the main mounting plate a; the tape fixing wheel is arranged at the top of the main mounting plate a for fixing a tape; the cutting mechanism is arranged at the lower part of the main mounting plate a; the cutting mechanism is provided with a cylinder to drive a prepressing module and a cutter to complete the tape adhering and cutting tasks; and the base is used for fixing the tape adhering head and conveying materials which are required to be adhered. The novel tape adhering machine utilizes the lever principle to complete the tape adhering and cutting tasks through a driving link which consists of the cylinder and a knuckle bearing, so the adhering efficiency is greatly increased, in addition, the structure of the tape adhering head is also correspondingly simplified, and the cost is lowered; and moreover, the novel tape adhering machine meets different specification requirements on the materials which are needed to be adhered, and the adhering effect is improved.

Owner:POLYGON AUTOMATION TECH CHENGDU

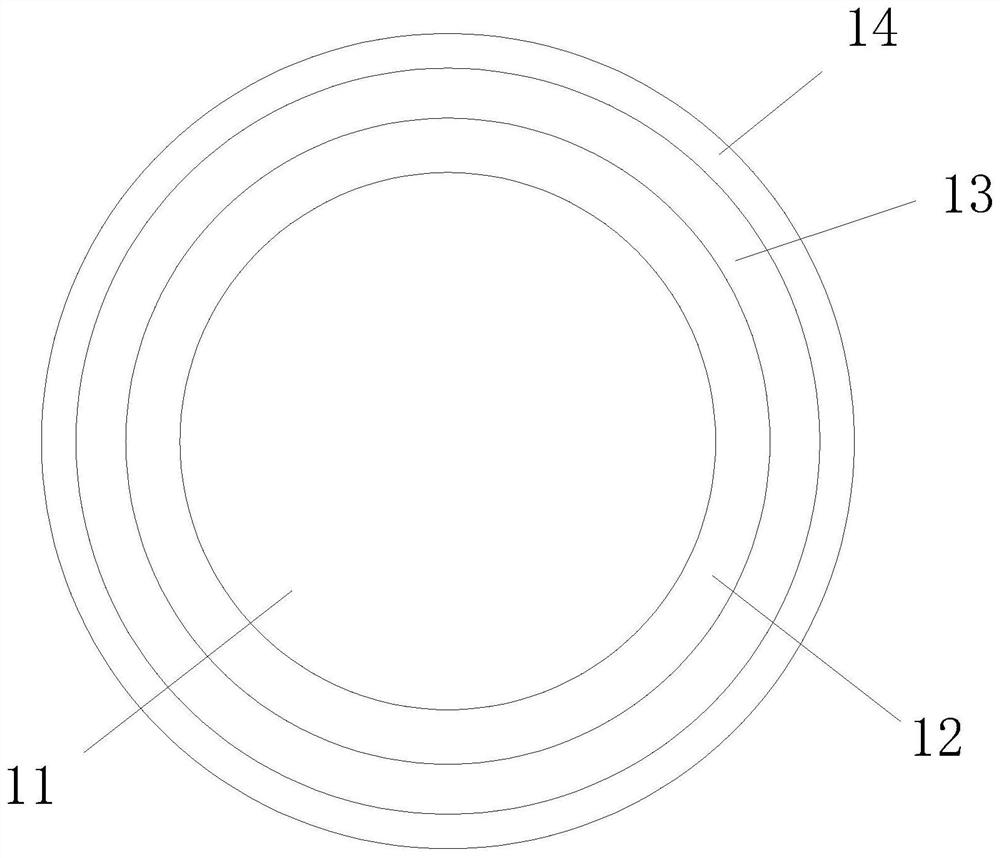

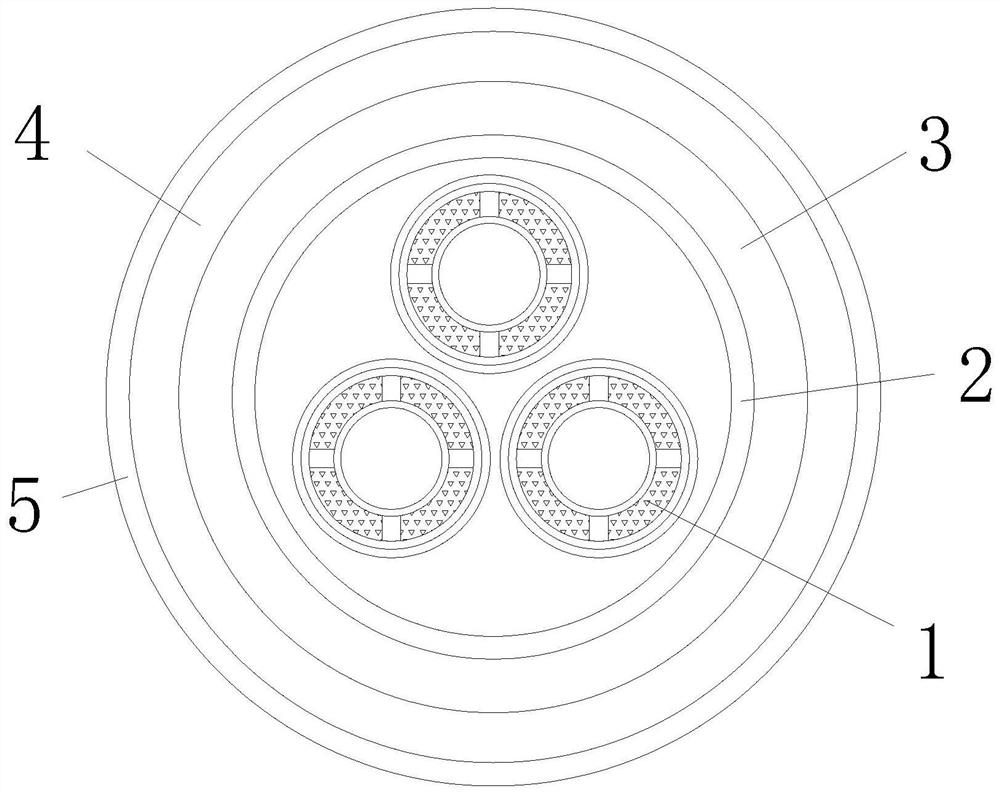

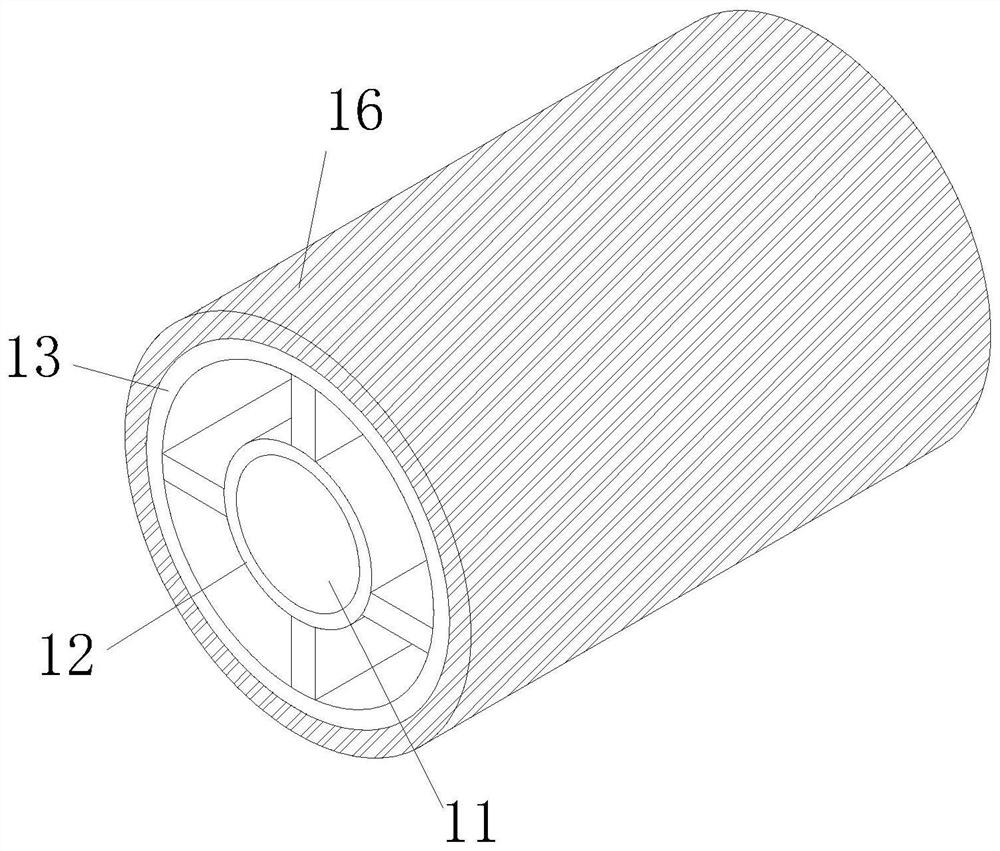

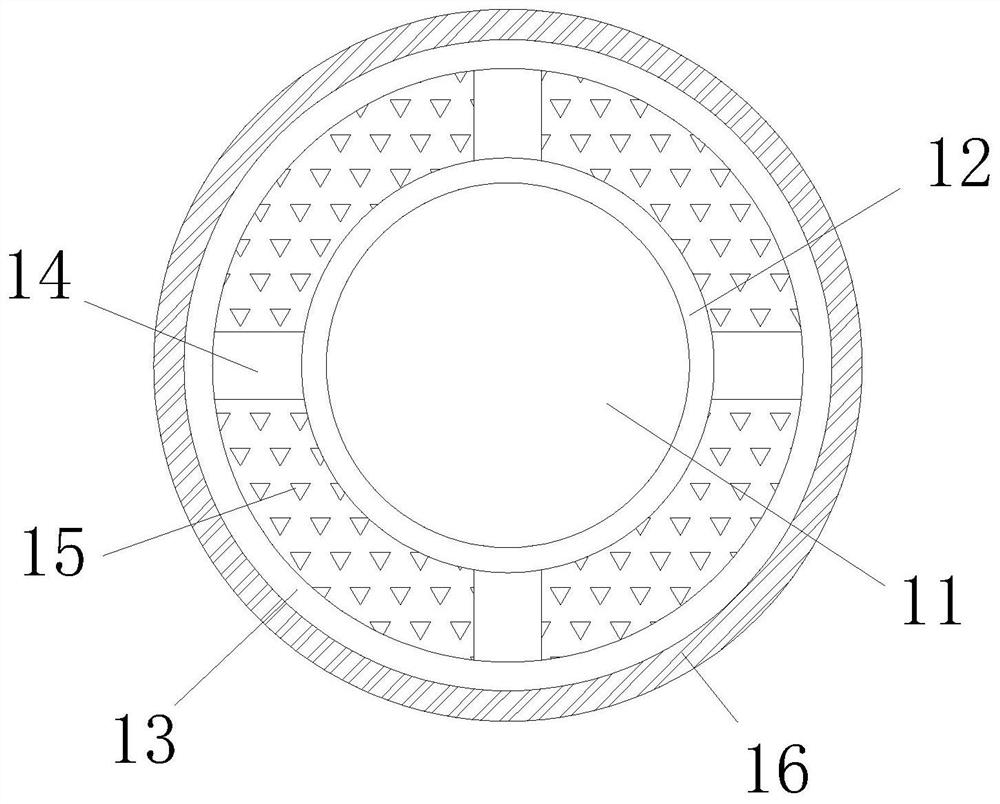

Bending-resistant and corrosion-resistant PVC power line and preparation forming method thereof

ActiveCN111883300AImprove scalabilityBig stretch and bend spacePlastic/resin/waxes insulatorsClimate change adaptationProtection layerMaterials science

The invention discloses a bending-resistant and corrosion-resistant PVC power line and a preparation forming method thereof. The bending-resistant and corrosion-resistant PVC power line comprises a plurality of protection wires and an outer protection layer wrapping all the protection wires. Each protection wire comprises a wire body, and the wire body is sequentially sleeved with an anti-radiation layer, an insulating layer and an inner protection layer from inside to outside. The outer protective layer is sequentially sleeved with a PVDF layer, a braided layer, a bending-resistant layer andan outer protective layer from inside to outside. The power line provided by the invention has good bendability and corrosion resistance, so that the power line is suitable for being used in special environments such as chemical laboratories and the like.

Owner:浙江海宁和金电子科技有限公司

An automatic paper cartoning machine

ActiveCN113264227BPlay a positioning and clamping effectImprove placement stabilityPackagingCartoning machineAdhesive

The invention relates to an automatic sheet-type cartoning machine, which comprises a pushing part, a side ear mechanism for folding boxes and a box-setting table arranged in the pushing direction. The box assembly and the movable type are provided with a positioning part connected with the box setting assembly, and the box setting assembly is used to drive the positioning part to move and locate the position of the paper sheet toward the center of the box setting table; The material is load-bearing, and the positioning part, the dust removal fan and the transmission component are linked together, so that the positioning plate can move laterally with the downward movement of the support table, which has the effect of positioning and clamping the paper, improving the stability of the placement of the paper. As the support table moves down, the dust removal fan is driven by the transmission component to rotate, which can form a wind flow on the side of the paper sheet and blow off the impurities attached to the paper sheet. Adhesion of the area to the adhesive.

Owner:南通恒力包装科技股份有限公司

Automatic gluing device

Owner:东莞华誉精密技术有限公司

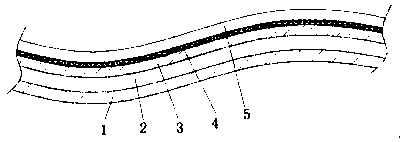

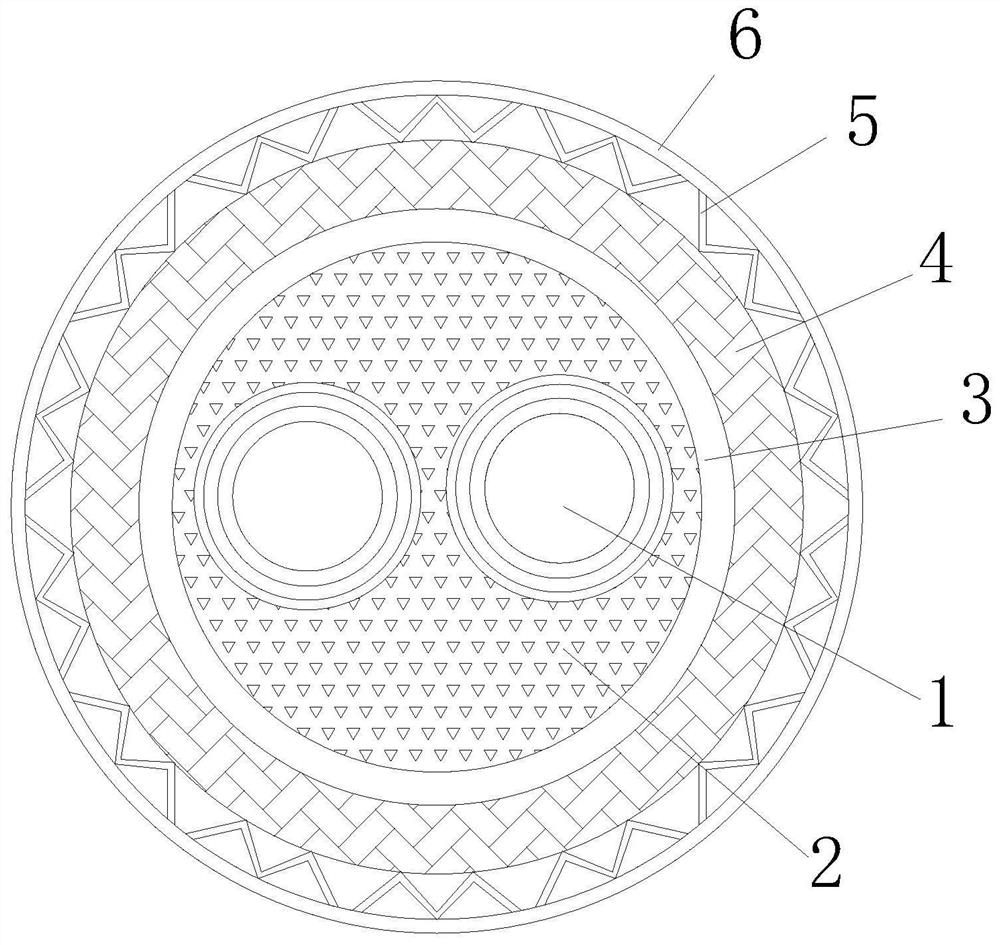

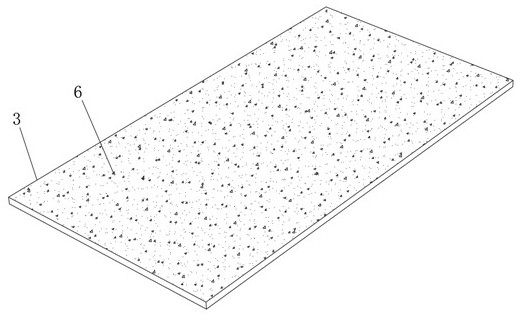

Sound insulation film and preparation method thereof

PendingCN114716712AImprove sound insulationImproves UV resistanceChemical industryCoatingsPolymer scienceShellac

The invention relates to the technical field of sound insulation films, and discloses a preparation method of a sound insulation film, which comprises the following steps: S1: heating and mixing 160-300 parts of polyvinyl chloride, 120-200 parts of polyethylene, 40-80 parts of polypropylene, 50-90 parts of polystyrene, 120-150 parts of polytetrafluoroethylene, 30-60 parts of an additive, 30-55 parts of lac and 20-30 parts of rosin. Which comprises a film body 4 and is characterized in that a first sound insulation resin layer 3 and a second sound insulation resin layer 5 are bonded to the top and the bottom of the film body 4 respectively, and a plurality of hollow insulation particles 6 are arranged in the first sound insulation resin layer 3 and the second sound insulation resin layer 5 respectively. The hollow insulating particles block sound to a certain degree, the sound insulation effect of the sound insulation film is improved, and the antibacterial agent is added, so that the film has great antibacterial performance, and the film is safer to use.

Owner:武汉简一科技有限公司

A film cutting machine

ActiveCN104308889BAvoid it happening againHigh glue cutting efficiencyPackagingMetal working apparatusEngineeringMechanical engineering

The invention relates to the field of LED (Light Emitting Diode) light emitting element processing equipment, in particular to a film-laminating and splitting machine. The film-laminating and splitting machine comprises a frame and a splitting mechanism, wherein the splitting mechanism is arranged on the frame, is used for laminating a film to a material and splitting the material, and comprises a material conveying guide rail which is used for conveying the material; an adhesive coating component for film lamination is arranged between the start end and the tail end of the material conveying guide rail; conveying sliding rails are arranged on two sides of the tail end of the material conveying guide rail respectively; a transporting component which is used for transporting the material to the conveying sliding rails is further arranged above the conveying sliding rails; an overturning piece which is used for overturning the material is arranged on the side, opposite to the material conveying guide rail, of the transporting component; a finished product sliding rail is further arranged at the tail end of each conveying sliding rail; a splitter component which is used for splitting the material is further arranged at the tail end of each conveying sliding rail. The whole process is automatically completed; an adhesive tape on an adhesive coating wheel needs to be replaced by a new adhesive tape only when being completely consumed, and finished products are stacked in a material falling box; the whole film-laminating and splitting process is automatically completed, the film-laminating and splitting efficiency is high, the adhesive coating effect is good, and the production efficiency is greatly improved.

Owner:深圳市泓普光电科技有限公司

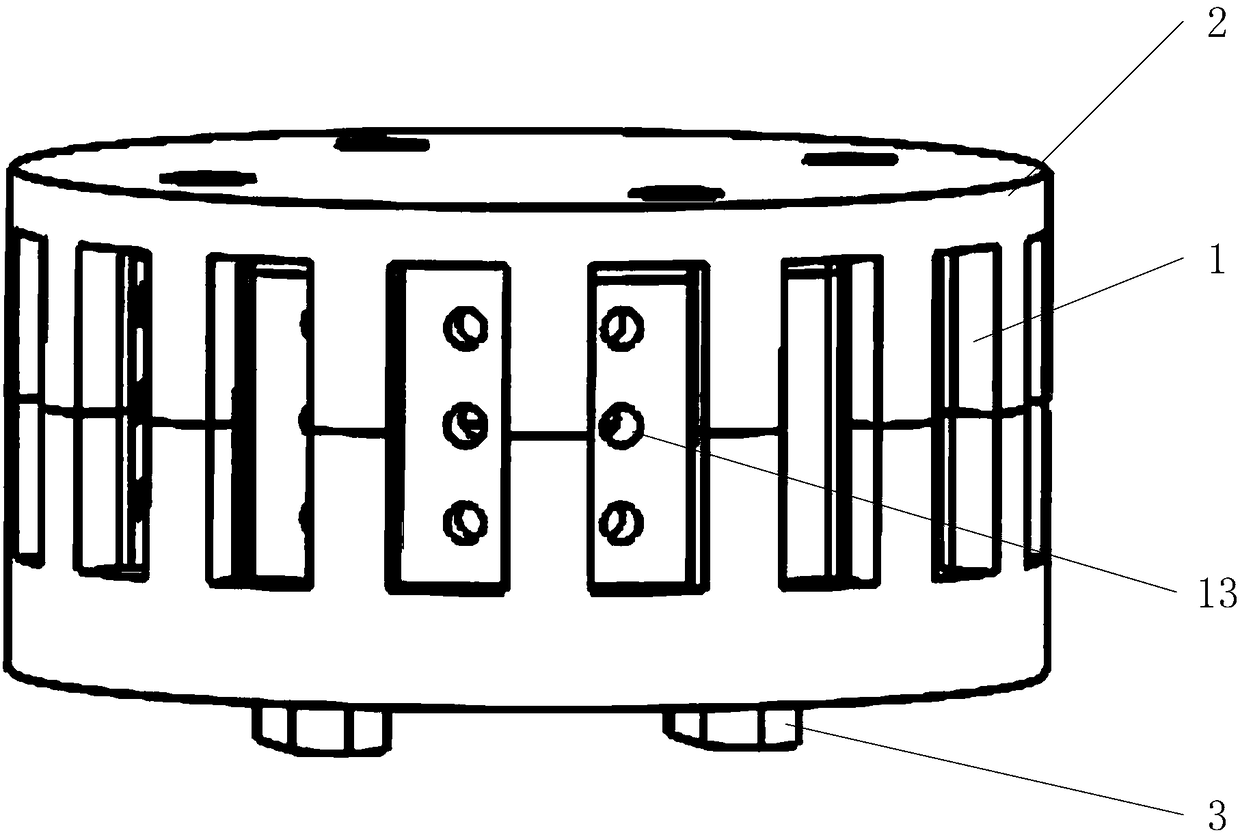

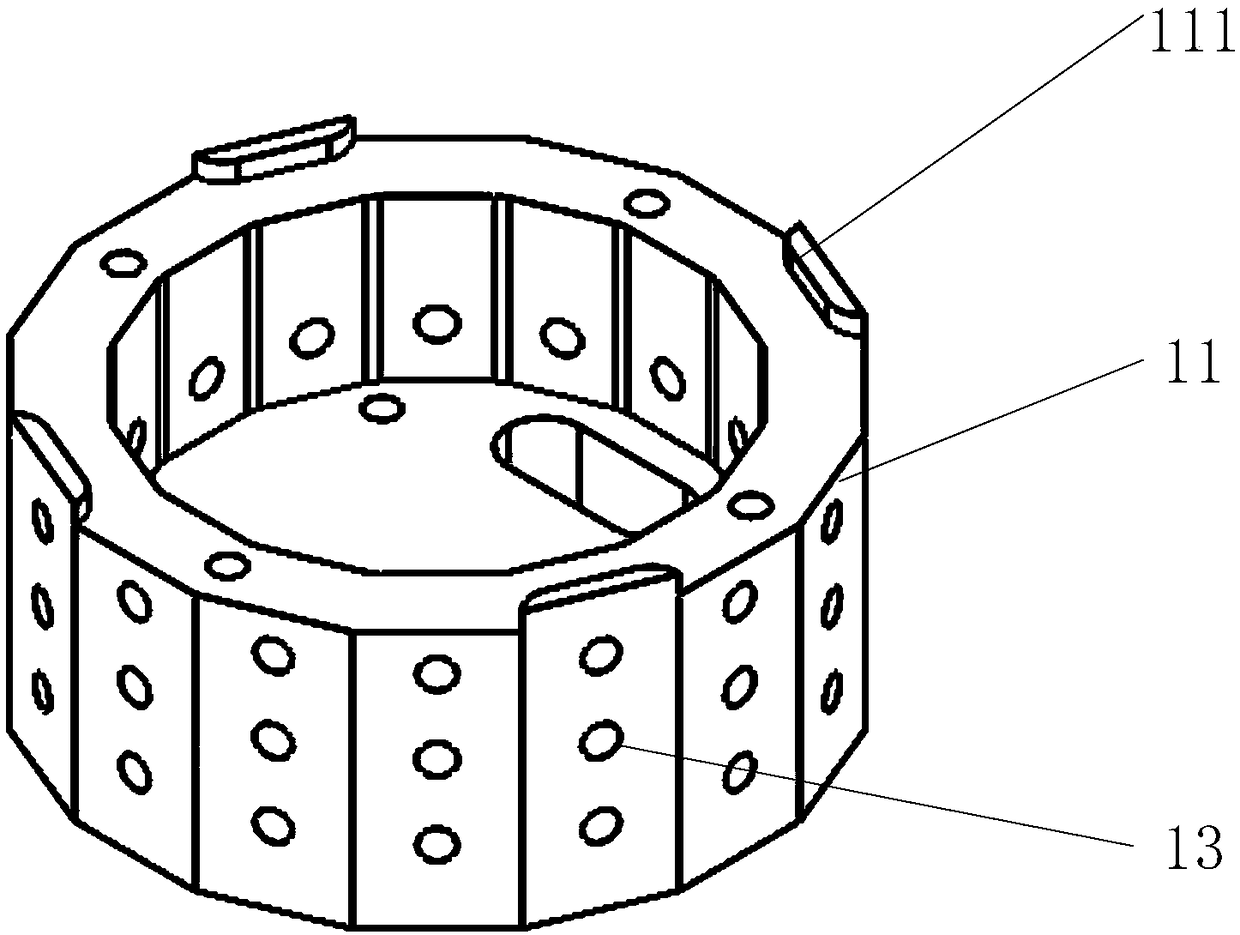

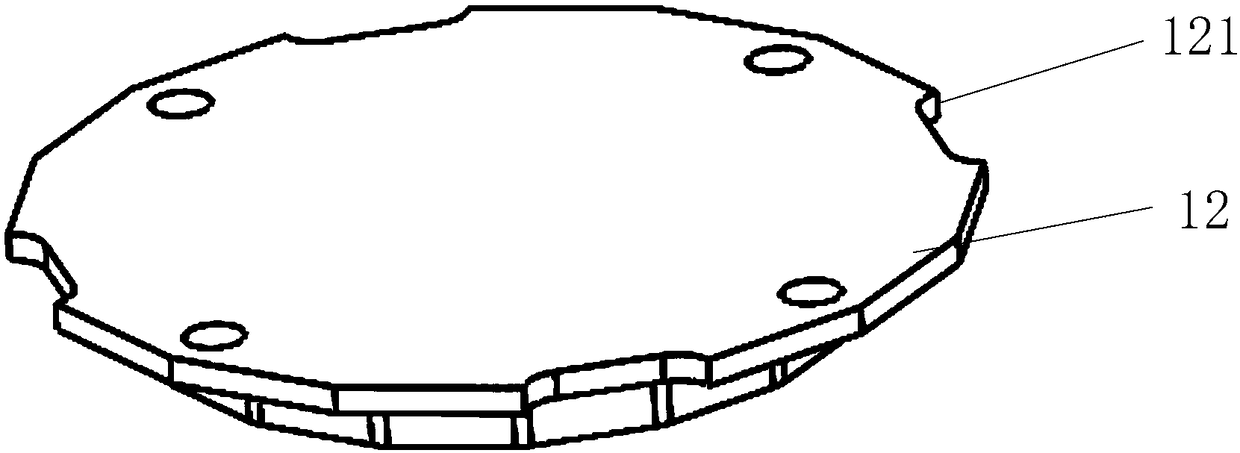

Quantum chip package device

ActiveCN108966624AAchieve shieldingGuaranteed working environmentScreening casingsWorking environmentQuantum

The present invention belongs to the field of chip package, and especially discloses a quantum chip package device. The quantum chip package device comprises: an electromagnetic shielding package boxconfigured to horizontally putting a quantum chip to be packaged and having an electromagnetic shielding effect; and a magnetostatic shielding cover coating the external portion of the electromagneticshielding package box and having a magnetostatic shielding effect. For the demand for the severe work environment of the quantum chip, the present invention provides a quantum chip package device with two layers of shielding structures, wherein the two layers of shielding structures are the electromagnetic shielding package box having the electromagnetic shielding effect and the magnetostatic shielding cover having the magnetostatic shielding effect coating the external portion of the electromagnetic shielding package box, the layers of the shielding structures work together to achieve shielding of different types of magnetic fields and magnetic fields with different intensities so as to commonly guarantee the work environment of the quantum chip to be packaged in the electromagnetic shielding package box.

Owner:ORIGIN QUANTUM COMPUTING TECH (HEFEI) CO LTD

Anti-static anti-interference PVC data line and its preparation method

ActiveCN111899928BImprove anti-staticImprove wear resistanceCommunication cablesInsulated cablesFiberAnti jamming

The invention discloses an anti-static and anti-interference PVC data line and a preparation and molding method thereof, comprising a plurality of twisted inner protective wires and an outer protective layer wrapping the inner protective wires; the inner protective wires include wires The body, the outer surface of the wire body is sleeved with an inner protective sleeve, the outer surface of the inner protective sleeve is sleeved with an outer protective sleeve, and there is a gap between the inner protective sleeve and the outer protective sleeve, and the outer wall of the inner protective sleeve The inner wall of the outer protective sheath is fixed by connecting strips and the annular array of connecting strips is arranged in the gap, and the outer surface of the outer protective sheath is wrapped with a metal shielding layer; the outer protective layer is wrapped with a fiber layer from the inside to the outside , insulation layer, electromagnetic shielding layer and outer sheath. The data line prepared by the invention has good antistatic properties and anti-electromagnetic interference, so that the data line is suitable for long-term use in some strong electromagnetic environments.

Owner:浙江海宁和金电子科技有限公司

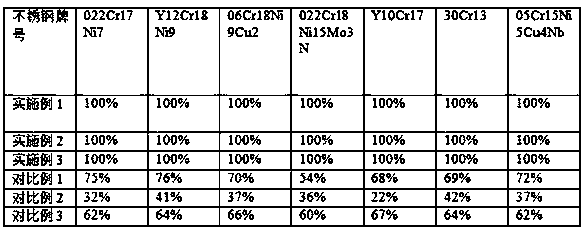

Stainless steel mother alloy cast ingot surface cleaning method

The invention discloses a stainless steel mother alloy cast ingot surface cleaning method. The stainless steel mother alloy cast ingot surface cleaning method comprises the steps that 1, a cleaning liquid component A is prepared; 2, phosphoric acid, p-toluene sulfo acid and ethyl sulfate are mixed according to the mass ratio of 1: 1: (0.2-0.4), and are stirred evenly to obtain a component B; 3, the component A and the component B are mixed evenly according to the mass ratio of 1: (0.18-0.25) to be prepared into cleaning liquid, then a mother alloy cast ingot obtained after casting is immediately soaked in the cleaning liquid, and the cast ingot is taken out after a wrapping layer is formed on the surface of the cast ingot; and 4, the surface of the cast ingot is dried under the condition of 50-60 DEG C, the curved wrapping layer is torn with external force after drying, and the mother alloy cast ingot with the surface being cleaned is obtained. According to the cleaning method, the wrapping layer with certain absorption performance and oil removal performance is formed on the surface of the stainless steel mother alloy cast ingot to be processed, and dirt on the surface of the stainless steel mother alloy cast ingot is removed while the wrapping layer is torn.

Owner:FOSHAN GAOMING LIGANG PRECISION CASTING CO LTD

Assembly line for producing wooden boxes

ActiveCN113021097AImprove the adhesion effectImprove adsorption capacityCircular sawsBark-zones/chip/dust/waste removalAssembly lineWood plank

The invention discloses an assembly line for producing wooden boxes, and relates to the technical field of wooden box production. The assembly line comprises a wood board grinding machine, a wood board cutting machine, an air dryer, a base, a grinding roller, a dust catching assembly, a transmission worm and a positioning assembly, wherein the wood board grinding machine, the wood board cutting machine and the air dryer are fixedly mounted at the top of the base from left to right, and transmission chain plates are transversely arranged in the wood board grinding machine, the wood board cutting machine and the air dryer. According to the scheme, the linkable dust catching assembly is mounted in the wood board grinding machine, when the wood boxes are produced and a wood board is ground firstly, the grinding roller can be driven to rotate, at the same time, a first side belt shaft outside the grinding roller can drive the dust catching assembly with a second side belt shaft to rotate through the transmission belt, a dust catching inner column in the dust catching assembly can effectively and quickly adsorb scraps in the grinding process, the cleanliness in the device is guaranteed, and the adhesion effect can be improved through the rotating dust catching assembly.

Owner:绍兴竺玉包装有限公司

A fully automatic processing machine for flexible cable tubes

ActiveCN106782888BImprove processing efficiencyImprove yield rateApparatus for feeding conductors/cablesDistance detectionProcess efficiency

The invention relates to a flexible flat cable processing machine for achieving convenient charging. The processing machine comprises a rack and a power distribution box. A conveying groove and a feeding device are arranged in / on the rack, wherein the conveying groove matches the feeding device. The feeding device comprises a feeding front-back moving device arranged on the rack. A feeding left-right moving device is arranged on the feeding front-back moving device. A feeding elevating device is arranged on the feeding left-right moving device. Feeding clamps cooperating with a product are uniformly arranged on the feeding elevating device. A feeding guidance rod cooperating with the conveying groove is arranged on the feeding elevating device. An edge distance detection device, a cable stripping device, a glue adhering device, a pressurizing device, an edge correction device, a vision detection device and a circuit detection device, cooperating with the product on the conveying groove, are successively arranged on the rack. According to the invention, through cooperation of the feeding device and the conveying groove, feeding of the product in the fixed distance is achieved; continuous integrated flexible flat cable processing can be achieved; processing efficiency is greatly improved; and meanwhile yield is improved.

Owner:大千纺织(安徽)有限公司

LED light bar gum and LED light bar gum coating technology

InactiveCN106833404AHigh viscosityWon't appear irregular afterFilm/foil adhesivesEngineeringLED lamp

The invention relates to LED light bar gum which comprises an adhesive layer and centrifugal paper, wherein one end of the adhesive layer is evenly adhered to the back of an LED light bar, the centrifugal paper is adhered to the other end of the glue layer, the adhesive layer is organic-silicon pressure-sensitive adhesive, and the thickness of the adhesive layer is 0.5mm to 2.0mm. The invention further relates to an LED light bar gum coating technology which comprises the following steps: step one: coating the back of an LED light bar complete board with the organic-silicon pressure-sensitive adhesive to form the adhesive layer; step two: attaching the centrifugal paper to the organic-silicon pressure-sensitive adhesive layer; step three: cutting the complete board after airing, and cutting the LED light bar complete board into a plurality of LED light bars. The gum disclosed by the invention has good adhesiveness and no adhesive residue at high temperature and high moisture, can be adhered to a plurality of materials which are difficult to adhere, and is convenient to use. According to the LED light bar complete board gum coating technology, complete board coating is performed before cutting, and then cutting into bars is performed; thus, production efficiency is greatly improved. Furthermore, cutting is performed after complete board coating, so that the problems that the gum is untidy and the centrifugal paper is broken are avoided.

Owner:广东三泰迈高光电科技有限公司

Degradable non-poisonous seed-coating agent and preparation method thereof

InactiveCN101416650BAvoid breedingImprove the adhesion effectBiocideAnimal repellantsApparent viscosityGlycerol

A degradable nontoxic seed coating agent comprises basic materials of water-soluble chitosan of 1.0-1.5wt%, gelatine of 0.05-0.1wt%, glycerol of 0.05-0.1wt%, PVA of 1.0-1.5wt% and plant extract of remainder, with the tensile strength of 18.7MPa, elongation of 10.1%, vapor transmission rate of 12.69g.mm / mm2.hr.mmHg, air permeability of (CO2)0.358*10-10ml.cm / cm2s.cmHg, air permeability of (O2)0.215*10-10ml.cm / cm2s.cmHg, hygroscopic rate of 47% and apparent viscosity of 290cp; uses water-soluble chitosan, PVA and plant extract to form seed coating film to not only meet performance requirement of conventional seed coating agents, but remarkably improve performance of film.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Coke oven exit passageway identification brick and preparation method thereof

The invention discloses a coke oven exit passageway identification brick and a preparation method thereof, and belongs to the technical field of coke oven safety. Aiming at the problems that the existing coke oven top sidewalk is easy to blur and fade and easy to cause potential safety hazards, the invention provides a coke oven exit passageway identification brick which comprises a green brick body, the surface of the green brick body is provided with a glaze layer, and the glaze layer comprises the following raw materials in percentage by weight: 55-61% of feldspar, 14-16% of quartz, 1.5-2.5% of kaolin, 9-11% of stalactite, 9-11% of raw talc, 3-5% of zircon powder, 0.8-1.2% of titanium dioxide, and 0.015-0.025% of zinc powder. The glaze layer is arranged on the green brick body, the glaze layer has the advantages of being striking in color code, resistant to corrosion and high in stability, the green brick body with the glaze layer is used as a coke oven top sidewalk, the problem that an interface of an oven top exit passageway is prone to fading is solved, and life safety of operators is guaranteed, and meanwhile, the green brick body has certain attractiveness while serving asa coke oven top safety passage. The whole preparation process is simple to operate, and the production cost is saved.

Owner:MAANSHAN IRON AND STEEL COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com