Food packaging equipment

A technology of food packaging and equipment, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of easy gaps, box cover gaps, and weak adhesive tapes, etc., and achieve power saving, wide application range, and adhesive effect better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Further detailed explanation through specific implementation mode below:

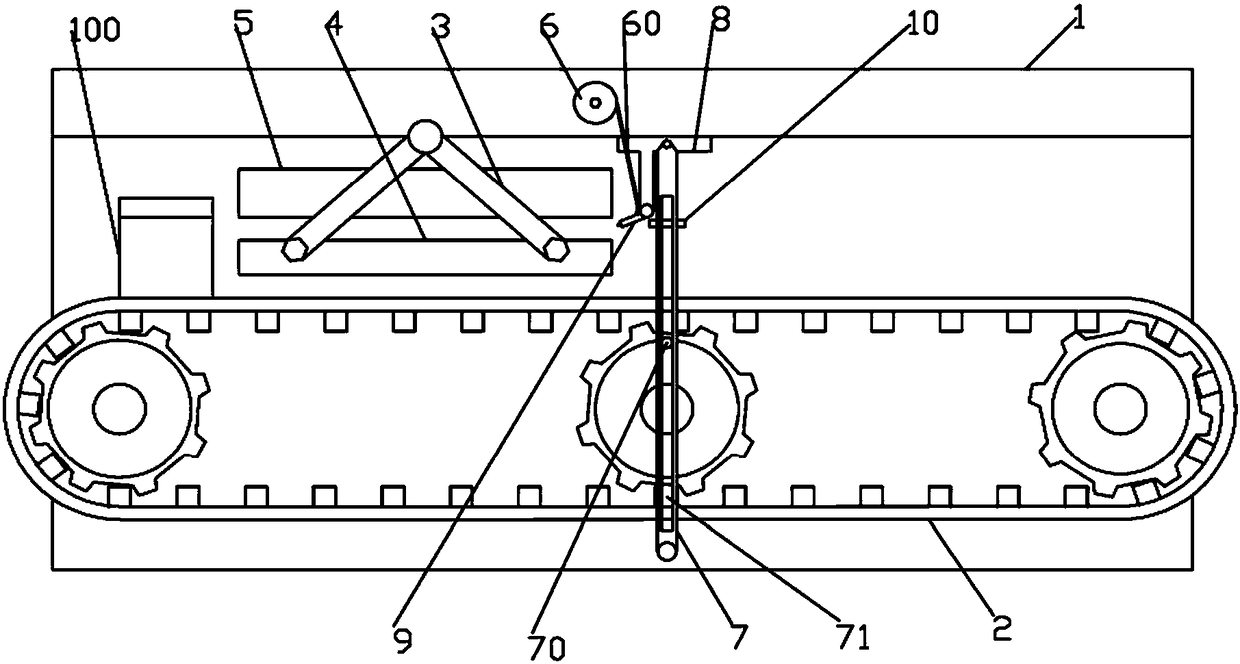

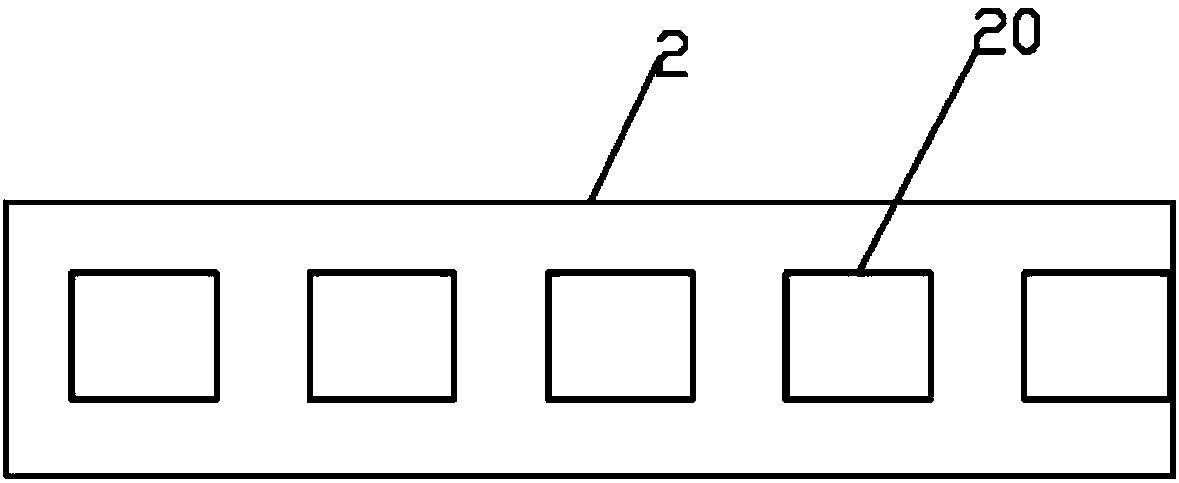

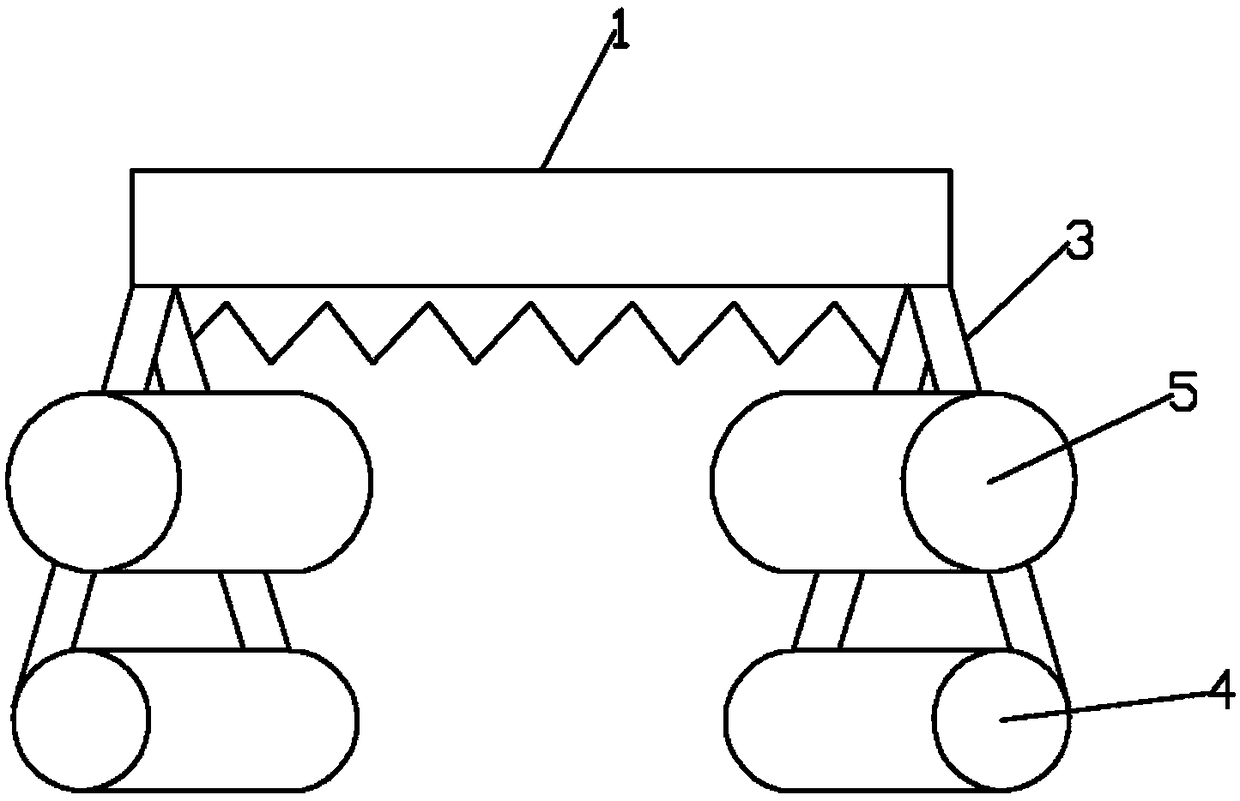

[0019] The reference signs in the accompanying drawings include: frame 1, conveyor belt 2, groove 20, fixed rod 3, squeezing roller 4, flattening roller 5, tape roll 6, tape 60, swing rod 7, sliding column 70, Through hole groove 71, slide block 8, traction plate 9, draw-in groove 90, cutter 10, carton 100.

[0020] The embodiment is basically as figure 1 Shown: food packaging equipment, including frame 1, conveying mechanism, leveling mechanism and sealing mechanism.

[0021] The transmission mechanism includes a motor, a conveyor belt 2 and at least two gears. In this embodiment, the number of gears is three, and the three gears are evenly distributed in the conveyor belt 2; The leftmost gear is driven by a motor to rotate. The drive structure can directly connect the output shaft of the motor to the center hole of the gear, or connect the worm to the output shaft of the motor, so that the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com