Degradable non-poisonous seed-coating agent and preparation method thereof

A technology of formula and plant extract is applied in the field of preparation of degradable and non-toxic seed coating agents, which can solve the problems of poor film formation uniformity, poor seed affinity, and reduced germination rate, and achieve high adhesion fastness, seed coating capacity and other problems. The effect of good expansion and improved film-forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] (1) Water-soluble chitosan Preparation of chitosan: Dissolve 50g chitosan in 2% HAc aqueous solution, rapidly heat up to 60-65°C temperature, add 300g 1-butyl-3-methylimidazolium chloride ion In the liquid (97wt%), add dropwise 30% H under stirring condition 2 o 2 60g, keep warm (85°C) and react for 3 hours, adjust the pH value to 7.1, cool to room temperature, separate the layered liquid by suction filtration, concentrate the filtrate at 40°C, precipitate with alcohol, wash, and dry to obtain water-soluble oligomeric chitosan .

[0070] (2) Preparation of plant extract: Soak rosemary, Sophora flavescens, Sophora flavescens, and ultrapure water for 24 hours according to the ratio of 1:1:1:50, and then distill it at 80-90°C for 2 hours, then cool down to 40°C Filter the plant extract.

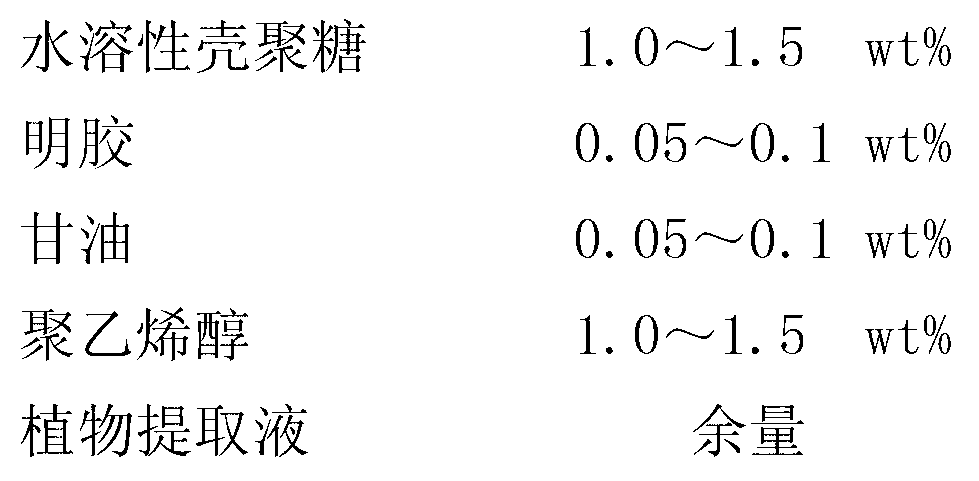

[0071] (3) Batching: take each component by formula ratio, first water-soluble chitosan and polyvinyl alcohol are fully mixed with plant extract, then add other components, in the mix...

Embodiment 2

[0074] (1) Water-soluble chitosan Preparation of chitosan: Dissolve 100g of chitosan in 2% HAc aqueous solution, rapidly heat up to 60-70°C temperature, add 500g of 1-butyl-3-methylimidazolium chloride salt ionic liquid (97wt%), add dropwise 30% H under stirring condition 2 o 2 110g, keep warm (80°C) for 2 hours, adjust the pH value to 7.2, cool to room temperature, separate the layered liquid by suction filtration, concentrate the filtrate at 45°C, precipitate with alcohol, wash, and dry to obtain water-soluble oligomeric chitosan sugar.

[0075] (2) Preparation of plant extract: Soak rosemary, Sophora flavescens, Sophora flavescens, and ultrapure water for 24 hours according to the ratio of 1.5:1.5:1:50, then fully back-distill at 80-90°C for 2 hours, and then lower the temperature by 50°C Filter the plant extract. Other steps and embodiment 1.

Embodiment 3

[0077] (1) Water-soluble chitosan Preparation of chitosan: Dissolve 70g of chitosan in 1.5% HAc aqueous solution, rapidly heat up to 70-85°C temperature, add 400g of 1-butyl-3-methylimidazolium chloride salt ionic liquid (97wt%), add dropwise 30% H under stirring condition 2 o 2 70g, keep warm (83°C) for 4 hours, adjust the pH value to 7.3, cool to room temperature, separate the layered liquid by suction filtration, concentrate the filtrate at 45°C, precipitate with alcohol, wash, and dry to obtain water-soluble oligomeric chitosan sugar.

[0078] (2) Preparation of plant extract: Soak rosemary, Sophora flavescens, Sophora flavescens, and ultrapure water for 24 hours according to the ratio of 1.5:1.5:1:50, then fully back-distill at 80-90°C for 2 hours, and then lower the temperature by 50°C Filter the plant extract. Other steps and embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com