Stainless steel mother alloy cast ingot surface cleaning method

A master alloy ingot, surface cleaning technology, applied in the field of stainless steel materials, can solve the problems of low alkali cleaning efficiency, secondary corrosion, stainless steel body loss, etc., to achieve good corrosion resistance and resistance to organic dissolution, heat resistance and Good water resistance and improved adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

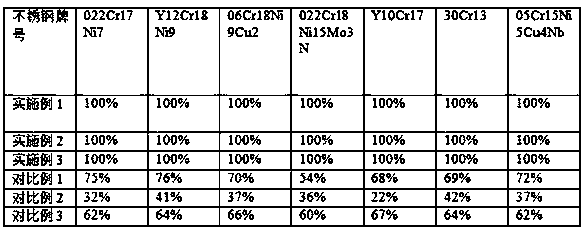

Examples

Embodiment 1

[0036] In the present embodiment, the steps of cleaning the surface of the stainless steel master alloy ingot are as follows:

[0037] Step 1, according to the following components and mass parts, take the raw materials to prepare cleaning solution component A:

[0038] Silica airgel 8 parts

[0039] 5 parts polytetrafluoroethylene fiber

[0040] High silica glass fiber 6 parts

[0041] Zinc oxide powder 6 parts

[0042] Furan resin 25 parts

[0043] Magnesium Hydroxysilicate 2 parts

[0044] Sodium carbonate 5 parts

[0045] 3 parts sodium bicarbonate

[0046] The density of silica airgel is 70kg / m 3 , the specific surface area is 240m 2 / g.

[0047] PTFE fibers and high silica glass fibers are 0.5 mm in length and 20 μm in diameter.

[0048] The particle size of zinc oxide powder and magnesium hydroxysilicate is 0.5 μm.

[0049] The above raw materials are mixed and ground in a planetary grinder until the size of the solid matter is less than 1 μm to obtain compon...

Embodiment 2

[0055] In the present embodiment, the cleaning steps are similar to those in Example 1, except that the components and parts by mass of the cleaning solution component A are:

[0056] Silica airgel 5 parts

[0057] 3 parts teflon fiber

[0058] High silica glass fiber 6 parts

[0059] Zinc oxide powder 8 parts

[0060] Furan resin 20 parts

[0061] Magnesium Hydroxysilicate 2 parts

[0062] Sodium carbonate 6 parts

[0063] Sodium bicarbonate 4 parts.

Embodiment 3

[0065] In the present embodiment, the cleaning steps are similar to those in Example 1, except that the components and parts by mass of the cleaning solution component A are:

[0066] Silica airgel 6 parts

[0067] 4 parts teflon fiber

[0068] High silica glass fiber 3 parts

[0069] Zinc oxide powder 8 parts

[0070] Furan resin 24 parts

[0071] Magnesium Hydroxysilicate 2 parts

[0072] Sodium carbonate 5 parts

[0073] Sodium bicarbonate 5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com